Applications and Implications

The garment construction

Textil industry

From an industrial perspective, the production of clothing is defined as a series of manufacturing activities that lead to the creation of clothing, based on a design previously made and with the help of the appropriate technological tools to optimize the necessary processes.

haute couture vs prêt à porter

Haute couture is made to measure, so each garment is unique, while prêt à porter is mass produced for a general audience. How can I get a little bit both?

Well... with digital fabrication

The Characteristics

of a common garment

Pattern making is the process of creating patterns or molds on paper or fabric that are

used as a guide to cut and make clothing and other textile products and is commonly done by hand.

Industrial patternmaking uses standardized patterns as a basis that are reproduced in large quantities because

they respond to massive demand. These sizes are known in the market as S, M, L, XL, etc., being this way for the different

types of standard bodies.

That is why sometimes we need to make some adjustments to the clothes we buy

The textile process can be divided into the subprocesses of spinning, weaving, dyeing and finishing, to which the subsequent

preparation of the final product should be added. Each of these subprocesses uses a large amount of machinery in order

to obtain threads and fabrics of the highest quality. So, a type of fabric with specific details would be very expensive

to manufacture in large quantities.

To join the pieces, an overlock machine is required that, while cutting, finishes the cut made with a special seam called a "chain".

The edges of fabrics mostly require closing to prevent them from fraying.

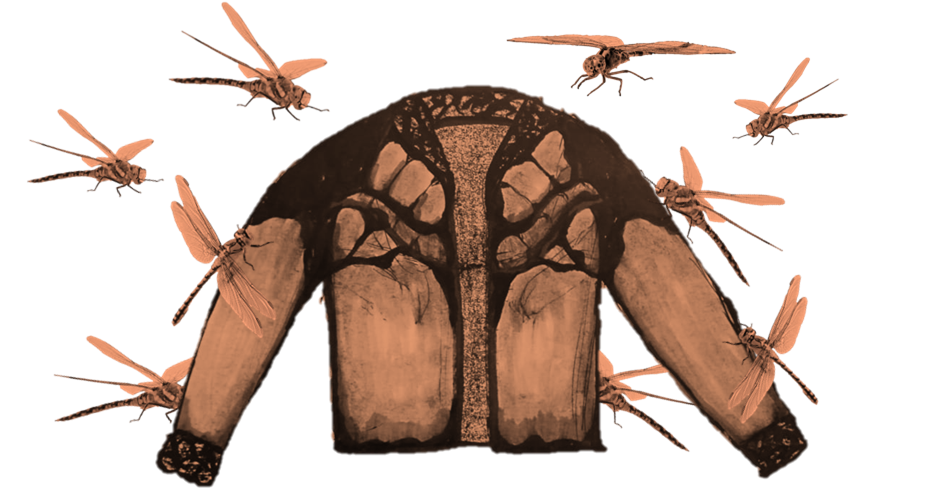

Wearable technology, body technology, technological clothing, smart clothing, or textile electronics, are intelligent electronic devices

incorporated into clothing or worn bodily as implants or accessories that can act as an extension of the user's body or mind but,

it is not very common on the market.

How to incorporate digital fabrication

in my manufacturing process

| Design 3D | To create this garment we can take advantage of 3D modeling software for pieces that require low-scale production and a personalized design. | 3D Print | In 3D printing, the materials that can be integrated into a textile project are becoming more varied every day. TPU, for example, is a very flexible material that can be integrated into any part of any garment. |

| Electronics | Including an electronic system that is removable can give the garment a unique and attractive feature but is still functional. | Sublimation | In 3D printing, the materials that can be integrated into a textile project are becoming more varied every day. TPU, for example, is a very flexible material that can be integrated into any part of any garment. |

| Design 2D | Software such as SolidWorks is very useful for pattern-making a garment if it is designed parametrically. No more ruler and squares. | Laser cutting | If you cut fabric that is mostly polyester in percentage, the cut cauterizes the edges of the fabric, which is very useful for tailoring, as it prevents the fabric from fraying. |

Some considerations

| Design 3D | - Most 3D design programs require a license. - Renders will never compare to textures in real life. |

3D Print | - In 3D printing, many tests are required to reach the desired result. - Materials are susceptible to environmental conditions - The best finishes take longer |

| Laser cutting | - You have to do several power and speed tests to make sure you do not overburn the fabrics of a textile. - Even reaching an ideal parameter, these values can change depending on the quality of the fabric to be cut. - The air expelled by a laser cutter tends to move small parts. |

Sublimation | - In sublimation, temperatures can change the fabric, especially if it has not been previously washed. - There may be errors in the printing that will be reflected in the fabric - The fabrics that can be sublimated best are synthetic |

| Electronics | - An electronic system could become very invasive on the garment if the

natural movement and conditions of use are not considered. - Most electronic systems require a power source, which is not always very discreet or easy to hide. |

Design 2D | - The colors of a design can always change when they are brought to real life, and that is not necessarily a problem with 2D design software, but it must be taken into consideration when selecting a color palette. |

Bill of materials

| PROGRAMS TO DESIGN | MATERIALS TO THE GARMENT CONSTRUCTION | TECHNOLOGIES | ELECTRONICS |

|

- Illustrator - SolidWorks - Ultimaker Cura - Wasatch's SOFTRIP - Smart Carve |

- Fabrics (Black blanket and white gabardine) $40.00 for each meter - Normal Threads $25.00 for each piece - Sublimate paper roll $1500.00 - Black TPU roll $400.00 - Black PLA roll $300.00 - Black polypropylene sheet $65.00 - 1 m black hose (3 mm) $30.00 |

- Laser Cut machine - 3D printer - Sublimation machine - Sewing machine - Soldering Iron |

You can see what components I used for the PCB in the Week 12 |