16. Applications and implications

Week asignments

1.Individual assignment: Propose a final project masterpiece that integrates the range of units covered, answering: a lot of questions already solved in my final project page. Check it out!

Questions solved

1. My project implicates: all the processes studied in the fab academy.

2. What will it do?

I have decided to make a car to help me transport my luggage through the airport. At the same time, I want to use this idea to test the different ways to control a vehicle: manually, semi-autonomous, and autonomous. It is hard to put a final name to it, so from now on it shall be referred to as "device".

In order to do this, I will have to identify the problem I want to solve (create a way to displace luggage), to gather data and analyze it, arrive to solutions based on this analysis, by selecting the best design and mechanisms to create the device. Teseting and documentatiosn will be also essential during the process.

3. Who has done what beforehand?

One of the most famous final projects in the Fab Academy program is the one from Omar AlDajani’s Strobot, which inspired the movement of objects without any manual intervention: https://fab.cba.mit.edu/classes/863.20/Architecture/people/OmarAlDajani/FinalProject/The%20Strobot.mp4

Another source of inspiration were the countless commercial models in the market that are already integrated in the carry-on luggage: https://www.travelandleisure.com/style/travel-accessories/smart-luggage

Finally, all sorts of animals riding the robotic vacuum are a great example as well.

4. What will you desing?

I will have to design the following:

a) Motor base: First thing to do is measure the component and sketch possible solutions while maintaining the design under 55 mm in height. After sketching a satisfactory solution, we should model the piece using SolidWorks.

b) Steering Mechanism: The idea came out of some RC cars that were in my collection. The principle for these mechanisms is a 4 bar linkage mechanism (now I understand why most of the car/robotic platforms in the market don’t use this). To the previous design we should add the bar connecting both front wheels and we should design the actuator that moves said bar using a servo.

c) Chasis: To fit the previous components, we should consider the standard area below the carry-on luggage which is 180 x 180 mm2. The displacement of the steering mechanism should be considered, and a minimum layout size for the electronics (100 x 60 mm2 for the Arduino Mega) The first iteration was designed to be 3D printed, the second version was designed to be laser-cut.

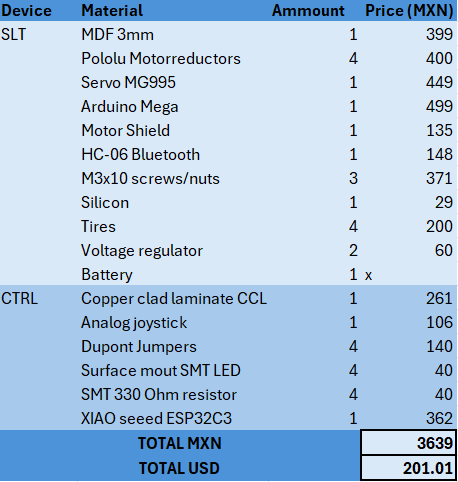

5. What materials and components will be used? Where will they come form? And how much will they cost?

a) Motor base

b) Steering Mechanism

c) Chasis

d) Casing

e) Electrical desing and integration of this items

7. What processes will be used? All of the except molding and casting

8. What questions need to be answered? Is it a viable business?

9. How will it be evaluated? With an A+, hopefully