10. Mechanical design & machine design

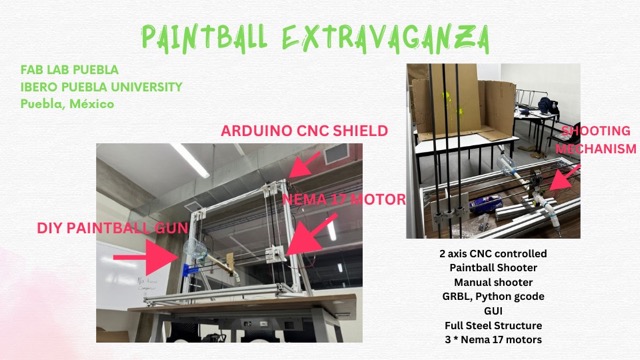

This assignment was really crazy, we were assigned a team to build a machine similar to a CNC, my team wanted to do something experimental, big and awesome, so we decided to create a machine that could paint with paintballs, the process was great you can find some more information on our team page.

My individual experience

For this assignment I helped with the planning and construction of the machine but my main focus was on the development of the custom paintball gun.

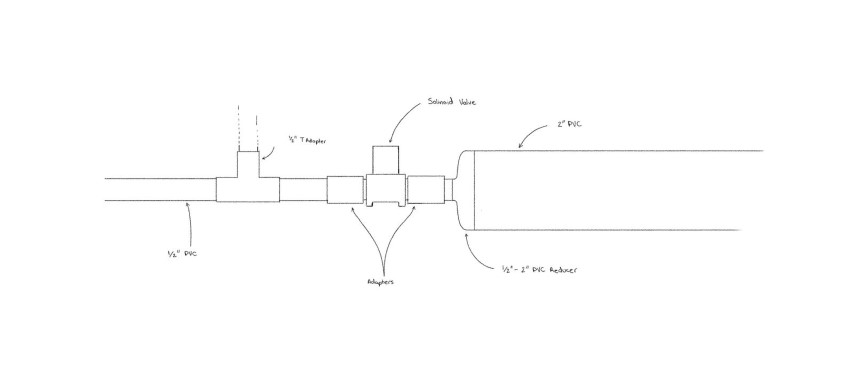

The starting point was to create a sketch to have an idea of the meassurements that we needed for it to fit on the machine and also for it to perform as needed, taking into account the distance the paintball had to travel, its diameter and the air pressure. This sketch was made by my partners Berna and Andrea using as the most important part of the design, this solenoid valve:

We opted for this valve because it's characteristics where perfect for our use, here are them:

- Model: ARD-317

- Power Supply: 12 Vcc (DC voltage)

- Type: Normally closed

- Current Consumption: 300 mA

- Hydraulic Connections: 12.8 mm (1/2")

- Operating Pressure: 0.02~0.8 Mpa

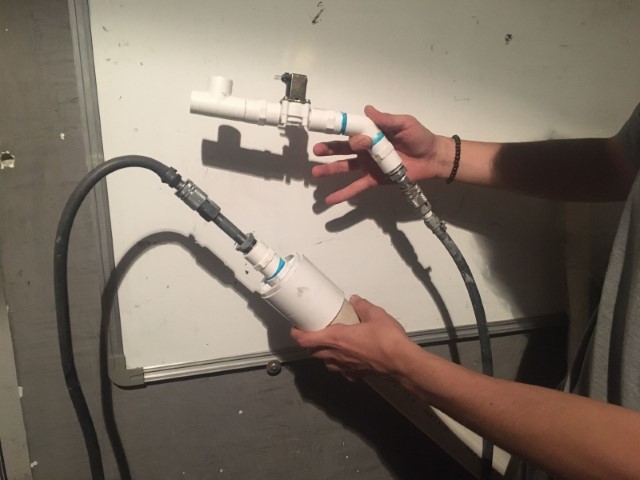

After we settled on how it would fit on the machine, I started crafting it. The first idea was to make the paintball gun and an air tank, both of them were made but the air tank wasn't used in the end because it couldn't hold enough air to perform more than 2 or 3 shots, so instead we connected the paintball gun to a compressor.

The building process was very fun, first we got all the materials, then I cutted the tubes to the size needed, glued the couplings and connectors together. The pieces needed for the gun where:

- 1 m of 1/2" pvc tube

- One 1/2" 45° pvc connector

- Three 1/2" pvc couplings with female screw

- One 1/2" pvc T type connector

- One metallic 1/2" to 1/4" reduction

- Female and male 1/4" quick release valves

- One high pressure hose for compressor

We used pvc glue and teflon to put everything, and then we started testing to properly use the pvc glue we need to sand the contact surface and then apply the glue.

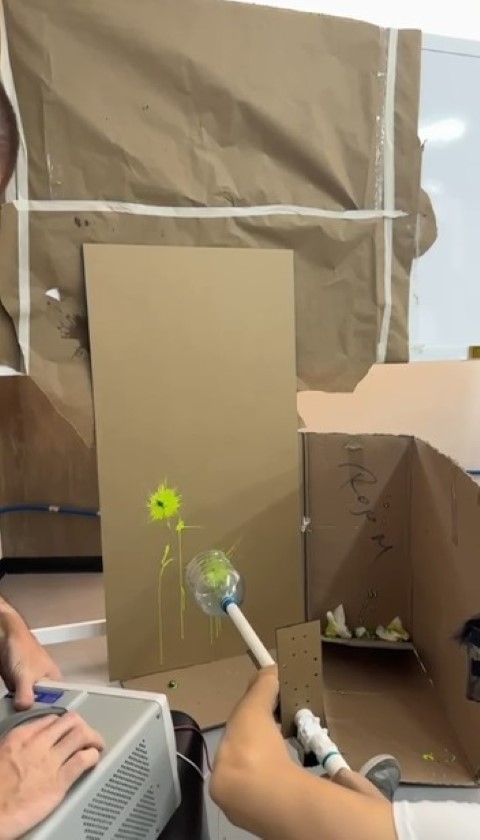

On the tests we determined the right preassure for the paintballs to explode, it was from about 60-90 psi that we could pop them from about 1-2 meters. We tested this with a power supply I set on 12 volts and 3.2 mA on a space we have at Ibero Puebla determined for painting.

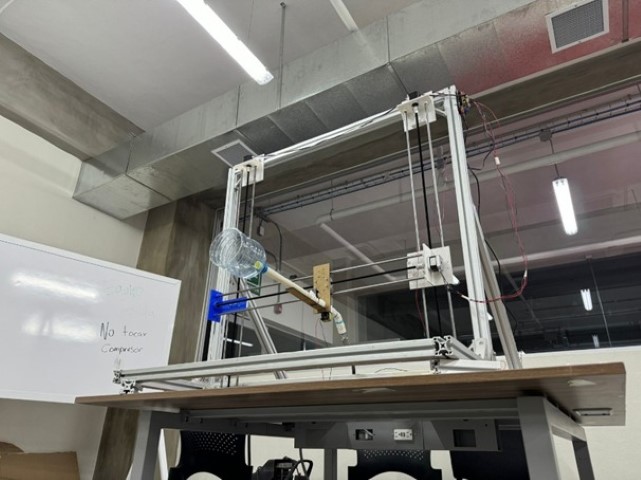

Finally, we mounted everything together and here is what the machine looks like

And here is a little sneak peak of how the machine works

I would like to thank my team, loved working with you guys!

Please check out our team page to see videos, files and the whole process of the construction of this paintball extravaganza.