17. Project management

What tasks have been completed?

- Design of the mechanical 7-segment display, inspired by a model made by: 7 Segment Mechanical Counter

- Motor programming

- Integration of motors with the display

- Pomodoro Timer

- Local weather programming

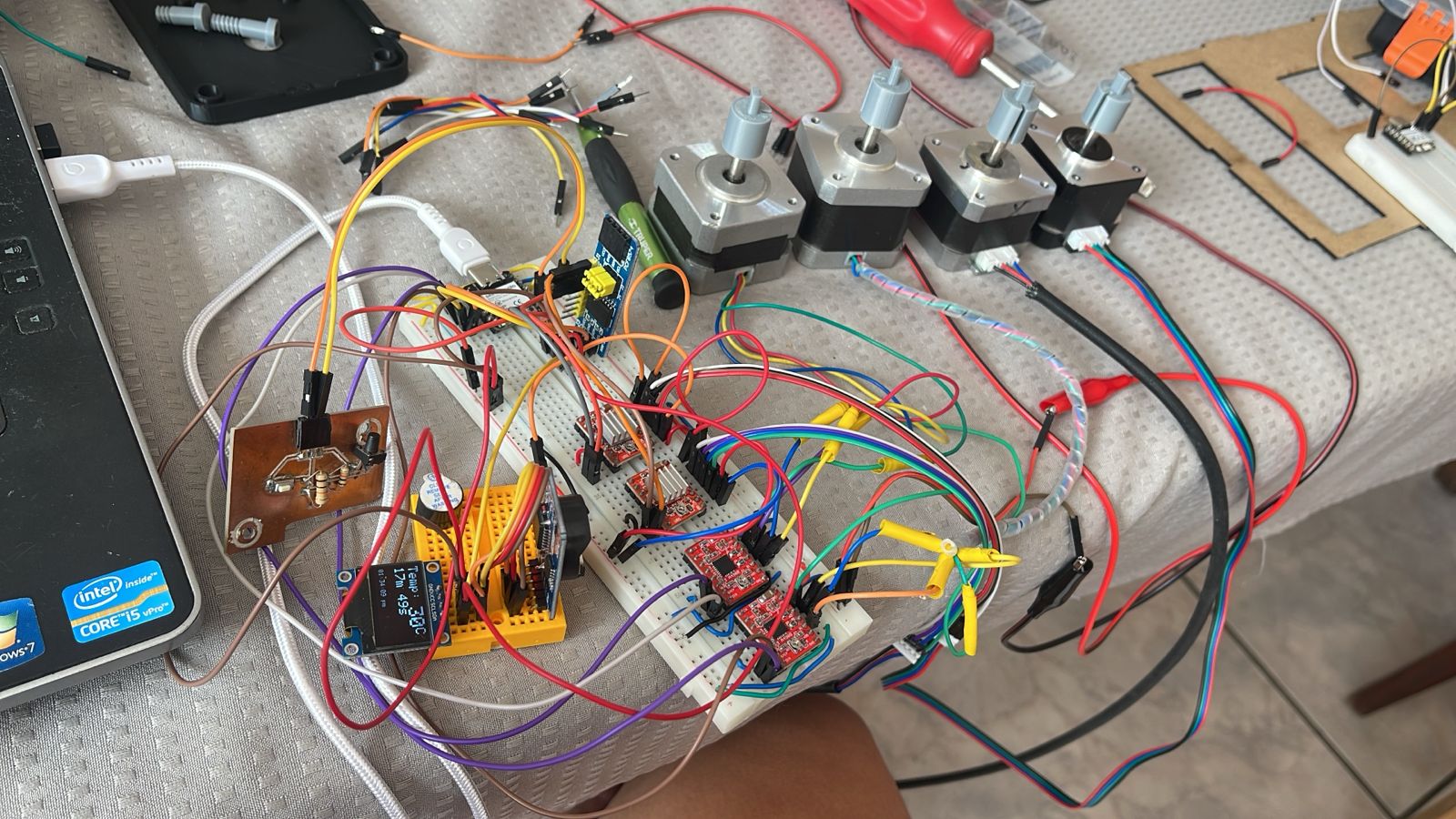

In the following image, you can see one of the tests I conducted still on a protoboard to verify that everything was working correctly. Once it was confirmed, I proceeded to design the PCB.

What tasks remain?

- Weather via API

- Case redesign

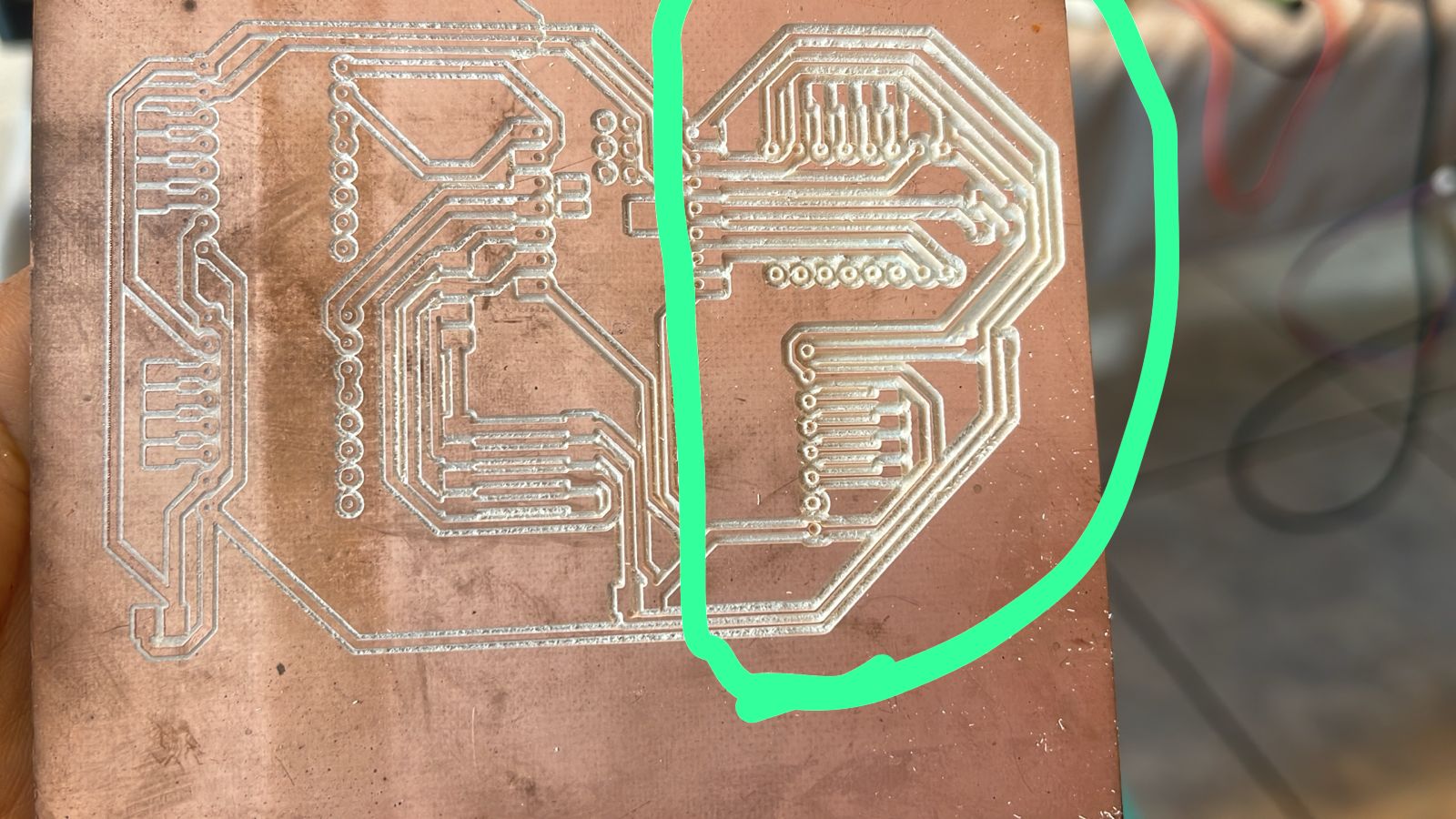

- Make PCB

What has worked? What hasn't?

So far, the function of mechanically changing the numbers for the clock part has been a bit difficult, but it is still in progress and I need to program it to change the numbers.

On the other hand, I made a case to place everything, but it didn't fit perfectly, so I need to redesign it.

I also had cut the PCB, but due to a small unevenness, some tracks were eaten up, so I need to redo it.

After many tests I conducted on the protoboard, I realized that I changed some of the pins I selected to move the motors, so I also have to redesign the PCB.

What questions need to be resolved?

- How can I make a coupler that adjusts better and has more force to turn the motor?

- How to obtain variables to indicate the number of steps the mechanical number should advance?

- How can I include the weather API?

What will happen when?

Up to this point, my progress includes 3D printing mechanical numbers, testing motors on a protoboard, as well as the RTC module saving the time and displaying the temperature, and starting the Pomodoro method by pressing a button.

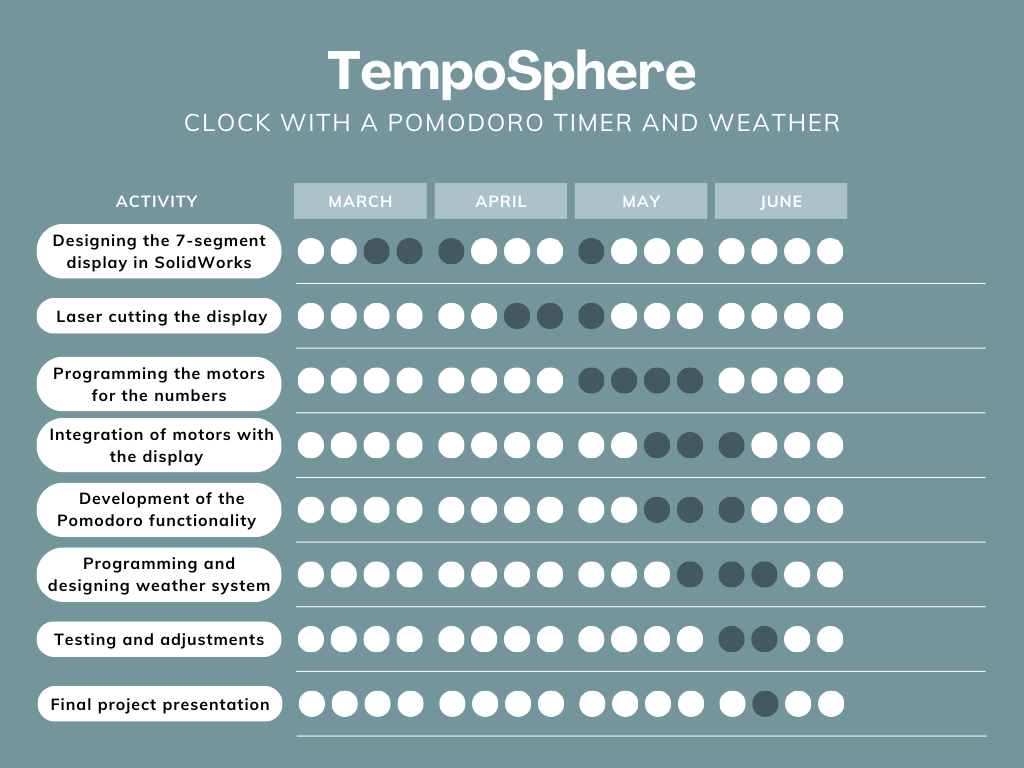

For now, I will follow the schedule, and the remaining parts will be taken as tests and adjustments, as well as system programming.

Schedule of Activities

- Week 1, 2, 3: Designing the 7-segment display in SolidWorks

- Week 4, 5, 6: Laser cutting the display.

- Week 6, 7, 8, 9: Programming the motors for the numbers.

- Week 8, 9, 10: Integration of motors with the display and Development of the Pomodoro functionality .

- Week 9, 10, 11: Programming and designing weather system.

What have you learned?

So far, I have learned many ways to control the NEMA 17 stepper motors. At first, I was testing with H-Bridge Modules, but they were too large and consumed a lot of current, losing power when placing 2, so they no longer had enough torque to turn the motor. I also discovered that there is a module that allows me to keep the time and display the temperature, RTC DS3231.

Project Plan

Purpose and Scope of the Project

Purpose: The purpose of this project is to create a clock with different functionalities to help organize better using the Pomodoro Technique. Additionally, the clock will display the weather on a screen.

Scope: This project involves designing and building the clock, integrating a Pomodoro timer, and implementing a screen to display the weather. The project will focus on creating a functional device that allows switching between the clock function and the Pomodoro Technique using a button.

Resources

- PLA for 3D printing the mechanical displays and casing.

- MDF for the casing.

- NEMA 17 stepper motors.

- A4988 stepper motor driver modules.

- Xiao ESP32C3 microcontroller.

- PCF8574 I2C GPIO Expander Module.

- OLED screen.

- RTC DS3231 module.

- Button.

- 220 ohm resistors.

Goals

- Design and fabricate the clock casing.

- Integrate and test the electronic components.

- Develop the basic software for the clock and Pomodoro timer.

- Implement the weather display functionality.

- Ensure the device works correctly and meets the project objectives.

Deliverables

- Completed and assembled clock casing.

- Integrated and functional electronic components.

- Operational clock and Pomodoro timer software.

- Implemented weather display functionality.

- Complete documentation of the process.