Computer-Aided Design

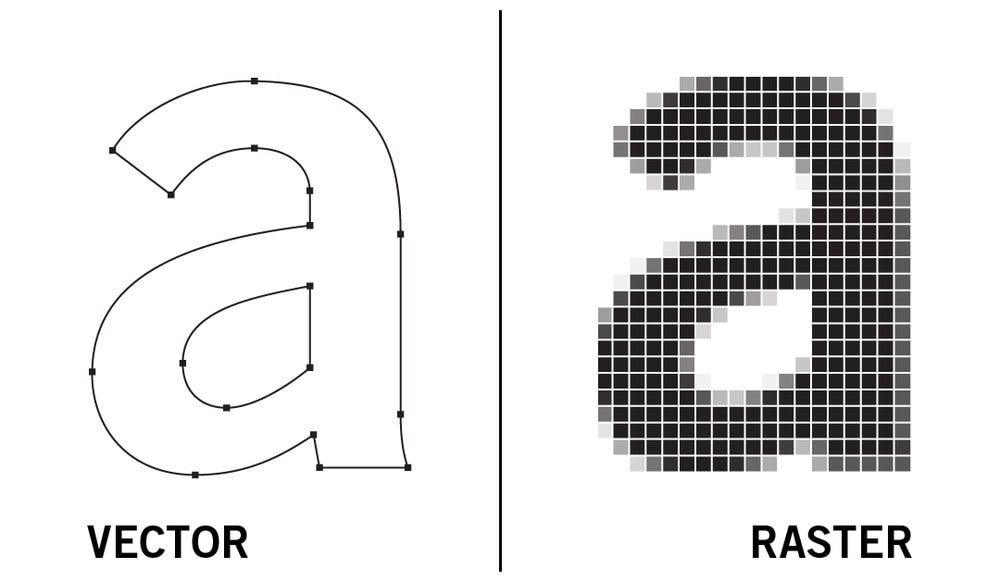

For this week, we were introduced to Computer Aided Design (CAD) a tool to create 2D and 3D models of product. 2D designs can be either Raster or Vectorized.

Raster design

Raster design refers to a bitmap graphics, where images are composed of a grid of pixels, where each pixel contains information about color and brightness. Common raster file formats include JPEG, PNG, and BMP. The negative side of raster is the quality of the image will be dependent to the resolution of the image, where a 1080p (1920 x 1080) will have over 2 million pixels and a 4K (3840 x 2160) will have 8 million pixels.

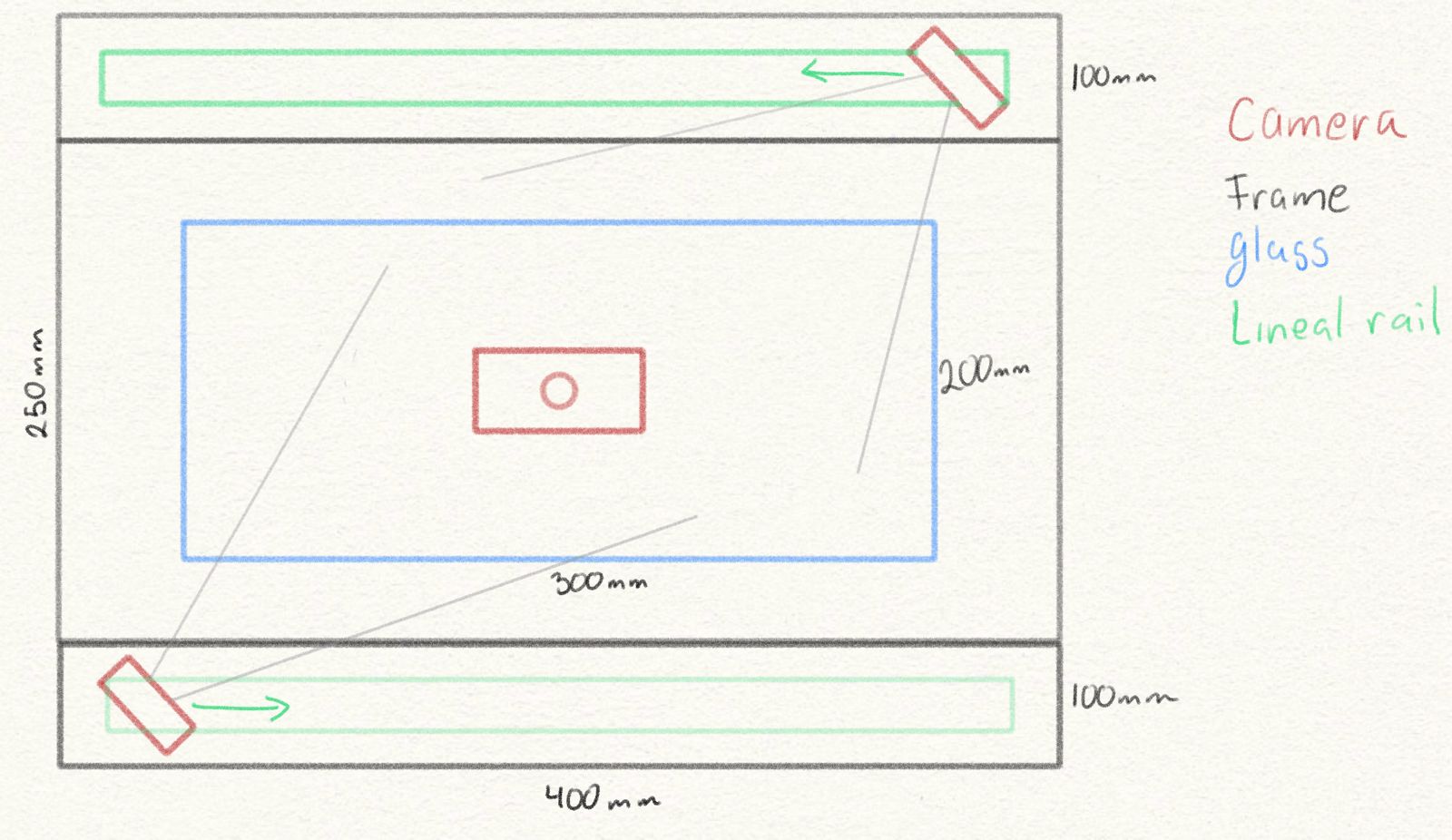

To start a preliminar design on my final project, the first step was to sketch on a raster app (Notability) the overall dimensions and idea of the photo-podoscope. This was really helpful as the sketch can be easily manipulated and modified

Vectorized design

When we talk about vectorized design, we use mathematical equations to define shapes that are created in our software such as lines, nodes and curves rather than a grid of pixels like raster graphics. This means that vector images are resolution-independent and can be scaled to any size without loss of quality. This will help to create a more precise design with aplications in graphic design and engineering.

Inkscape

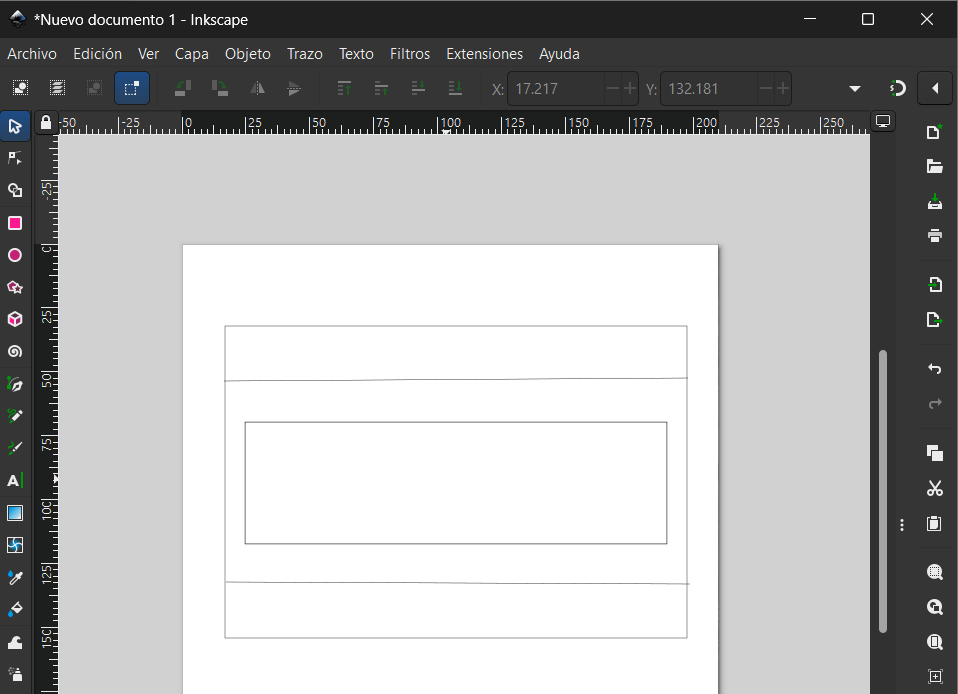

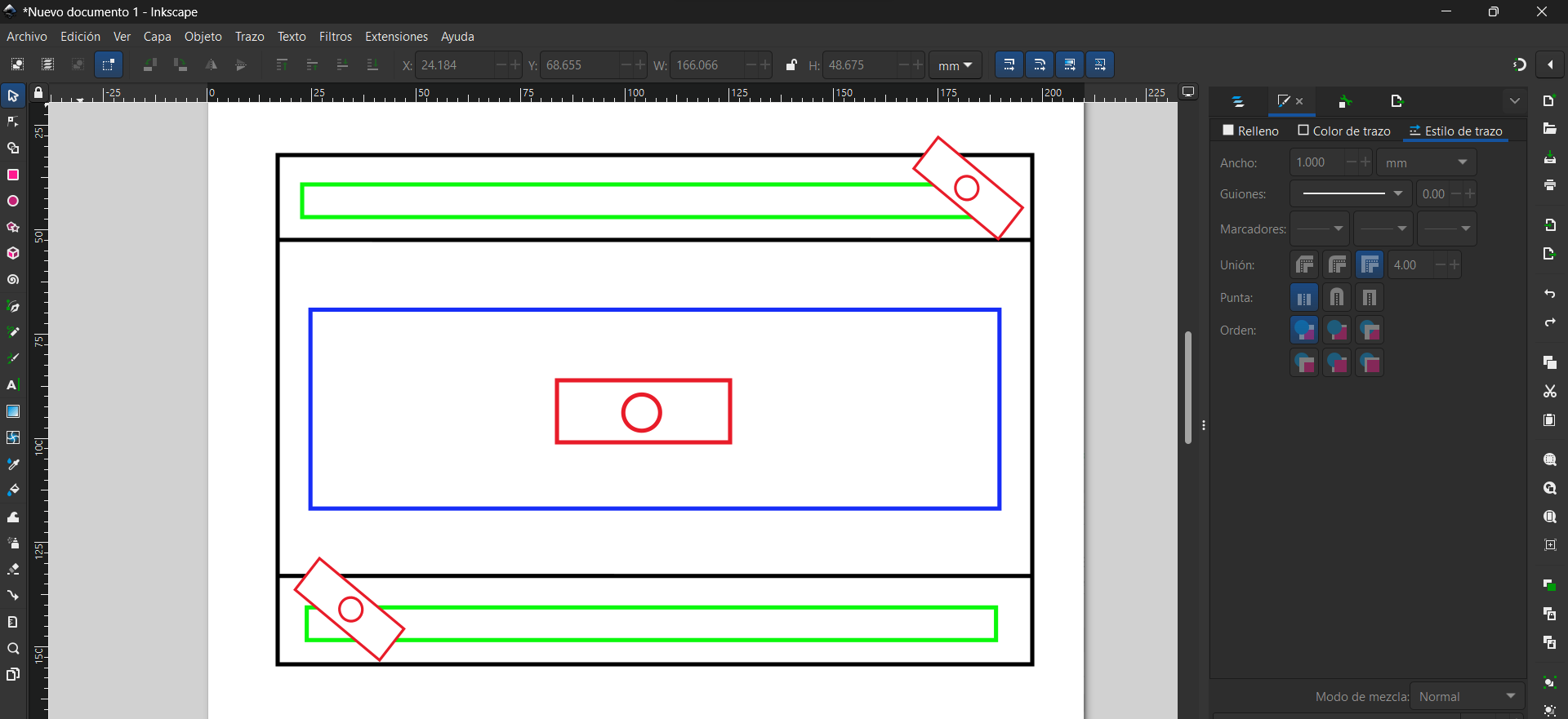

Inkscape is a Free and open source vector graphics editor for GNU/Linux, Windows and macOS. It offers a rich set of features and is widely used for both artistic and technical illustrations such as cartoons, clip art, logos, typography, diagramming and flowcharting. It uses vector graphics to allow for sharp printouts and renderings at unlimited resolution and is not bound to a fixed number of pixels like raster graphics. Inkscape uses the standardized SVG file format as its main format, which is supported by many other applications including web browsers. I recreated the same design in a vectorized form, however it took significantly more time but the result is cleaner and resizable, so depending on the application I could recommend to use vectors

3D design

3D design will provide a new dimension to what we are used to in the 2D design which is limited by height and width by incorporating depth to provide a more realistic experience. some of the key aspect of 3D design are:

The CAD software that will be used in this assigments are SolidWorks and Fusion 360, both are robust software used in the educational and engineering community with similar applications.

Fusion 360

Fusion 360 is a software by Autodesk that is described on their own website as

"The first and only integrated cloud CAD, CAM, CAE, and PCB software platform of its kind"..."Trusted by 4.6 million design and manufacturing professionals"

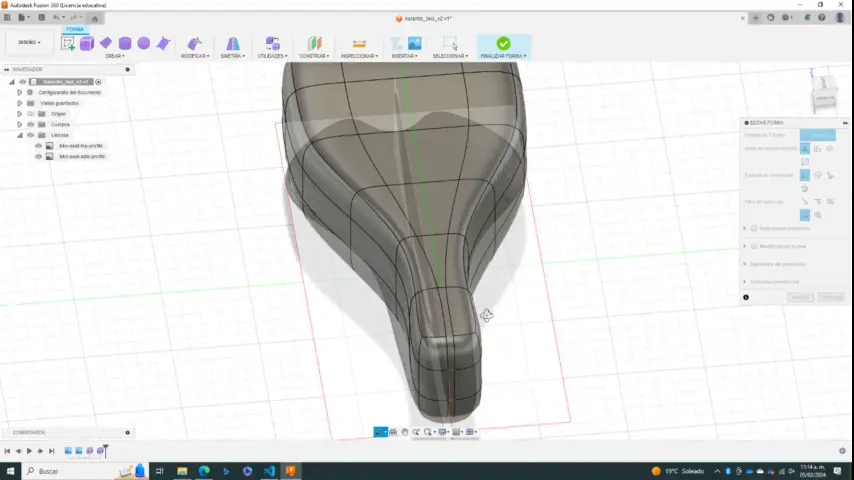

In Fusion 360 I explored the mesh option, this modeling technique is not available in other softwares like SolidWorks or CATIA V5 which I had used before. This is a completly different style and a bit difficult to grasp on the first try, however after a lot of mistakes and a few cups of coffee I was able to create a bike seat using this tool.

SolidWorks

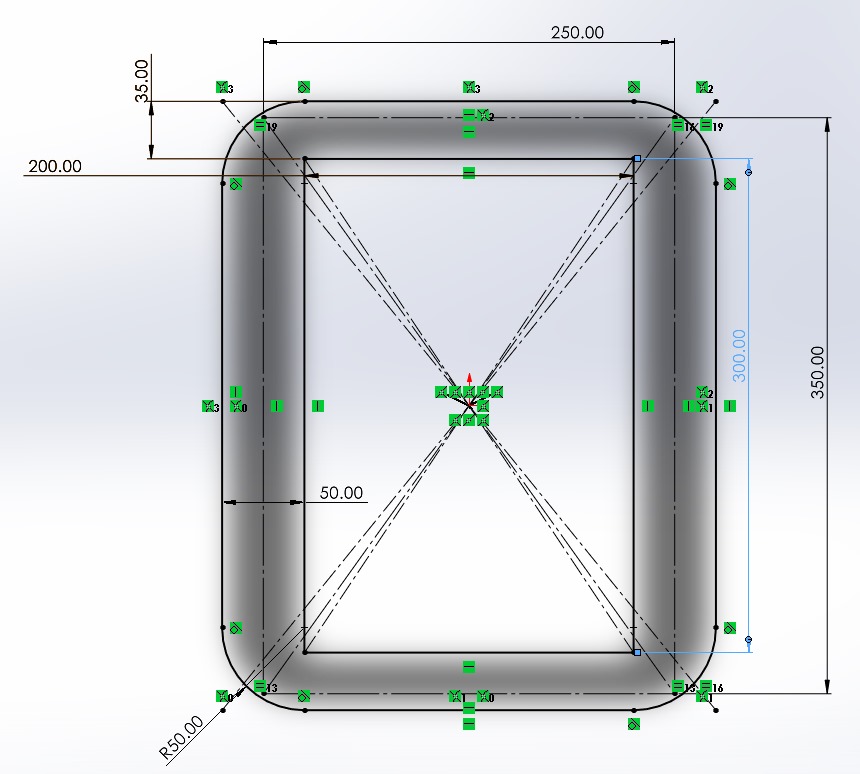

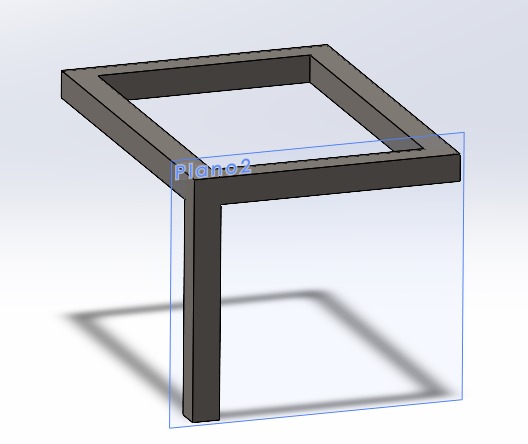

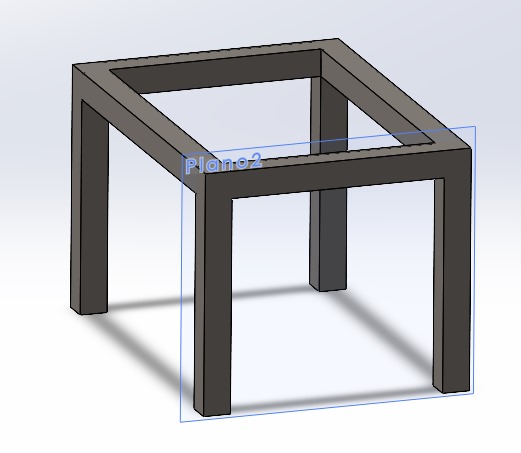

For solid works I started to create some of my final project parts and an assembly. so far therre are 3 main parts that will be the overall structure of the device, (not counting motors and mechanisms). One of the most important things in 3D modeling for engineering is to ensure the model is parametric. This will help to make sure the design is resizable if needed according to the antropometric needs.

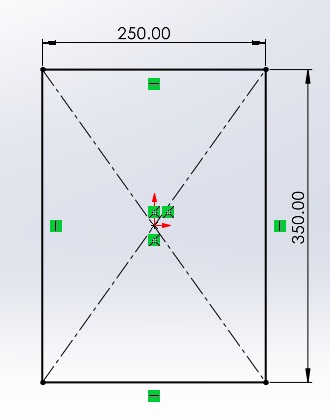

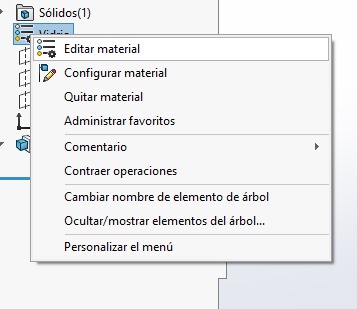

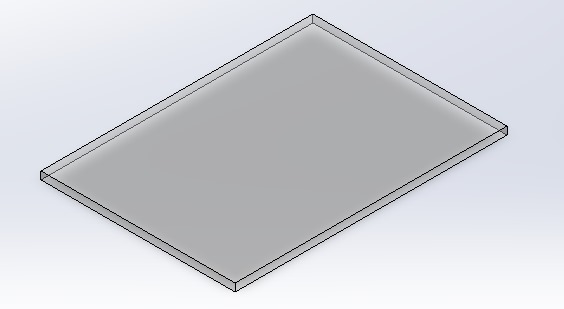

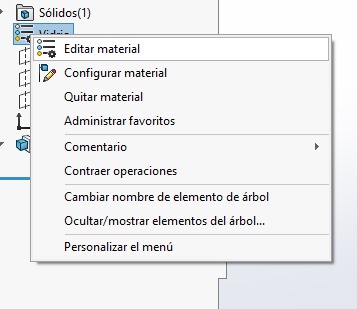

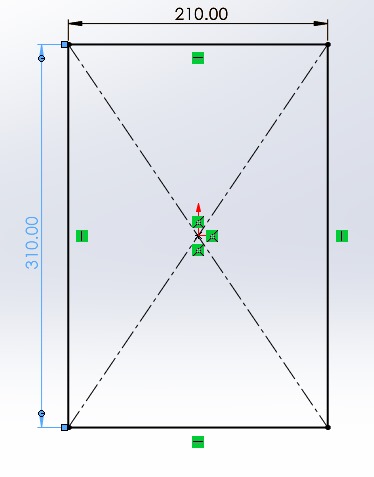

My first part for this project will be a tempered glass where the patient will step on. this was quite a simple part as only an extruded rectangle was needed. to add the material we just go to Material selection and choose from the library.

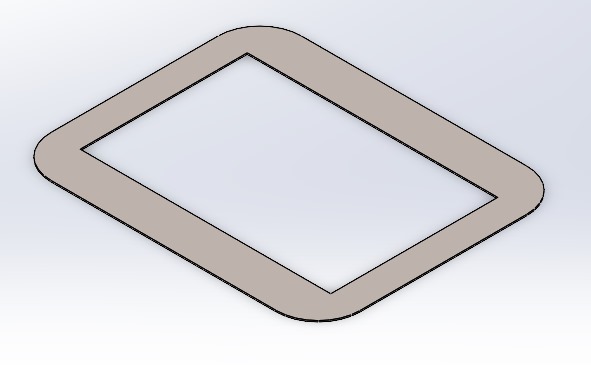

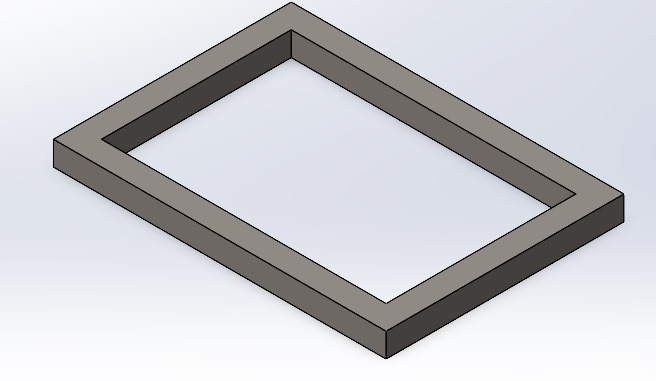

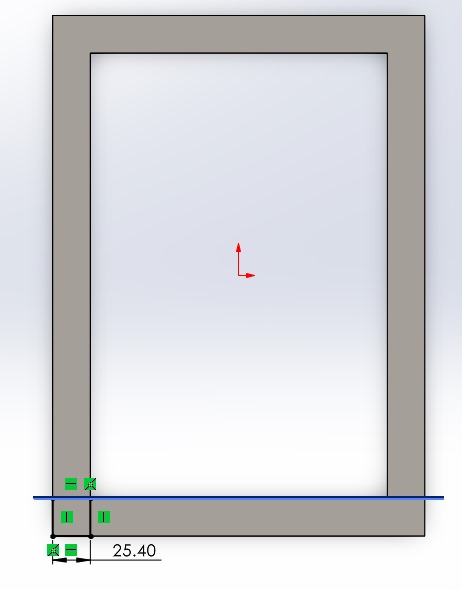

The second element of the assembly was a stainless steel plate to cover the glass corners. This will be the support where the frame will be welded to. This part as well is only a 2D sketch with an extrusion. This part will be made of stainless steel so we select that material from our library as well

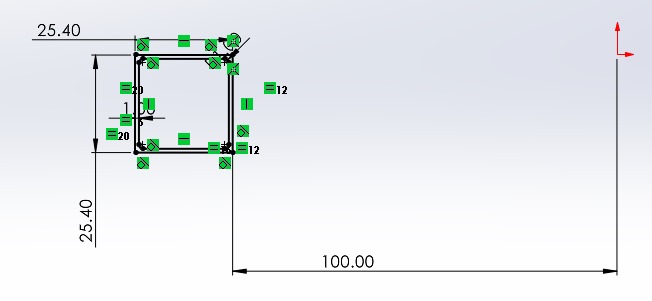

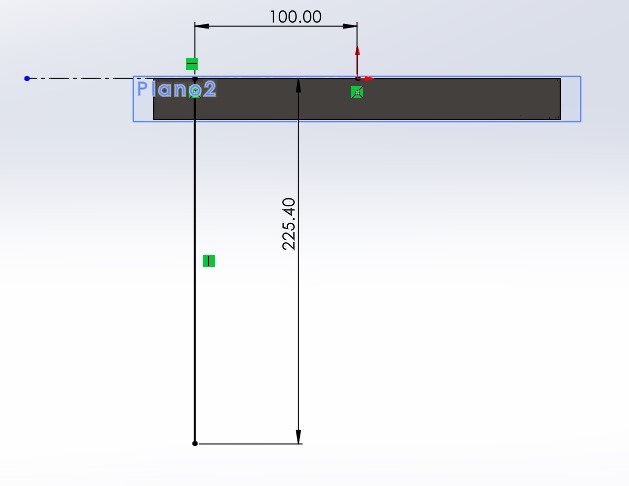

The third part is a support that will be welded. to create it, first a square profile was made os 1 inch per side and a trajectory for a rectangle. After making a swept operation, we have a rectangular profile with a square contour. For the next step I created a leg with the same idea and finalize with a mirror to add the other 3 legs.

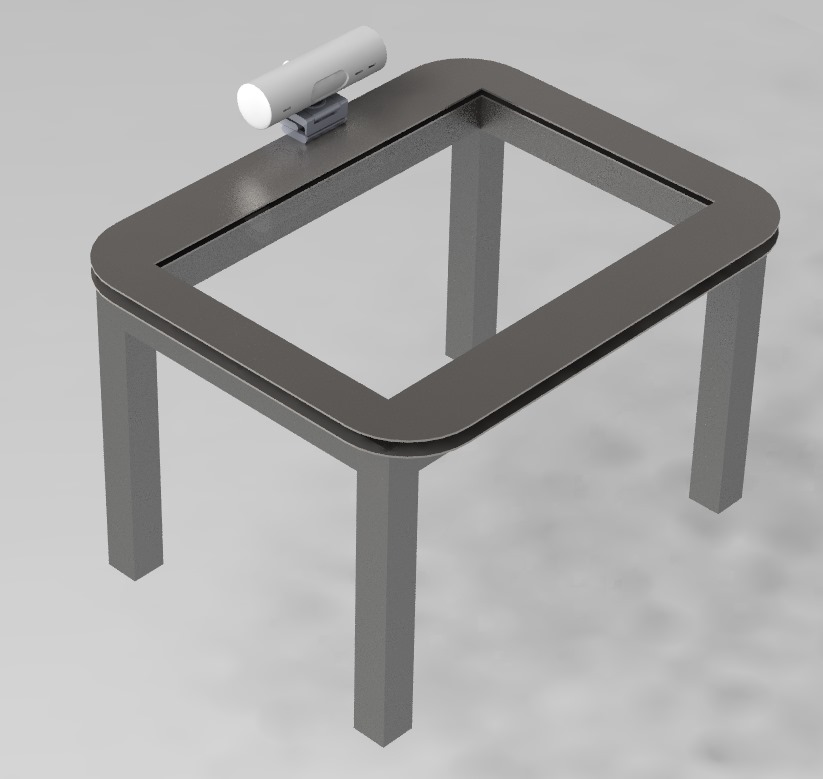

Finally to have an overall perspective of the device a camera was added ( From GRAB CAD available here) and a render was created. This render has all components together after making an assembly in SolidWorks and its intention is to have a better understanding of what the final project will look like.

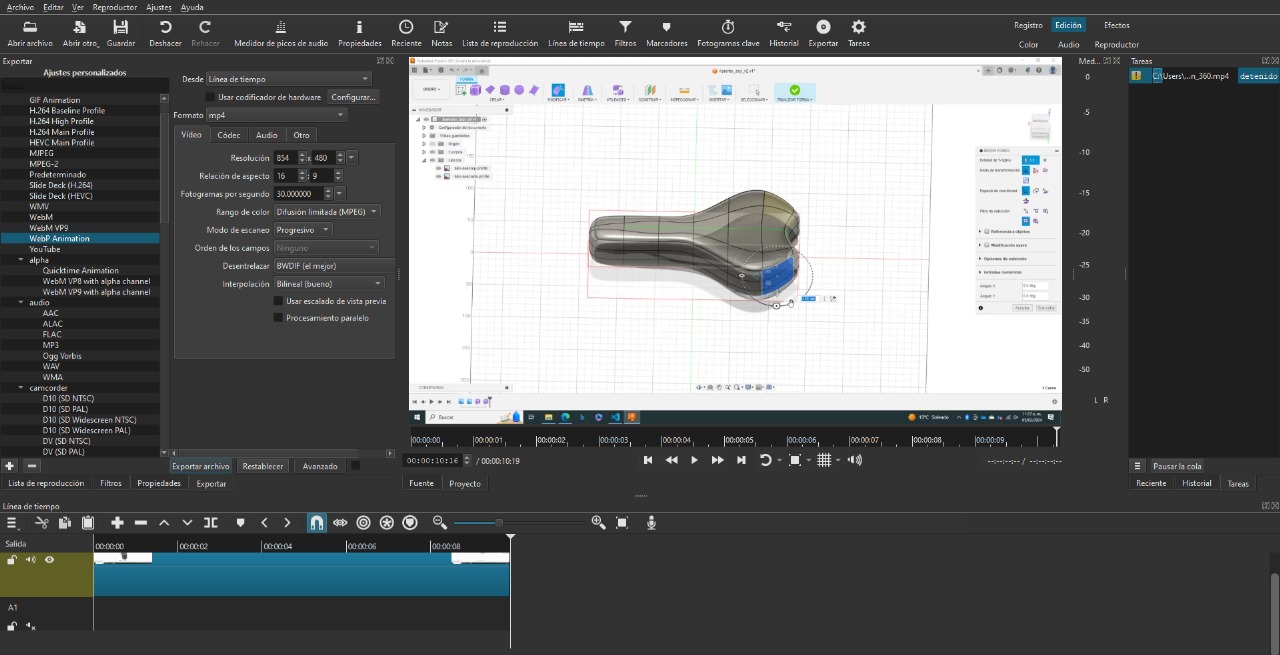

Video editing - Shotcut

To create the video for Fusion 360 I used an open source APP called Shotcut, where for this week's assigment I only used it to edit a screen recorded video of the making of the bike seat in Fusion 360 using mesh. The app is simple enough to find the basics tools to speedup the video and save it as a .webp file

My experience

Overall, I am more used to Raster design, so for an easier and quicker design it feels more natural and easy, specially when using a tablet like an iPad rather than a vectorized design. However I do recognize the lack of scalability for Raster and need to be assessed based on the design purpose. Inkscape has proven to be really good and I will definitely use it on future assignments. For the CAD software I already have a SolidWorks associate Certification and a Professional Certification so for me It was quite easy to use it, but FAB is about to challenging myself and I really liked Fusion 360, specially for the online cloud system that allows me to work on different computers and not lose any information. I will be using Fusion 360 on my future assignments as I want to be more proficient at it.

Files

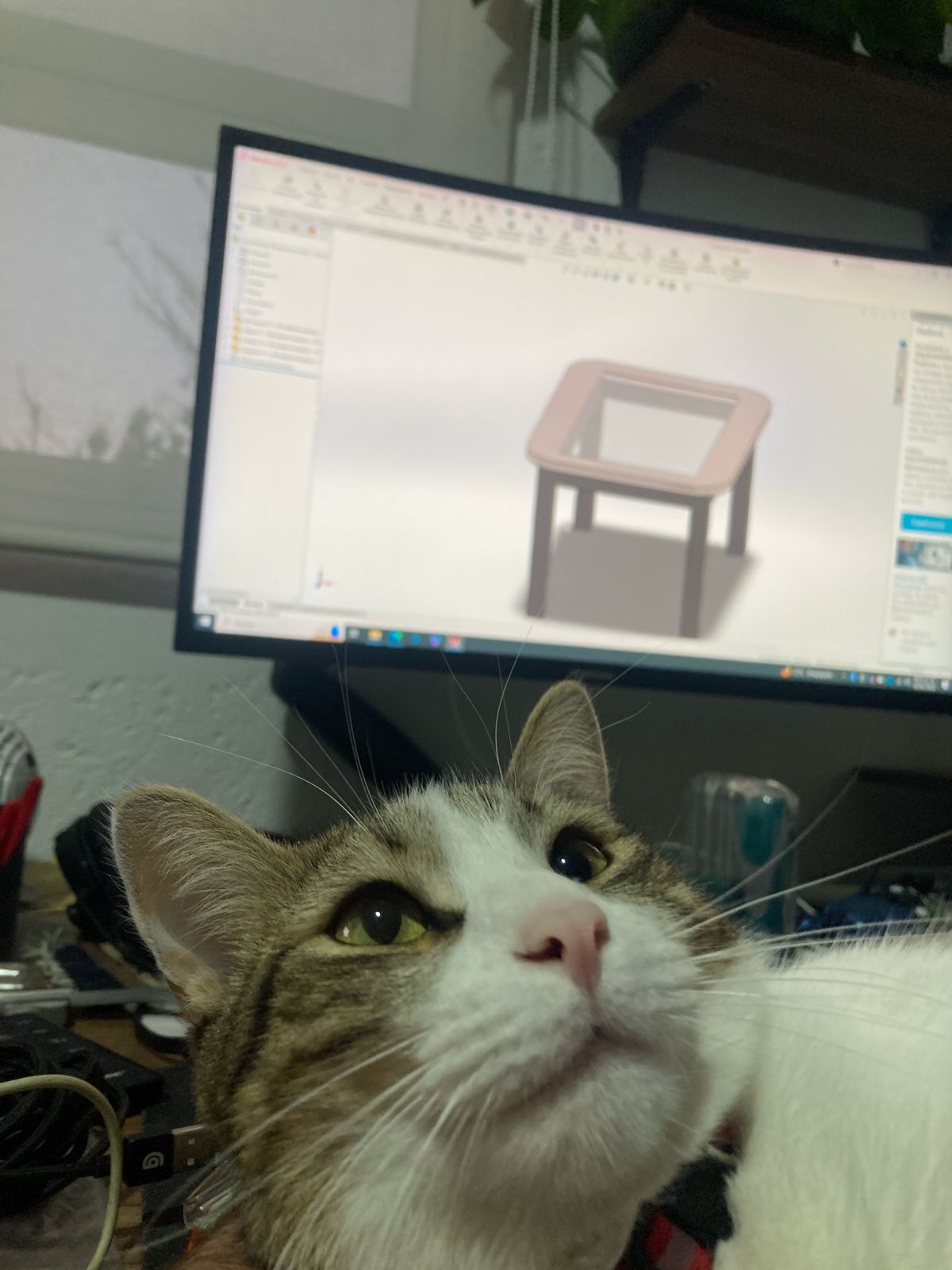

Get to know Aang the CAD Assistant

His one job is to sit on my keyboard everytime I'm about to do some CAD designs. Not very efficient TBH.