Development of custom electronic boards with CNC Router.

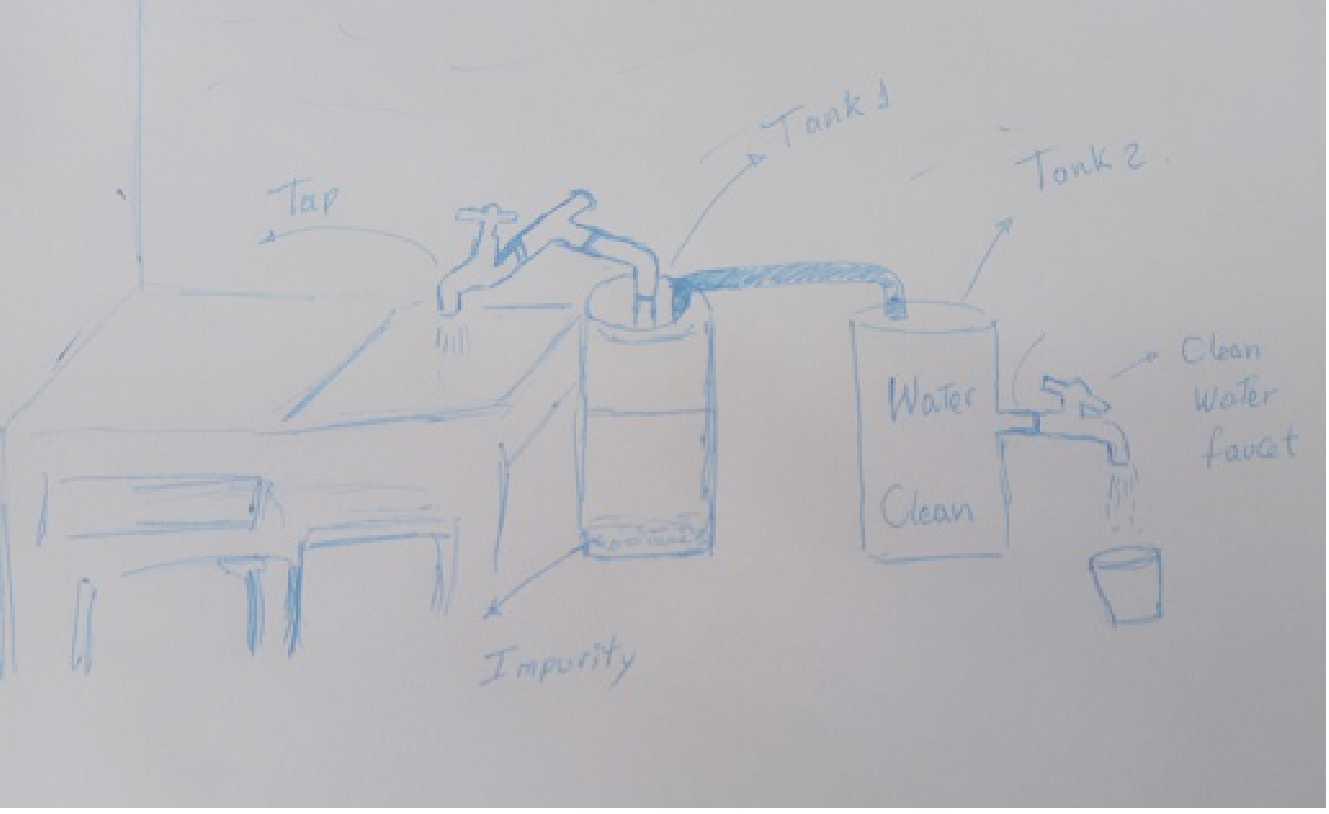

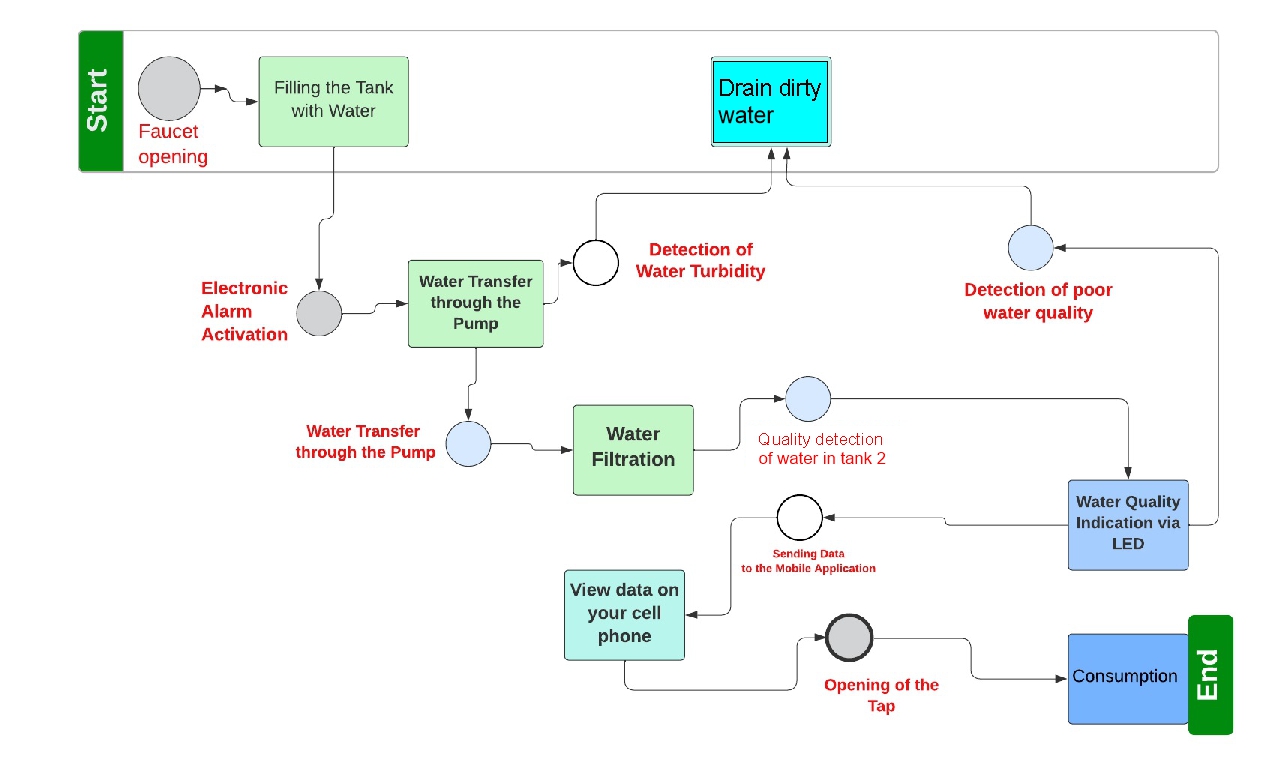

The project is a water treatment and water quality and liquid level sensors will be used to monitor and control the quality of the water supply. These sensors will collect data on different parameters, such as the presence of impurities and the level of liquid in the storage tanks. The collected data will be sent to the cloud, where it will be stored securely and available for access in real time

In the city of Pillco Marca, the water supply has notable impurities when collected from the tap, especially during and after maintenance and treatment periods in the reservoirs. The water supplied can arrive dirty and cloudy, forcing residents to let the water run until it is cleaned. Additionally, when collecting water, it is common to have to let it sit so that it settles a whitish color, which raises serious concerns about its quality and safety for human consumption.

The presence of impurities, identified by white particles and sediment in the pots, raises not only health concerns but also challenges in terms of quality of life for the residents of Pillcomarca. This often overlooked issue has a direct impact on community well-being.

The lack of an adequate filtration system in the home contributes to the persistence of this problem. Consequently, I propose the development of a project that comprehensively addresses the improvement of water supply in homes. This project will seek to design, implement and test an accessible and effective filtration system that can be adopted by me and then transferred to the inhabitants of the city.

Final project design

This project is closely related to Sustainable Development Goal number 6, which seeks to guarantee the availability and sustainable management of water and sanitation for all. By addressing the quality of water supply and promoting safe drinking practices, the project directly contributes to achieving this goal. By improving access to clean, safe water, the risk of water-related diseases can be significantly reduced and the quality of life of affected communities improved. Furthermore, by promoting sustainable water management practices, the project also contributes to the conservation and protection of water resources for future generations.

By facing this challenge, I not only aspire to improve water quality in Pillcomarca, but also to empower the community with a practical and sustainable solution. Participation in Fabacademy will provide the tools and knowledge necessary to carry out this project effectively, leveraging innovation and technology for the benefit of the community.

In summary, the problem that I will address is a challenge that I face with great joy and desire to contribute to my city. With this project I want to provide families with quality water free of impurities and my goal is to design and implement a domestic filtration system. that improves the quality of water and, therefore, the quality of life of the residents of this city, the process of which I mention below.

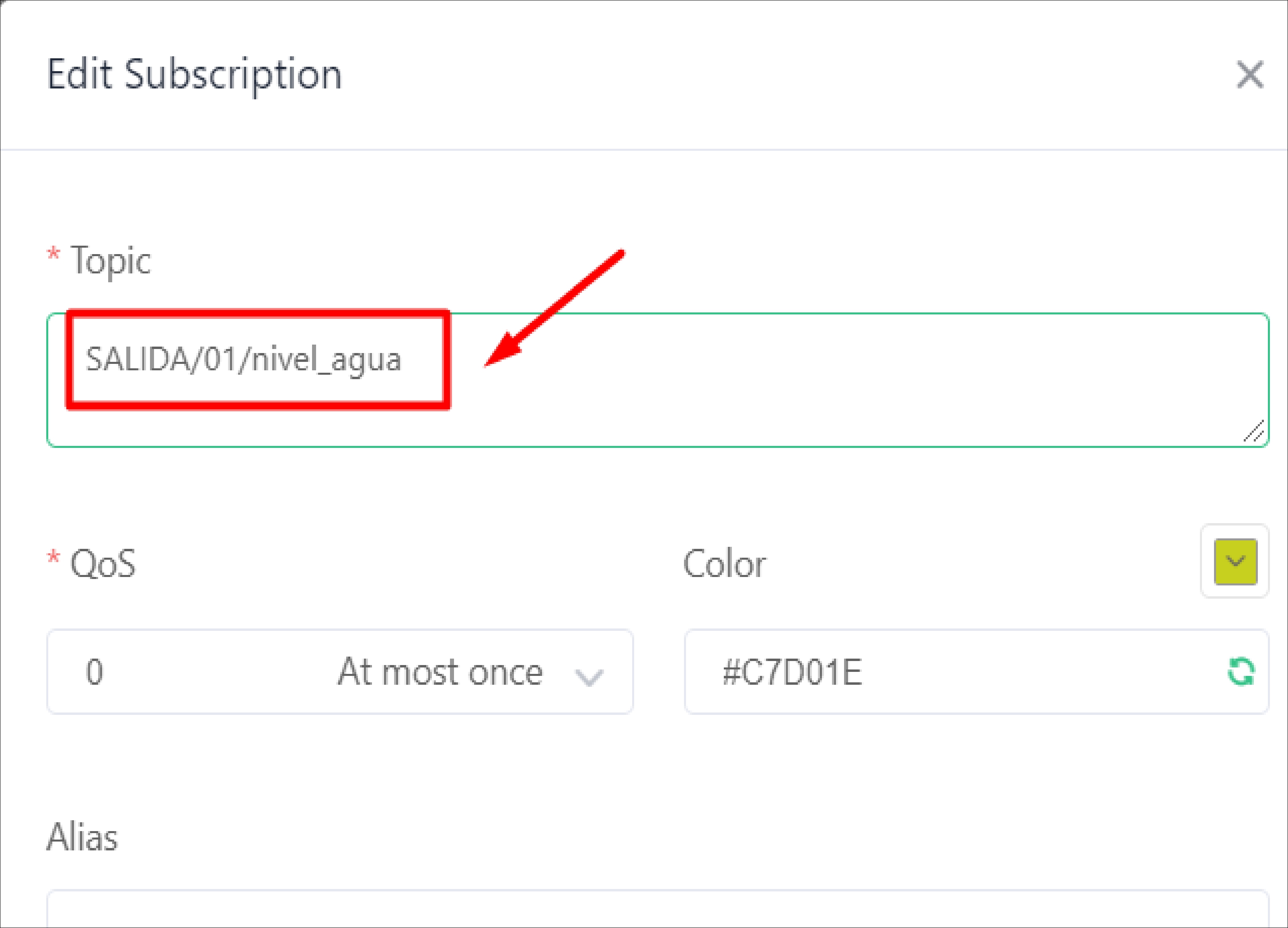

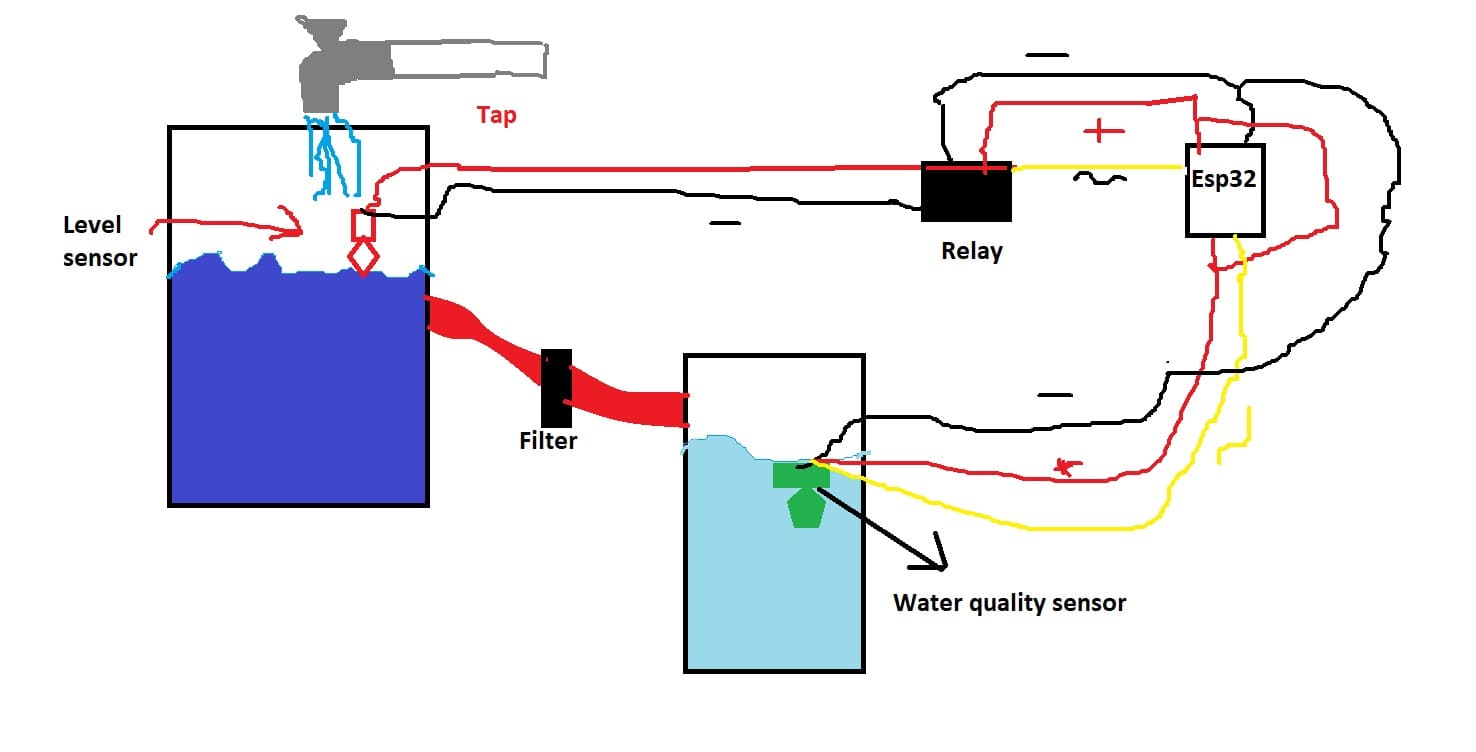

The management of this process will be in charge of a level sensor that will automatically control the opening and closing of the tap, ensuring an effective sedimentation cycle. In addition, pH and water quality sensors will be integrated to evaluate the purity and chemical characteristics of the liquid.

Subsequently, through a pumping system, the treated water will be directed to a second tank, specifically intended for home consumption. This tank will also be equipped with a level sensor and a water quality sensor to ensure the safety and drinkability of the supply.

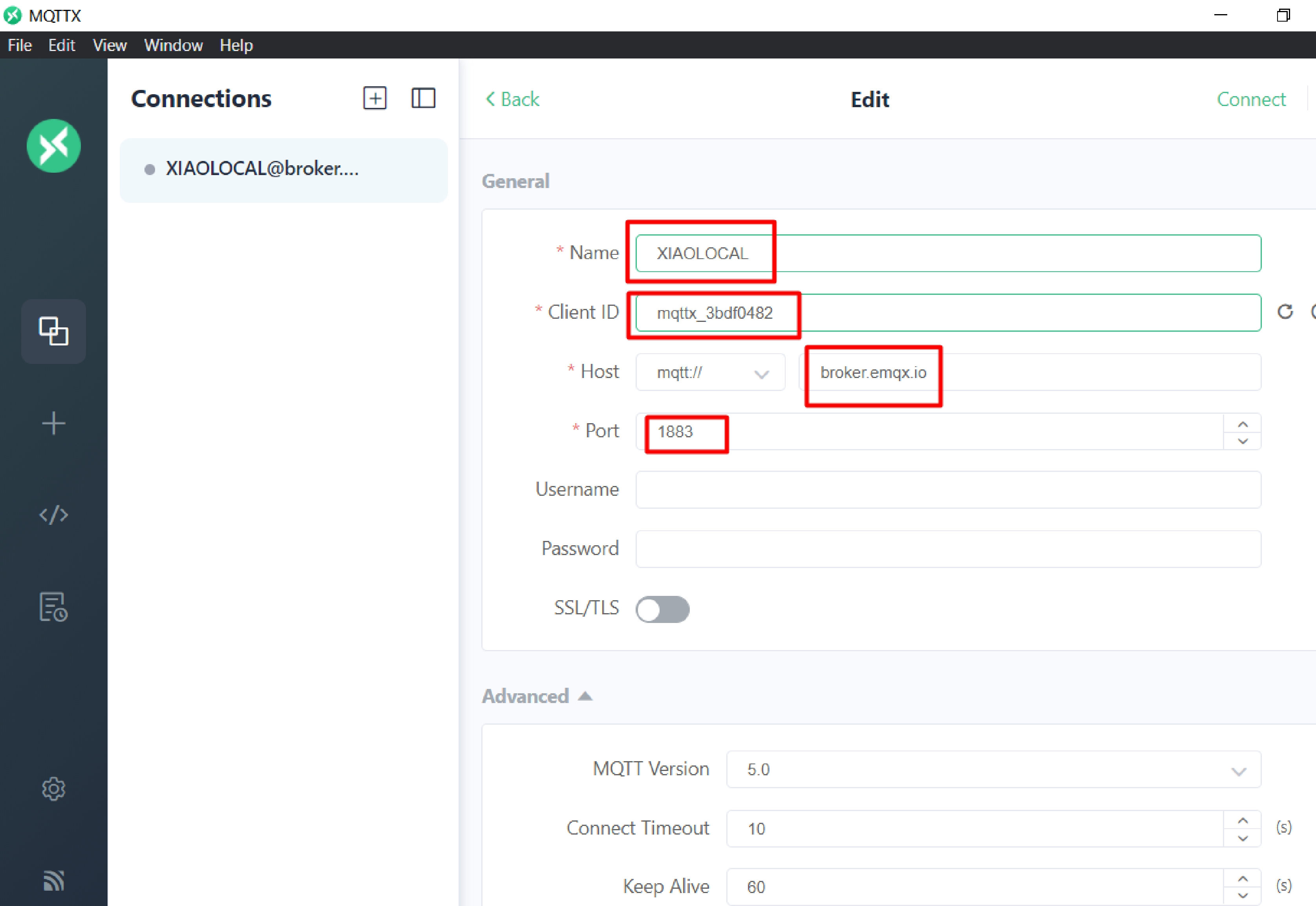

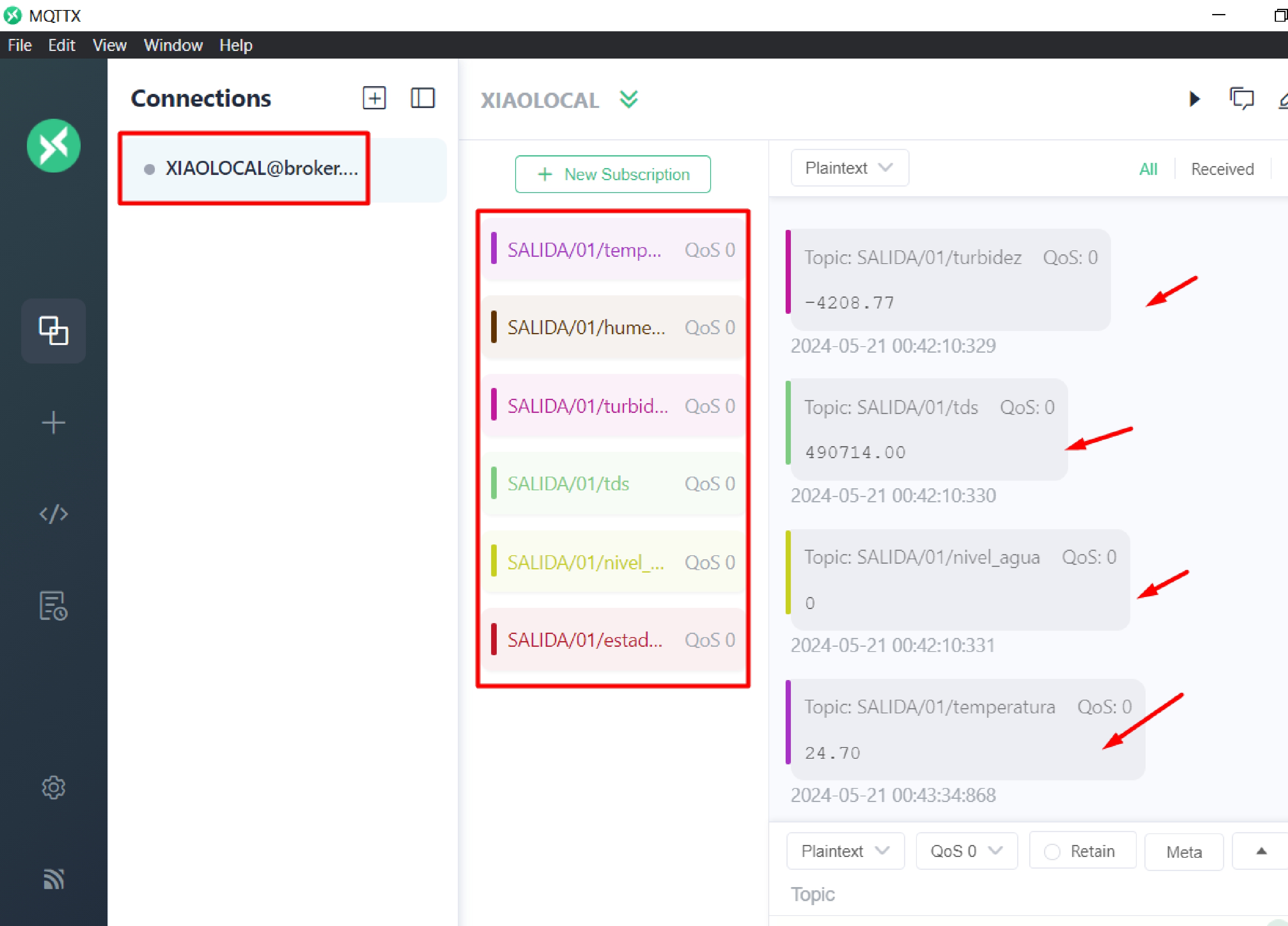

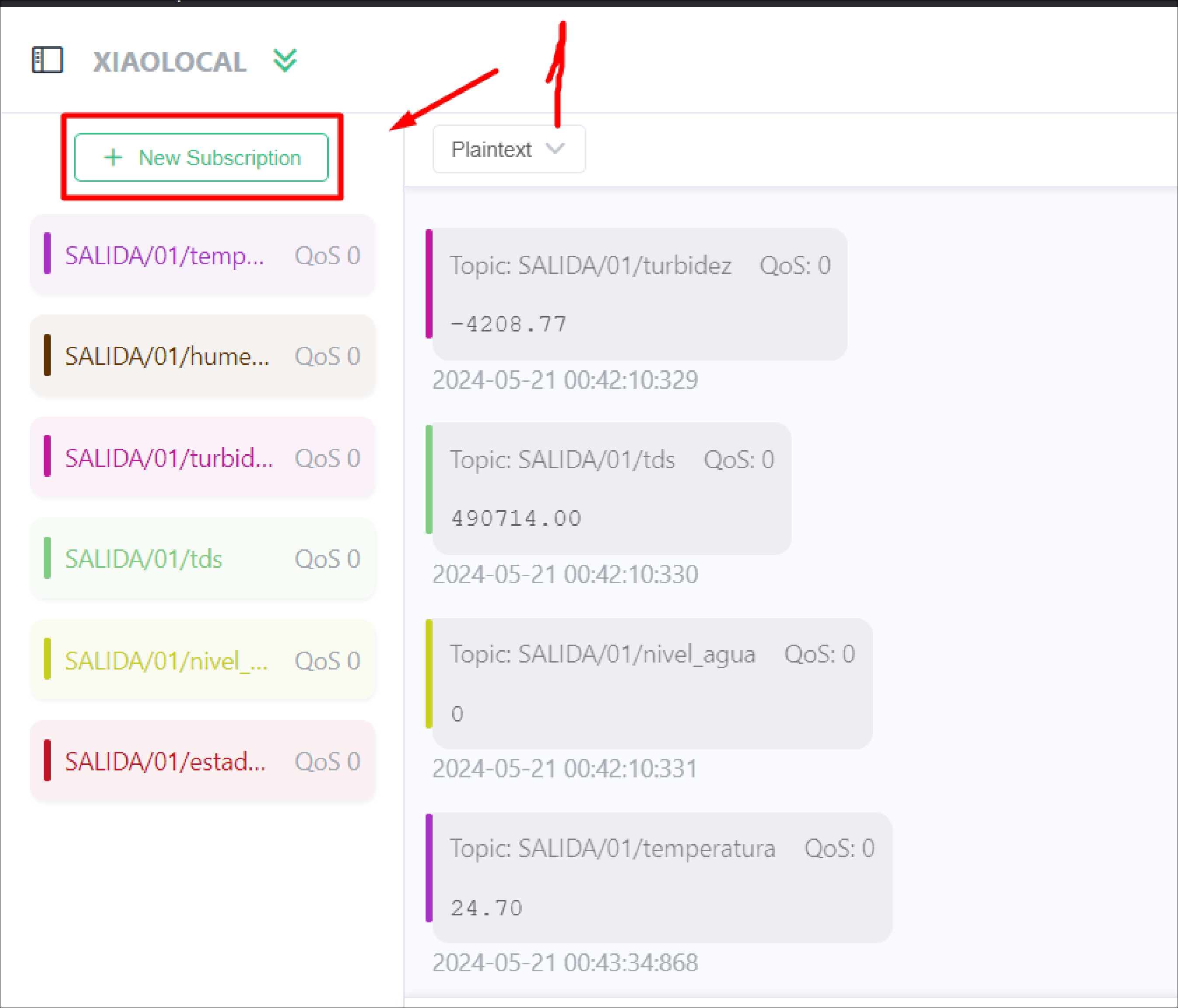

Real-time data collection will be possible thanks to a central electronic circuit, which will be connected via Wi-Fi. The data collected by the water level and quality sensors will be continuously transmitted to a mobile device, allowing constant monitoring and facilitating informed decision-making about water consumption at home.

This holistic approach will not only provide a reliable supply of clean water, but will also offer an intuitive and accessible user interface to monitor and control parameters in real time, providing a complete and technologically advanced solution for efficient water resource management in the domestic environment.

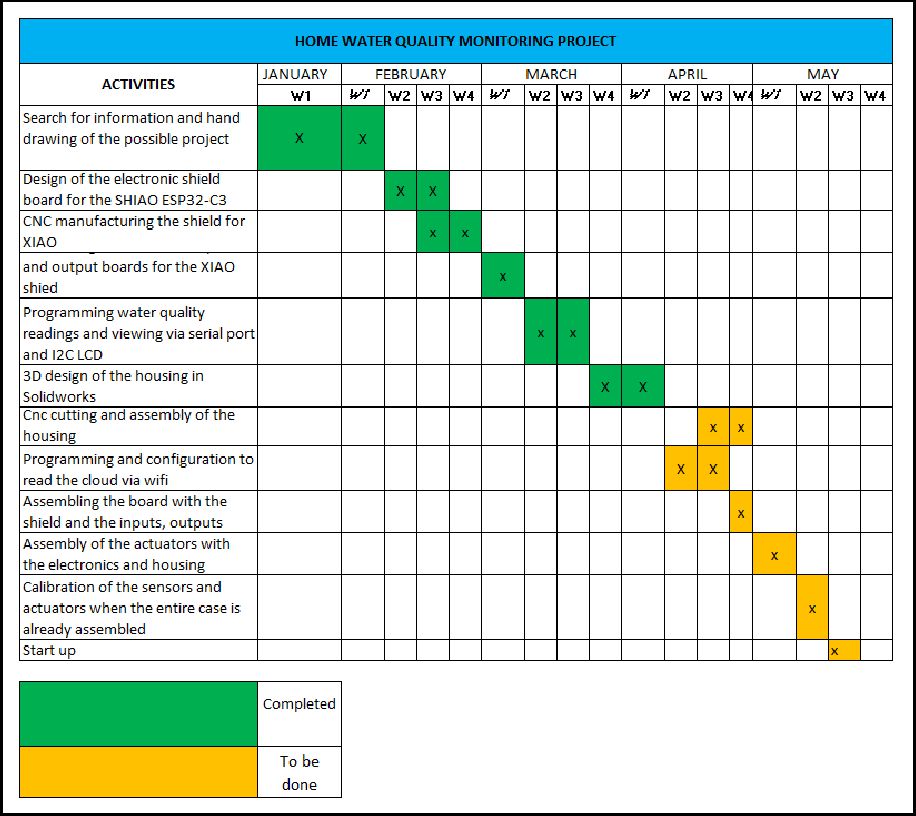

The following image shows in detail the schedule of activities of the final project, where the tasks, their start and end dates, as well as those responsible for each activity are specified.

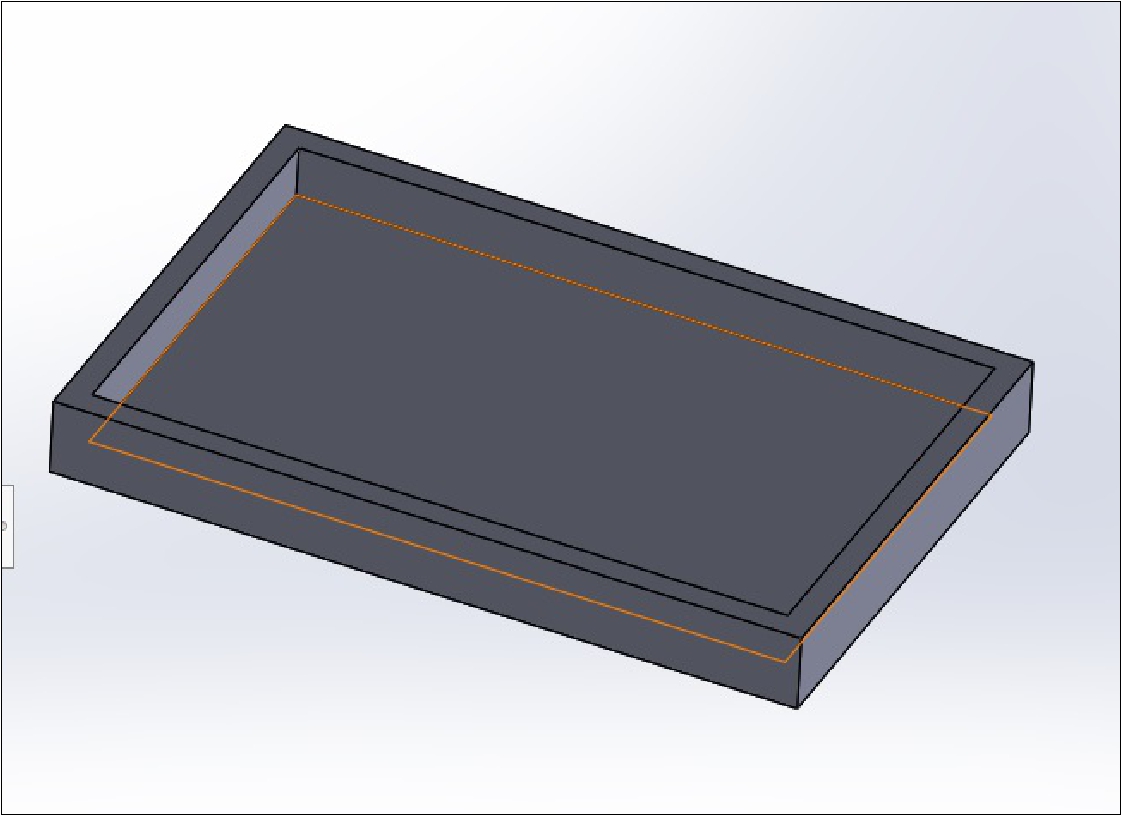

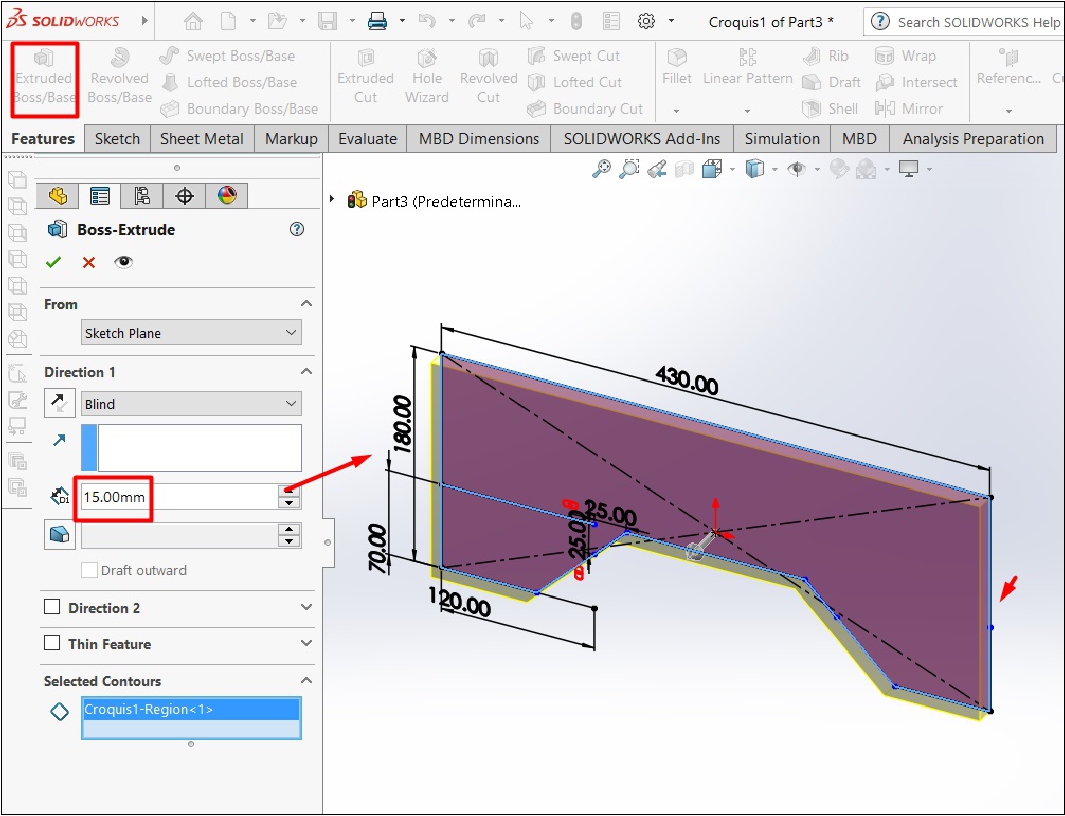

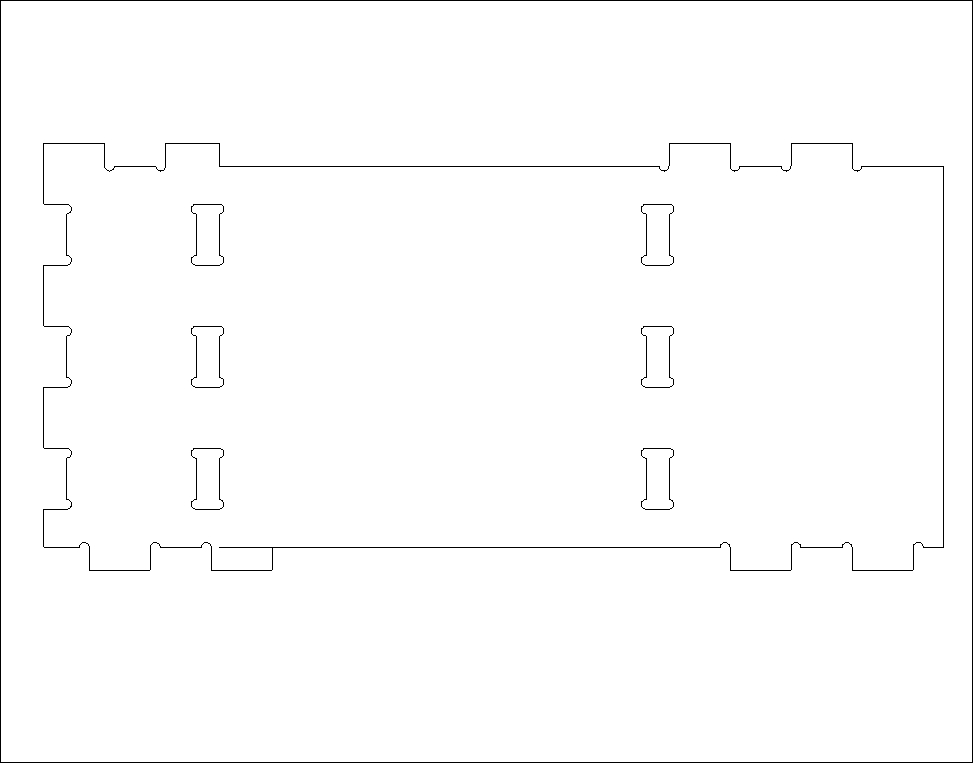

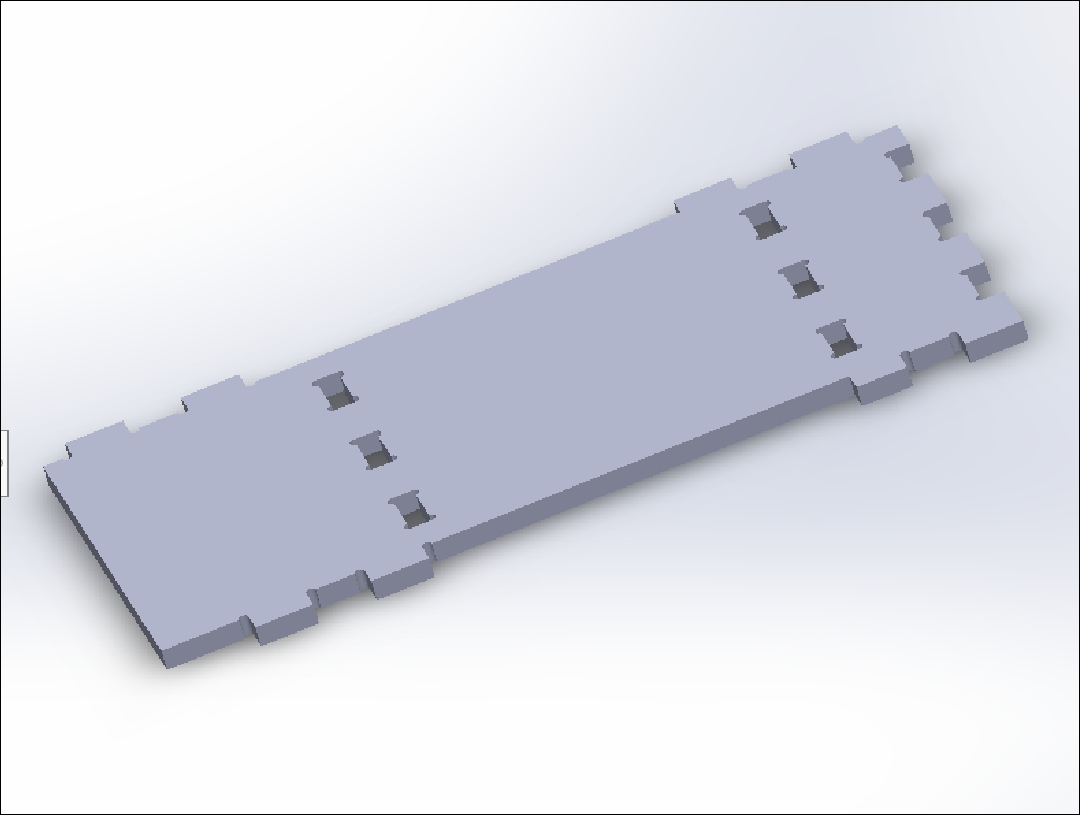

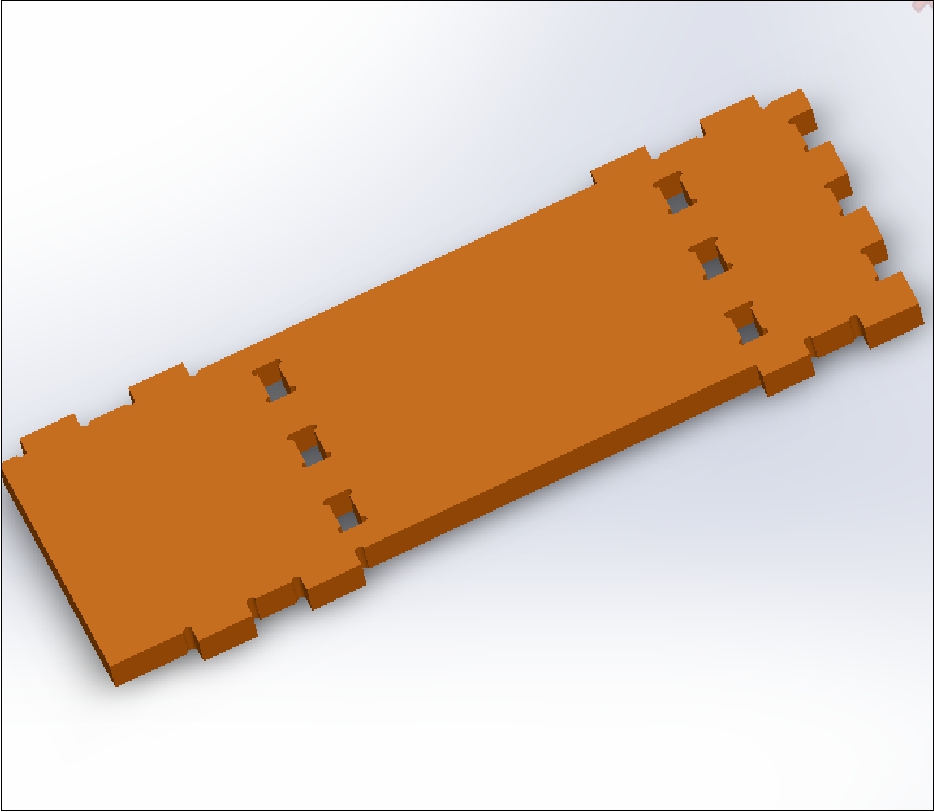

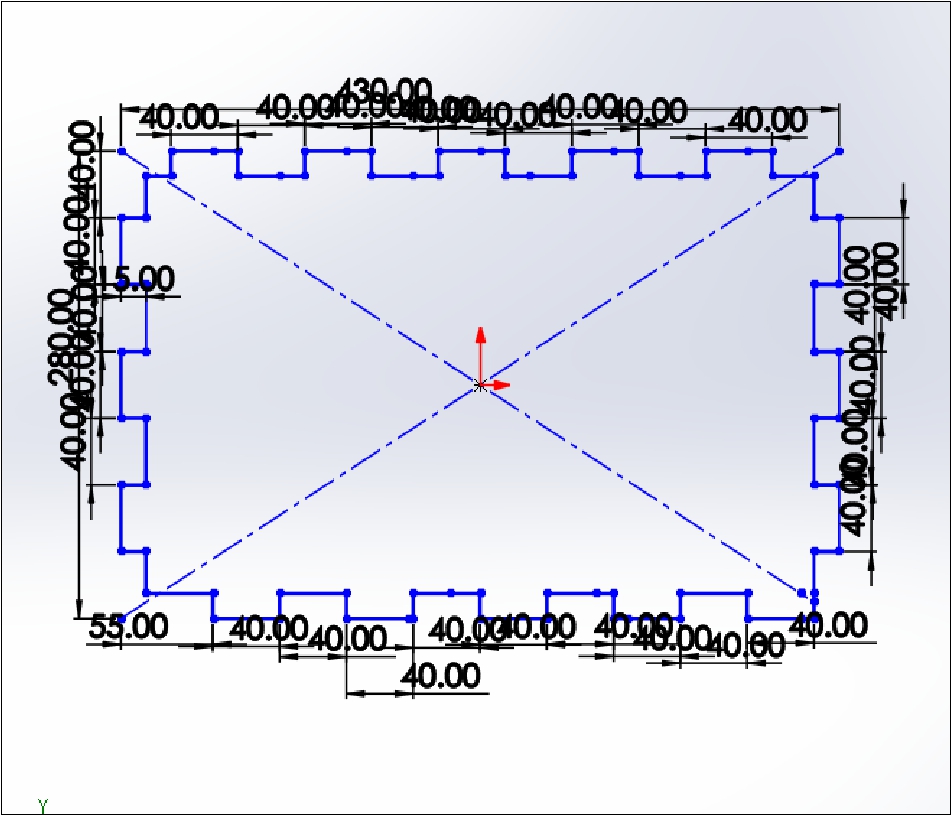

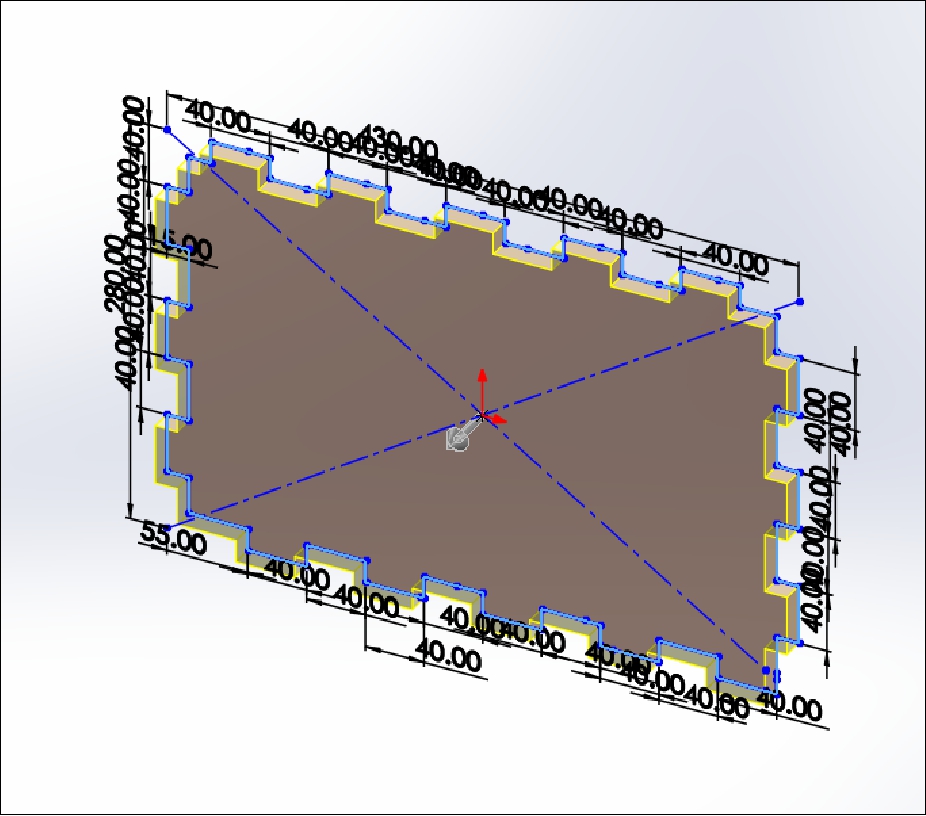

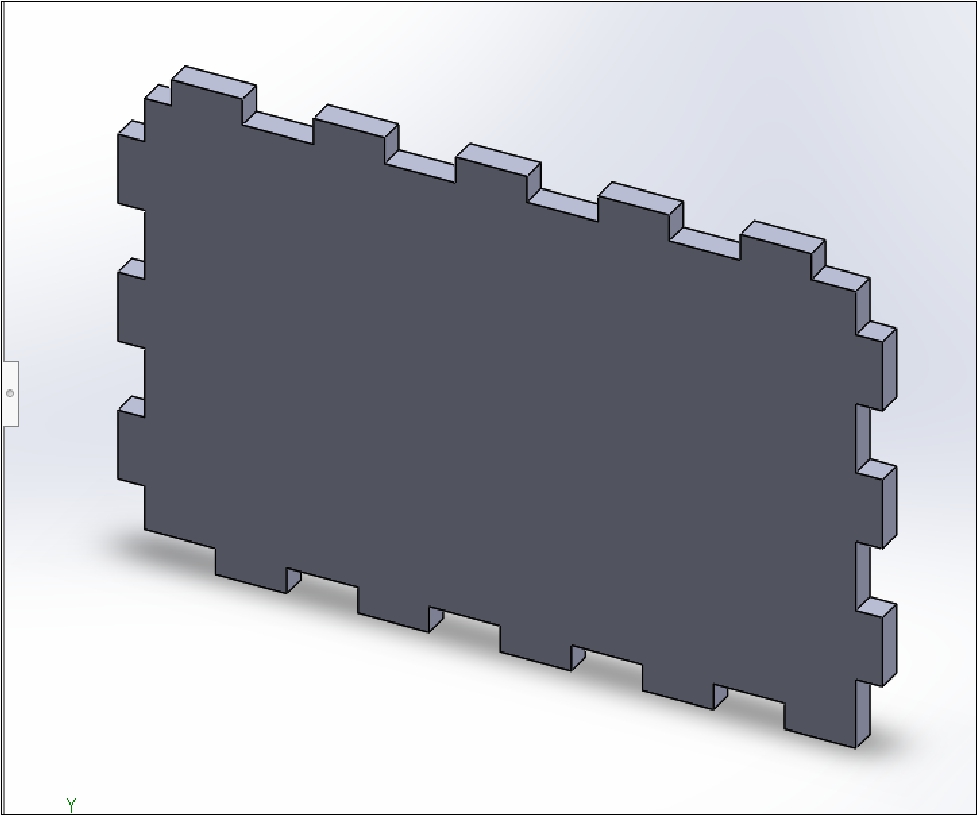

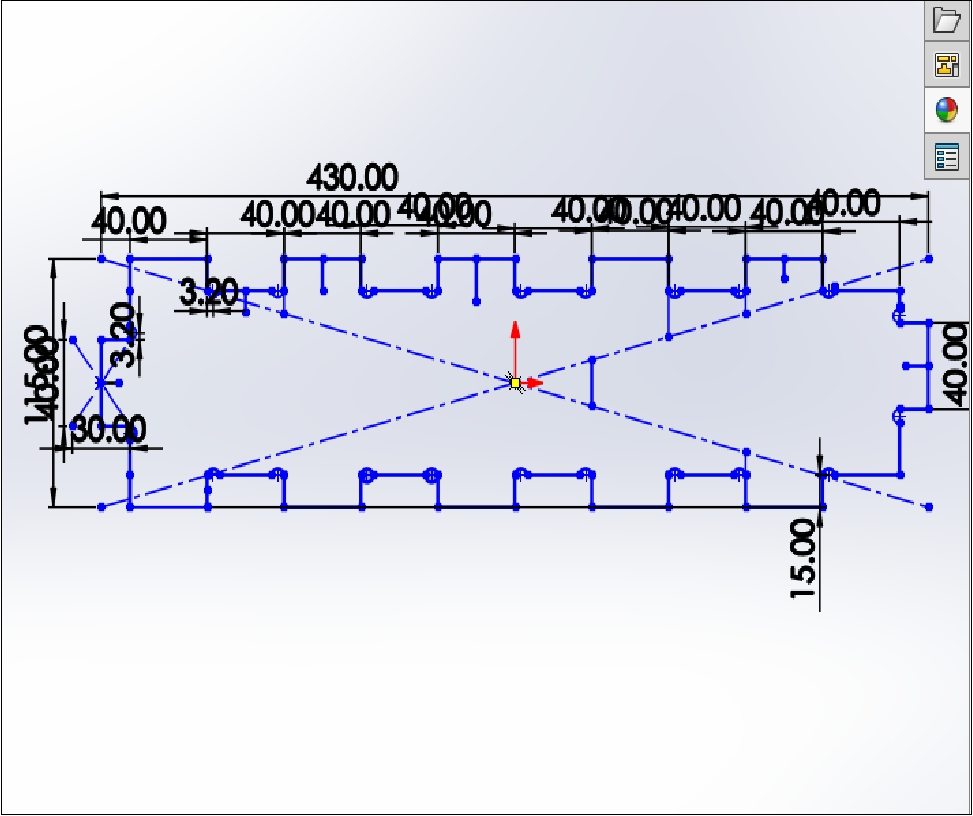

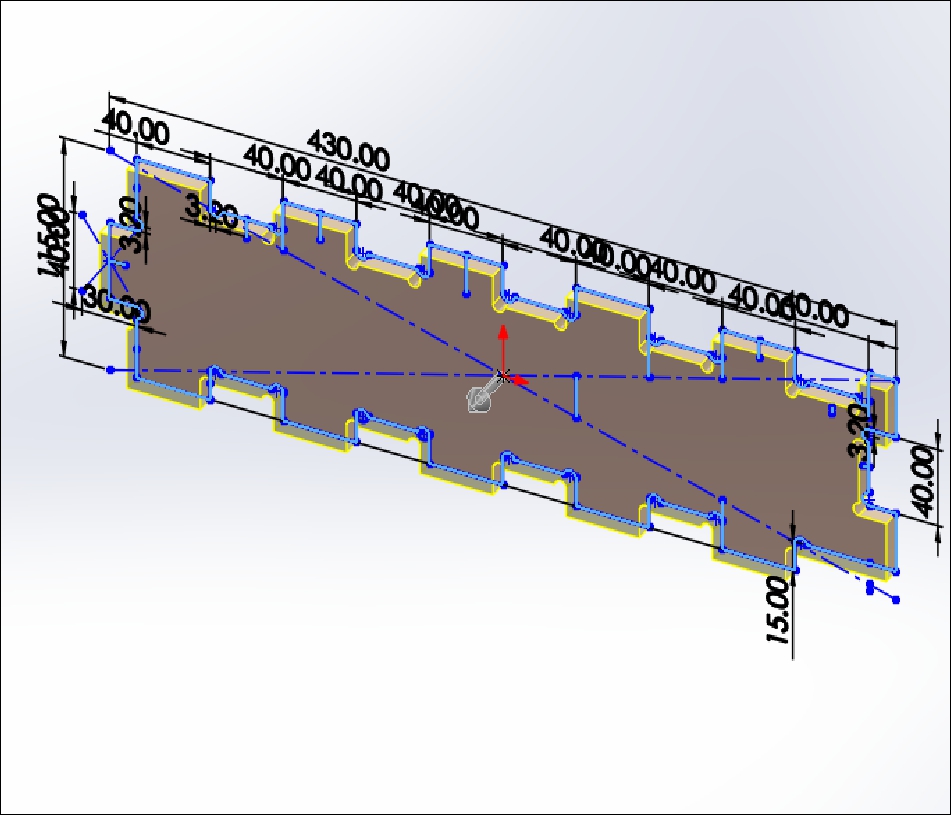

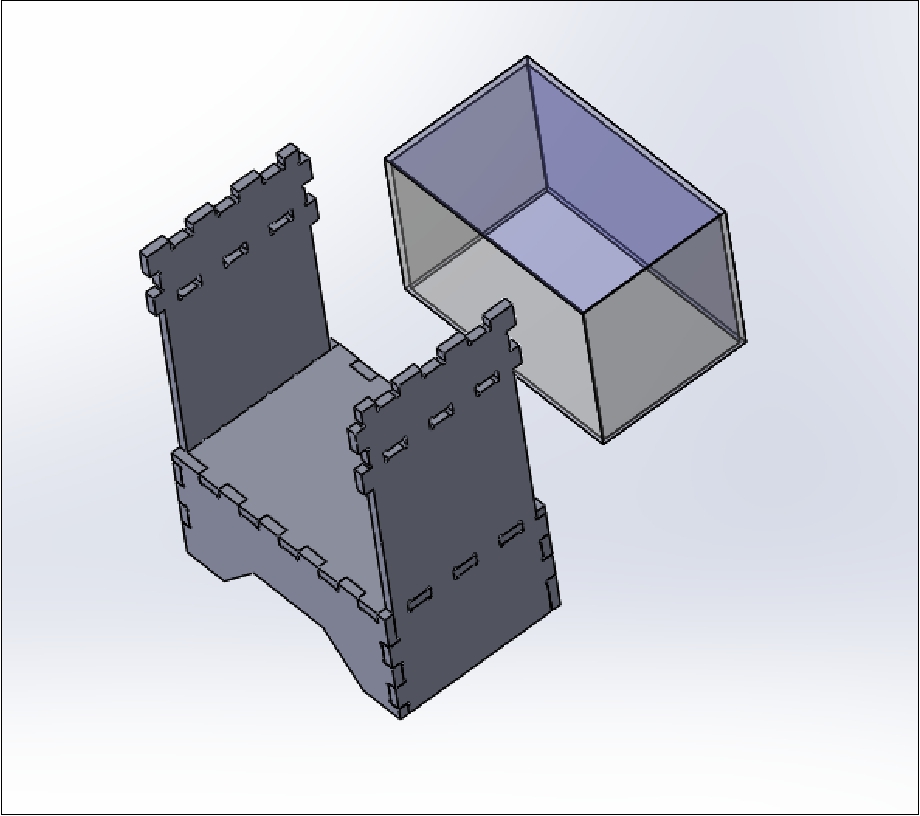

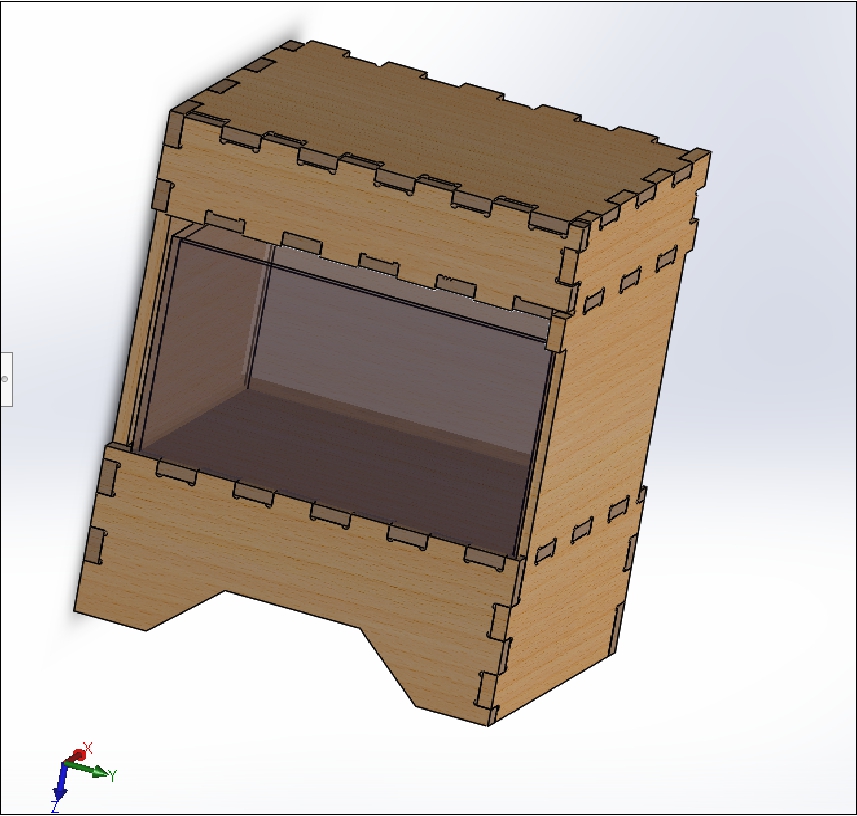

For the past few days, my focus has been completely dedicated to the meticulous design of two elements essential to the completion of my project: the case and the glass in SolidWorks software.

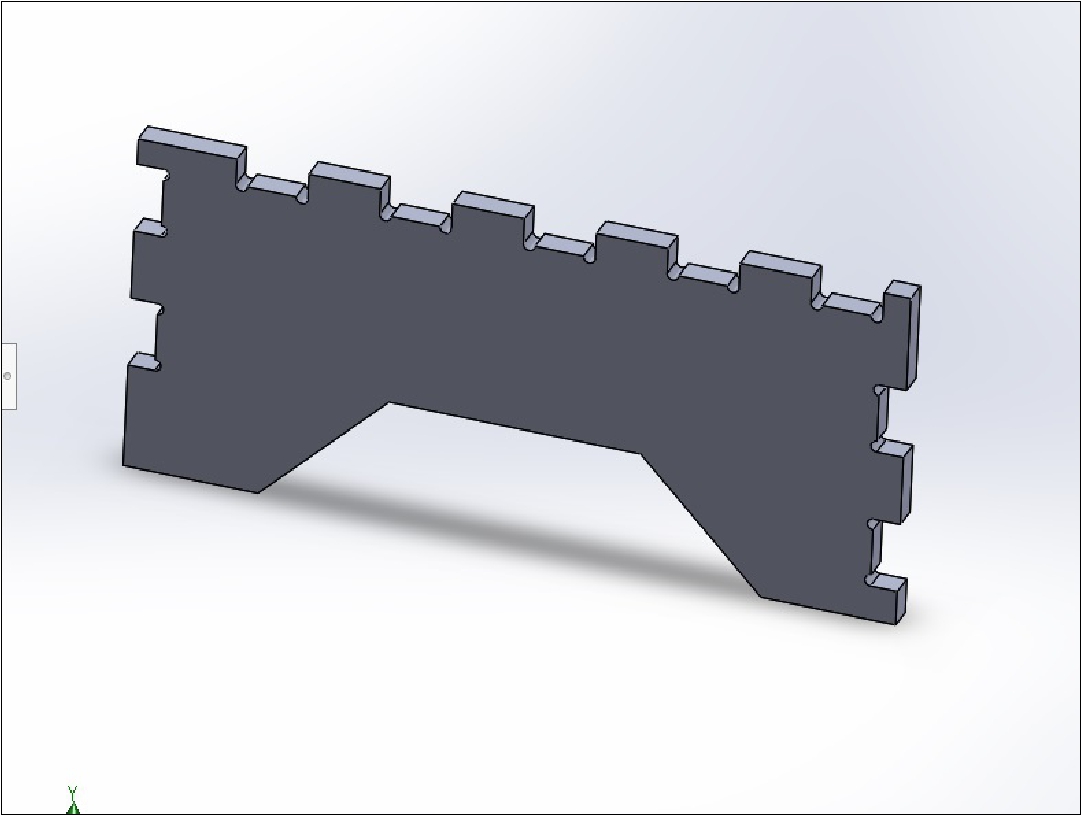

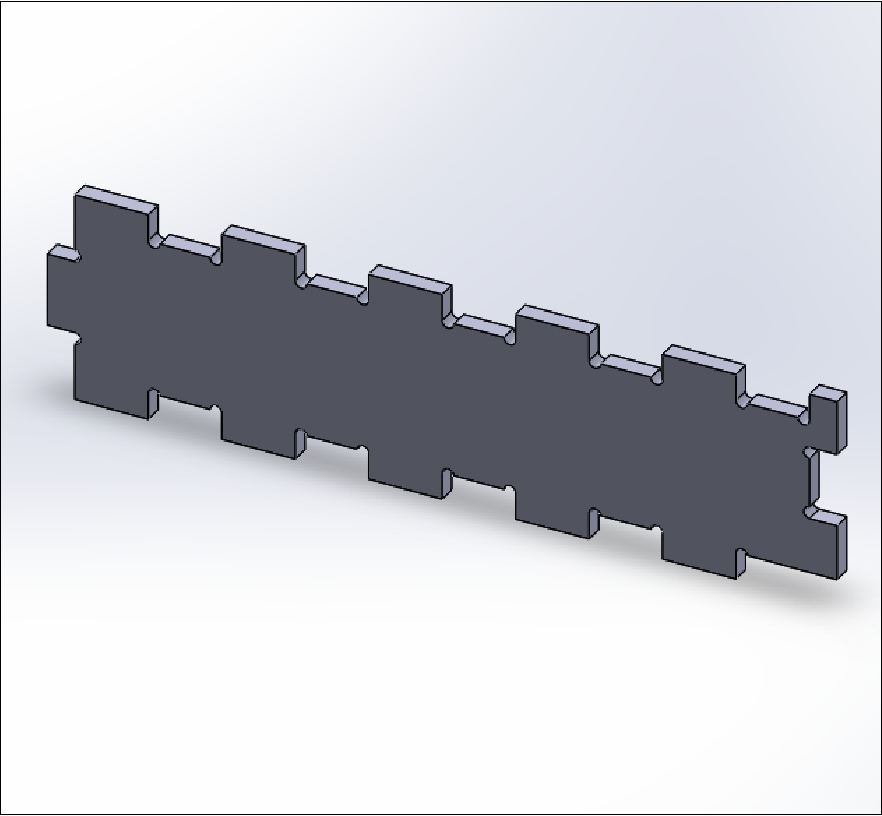

These pieces are the supports of the project, which will be built with OSB material.

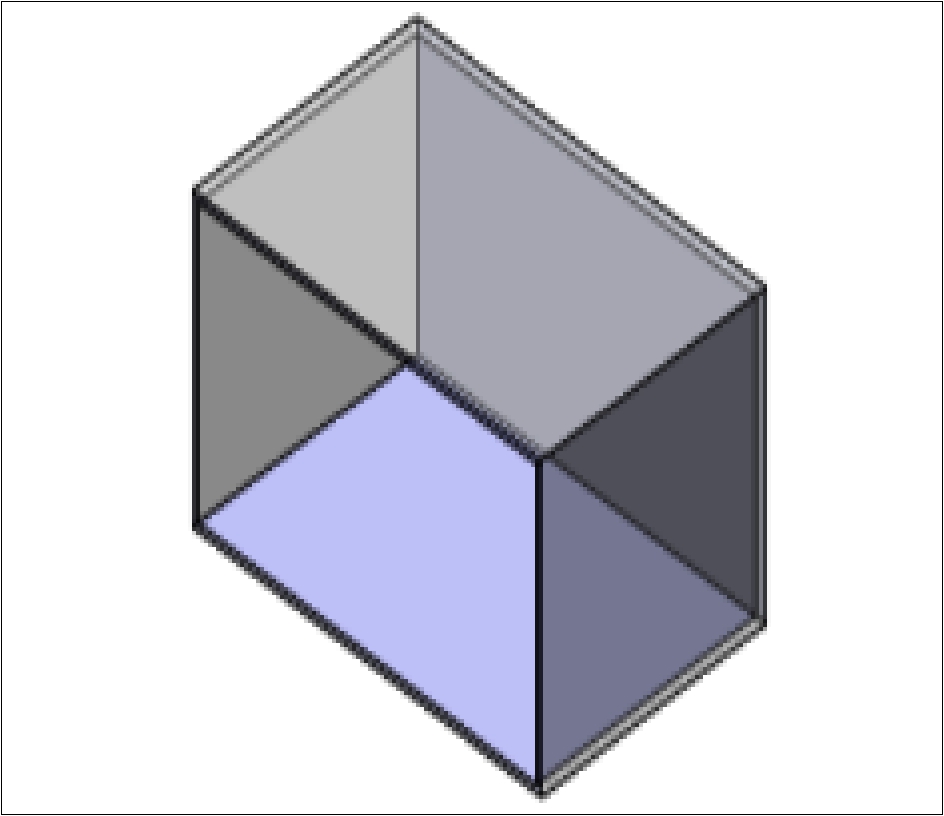

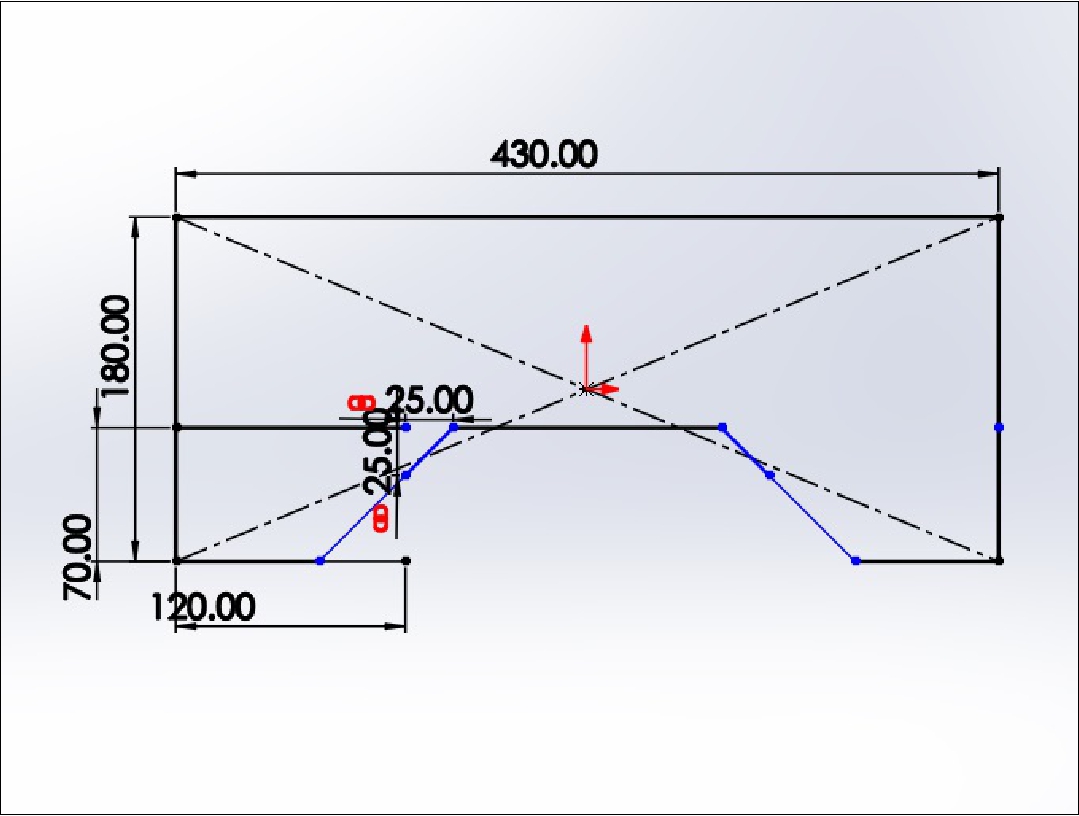

The third piece corresponds to the side supports of the project, which are also made of 15 mm thick OSB.

The fourth piece is the platform or table on which the container with water will be placed, which will also be made of 15 mm thick OSB. It is also the top cover of the project

The fifth piece acts as a support and cover for the electronic part that will be placed on top.

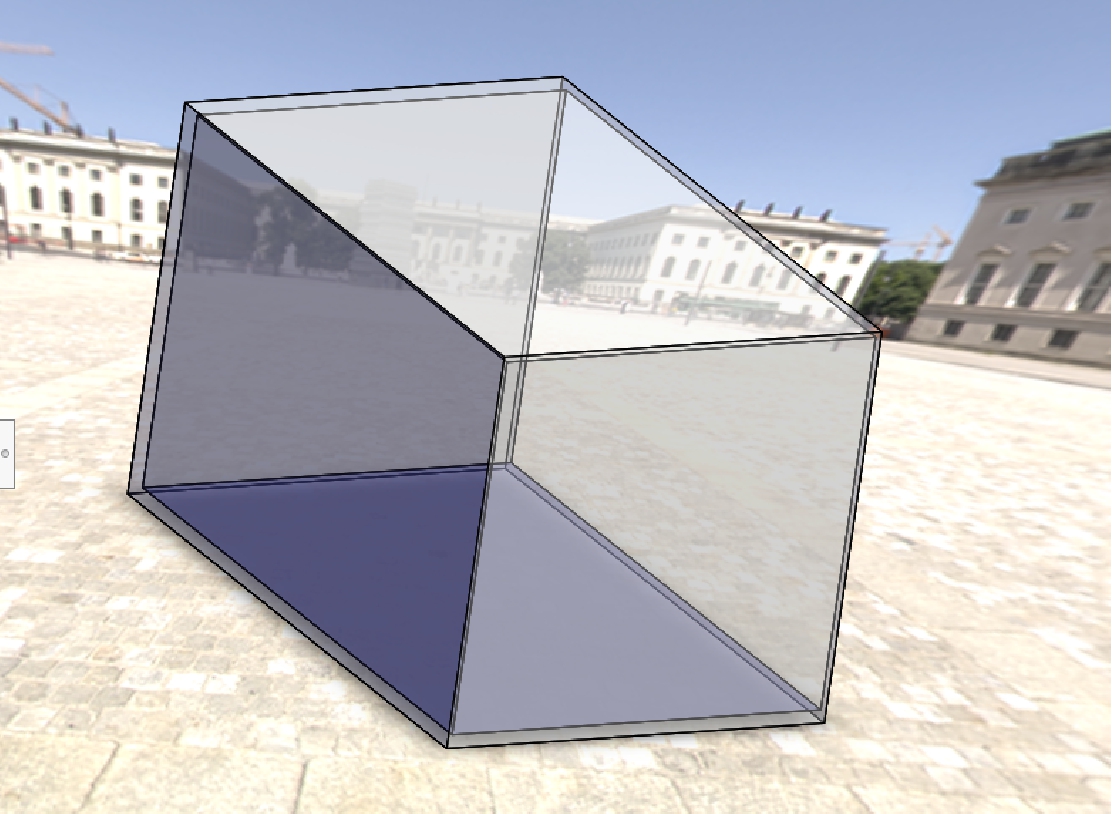

This image illustrates part of the final appearance of the 3D project designed in the software SolidWorks.

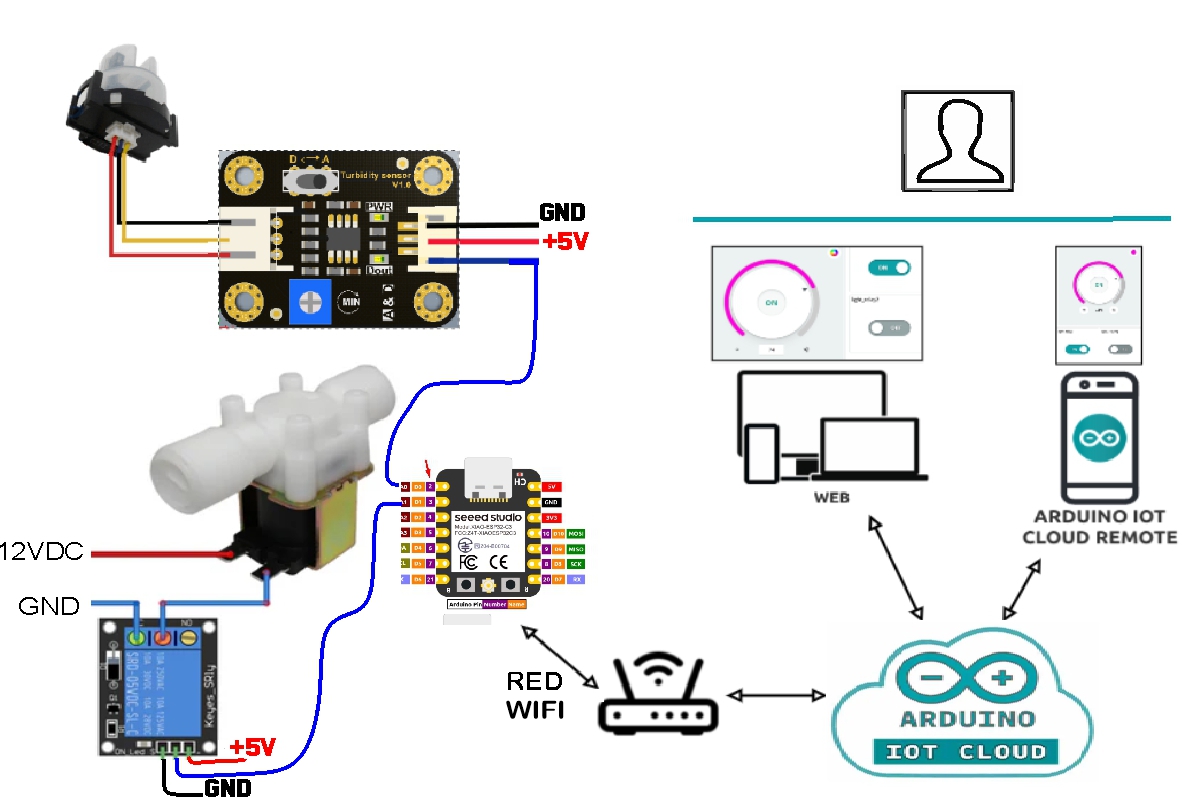

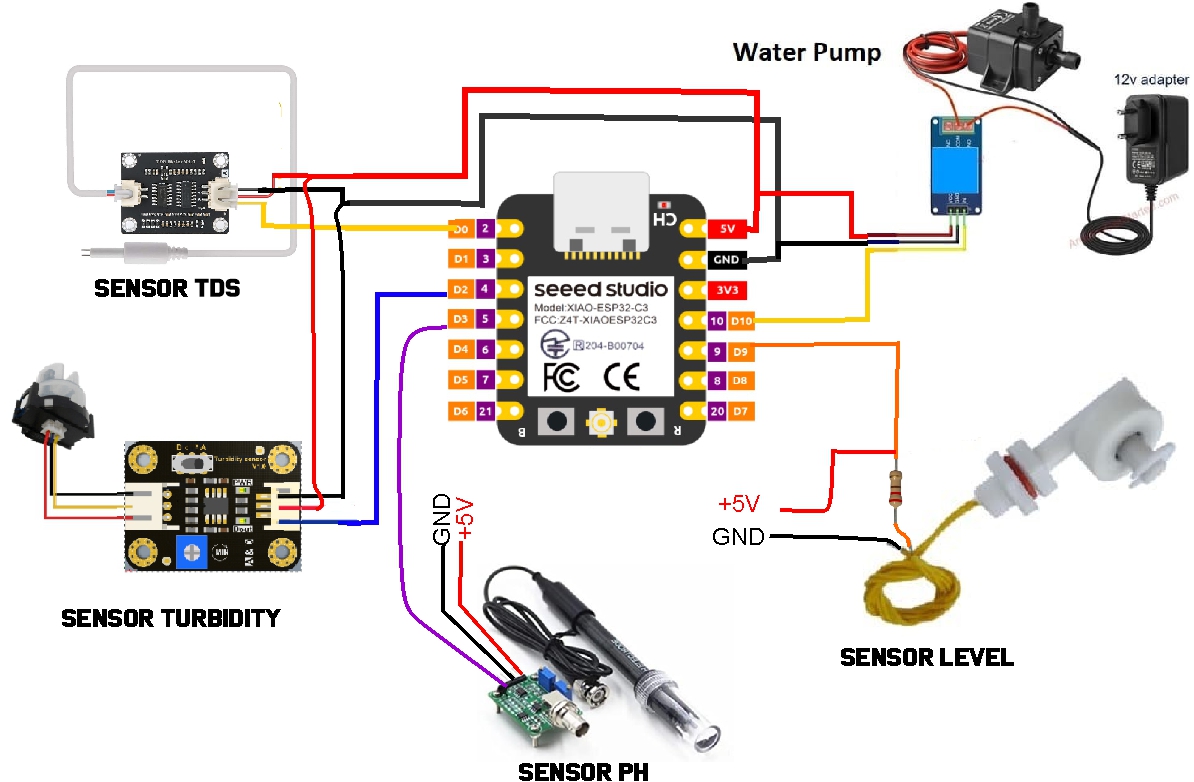

Before starting the electronic design of my project, it is essential to develop a general diagram that specifies the sensors and components that I will integrate. The list of planned sensors and devices includes the following items:

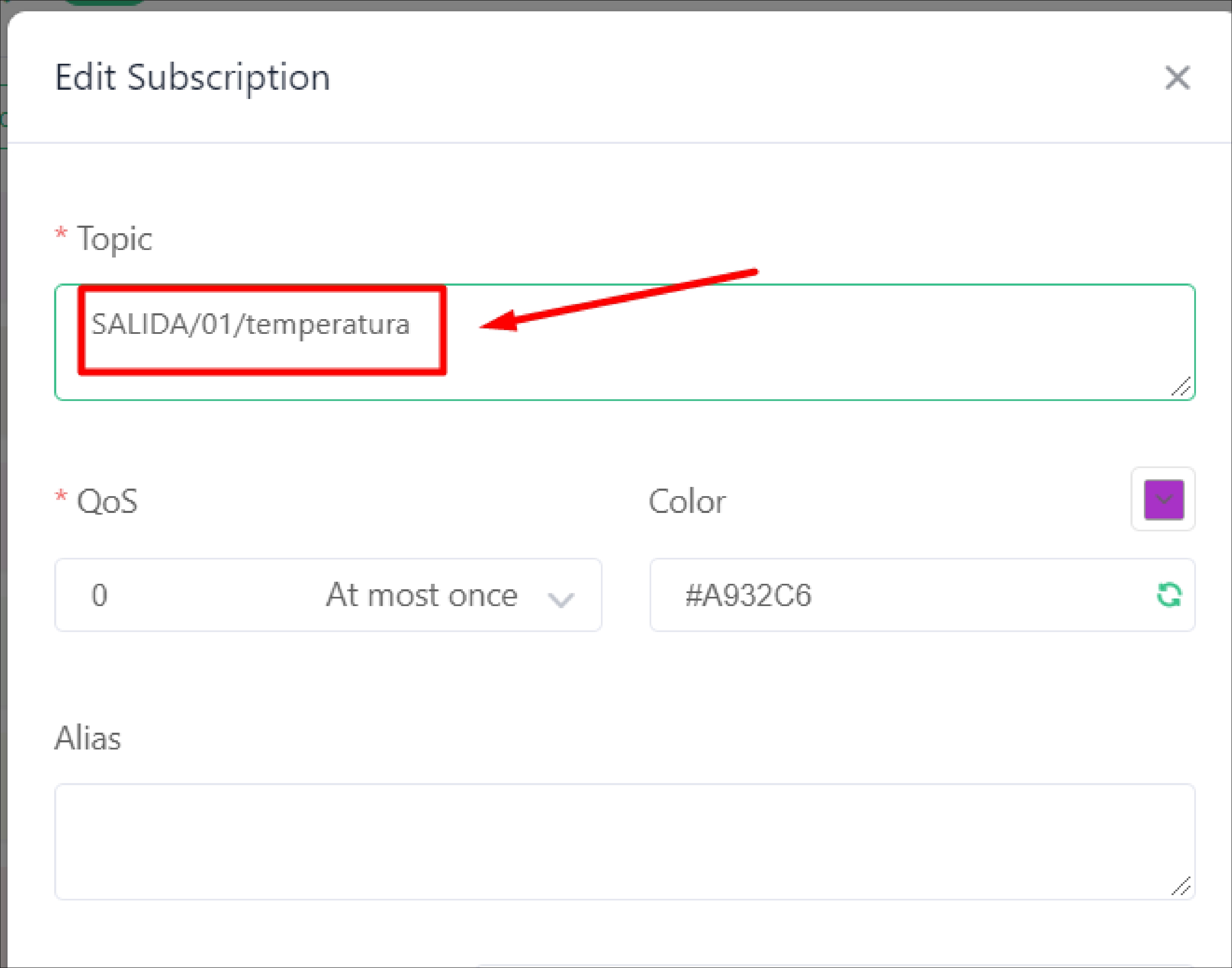

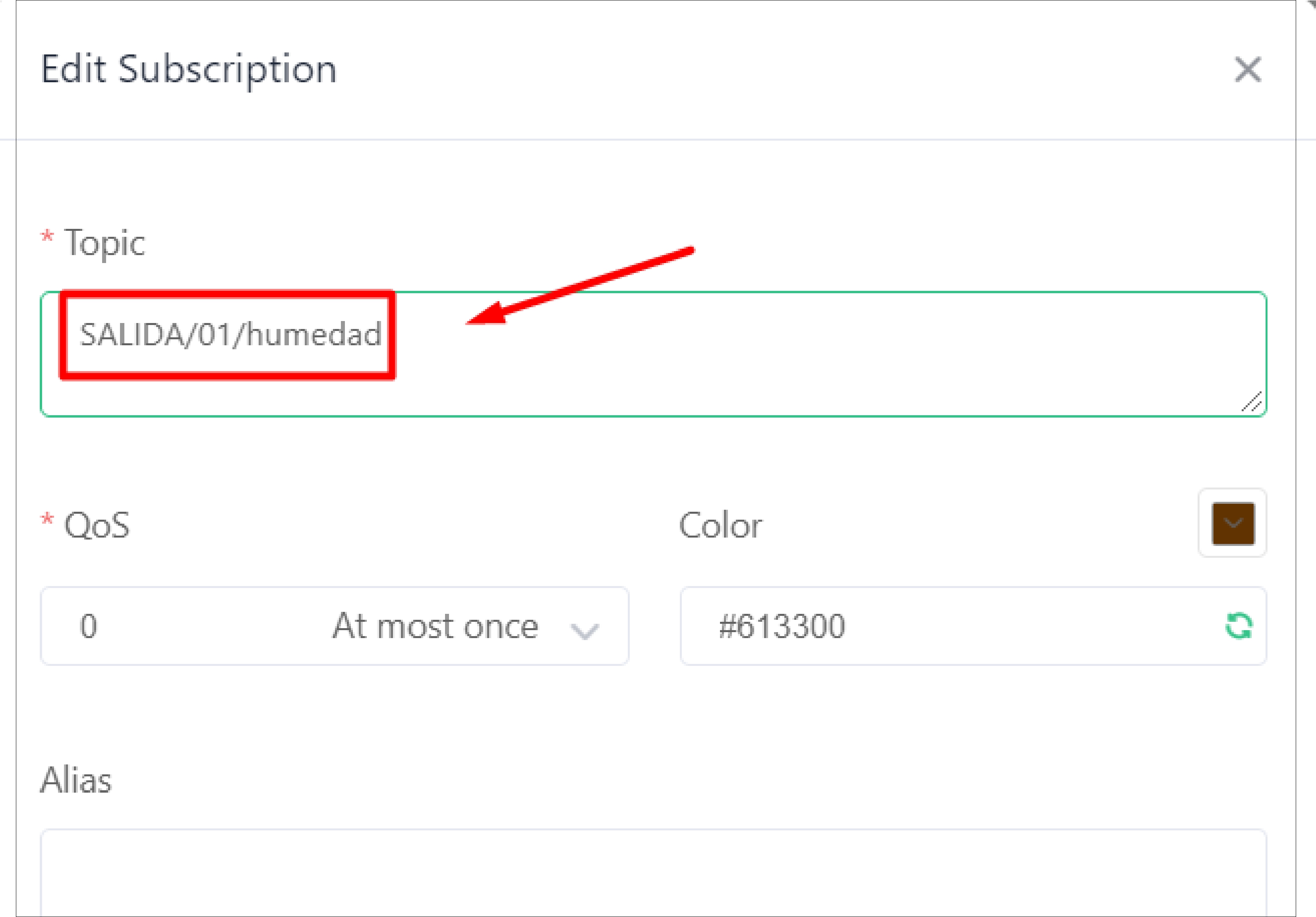

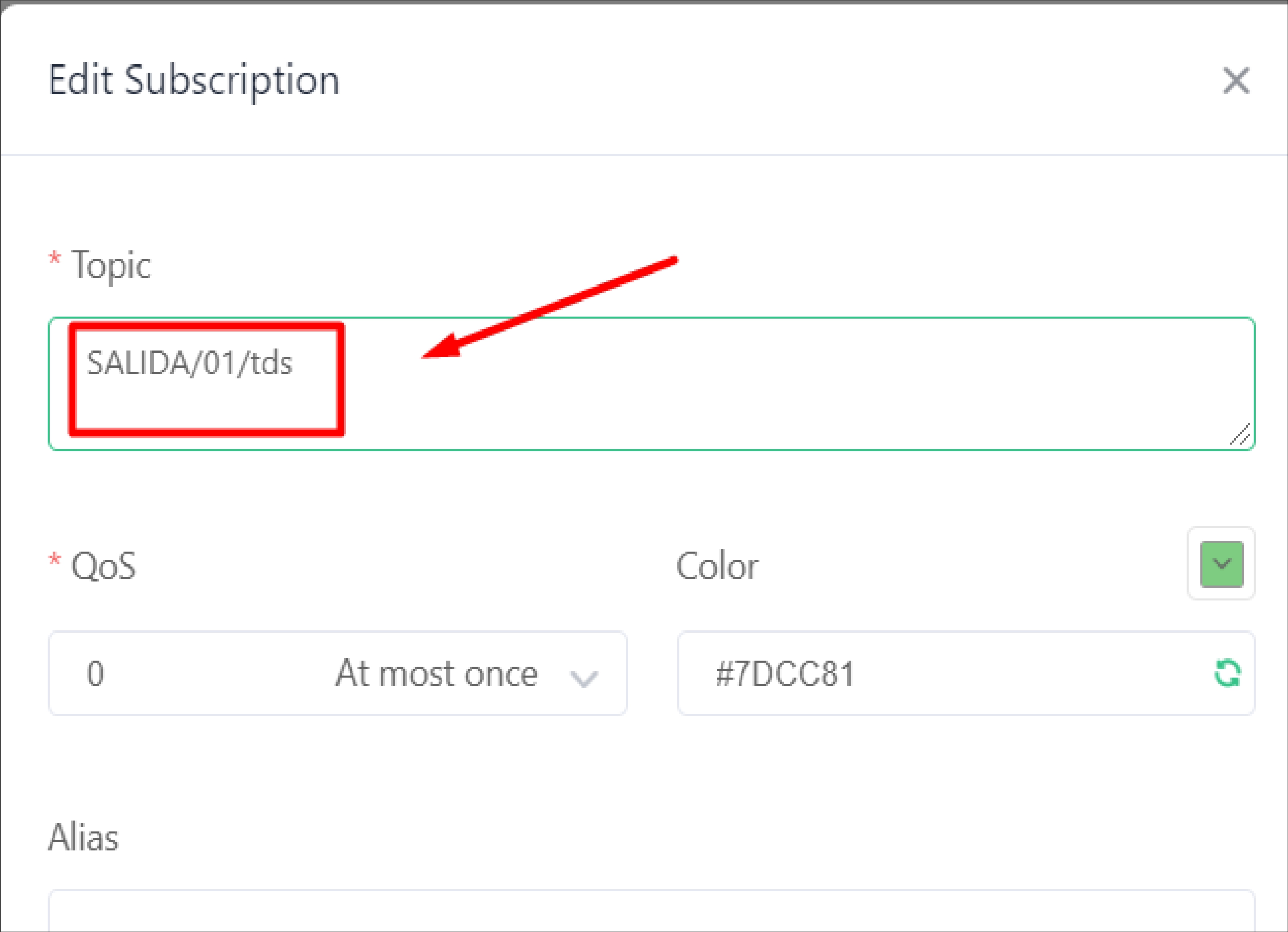

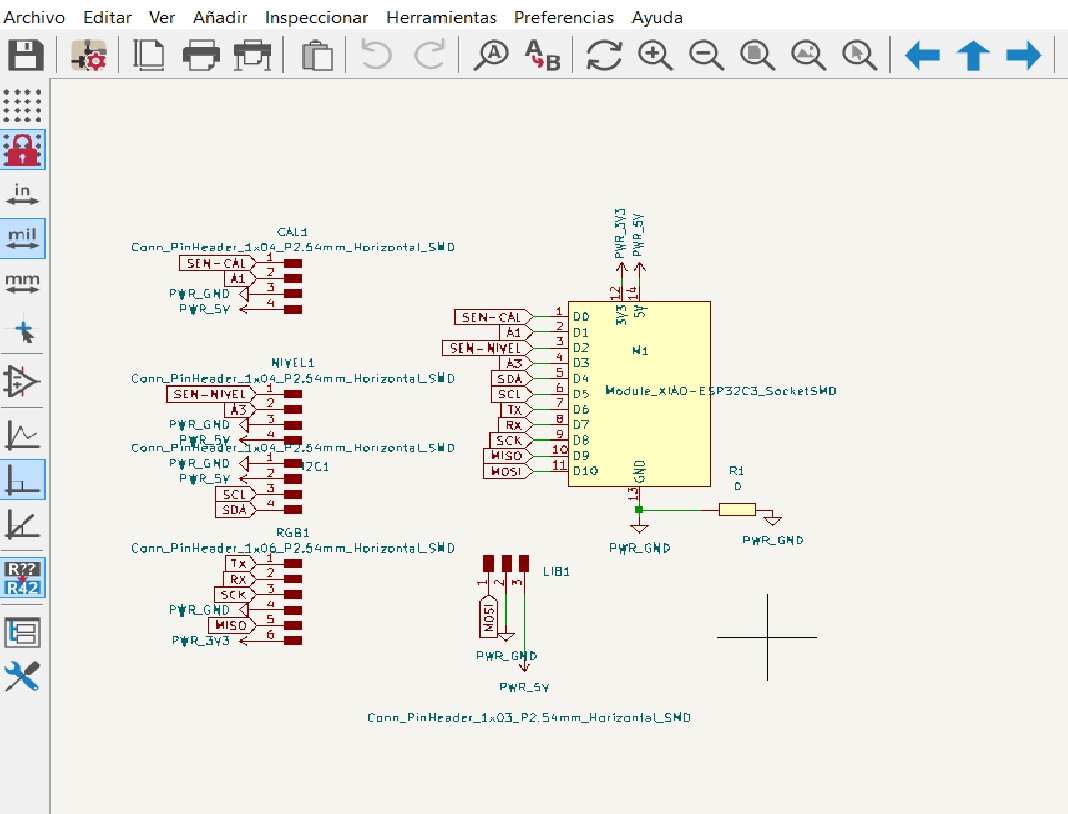

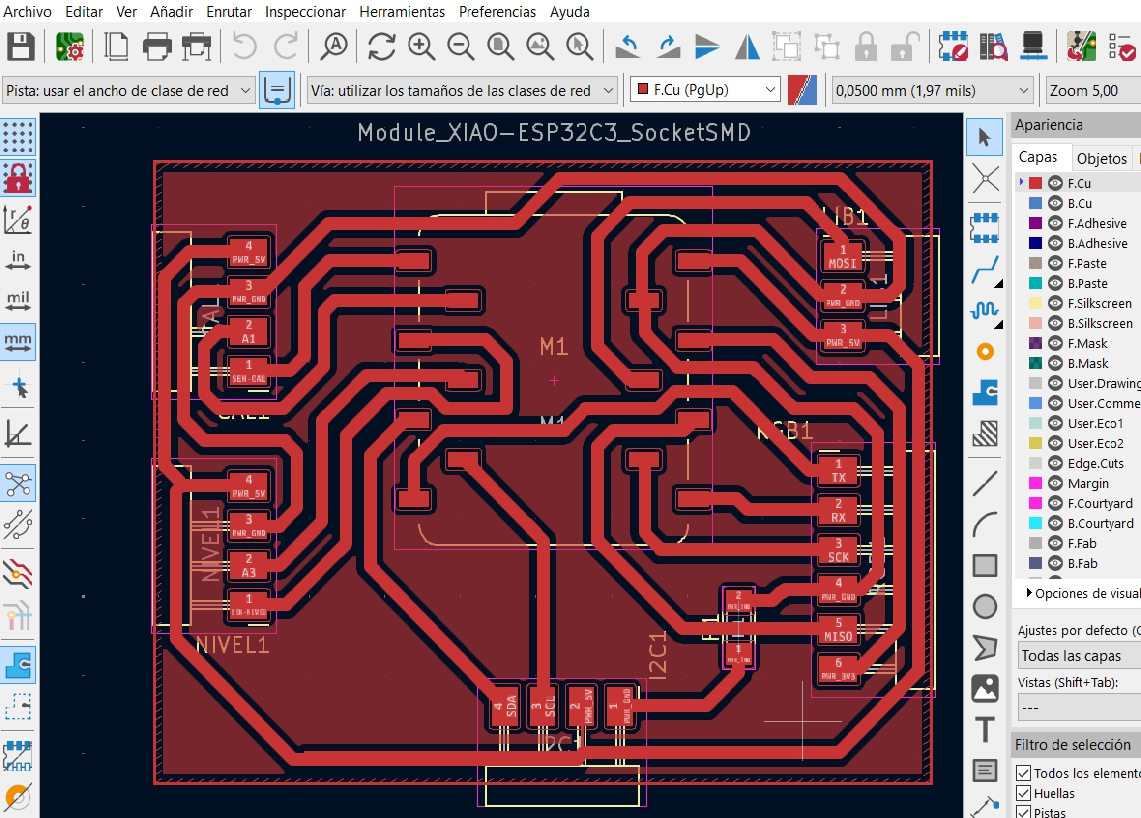

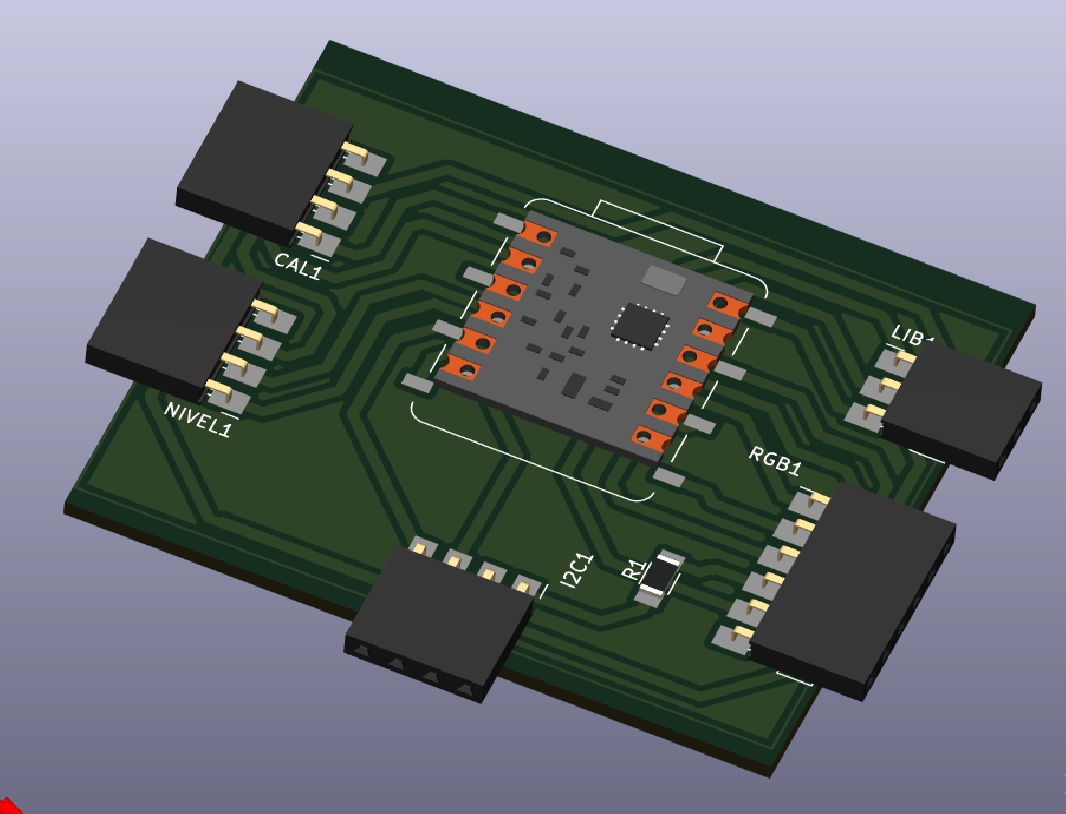

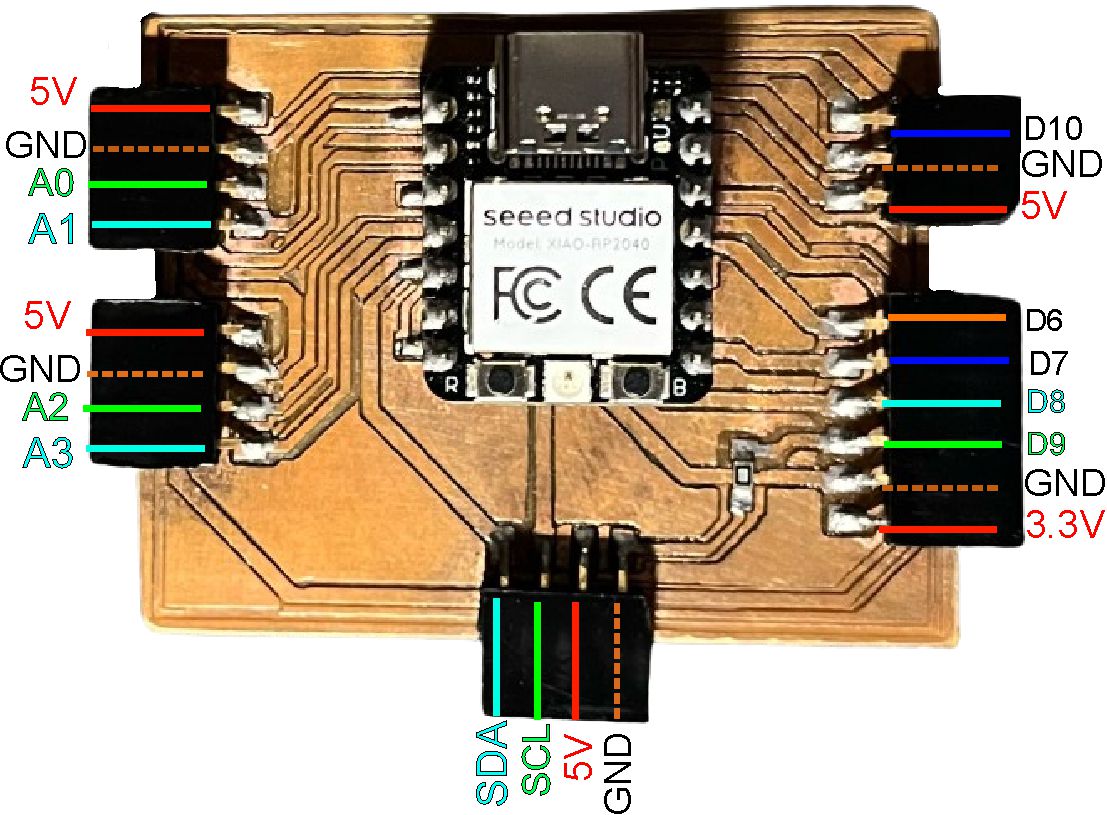

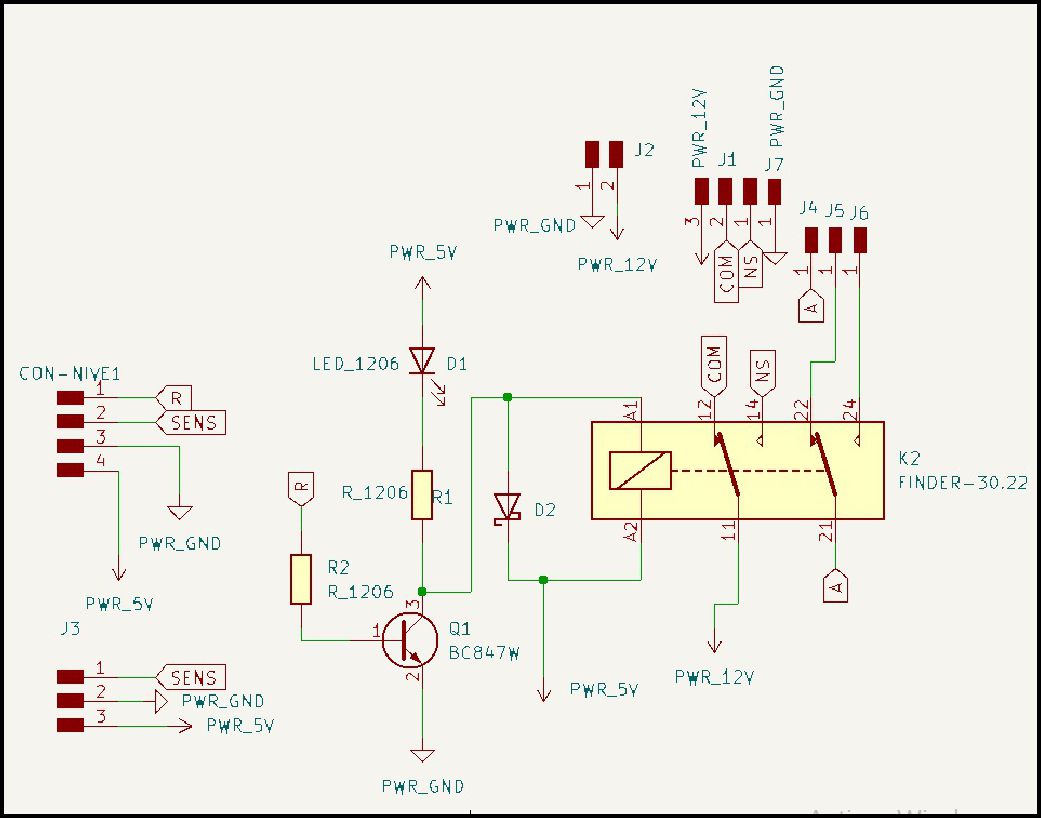

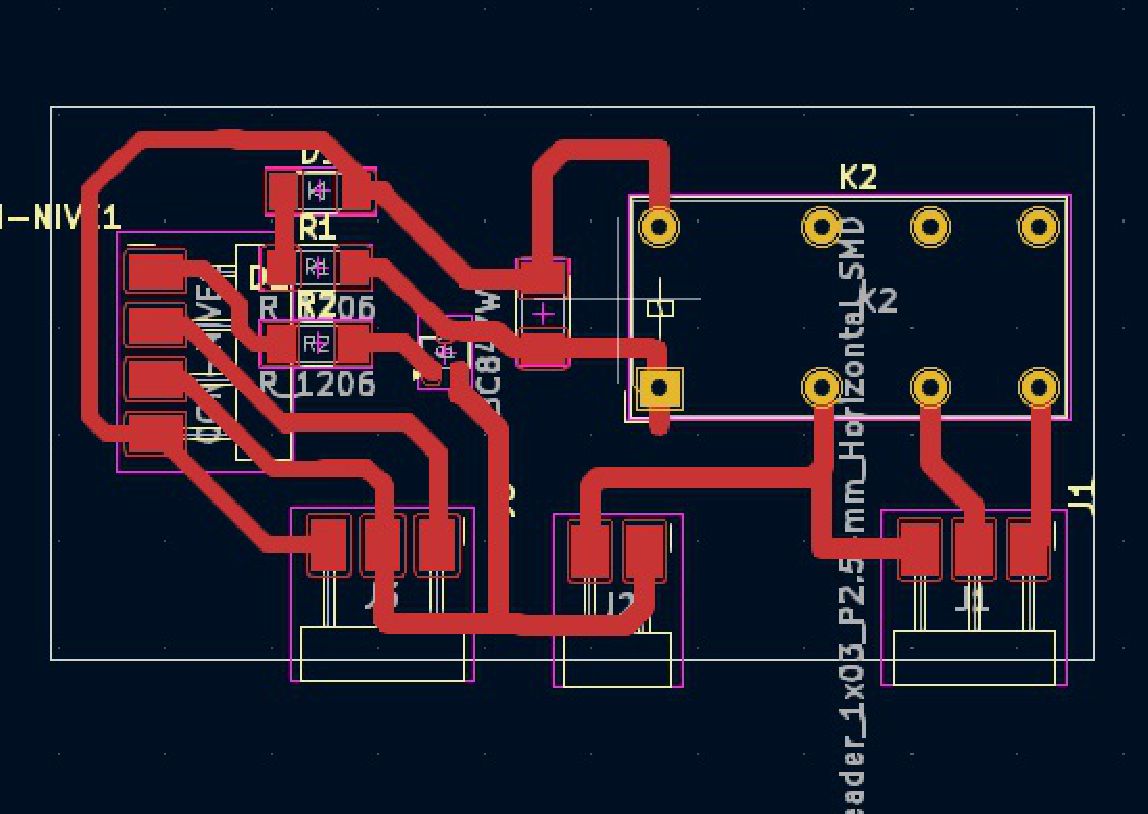

To create the main board of my project, I am using KiCAD software. My goal is to develop an electronic design that allows efficient and well-organized distribution of essential sensors including electrical conductivity sensor (TDS), turbidity sensor, pH sensor, water level sensor, as well as control devices such as pumps. and solenoid valves. Using KiCAD allows me to visualize and design the optimal arrangement of these components, ensuring effective and reliable operation of the entire system.

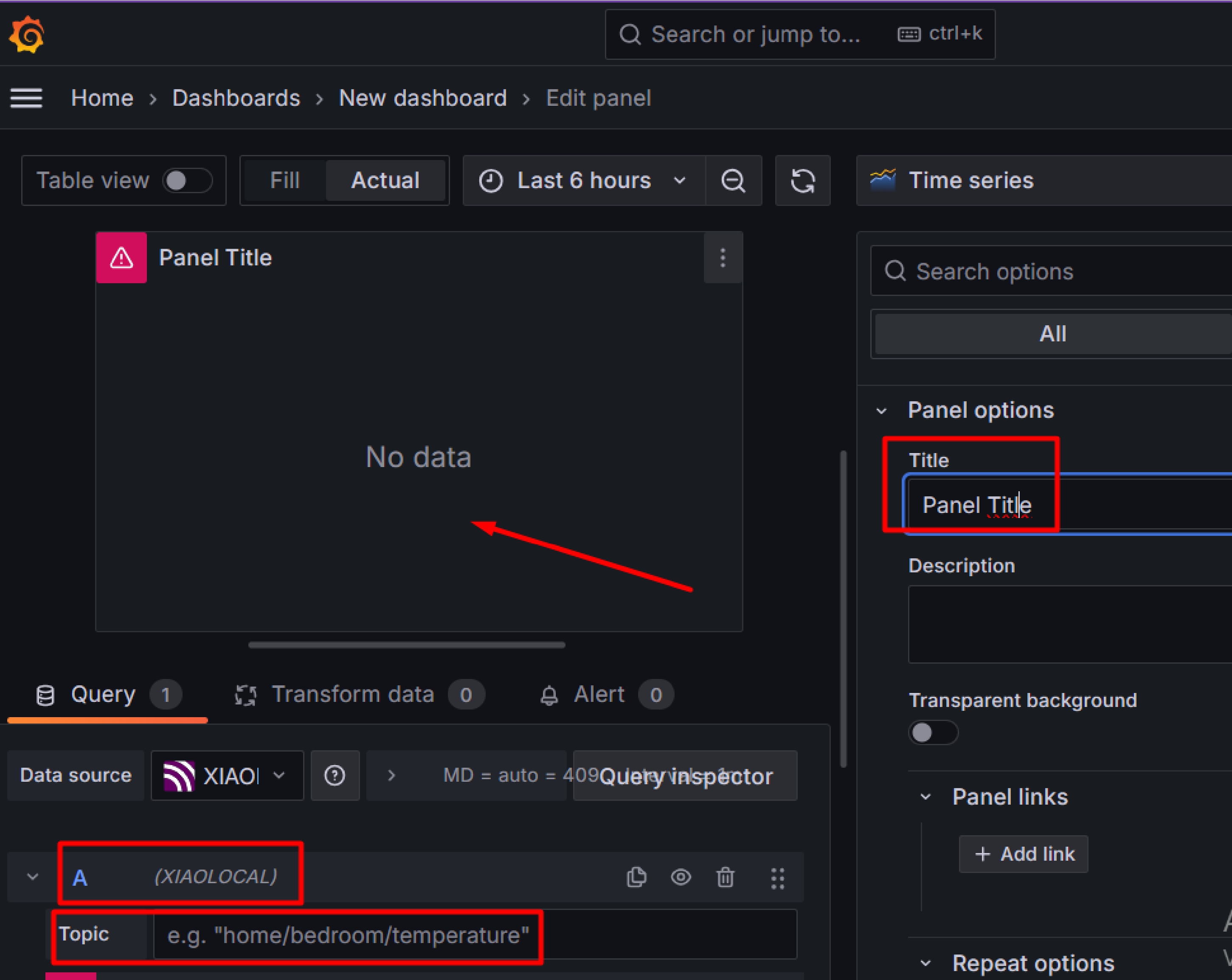

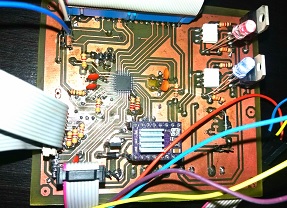

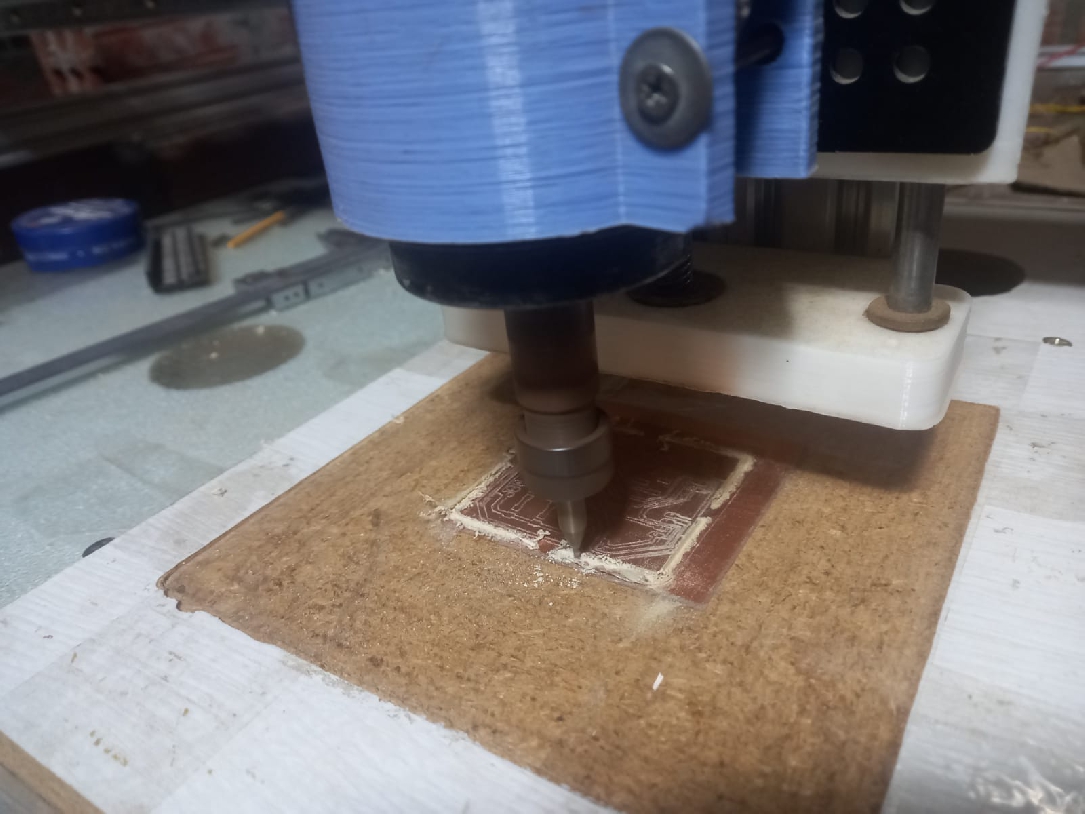

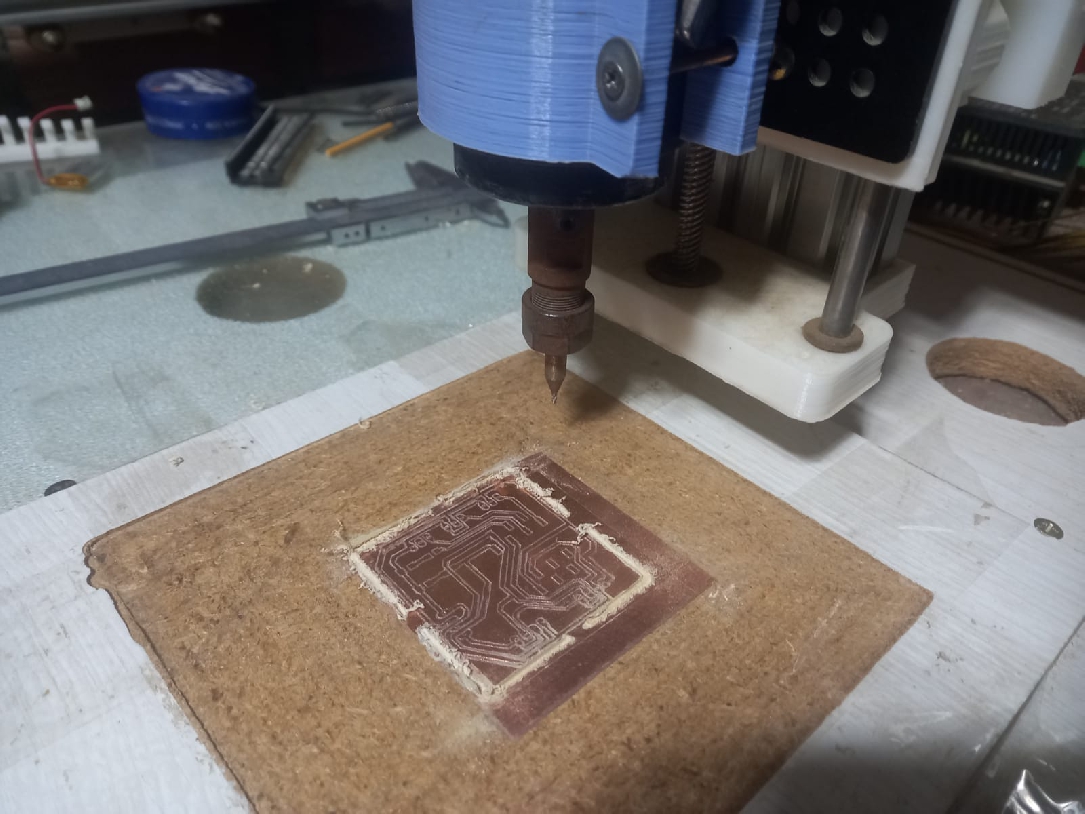

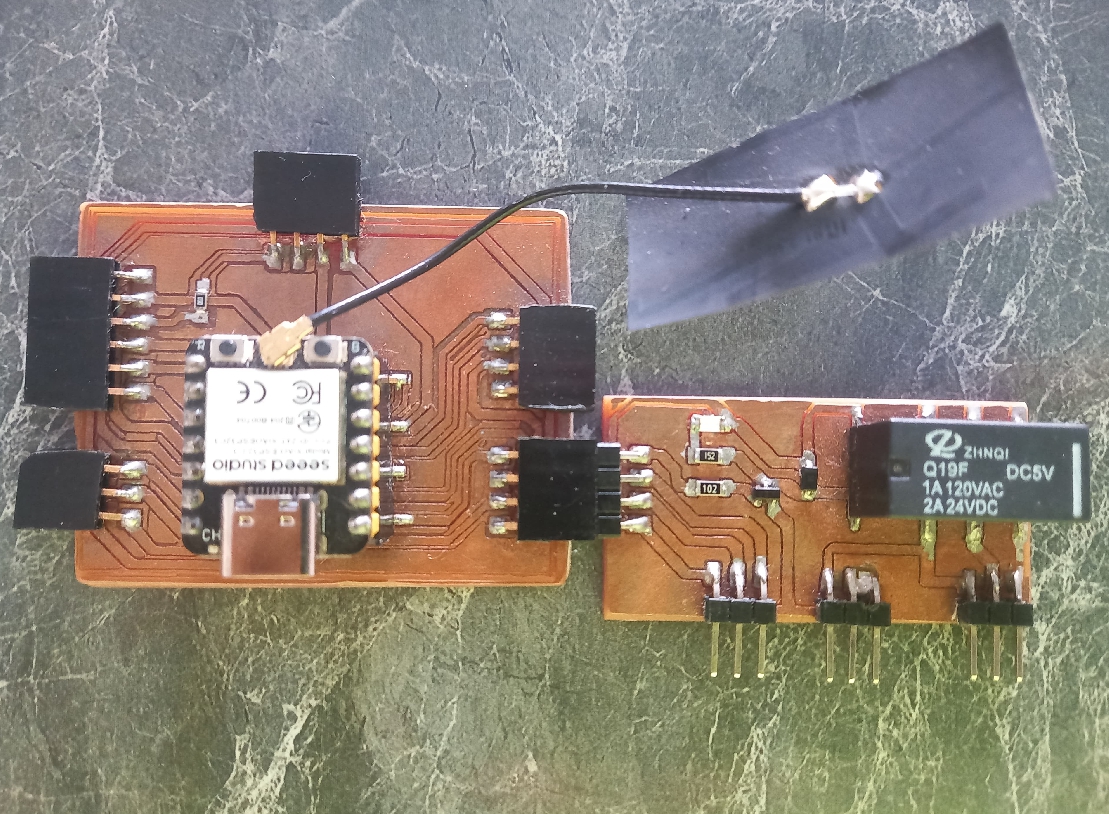

To manufacture the electronic board for my project, I chose to use a homemade CNC router. This process was especially interesting and rewarding as I was able to customize the production to my specific needs. The CNC router allowed me to carry out precise and detailed cuts in different materials, facilitating the creation of printed circuit boards and other electronic components in an efficient and adaptable manner.

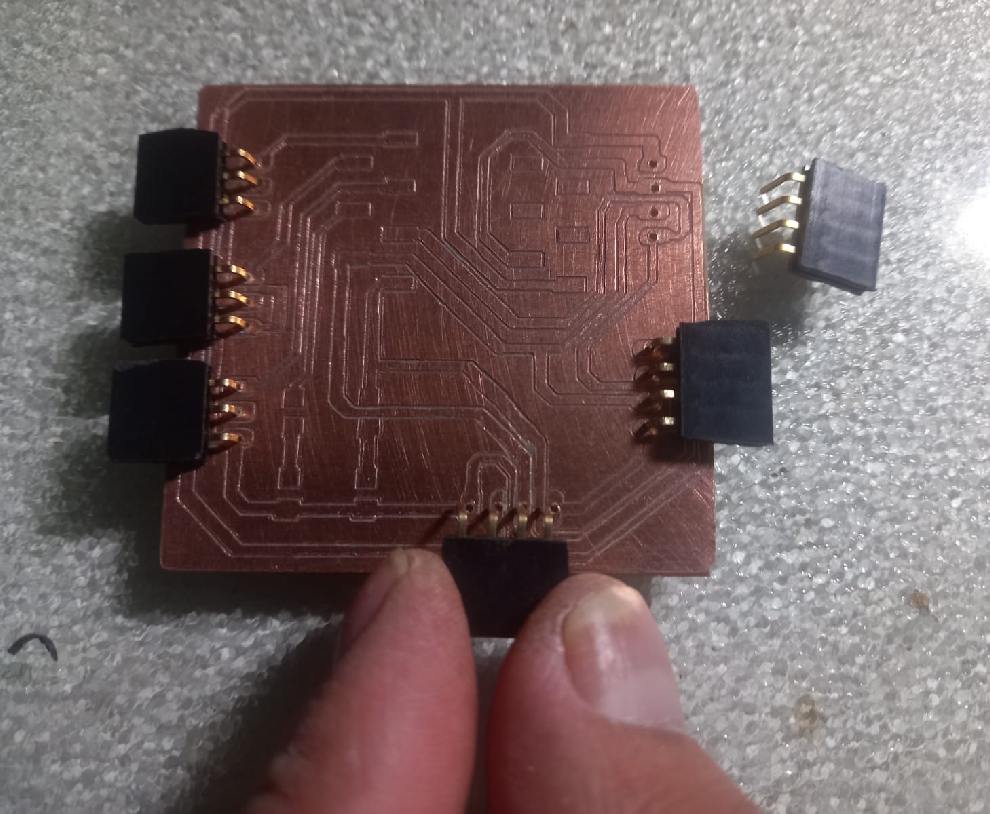

Once I finished the process of soldering the components, the electronic board took on the appearance that you can see in the attached image. This step was crucial to complete the assembly stage, ensuring that all elements are correctly integrated into the board and ready for operation.

The design of this electronic card was made with the specific objective of controlling a 220 VAC light bulb, as well as a 220 VAC water pump or a mini pump. The card is designed to provide safe and efficient power management and control functions for these high-power devices.

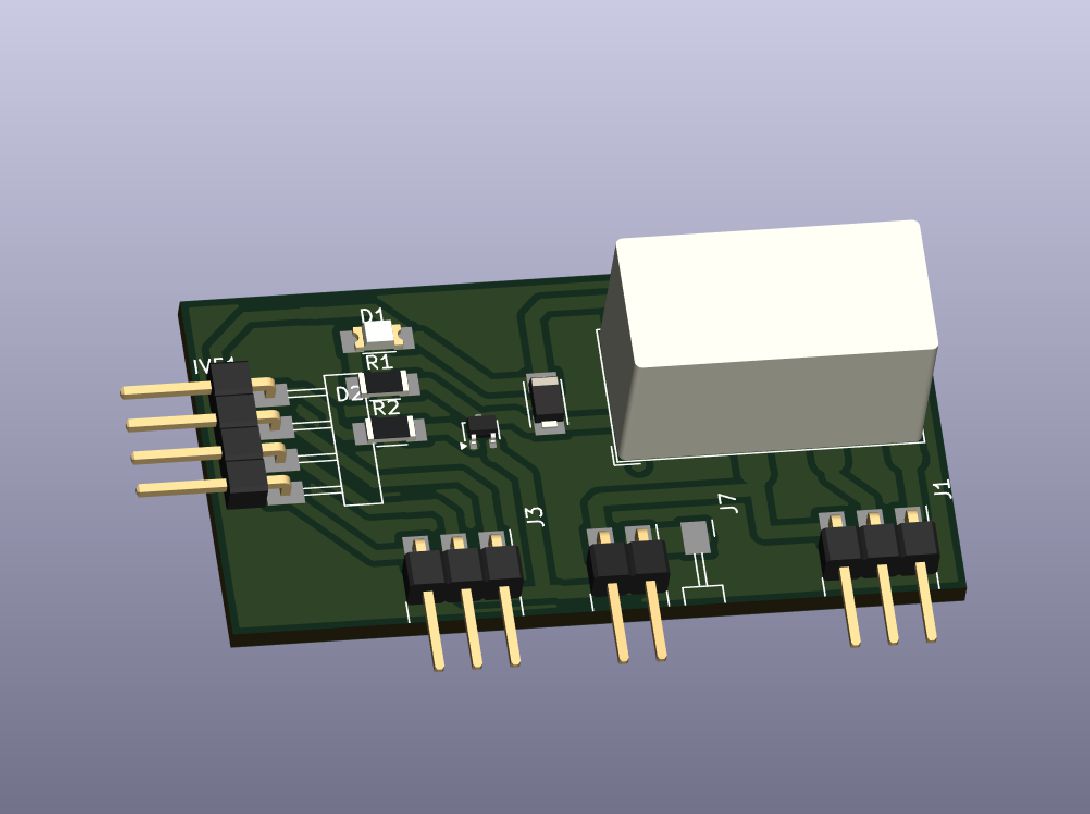

Thanks to the functionality integrated into the KiCAD software, we can obtain a 3D representation of the designed control module. This feature allows us to view the layout of the electronic board from different angles and perspectives, making it easier to evaluate the arrangement of components and check for possible assembly problems or interferences.

After having completed the manufacturing of the electronic board, the next step is to carry out extensive tests to verify its operation and ensure its quality. These tests are essential to identify any possible failure in the components or in the connection of the board.

Connection between the motherboard and the output device.

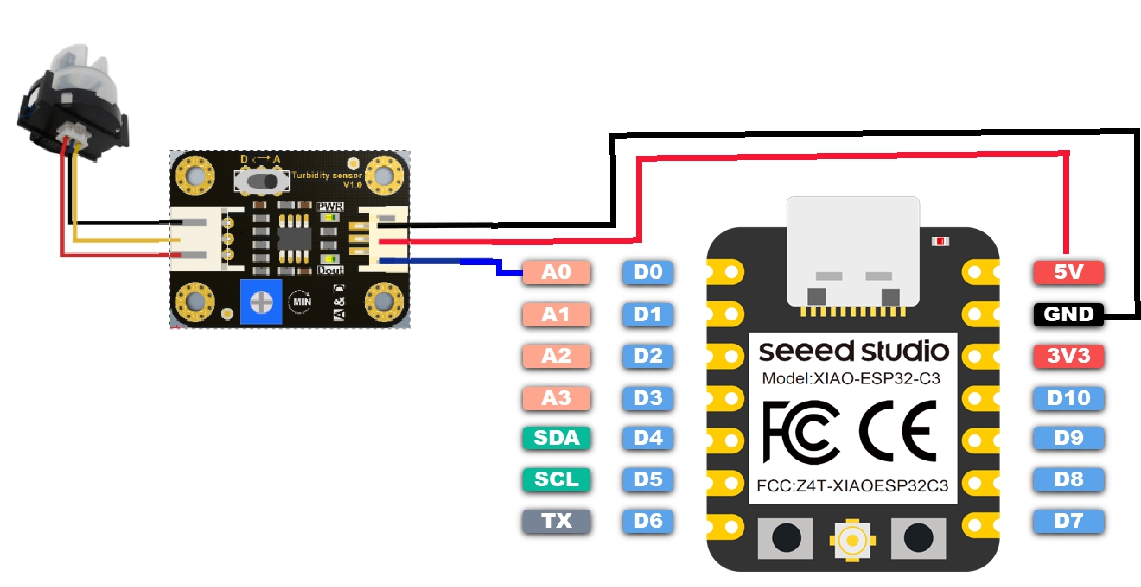

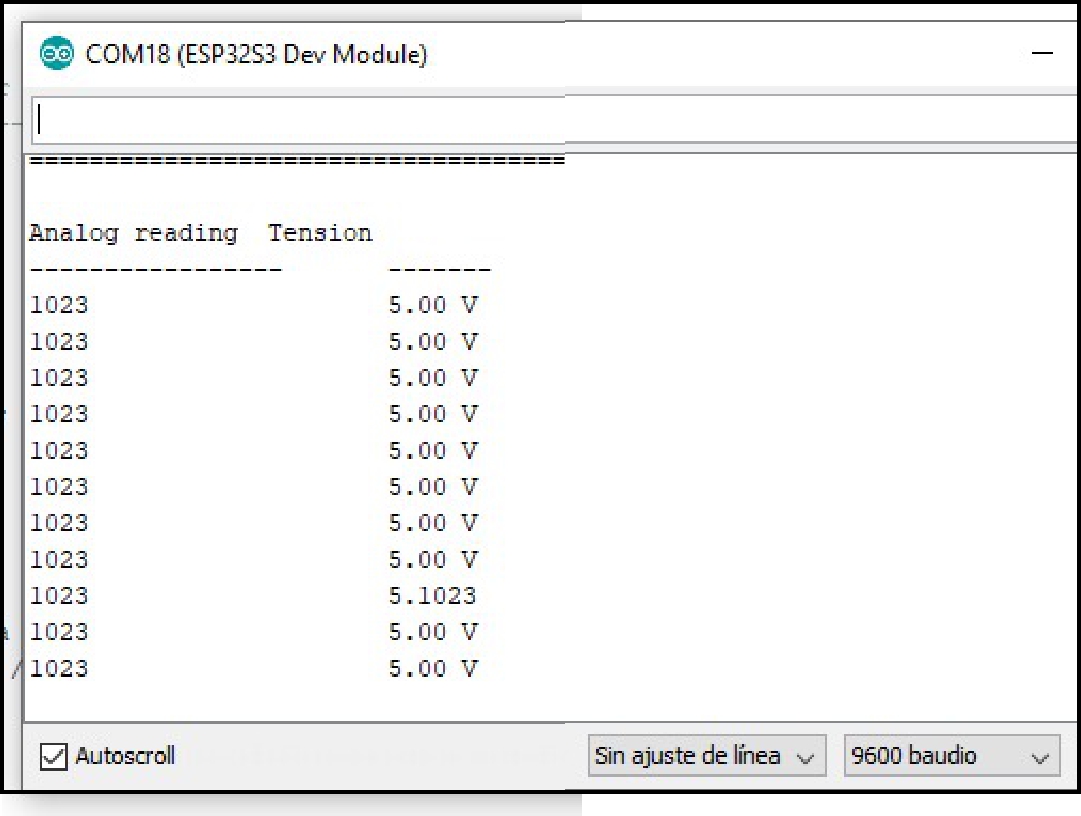

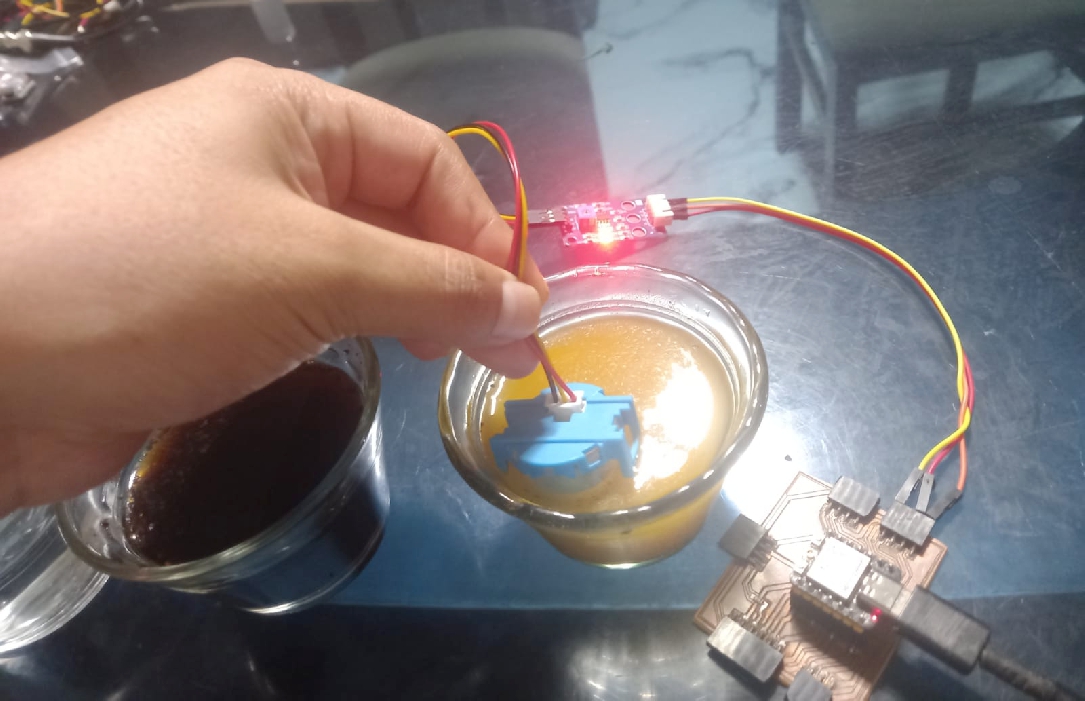

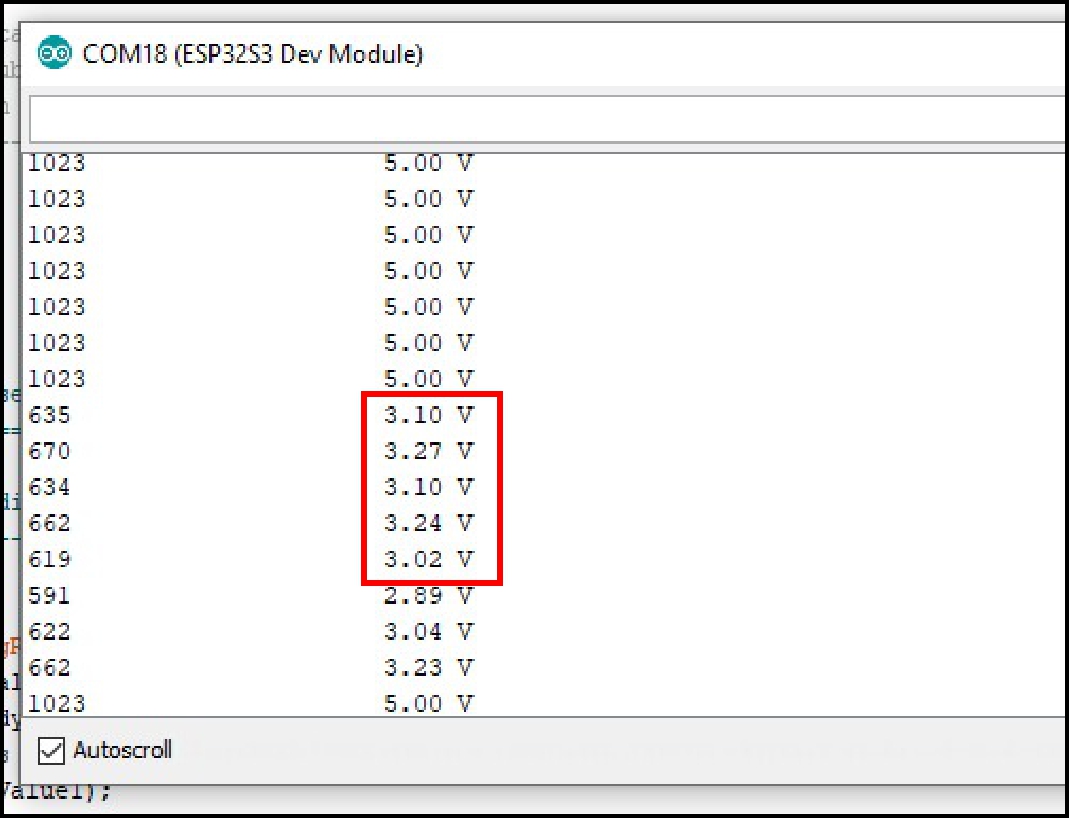

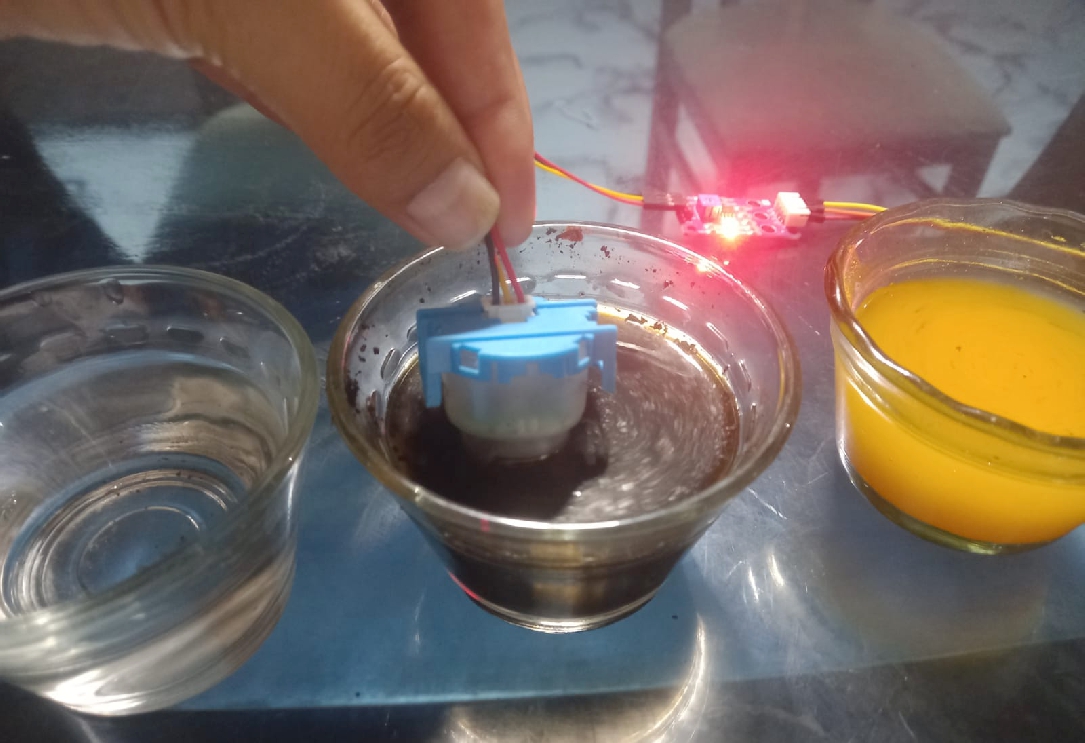

For communication via Serial, I used the turbidity sensor, which will be evaluated with different types of water during the tests.

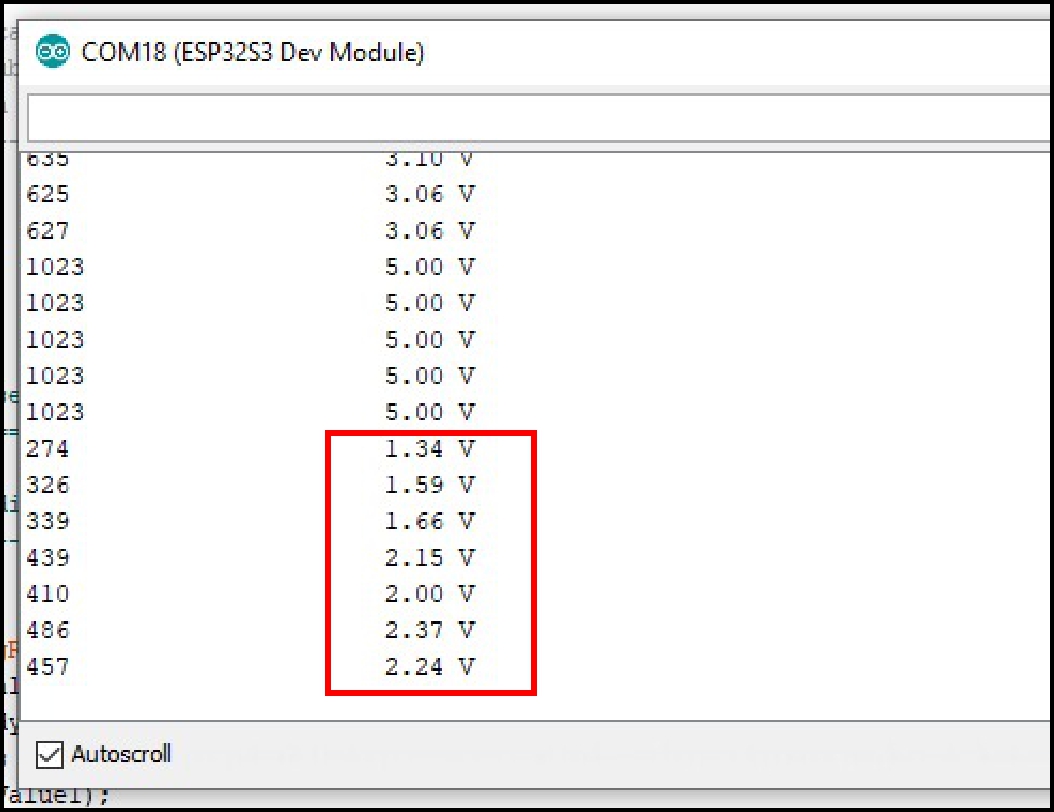

Test with different types of water using serial connection, which is detailed below.

The following images show the testing process carried out with different types of water.

| Clean Water | Curcuma | Cafe |

|---|---|---|

| 5V | 3.10V | 1.34V |

| 5V | 3.27V | 1.59V |

| 5V | 3.10V | 1.66V |

| 5V | 3.24V | 2.15V |

| 5V | 3.02V | 2.00V |

This table indicates that when the water is cleaner, the measured voltage will be maximum, as it was calibrated at the 5V supplied to the XIAO. Likewise, as the water becomes more cloudy, the measured value will be lower.

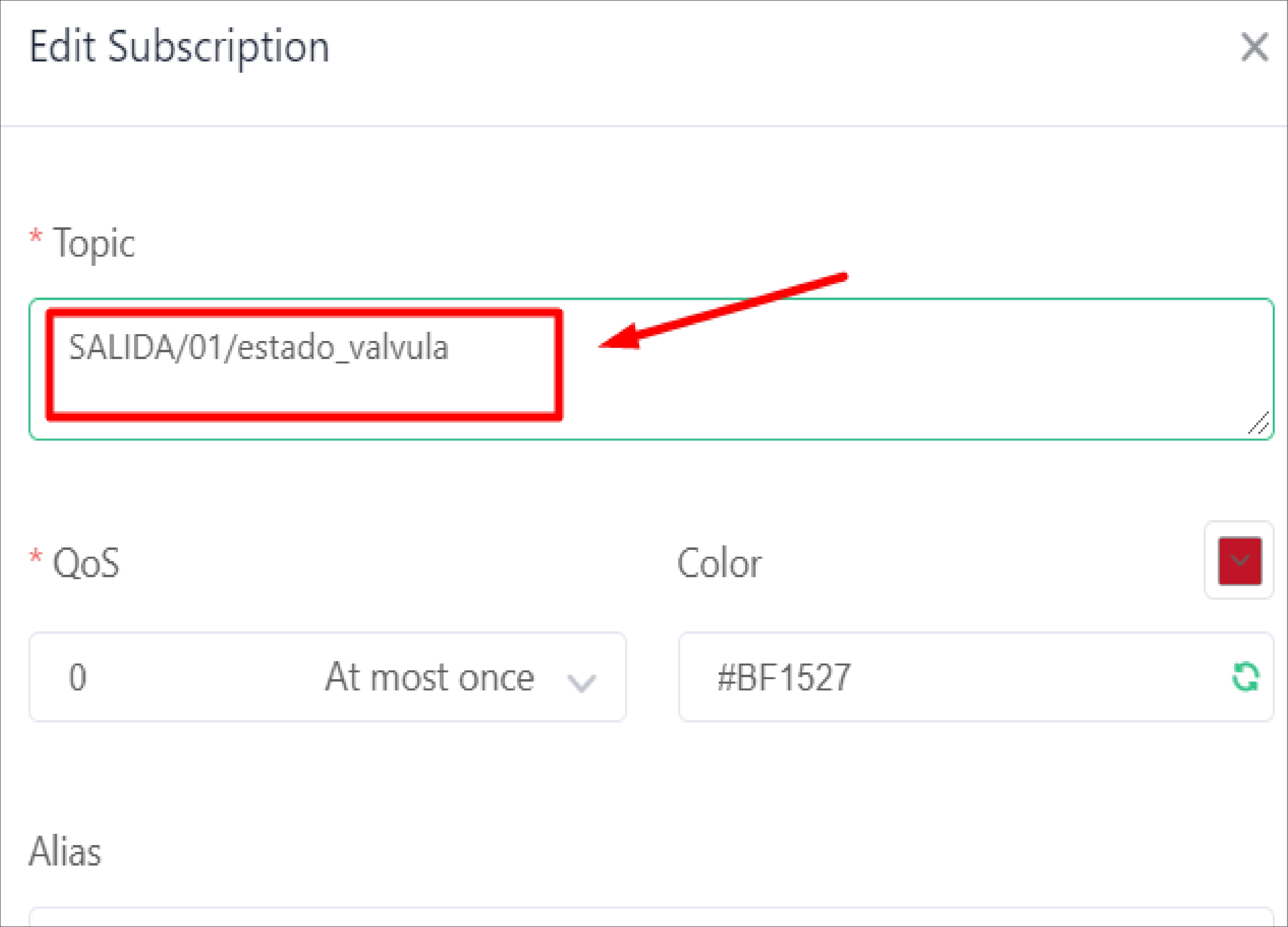

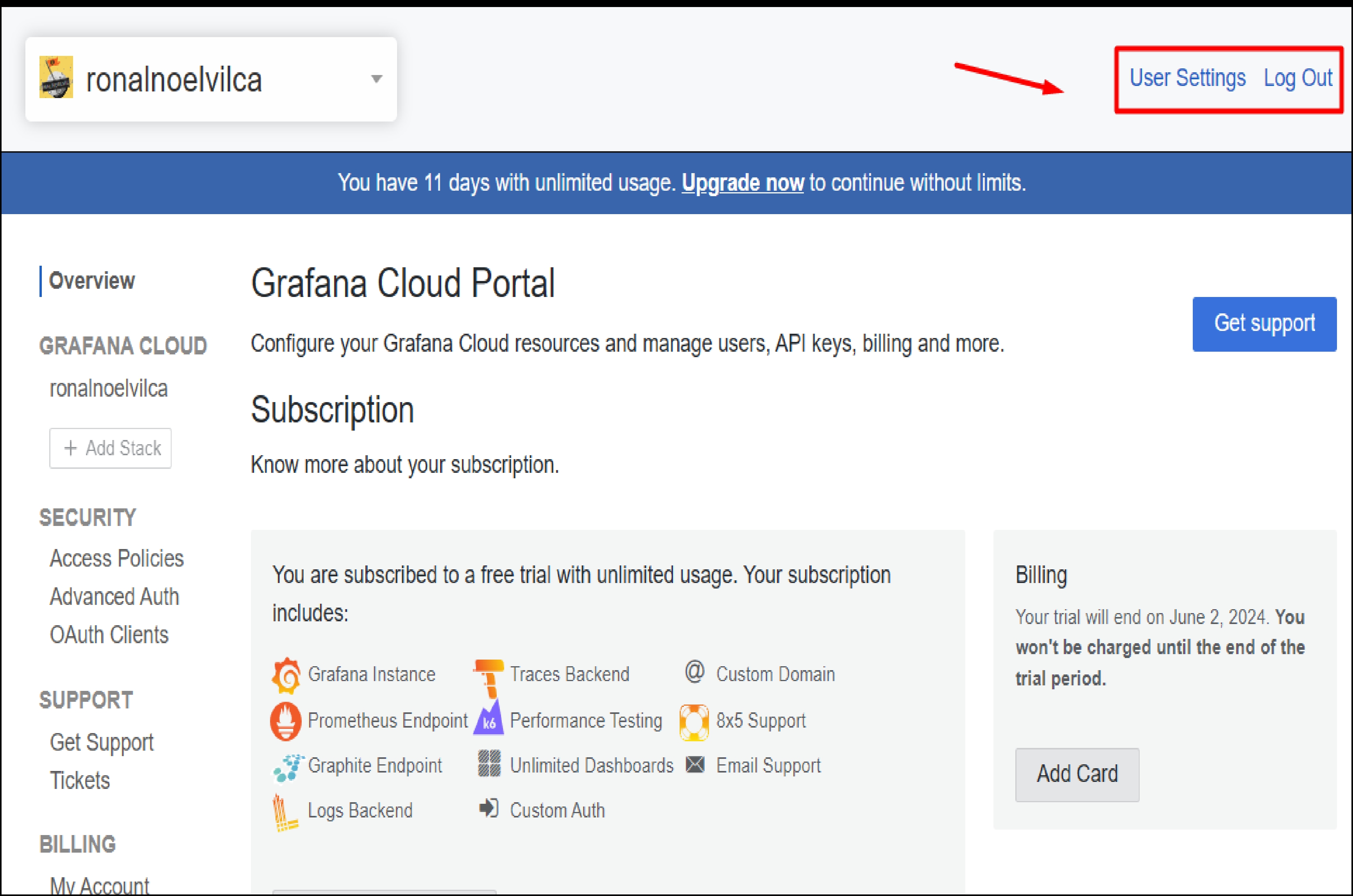

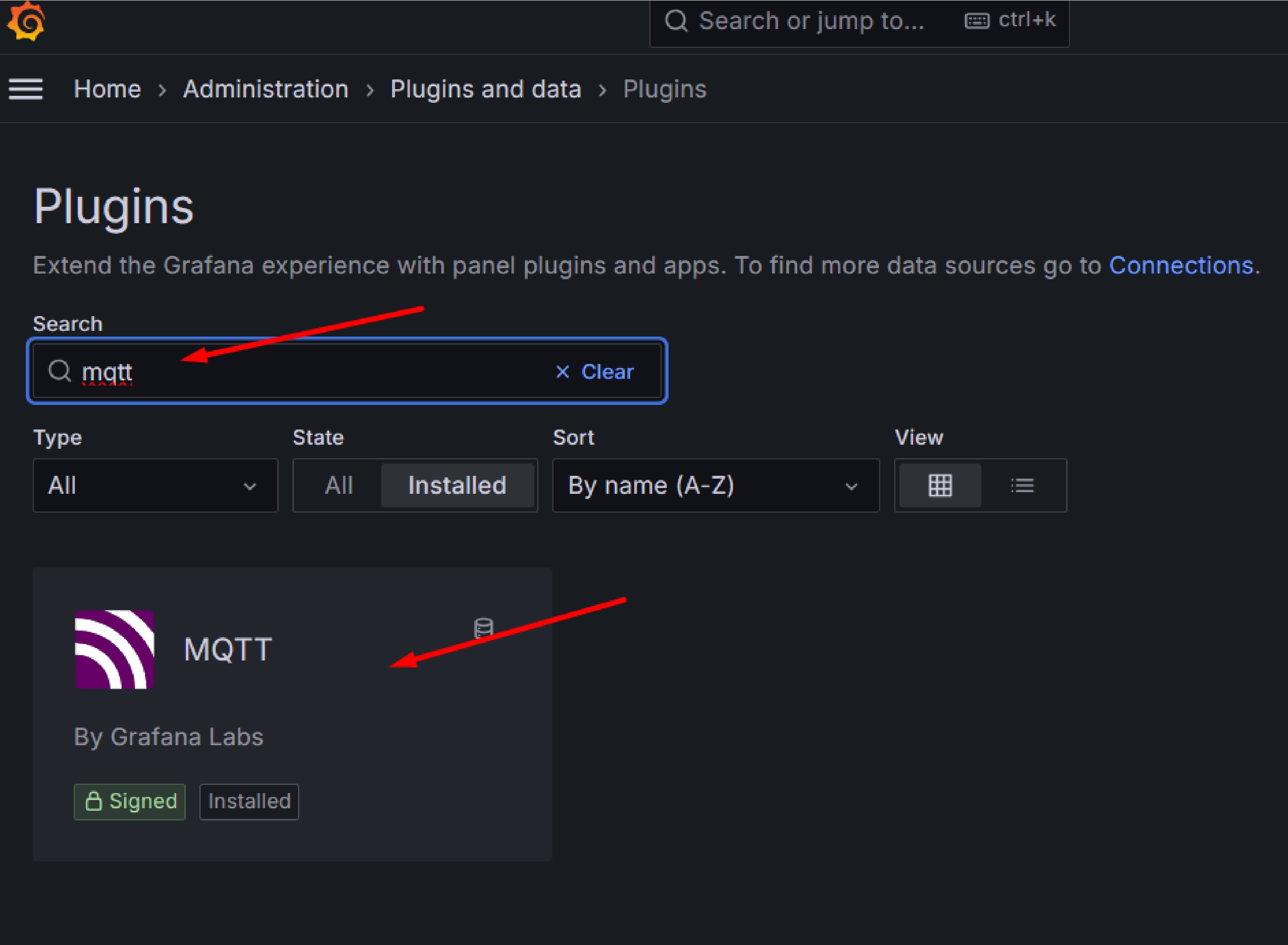

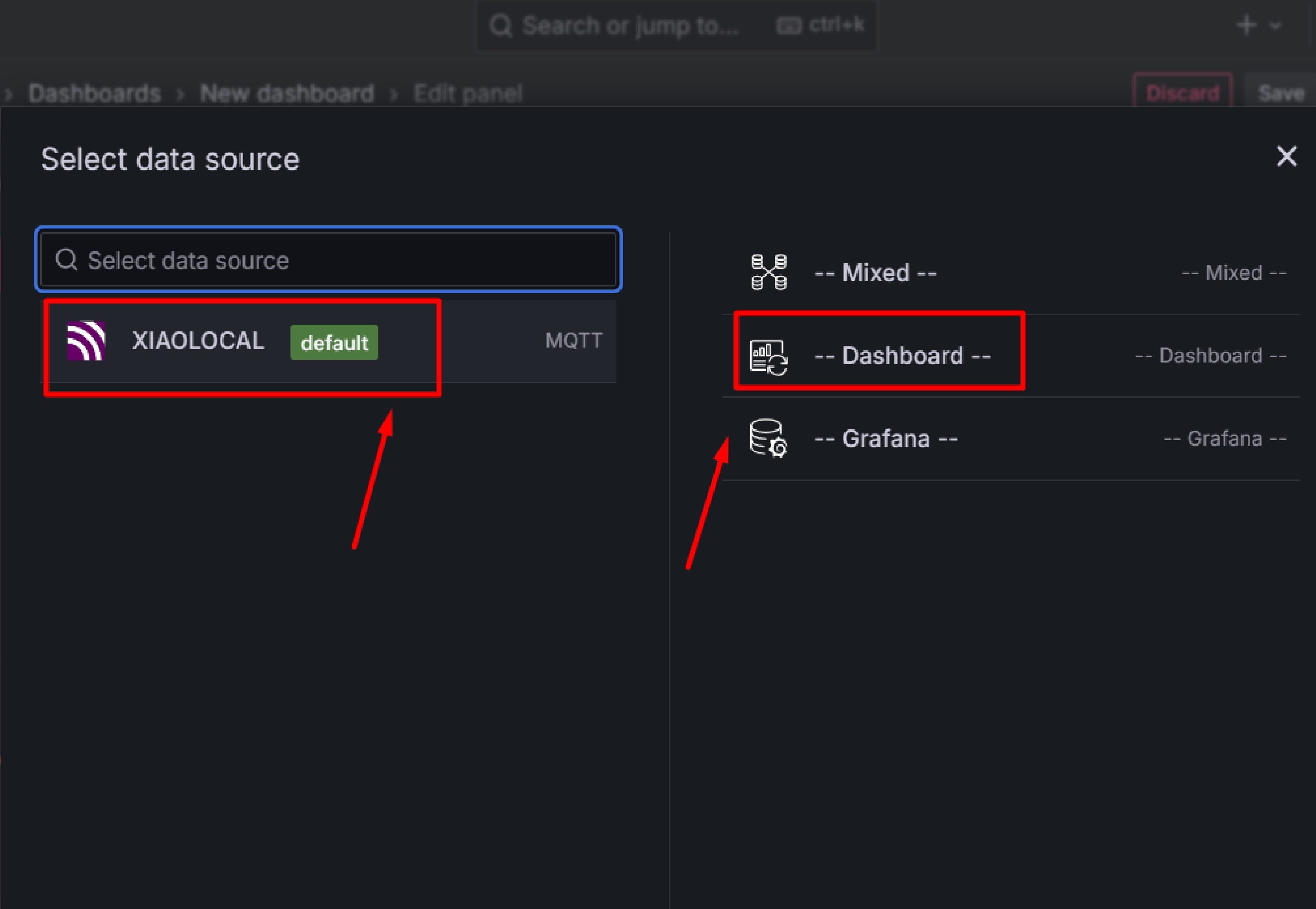

The following image illustrates how communication via WiFi with the Arduino IoT Cloud platform will be configured and will work in the project.