7. Computer-Controlled Machining

This we we are making our own furniture with large format CNC machine.

Assignment

-

Group assignment:

- Complete your lab's safety training

- Test runout, alignment, fixturing, speeds, feeds, materials and toolpaths for your machine

- Document your work to the group work page and reflect on your individual page what you learned

-

Individual project

- Make (design+mill+assemble) something big

Group Assignment

This week we tested and learned all the procesess to use the large format CNC machine. It's my first time using these kind of machine and cutting furniture, and it gave me much deeper knowledge on CNC machining. I'll definately cut more furnitures in the future.

Link to this week's group assignment

Modeling the Bar Stool

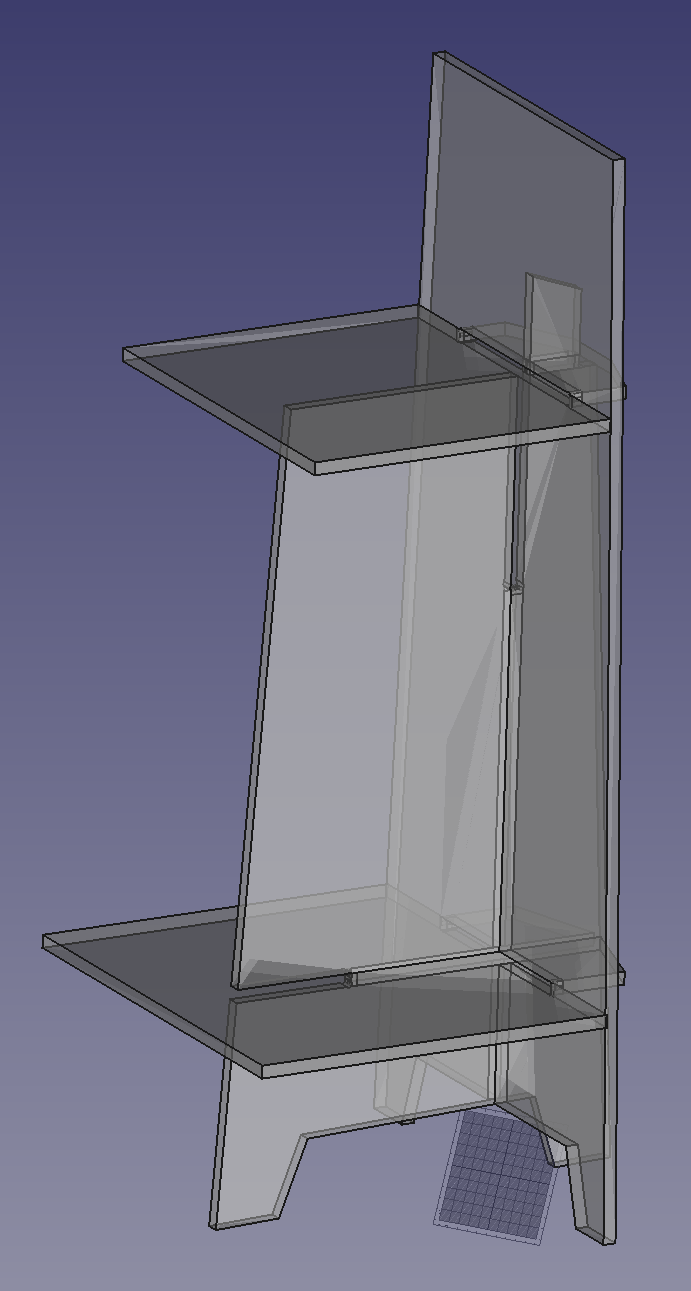

For this week's furniture I want to design a high-legged bar stool. I first start making the model in FreeCAD.

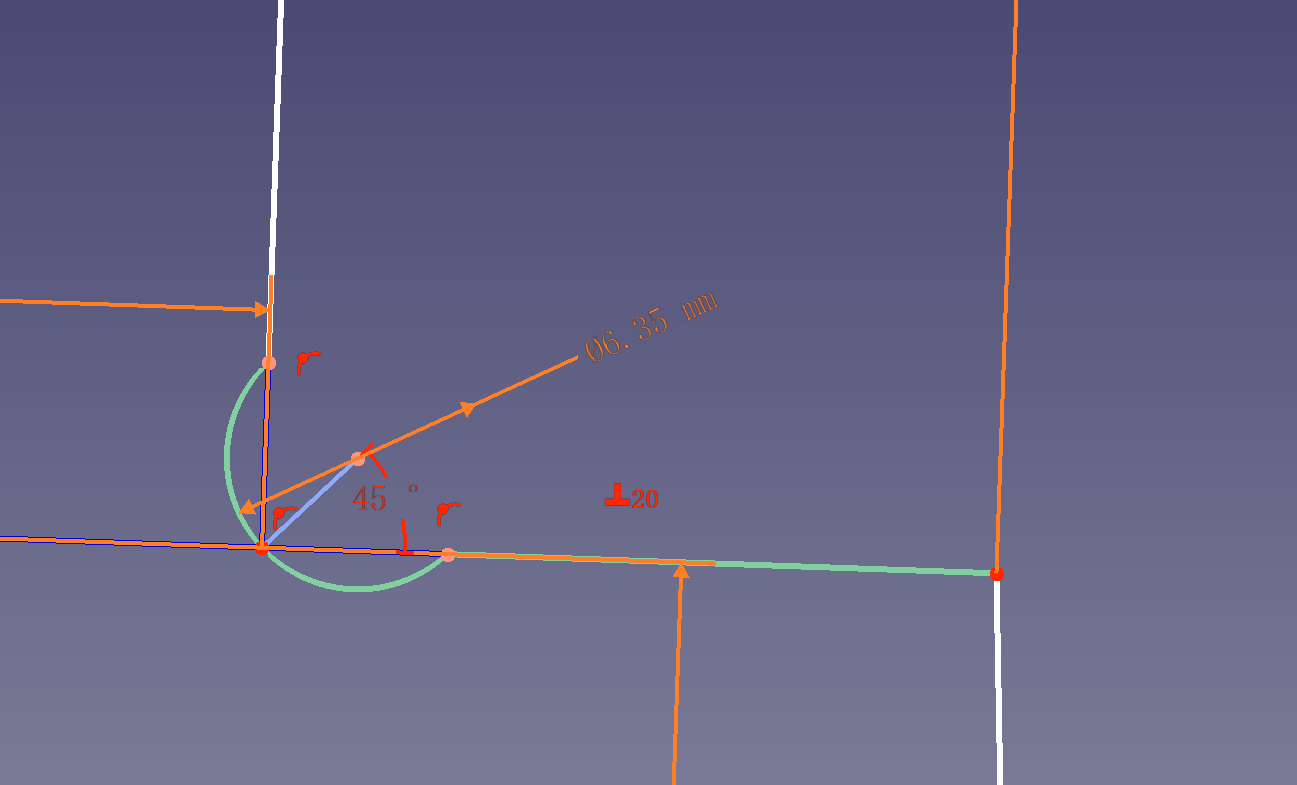

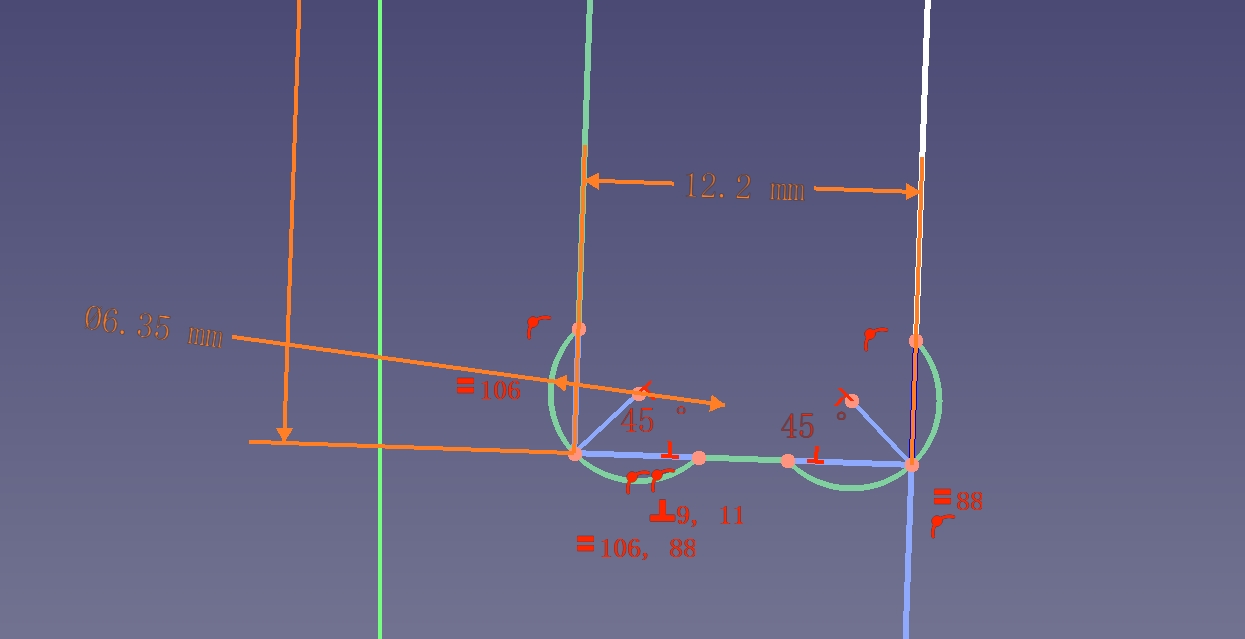

First using the FreeCAD Sketcher to sketch out the multiple pieces of my design.

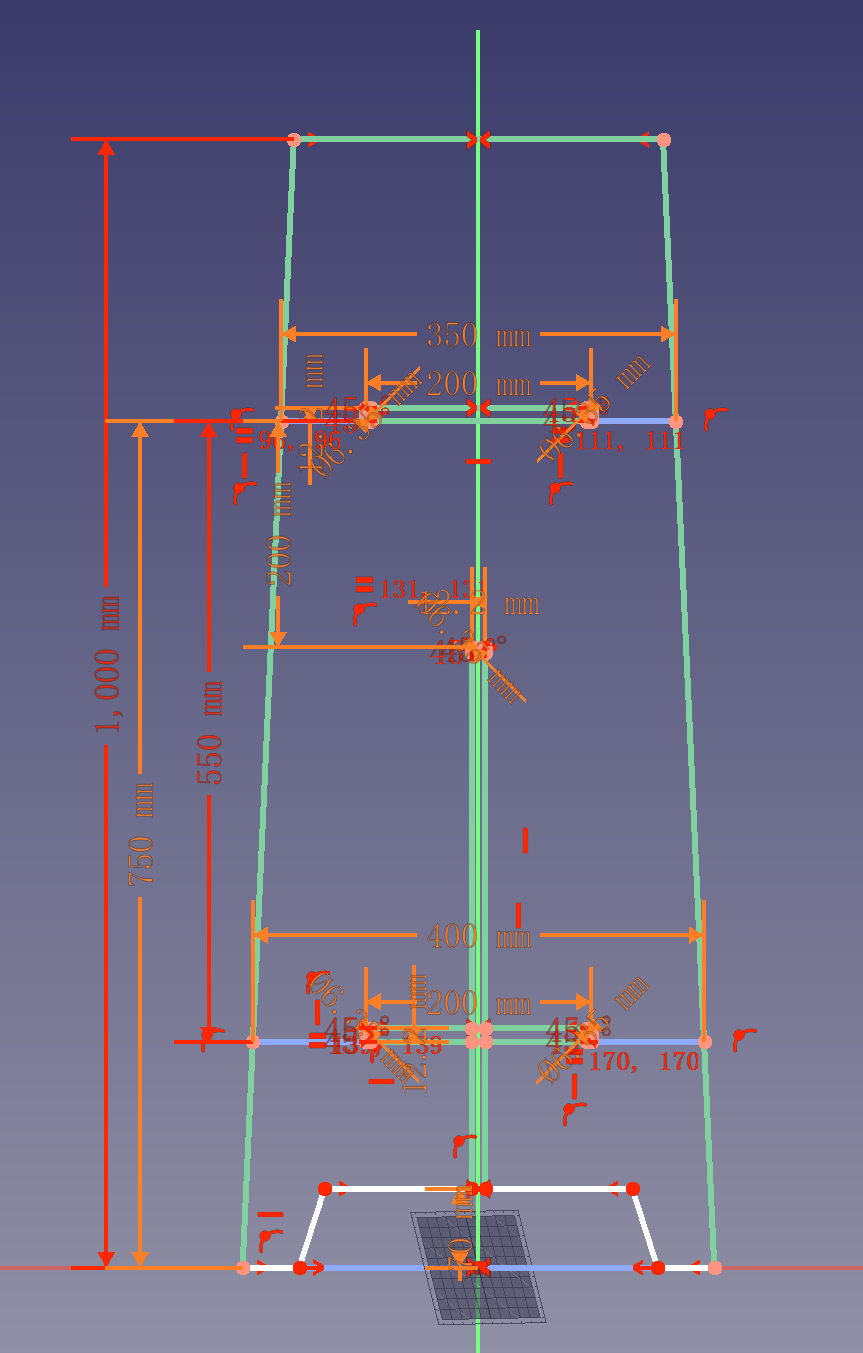

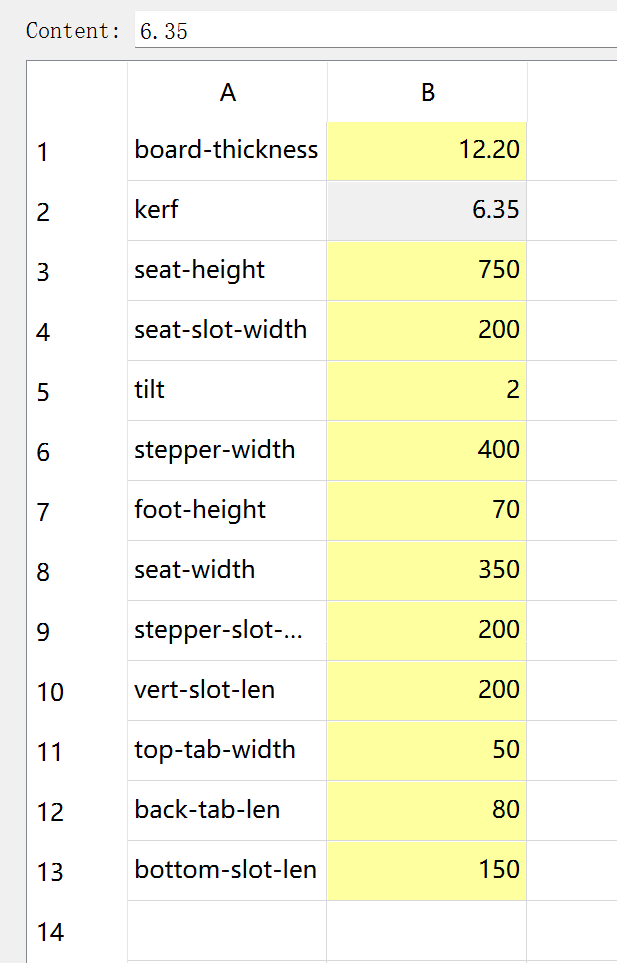

I set different parameters in the FreeCAD spreadsheet to make my design in the sketch automatcally adapt to the maching and material status we are going to use.

The parameters defined in the spreadsheet also constrain and connect different parts of the geometry together.

Also add the dog bone cutout at every joints, the size of which is also controlled by the spreadsheet.

Here's a tech drawing of my final design.

Cutting

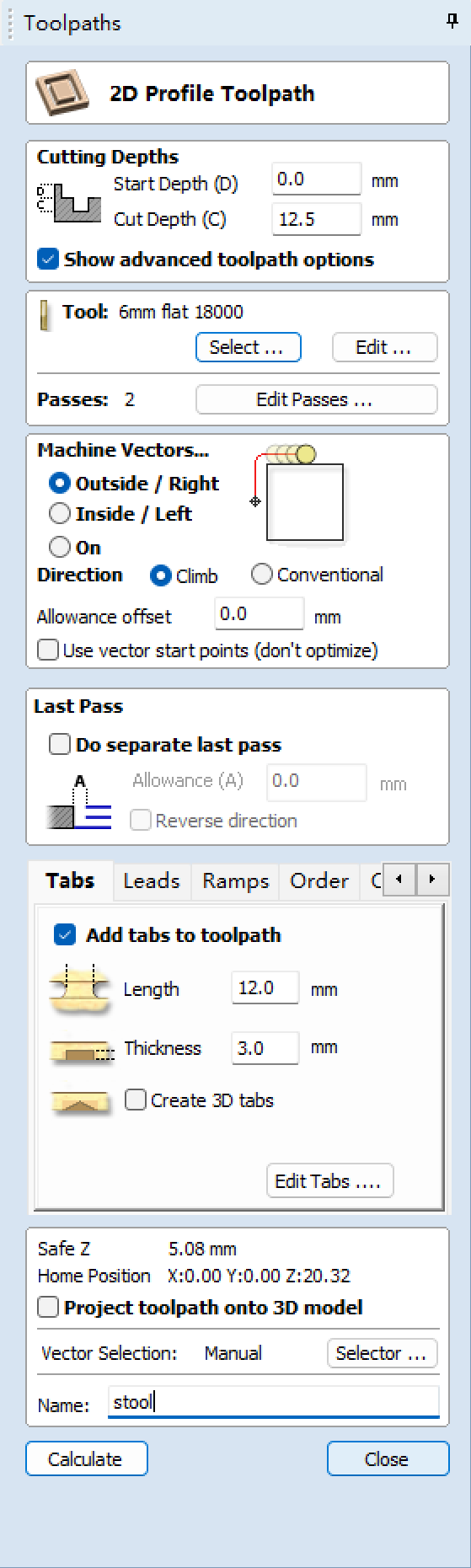

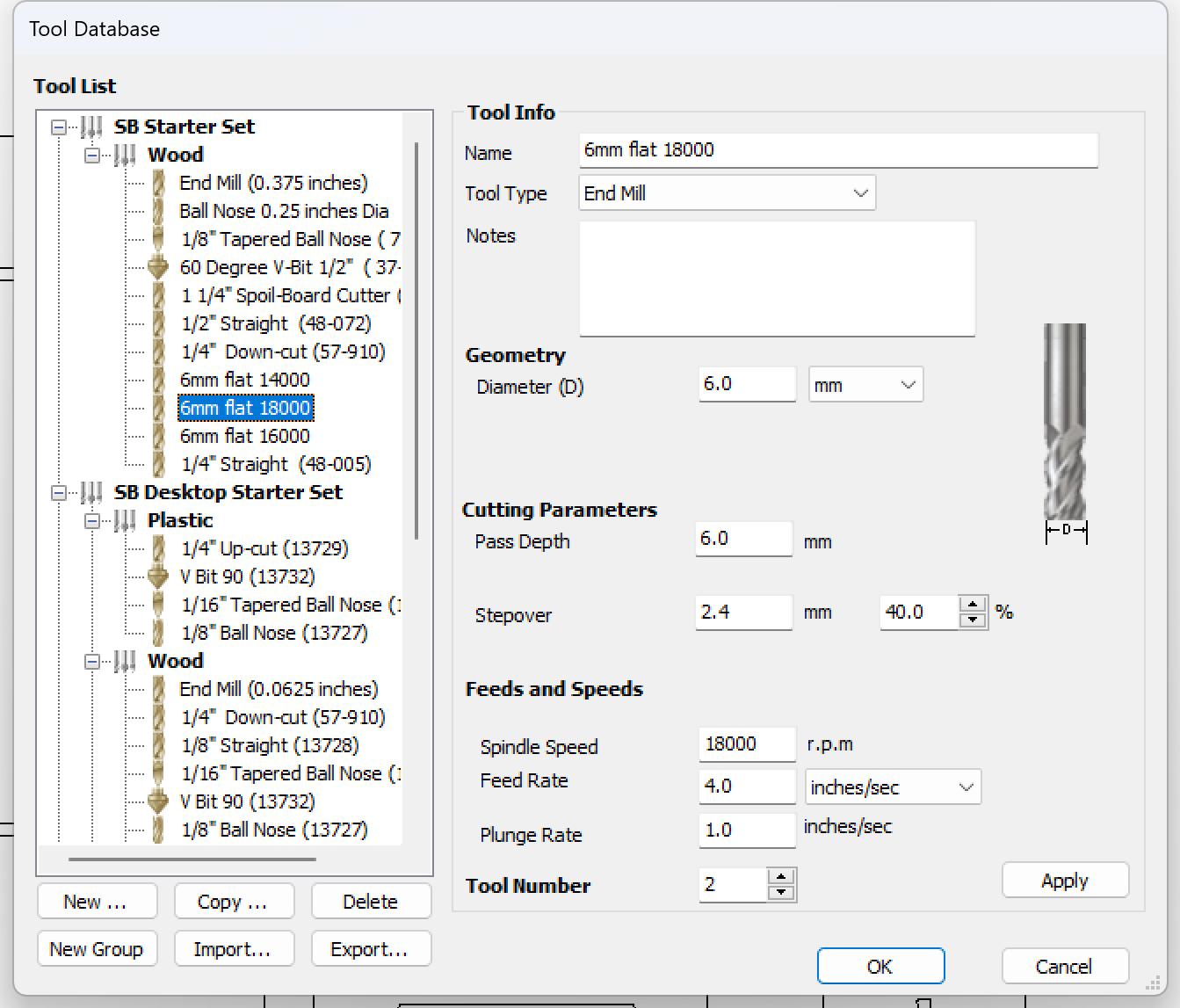

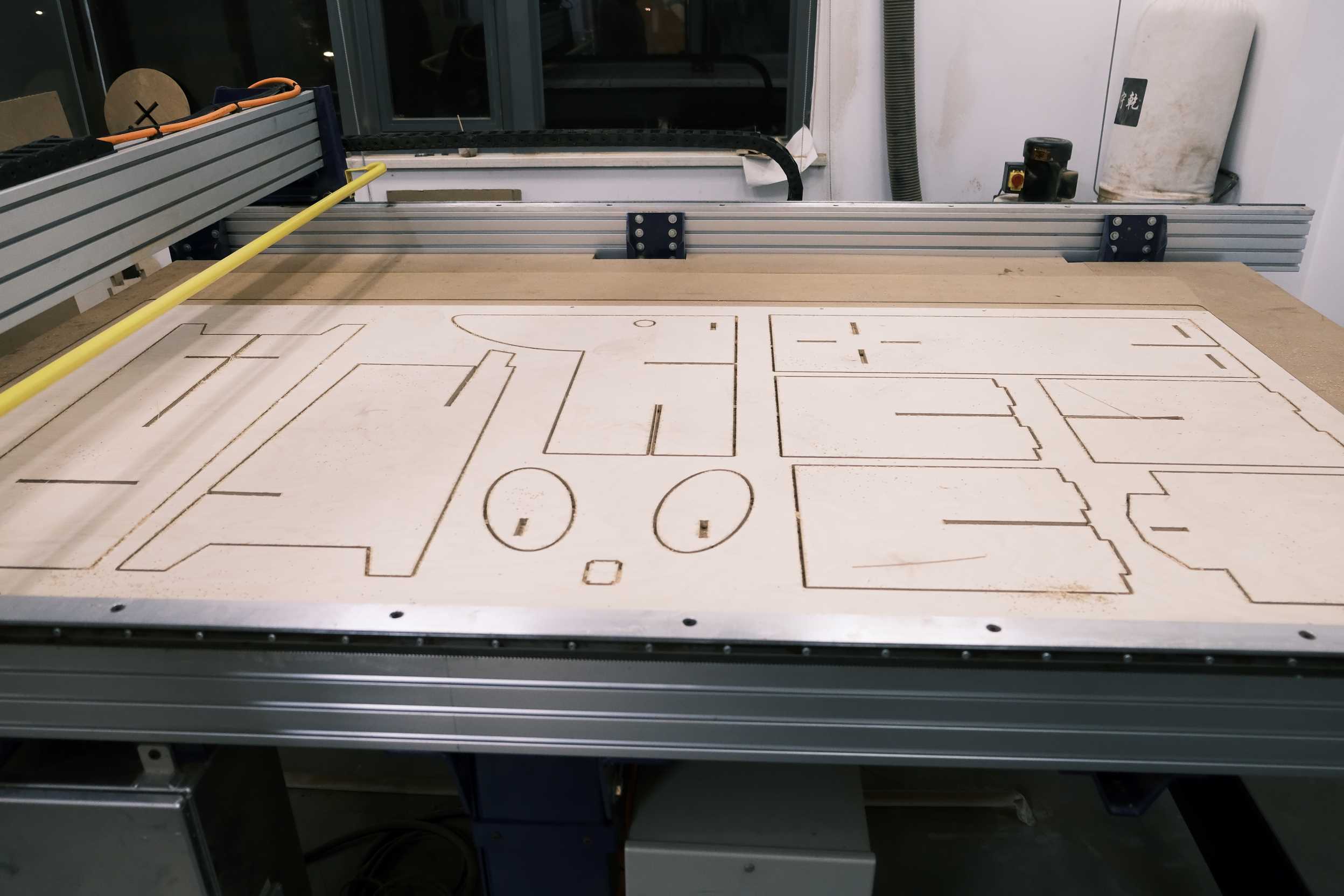

Then it's time for cutting, the large format machine we are using is Shopbot. The material we are using are 12mm thick plywood boards, and we are using a 6mm diameter end mill for cutting.

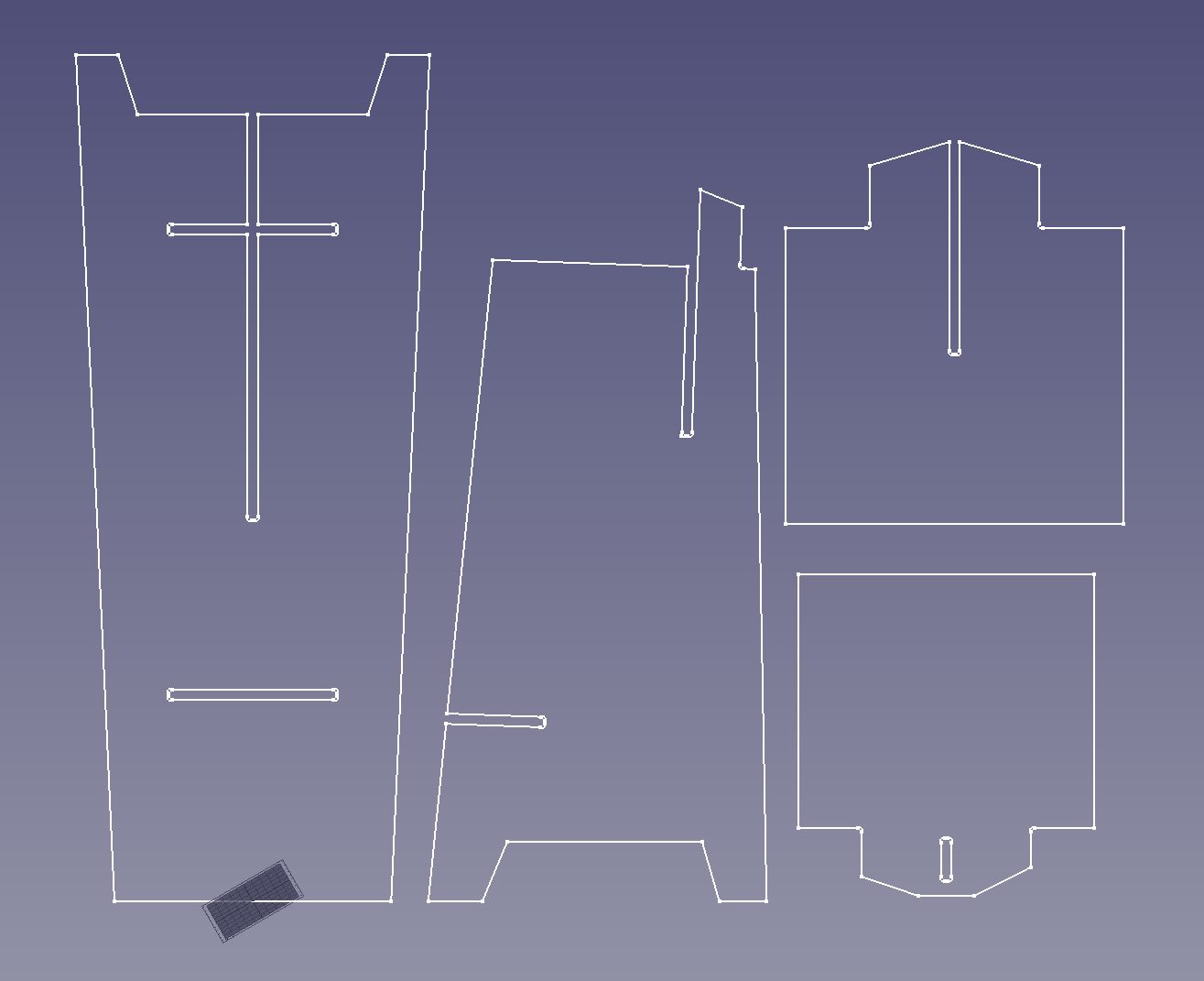

I exported the sketches as dxf and imported them to Vcarve to plan the tool path, adjust the tool's parameters as following.

Assembling

Finally it's assembling, the long joints of the stool are a bit tight, but after some sanding and hammering they eventually locks in very well.

After the stool is full assembled, we tried it for a bit and found that it's center of mass is likely to move due to stepping the small piece for you to rest your feet.

And because the seat is a bit high, is a bit difficult for some of the users to get seated on the stool. One has to use their arms to lit themselves up to sit and cannot step the foot-rest to get on.

But overall it's usable and it fits me kinda well, so I'm happy with it.

Here's a video of our local instructor Nancy trying the stool.

Project files

- FreeCAD design file: stool.FCStd

- DXF file: stool.dxf

- Tech drawing: stool-tech-draw.pdf