Computer-Controlled Cutting

This week, I met and learned to use a laser cutter and a vinyl cutter in our lab. The laser cutting machine is really super fun and can do a lot of interesting devices and designs, so that my imagination can be realized. At the same time, I continued to learn the constraint modeling and parameter modeling functions of Fusion 360, which provided a good operating space for modifying parameters in the future.

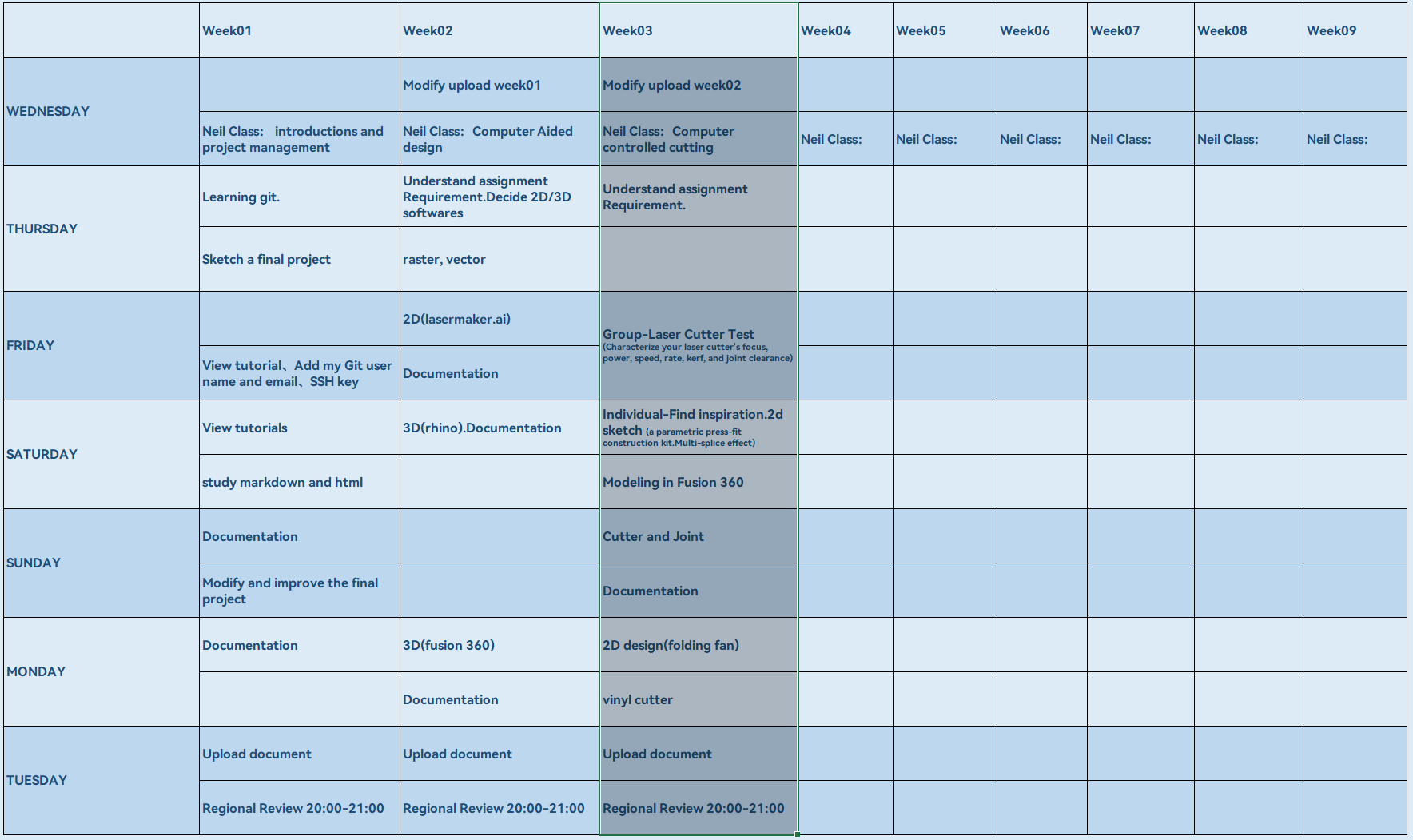

1.1 Assignments of the Week

- Group assignment:

Characterize your laser cutter's focus, power, speed, rate, kerf, and joint clearance.

document your work to the group work page and reflect on your individual page what you learned.

- Individual assignments:

Design, lasercut, and document a parametric press-fit construction kit, which can be assembled in multiple ways.

Cut something on the vinyl cutter.

1.2 Laser Cutter Test (Group Work)

There are three people in our team, and I am mainly responsible for offline drawing and laser cutting. Please refer to this for experimental records

week03-group-assignment-characterize-lasercutter

1.3 Press-fit Construction Kit (Individual)

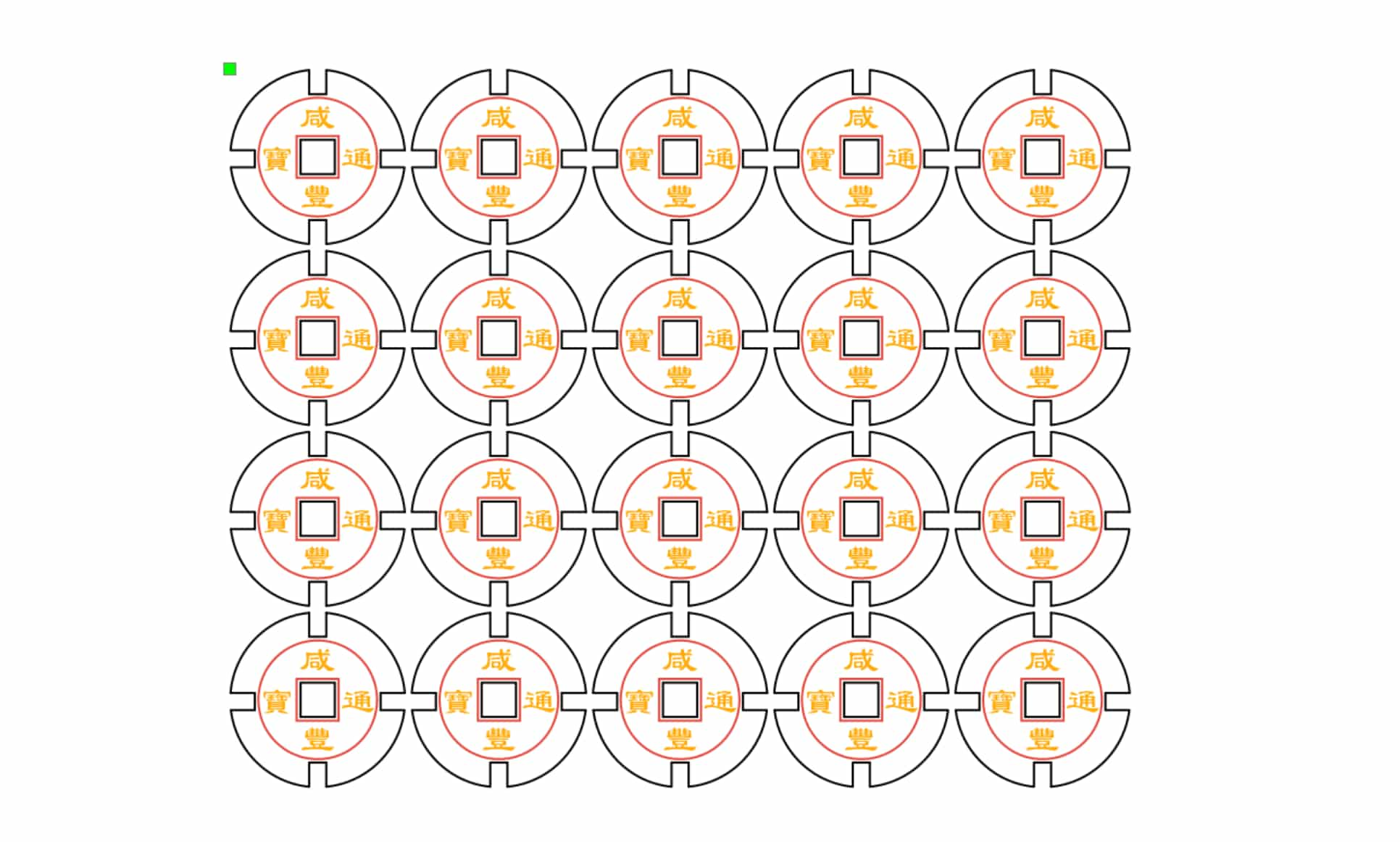

My inspiration comes from Xianfeng Tongbao in the Qing Dynasty, which is highly valuable due to its complex craftsmanship and scarcity. Generally speaking, it is between 2.2-2.8cm, I chose a fixed value of 2.5.

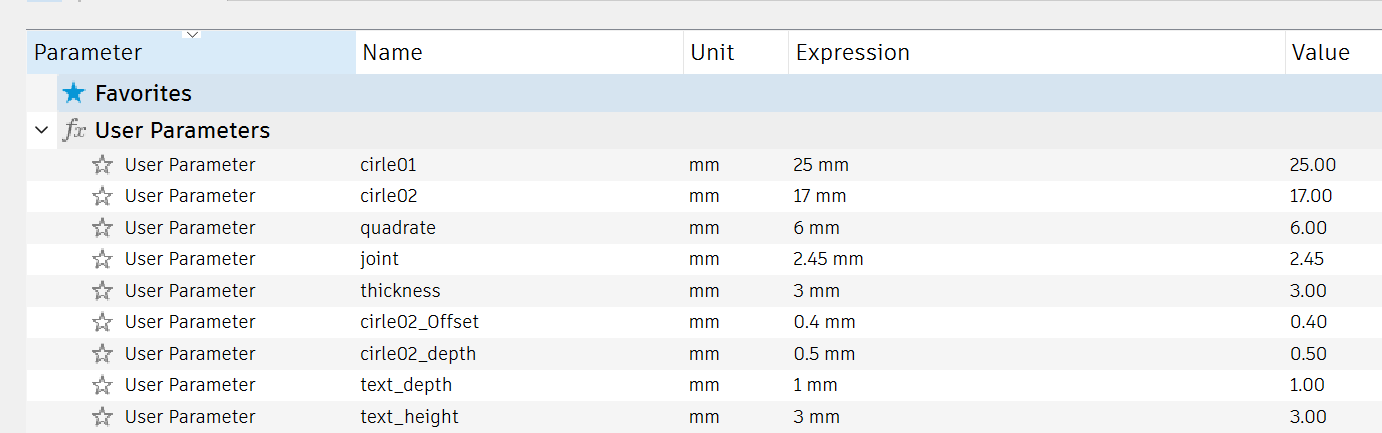

(1) Modeling in Fusion 360

a. According to the joint in my group work, I created a set of "Xianfeng Tongbao" using Fusion 360.

b. I set parameterization at the same time in the design, and I only need to modify one parameter in the subsequent modification, which reduces a lot of repetitive work and saves design time.

c.Cut the extra line segment, you're good to go!

(2) Laser cut and combination

a.According to the measured data, start cutting!

| material | power(%) | speed(mm/s) |

|---|---|---|

| 3mm basswood | 18 | 16 |

b.Some fun combinations

- Earrings

- Flower

- Meal mat

Insert the PVC material from below.

-

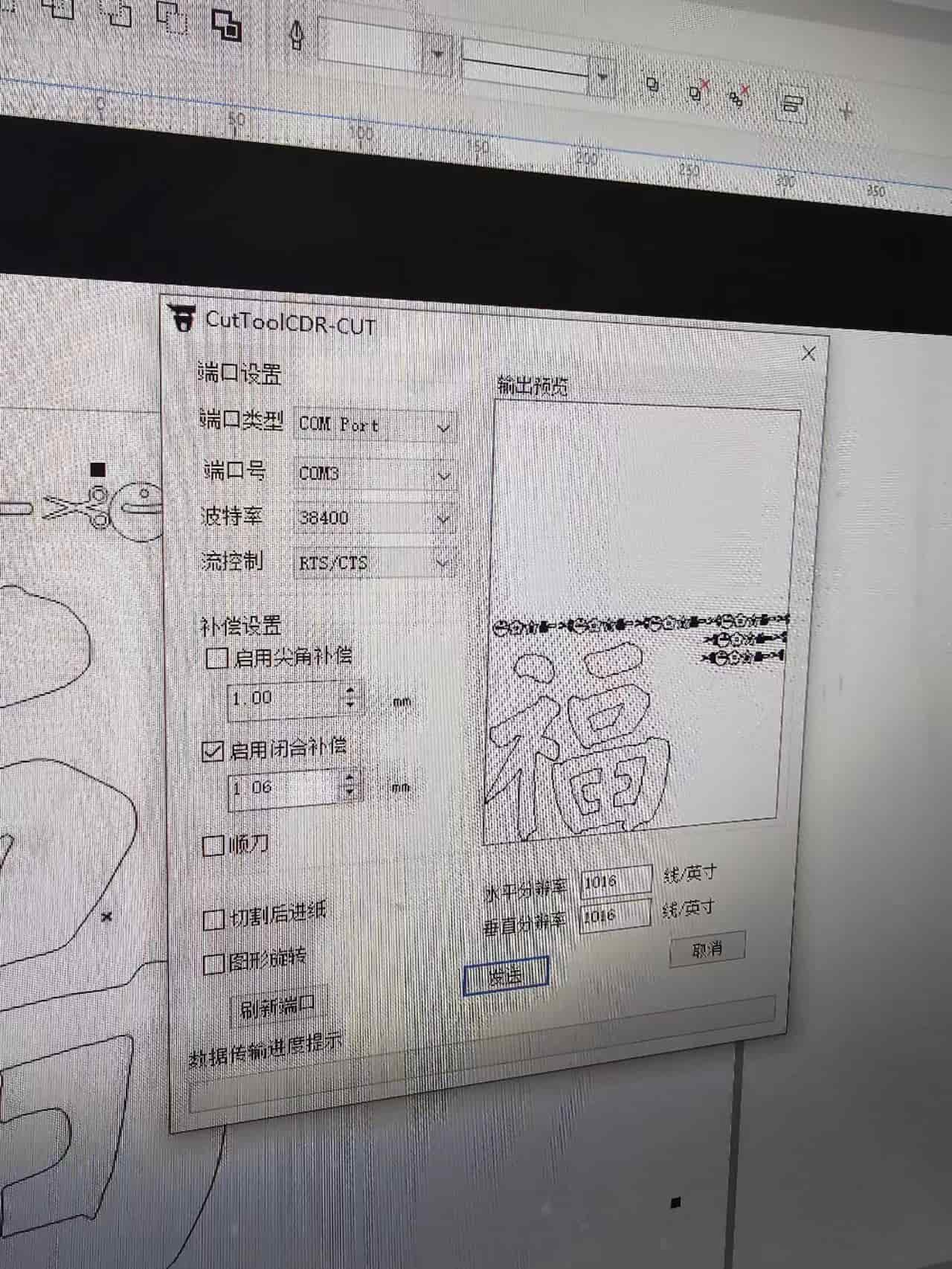

Open the file using CorelDRAW, adjust the position, and transfer it to the machine.

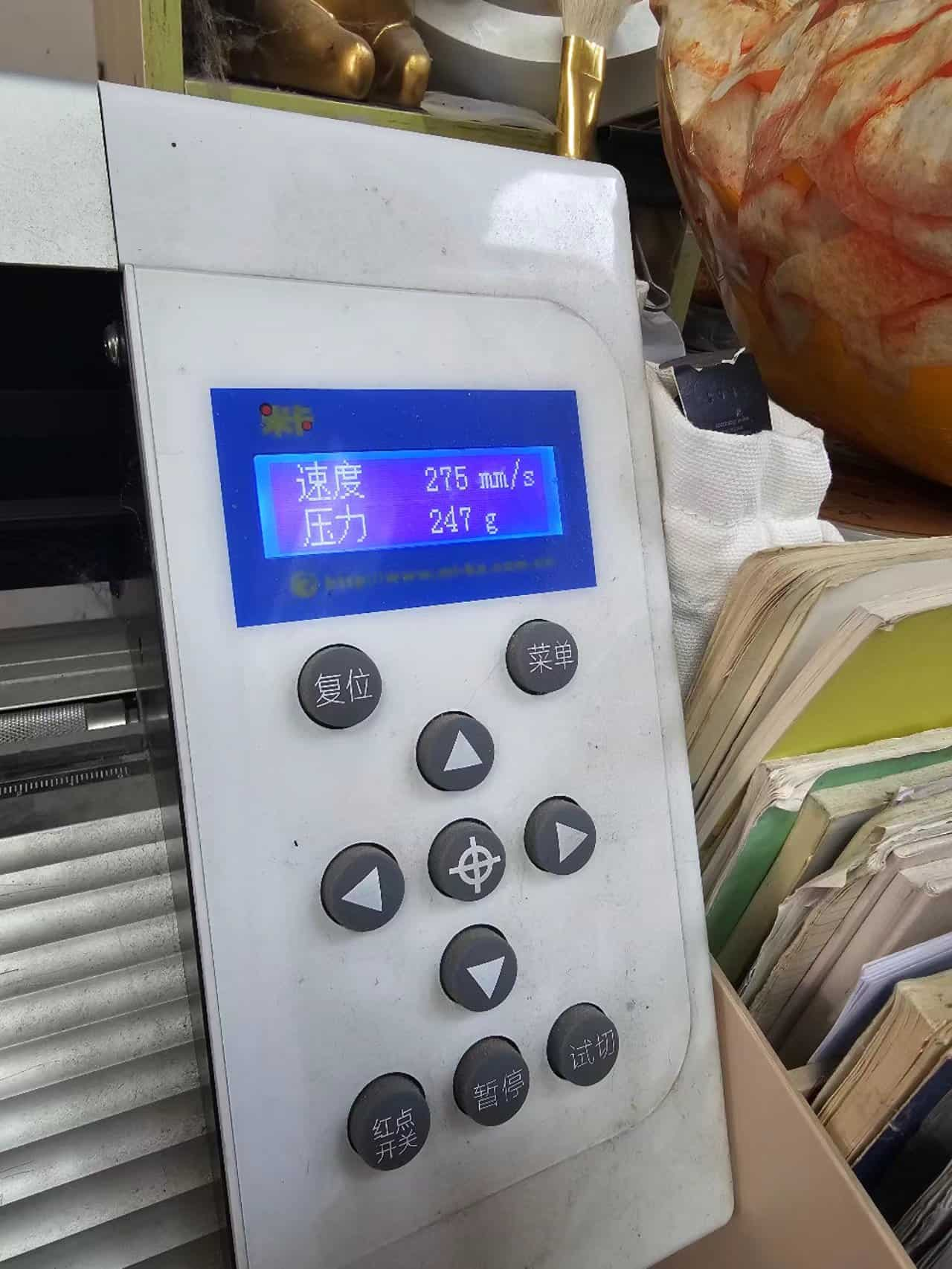

Speed:275mm/s Press:247g( "Pressure" refers to the force applied by the cutting blade onto the material. It affects the cutting depth and effectiveness of the cutting blade on the material during cutting.)

-

Cutting.......

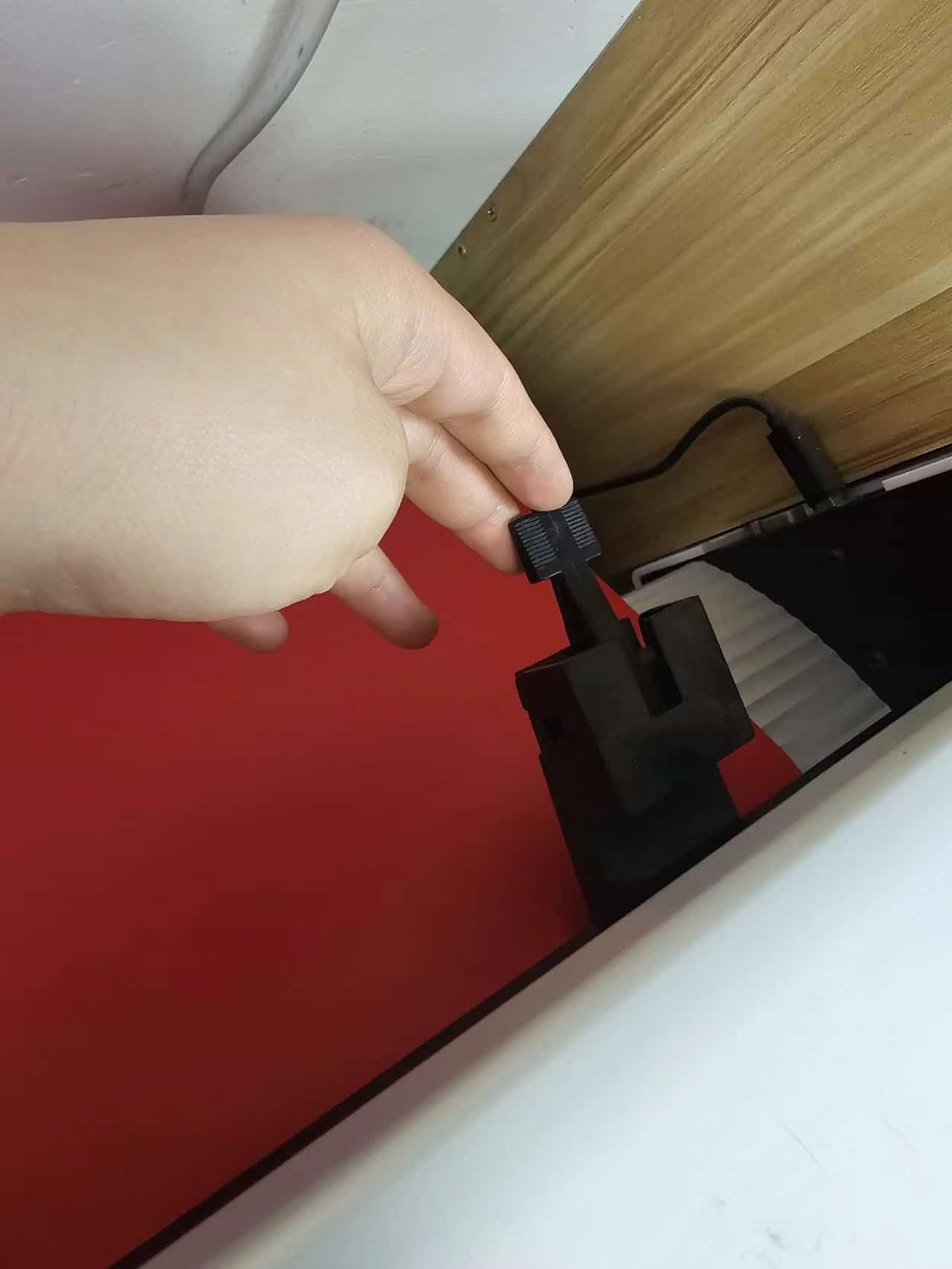

- After the machine stops, lift the rear pedal of the machine, pull the PVC material forward, and then cut it open with a small knife.

-

Peel away the unnecessary PVC, and your cute little designs will appear!

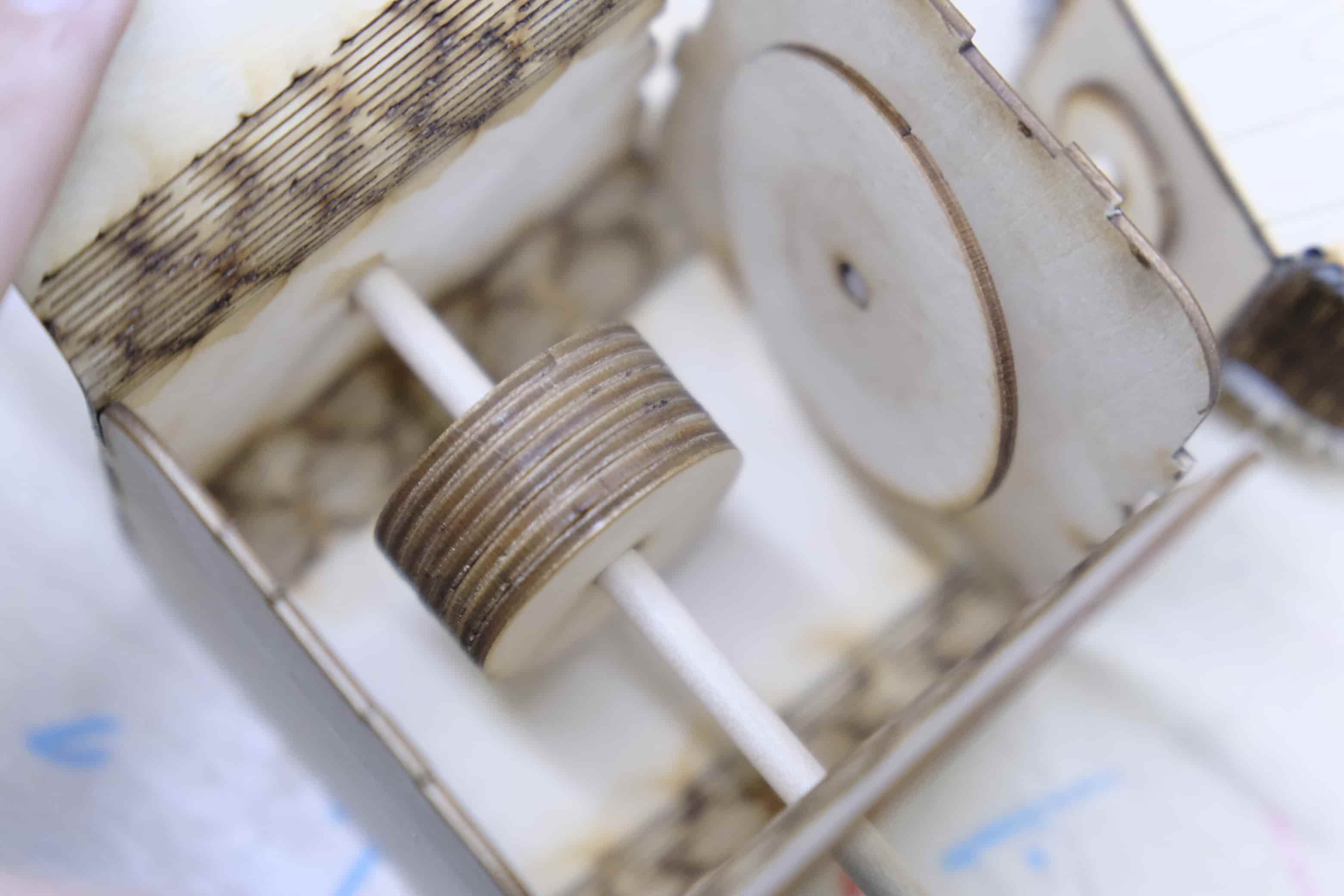

c.A swinging cactus. Using the bending characteristics of different material shapes, combined with the CAM in the mechanical structure

1.4 Vinyl Cut (Individual)

Vinyl cutter" refers to a device used for cutting intricate and detailed designs. It operates by cutting soft vinyl film or similar materials to create labels, stickers, signage, decorations, and other graphics. This type of equipment is typically used in conjunction with computer software, where users design graphics and then send them to the cutter for precision cutting based on the specified paths and shapes.

Due to the young age of my students, they really like colorful stickers, so I used Illustrator to draw some cute designs as classroom rewards.

I created some cute designs using basic shapes.

This is my first time using an vinyl cutter, the machine is MIKA

Here are the operating steps: