Week03 Group Assignmnet - Characterize Lasercutter

For this week's group assignment, we need to test and characterize our lasercutter's different cutting parameters.

The lasercutter we use is from a company called Thunderlaser and is focused on STEM education and the ease of use. It comes with a custom controlling software. We made the test files in the software and recorded the results as follows.

The focus of the lens is 6mm.

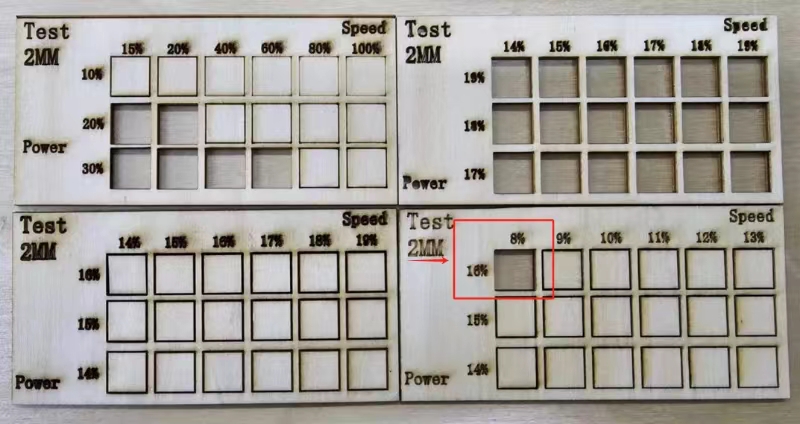

The optimal cutting parameter for 2mm plywood material is: speed: 8mm/s, power: 16%

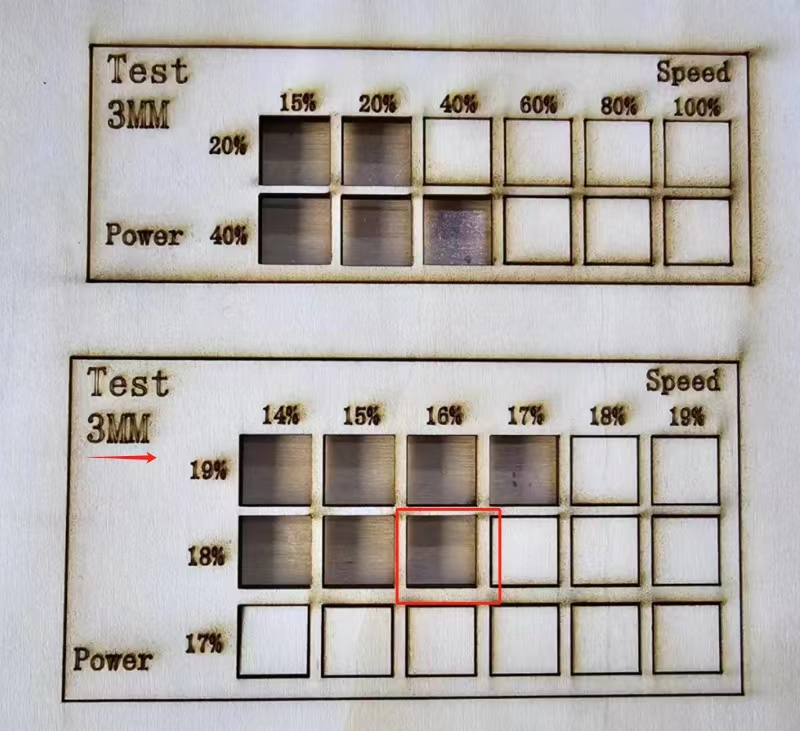

The optimal cutting parameter for 3mm plywood material is: speed: 16mm/s, power: 18%

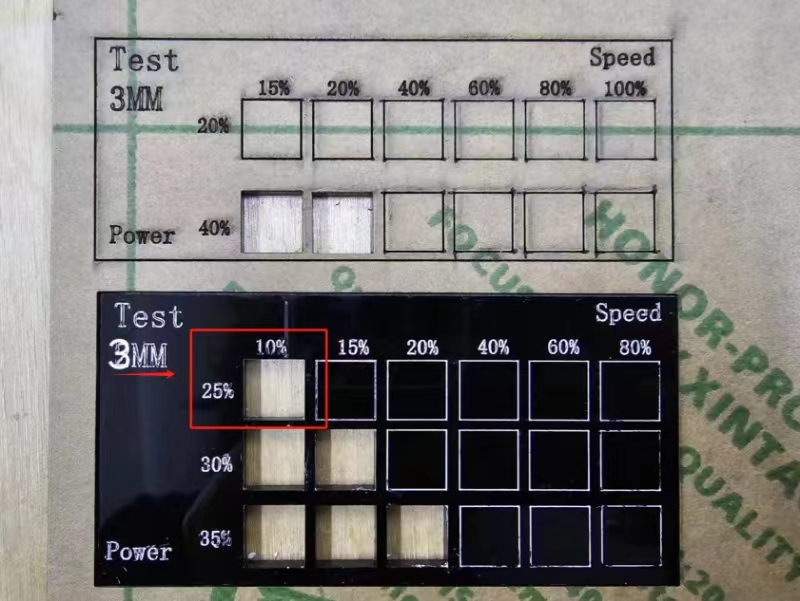

The optimal cutting parameter for 3mm acrylic material is: speed: 10mm/s, power: 25%

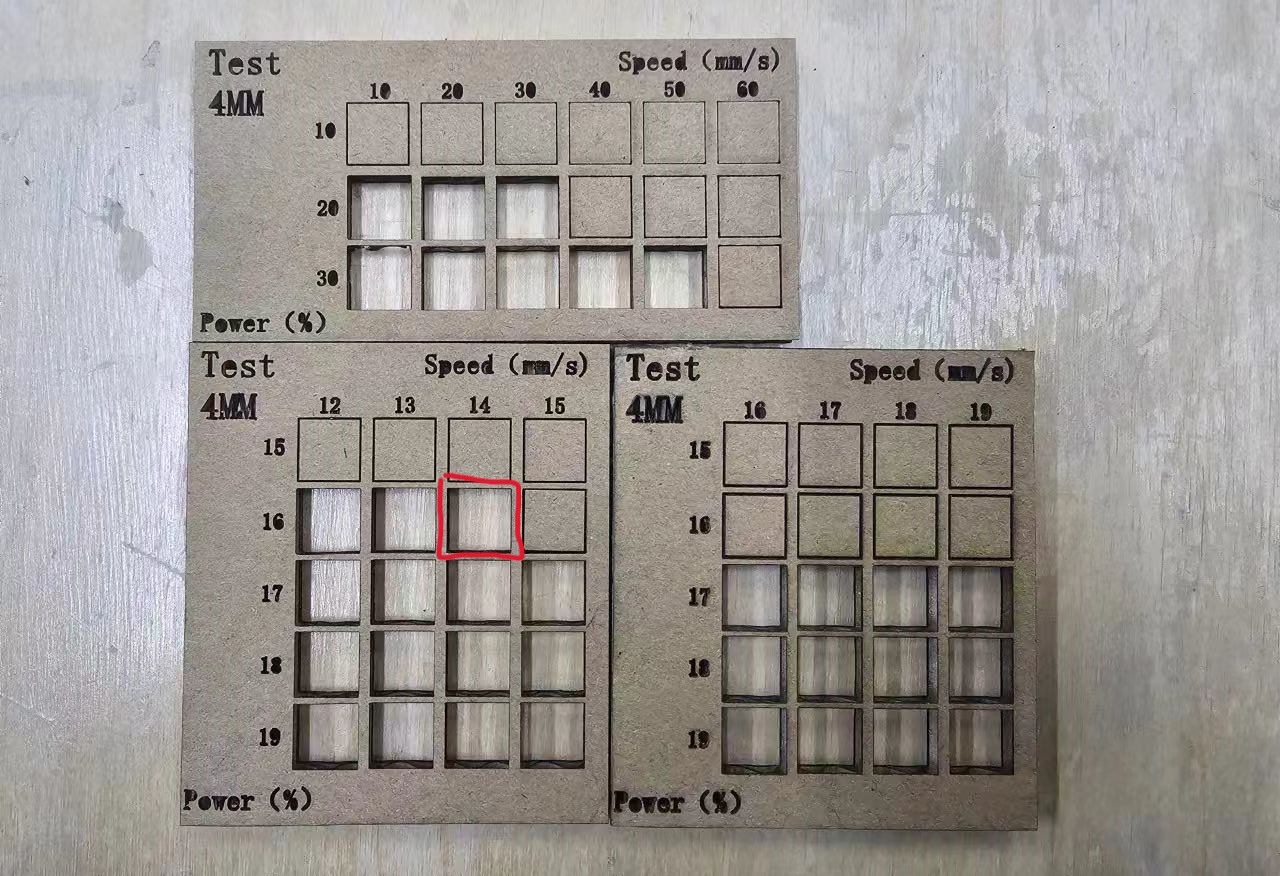

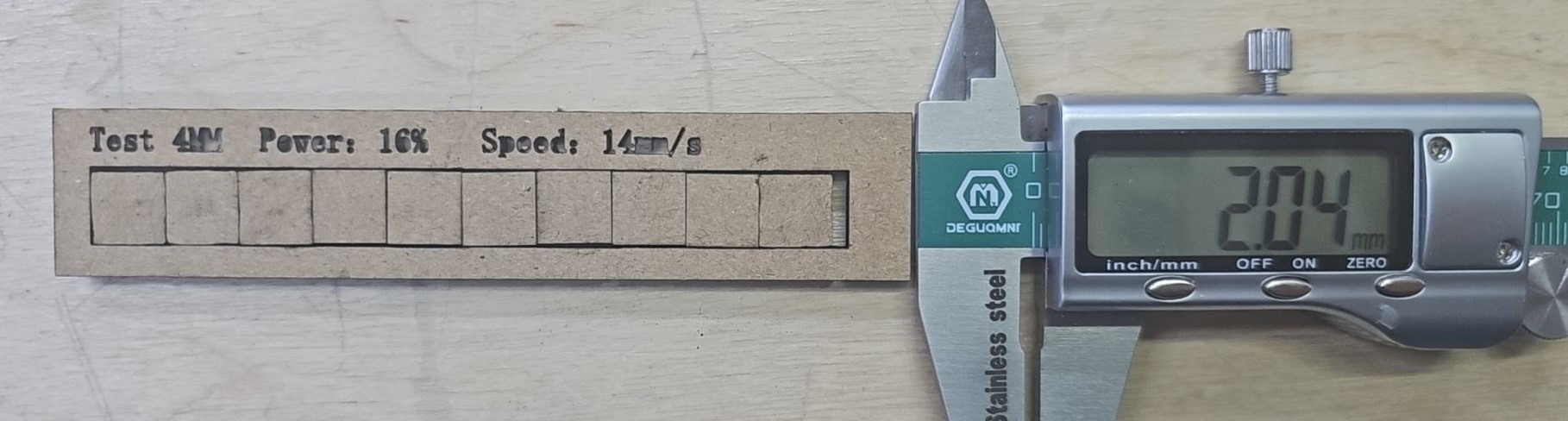

The optimal cutting parameter for 4mm cardboard material is: speed: 14mm/s, power: 16%

Kerf of the machine when cutting 3mm plywood is 3 - 2.45 = 0.55mm

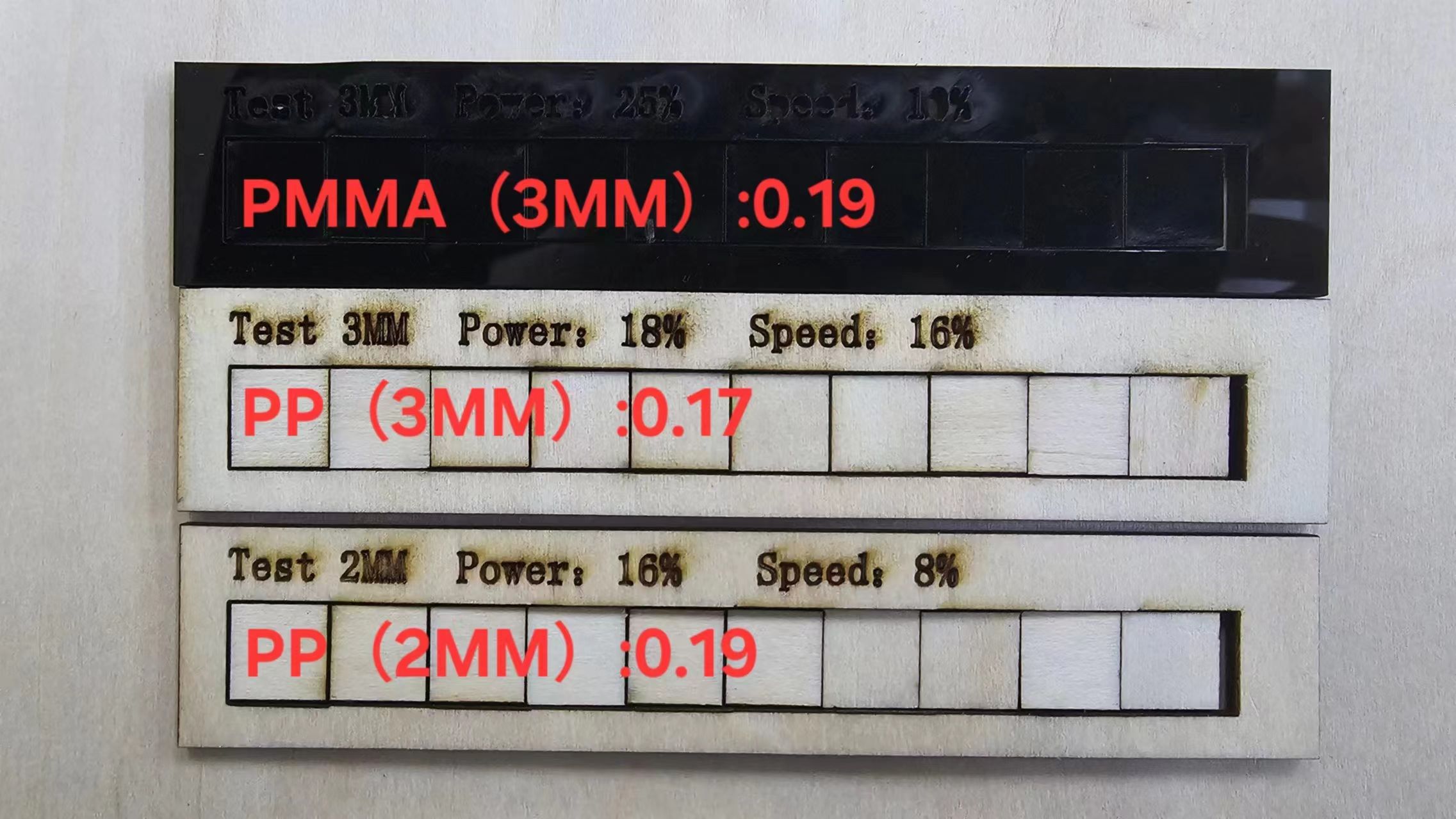

Error of the machine using different materials:

- 3mm PMMA acrylic:

0.19mm/10mm - 3mm plywood:

0.17mm/10mm - 2mm plywood:

0.19mm/10mm - 4mm cardboard:

0.204mm/10mm

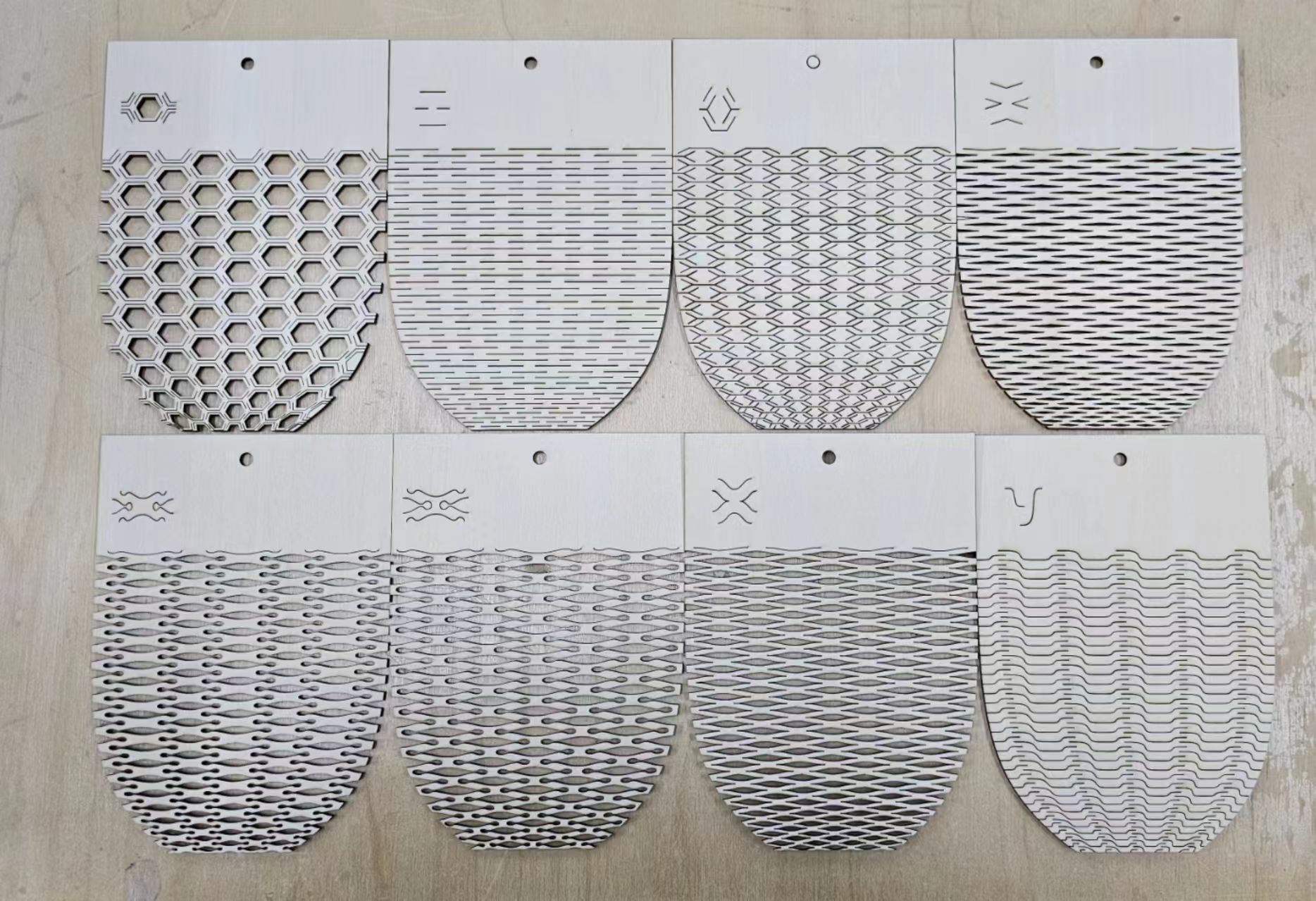

Test of the bending structure is ok.