WEEK 17

Applications and implications

Assignment:

Propose a final project masterpiece that integrates the range of units covered, answering:

- What will it do?

- Who's done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, embedded microcontroller interfacing and programming, system integration and packaging.

Where possible, you should make rather than buy the parts of your project

Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

Assignment

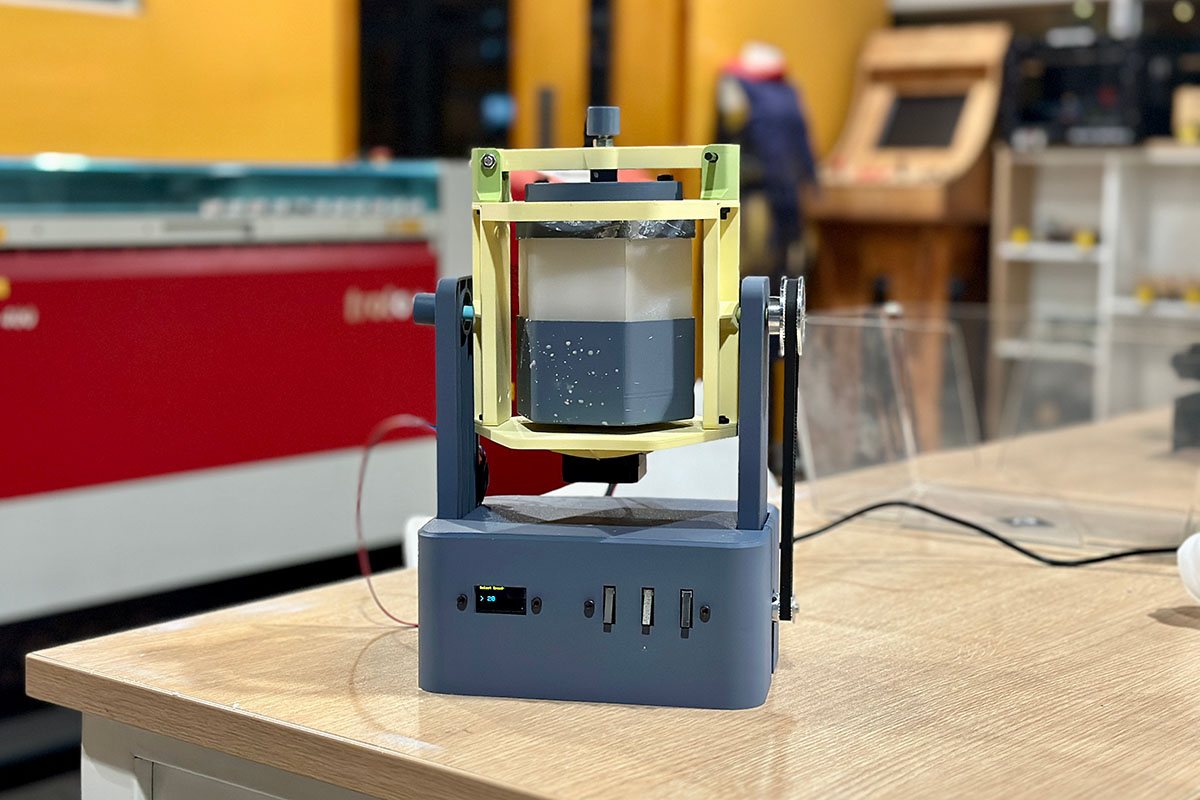

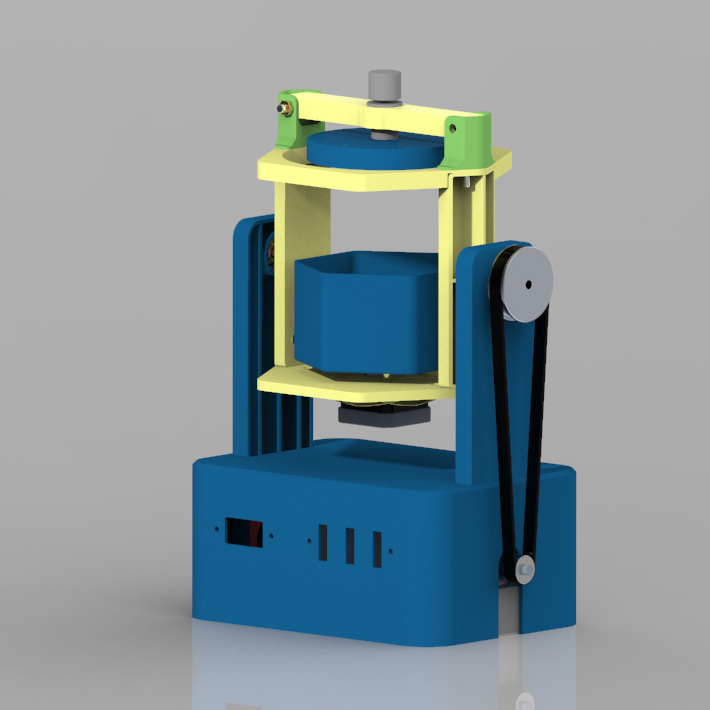

The project I propose is a rotational molding machine. The idea is to pour a liquid material into a silicone mold. The mold will rotate on two main axes. The goal is that the material adhere to the mold walls as it solidifies, thus creating hollow objects.

What will it do?

The machine will rotate a mold on two main axes and will have the following features:

- It should allow select the rotation speed.

- It should allow select the rotation time.

- It will use three switches and an LED screen to navigate the menu.

- It should allow easy loading and unloading of the mold.

- It should facilitate easy pouring of the material.

The rotation time and speed should be adjustable to accommodate materials with different viscosities and solidification times.

Regarding the mold design:

- The negatives should allow for easy removal of the silicone.

- The molds should align easily.

- The molds should prevent the liquid material from leaking through the parting lines.

- The mold should have a lid that allows for easy pouring of the material and secure closure.

Who's done what beforehand?

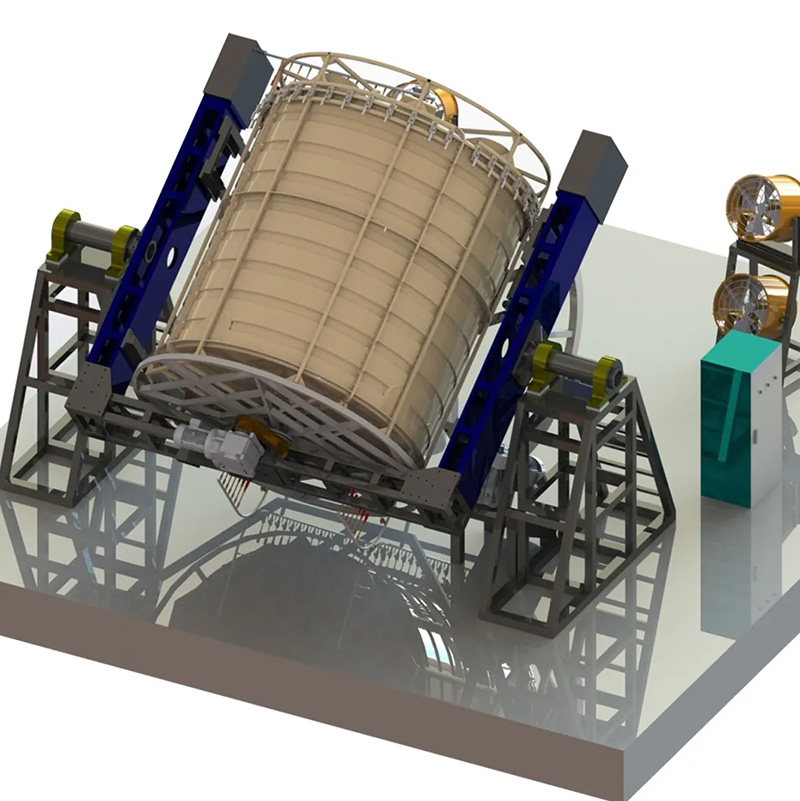

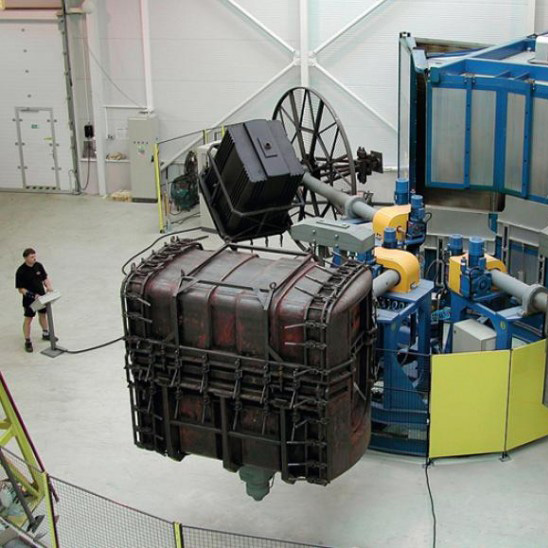

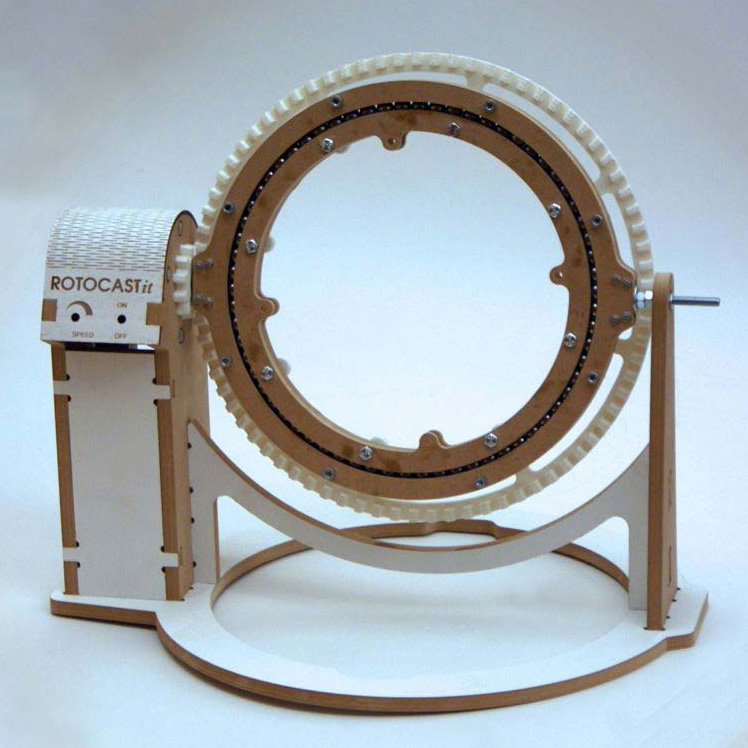

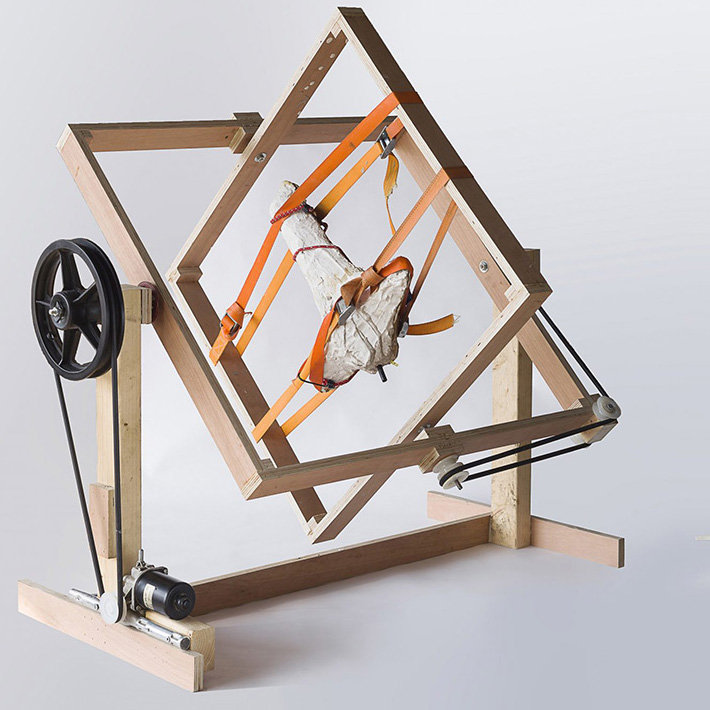

Rotational molding is primarily used to make large items like tanks, containers, or any hollow plastic objects, so rotational molding machines are usually quite large. Smaller versions are typically manual, as seen in the images below. Saverio Silli also created a version during Fab Academy 2015. In my design, I aim for a compact and user-friendly machine.

What will you design?

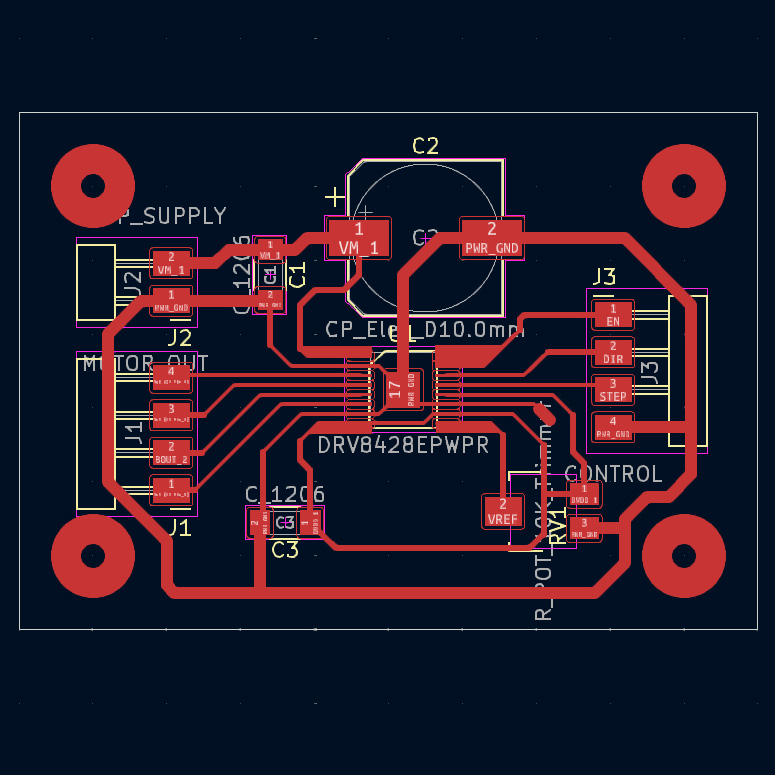

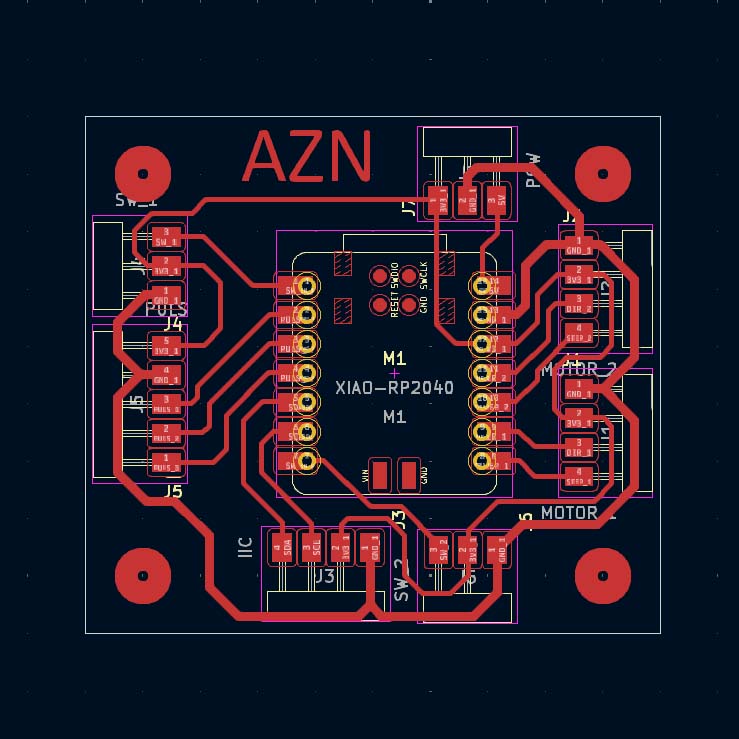

To develop the project, I will design the mechanical structure, which will consist mainly of 3D-printed components and some commercial parts. Additionally, I will design the electronic boards for the motor controllers, the main board, and the board for connecting the switches.

What materials and components will be used?

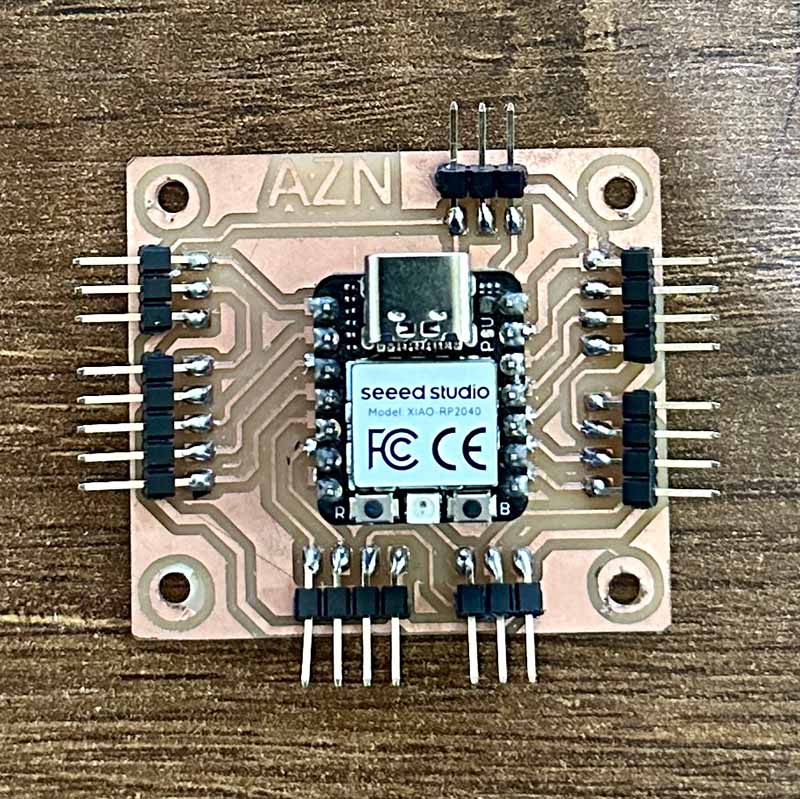

Main board: Total $7.0

| Item | Components | Amount | Price per Unit ($) |

|---|---|---|---|

| 1 | SEEED STUDIO XIAO RP2040 | 1 | 6.0 |

| 2 | MALE BERG STRIP | 1 | 0.5 |

| 3 | FEMALE BERG STRIP | 1 | 0.5 |

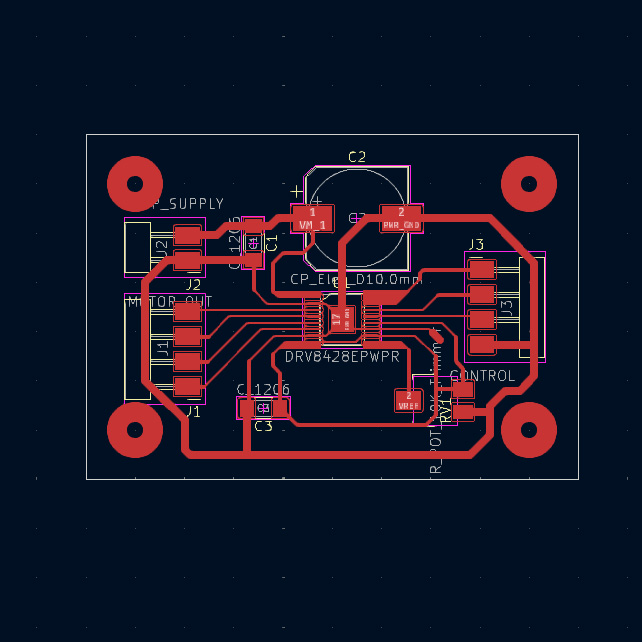

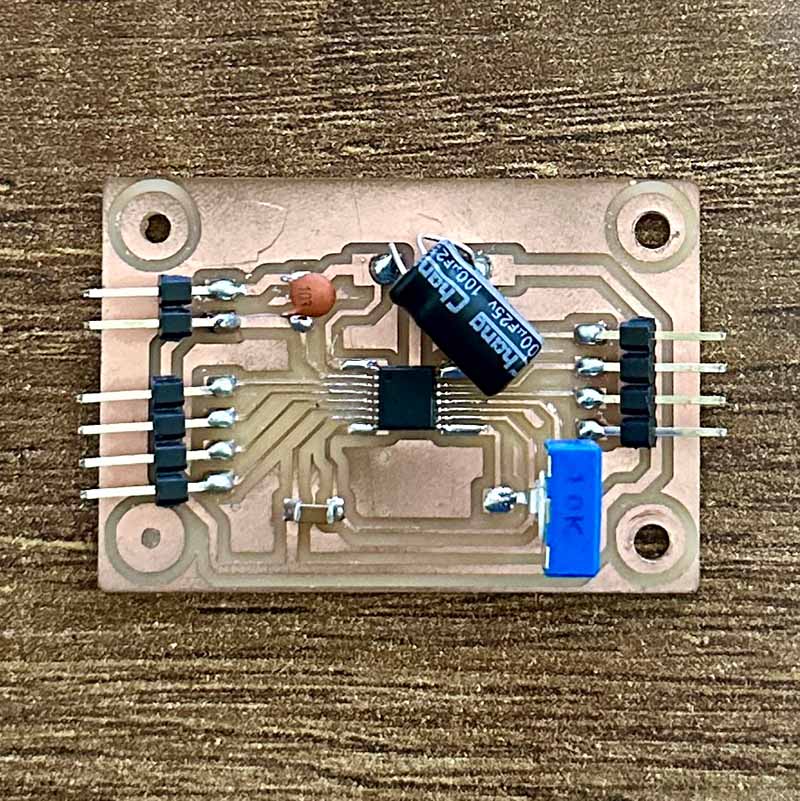

Stepper motor driver board: Total $11.5

| Item | Components | Amount | Price per Unit ($) |

|---|---|---|---|

| 1 | DRV8428 | 1 | 8.0 |

| 2 | ELECTROLYTIC CAPACITOR 100 uF | 1 | 1.0 |

| 3 | CAPACITOR 0.01 uF | 1 | 0.5 |

| 4 | CAPACITOR 1 uF SMD | 1 | 0.5 |

| 5 | TRIMMER 10k | 1 | 1.0 |

| 6 | MALE BERG STRIP | 1 | 0.5 |

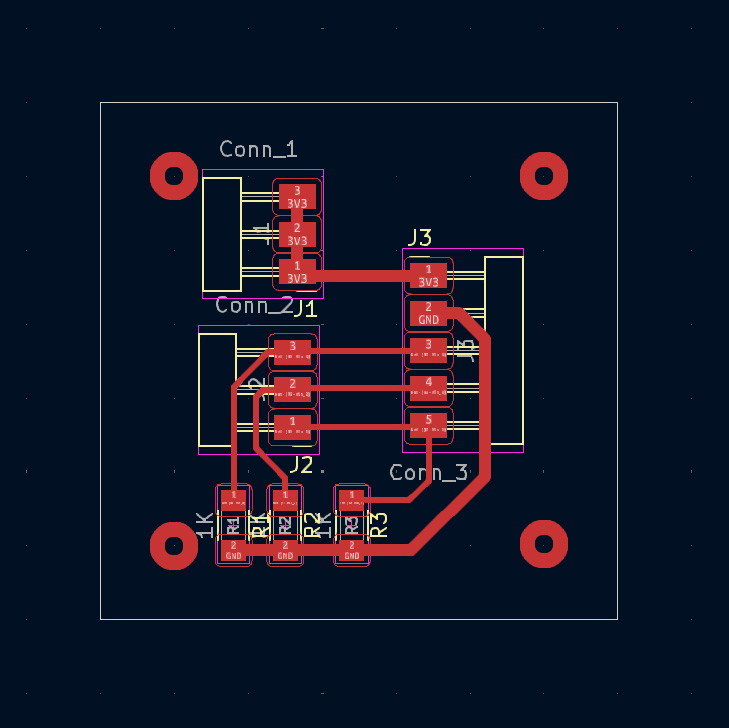

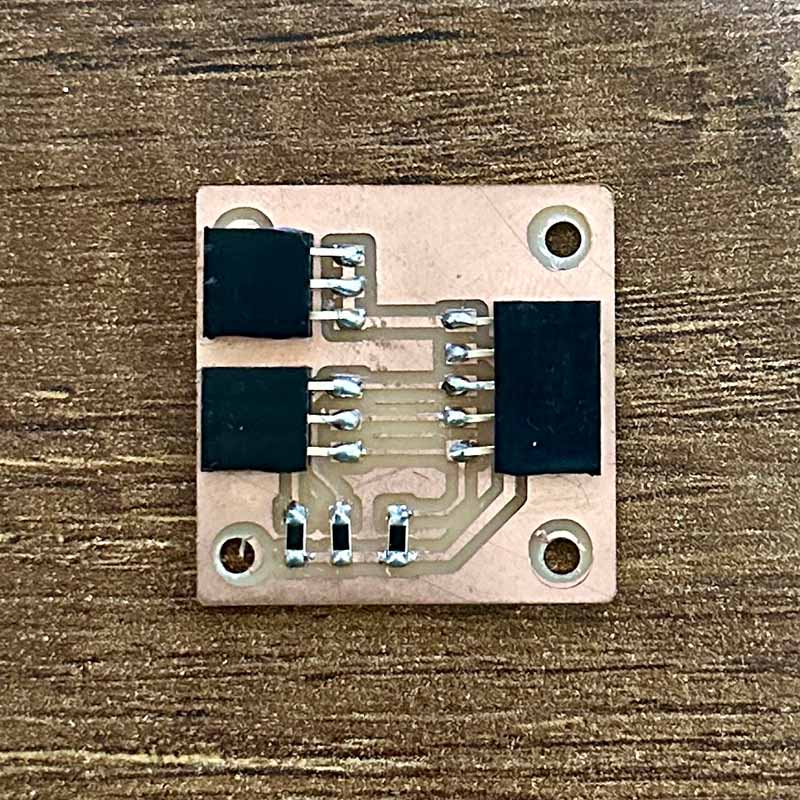

Swithc board: Total $0.8

| Item | Components | Amount | Price per Unit ($) |

|---|---|---|---|

| 1 | RESISTOR 1K SMD | 3 | 0.1 |

| 2 | FEMALE BERG STRIP | 1 | 0.5 |

Other additional componets I bought were: Total $65.7

| Item | Components | Amount | Price per Unit ($) |

|---|---|---|---|

| 1 | NEMA 17 STEPPER MOTOR | 1 | 12.0 |

| 2 | NEMA 17 STEPPER MOTOR LOW PROFILE | 1 | 12.0 |

| 3 | NEMA 17 STEPPER MOTOR 90° BRACKET | 2 | 3.0 |

| 4 | 2GT16-5MM PULLEY | 1 | 1.0 |

| 5 | 2GT60-5MM PULLEY | 1 | 2.5 |

| 6 | 2GT-400MM BELT | 1 | 3.0 |

| 7 | 608 BEARING | 3 | 1.0 |

| 8 | LM2596S VOLTAGE REGULATOR | 1 | 2.0 |

| 9 | POWER JACK SOCKET | 1 | 0.5 |

| 10 | POWER SUPPLY 12V 3A | 1 | 3.0 |

| 11 | SSD1306 DISPLAY | 1 | 5.0 |

| 12 | LIMIT SWITCH | 3 | 1.0 |

| 13 | M5x30 SCREW | 3 | 1.0 |

| 14 | 1/4"x2" SCREW | 1 | 1.0 |

| 15 | 1/4" HEX NUT | 1 | 0.5 |

| 16 | M3x8 SOCKET HEAD SCREW | 20 | 0.1 |

| 17 | M3 HEX NUT | 5 | 0.1 |

| 18 | M4x12 SOCKET HEAD SCREW | 16 | 0.1 |

| 19 | M4 HEX NUT | 16 | 0.1 |

| 20 | USB C CABLE | 1 | 5.0 |

Where will come from?

Most of the components I used were already available at the Fab Lab; however, they can also be bought from local suppliers. There are many local physical stores and websites where electronic and mechanical components can be purchased. Additionally, I bought some components like screws and nuts from Amazon.

How much will they cost?

The components described in the tables above total $99.0 considering that two stepper motor drivers will be manufactured; however, this does not include the cost of the filament used for the printed parts, as well as the FR1 boards and the components used for soldering and making the silicone molds.

What parts and systems will be made?

The parts that will be fabricated include the electronic boards (2 stepper motor drivers, 1 main board, 1 switch board) and the machine's structure, and the molds.

What processes will be used?

The main manufacturing processes used in the project will be the following:

- CNC milling and soldering: for the fabrication of electronic boards and connect the electronic componets.

- 3D printing: for the machine's structure.

- Molding and casting: for the creation of the molds.

- Embedded programming: to develop the software that will control the system.

What questions need to be answered?

At this moment, the following questions arise:

- Can a program be created to continuously moves the mold on both axes at the same time?

- Whatv other materials can be used in the machine?

- What rotation time and speed should be selected for each type of material?

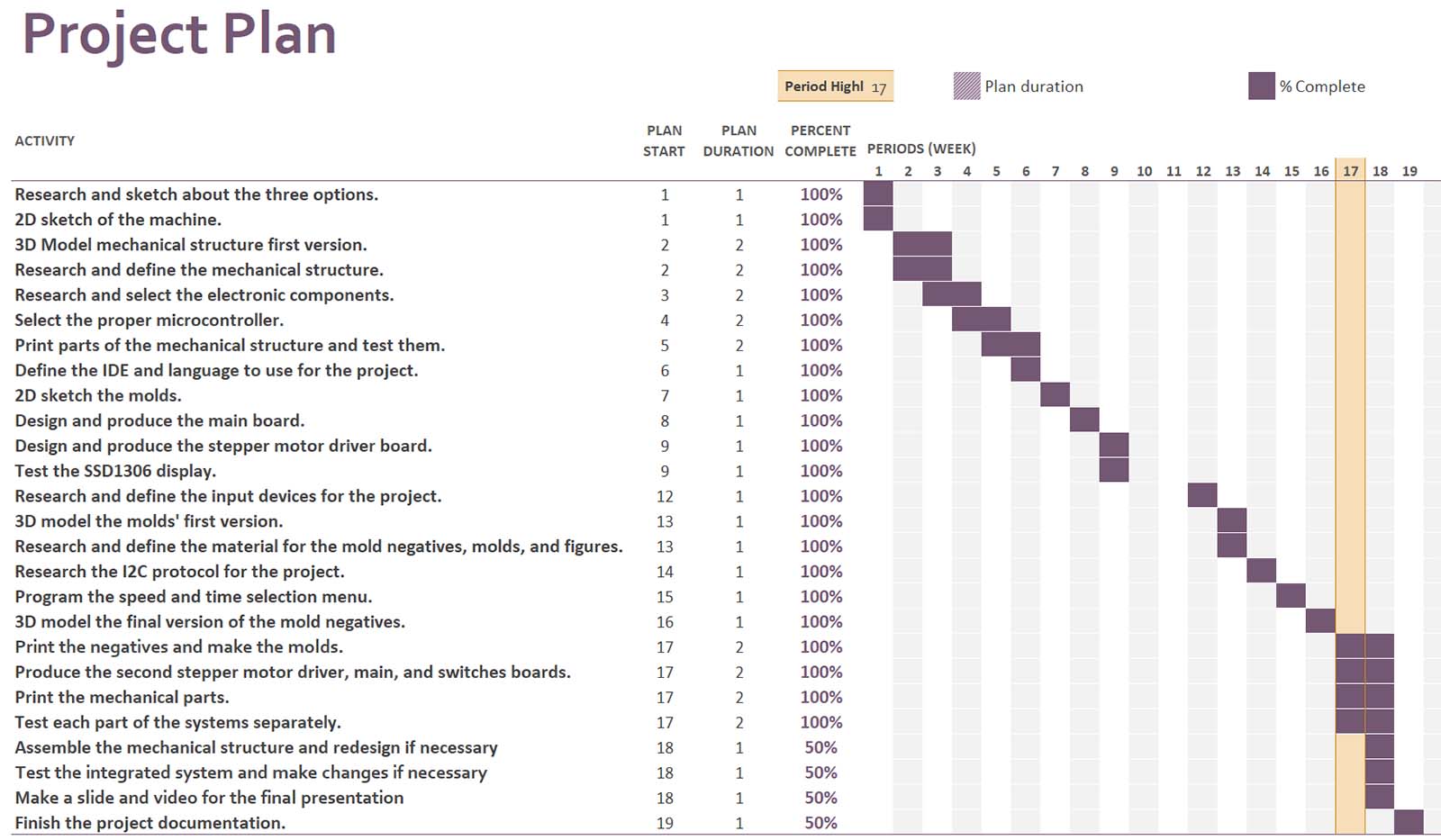

I will work on this questions in the following weeks, this is the plan of the project:

How will it be evaluated?

The main function of the machine is to create hollow objects, so the project will be evaluated based on achieving this objective. For testing purposes, melted wax will be used because it is easier to handle, as it doesn't require very high temperatures to melt and has a relatively quick solidification time. Additionally, each system must be tested separately: The machine should allow the selection of rotation speed and time through the LED screen and three switches, the motors must move correctly, the mechanical structure should be stable and withstand vibrations when the mold rotates and the mold should not allow the liquid material to leak.

Download:

Here you can download de printable parts of the machine: