Group Assignment:

Group Assignment Link:

____________

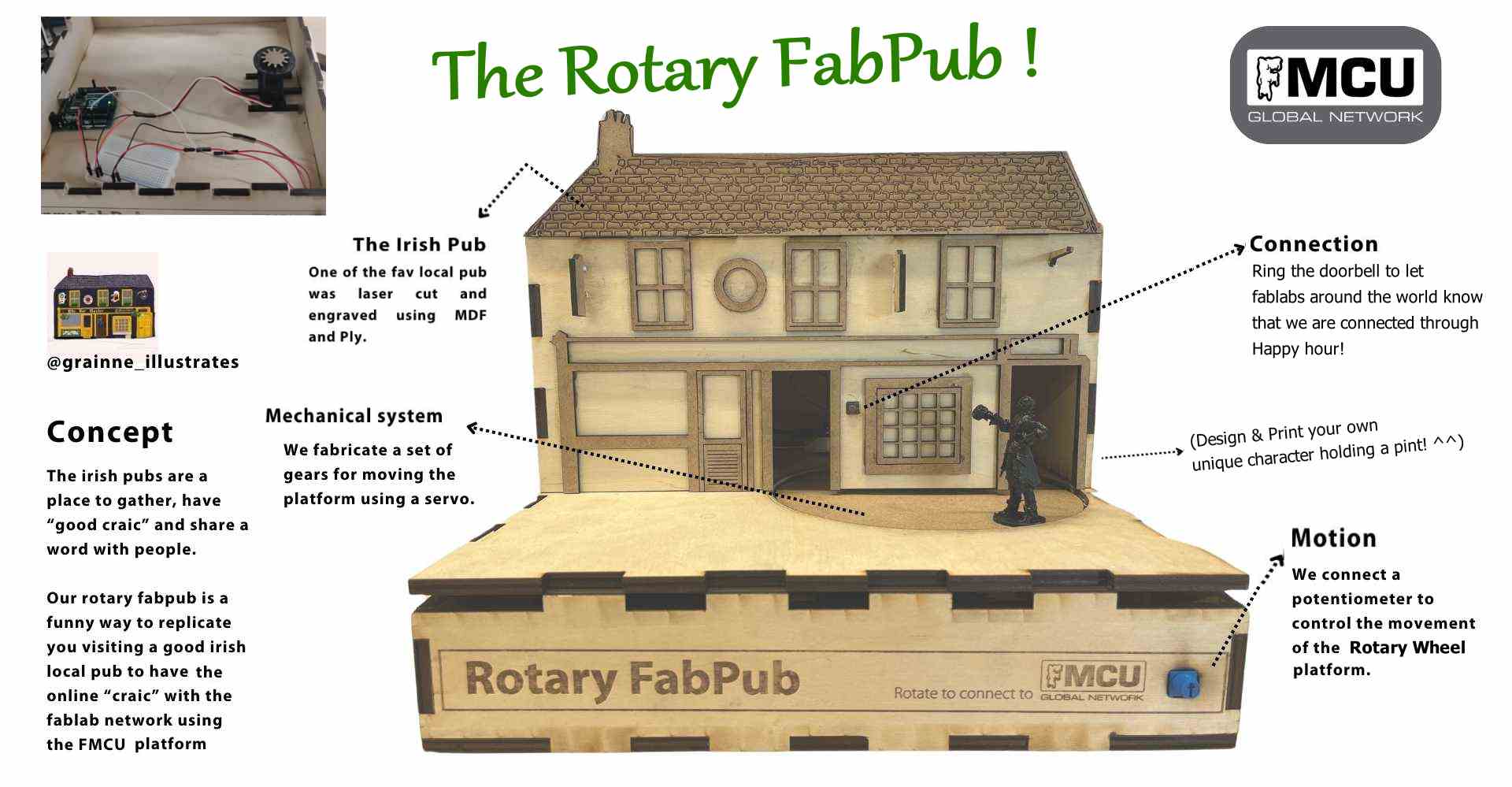

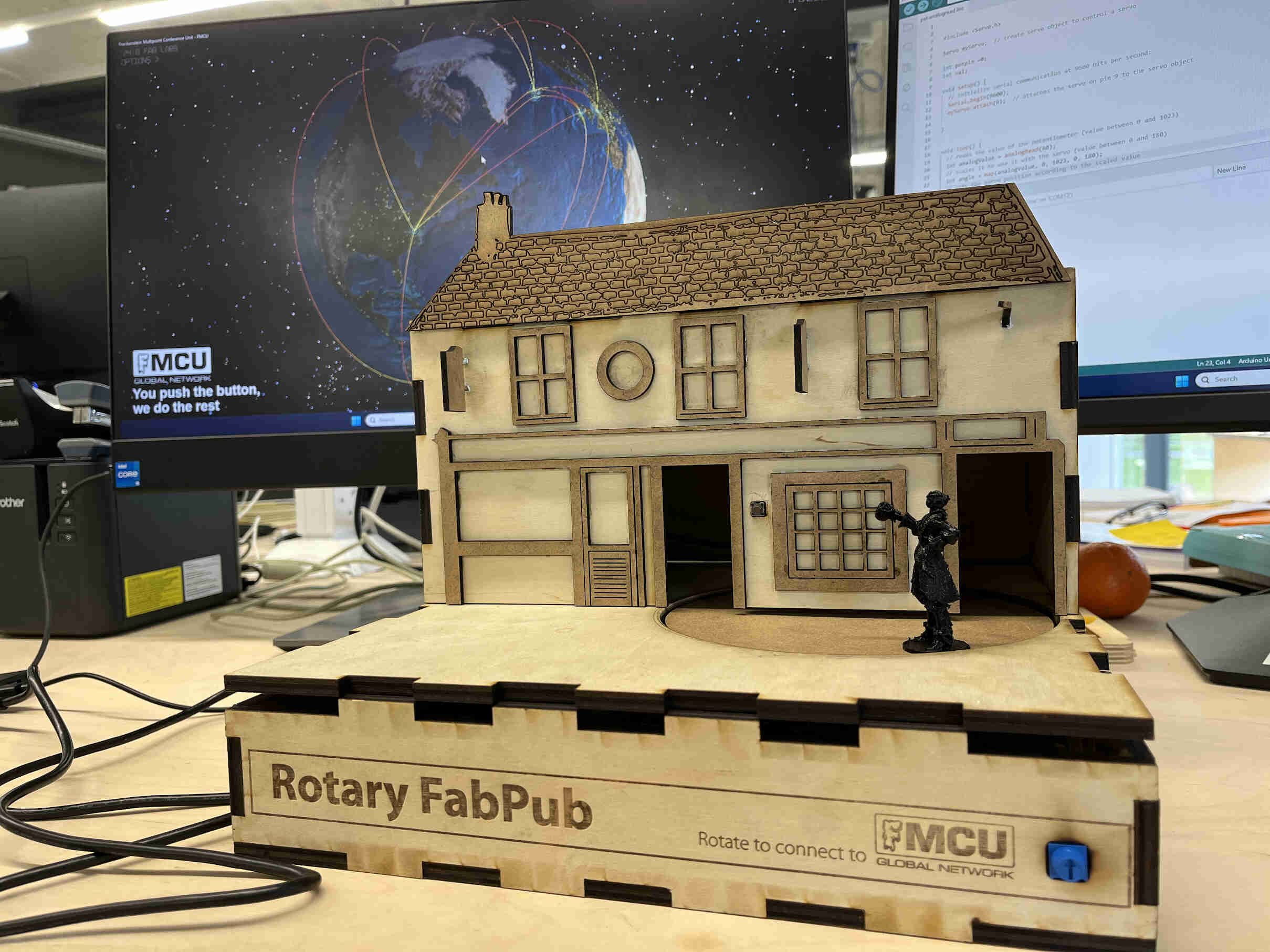

Our Machine: The Rotary FabPub!

____________

Assignment Progression

For Group assignments, as I am the only person in Ireland taking the Fab Academy course, my instructor Oscar has been teaming up with me. For this assignment we got out the pen and paper and decided what type of machine we would like to build. The past few weeks have been focusing on Electronics and Circuitry which I’ve been having difficulty with, I was delighted to start working on something design-related.Oscar said there was a desire to see something Irish-related in Fab Academy. I wouldn’t exactly say that I’m engrained in Irish culture as my influences lie elsewhere, but I agreed to try for this assignment.

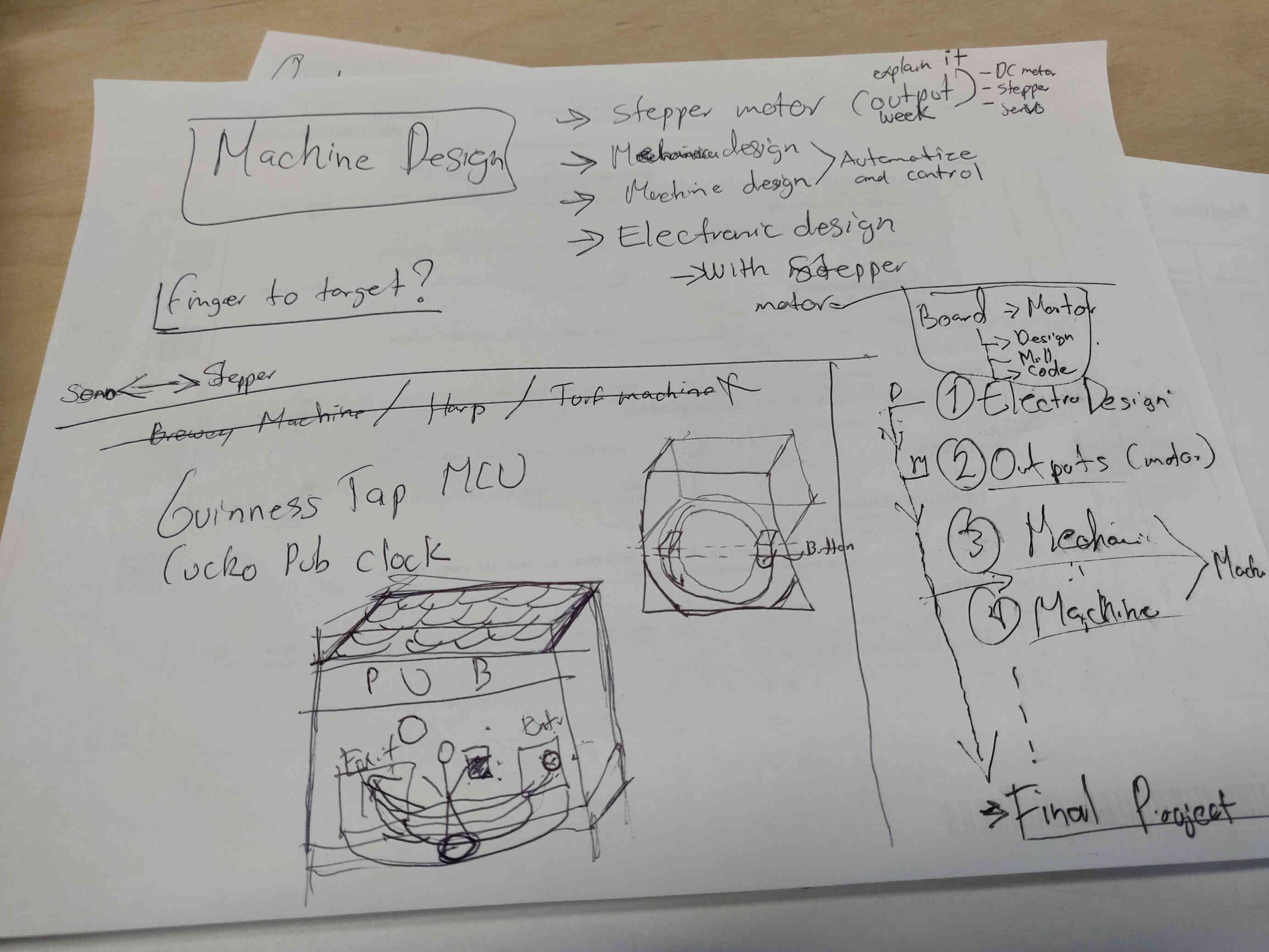

Concept Brainstorming

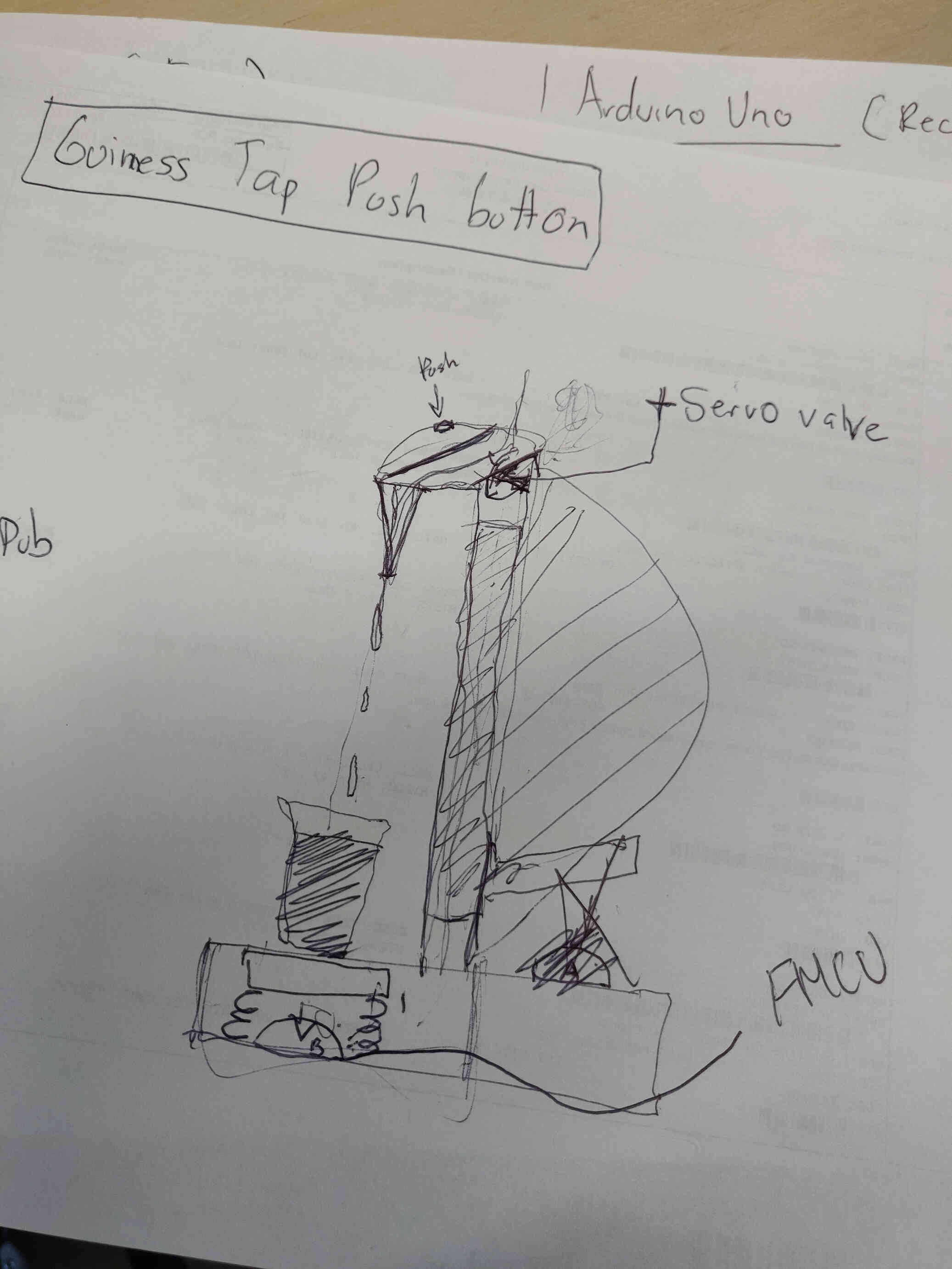

We discussed possibilities for machine designs that are representative of Irish culture. After some discussion, we took a look on Google for famous Irish machinery. The results that followed were classically stereotypical:We were considering designing a type of lever, valve and pressure plate design where filling a pint glass will ‘turn on’ our machine, or a Guinness Pressure Tap with a Harp woodcut design and spent some time breaking down what we would need. We researched the code needed along with mechanical / automation designs related to pressure taps and found that there was certainly a possibility that we could make something in this nature with ease, but it would require us acquiring some plumbing equipment and tools along with researching pump pressures, etc. We weren’t 100% on this concept, so we looked into other possibilities.

I’ve been fascinated with some of the cuckoo designs made by other Fab Academy students and was interested in designing one myself in an interesting way. Also keeping in mind how relevant Irish print design culture is, I was inspired by a piece made by a colleague of ours, local irish printmaster ‘Grainne Murphy’ and considered implementing her work into our design. Grainne would print designs she made of Dundalk architecture and one in particular caught my eye. One of ‘The Bartender’, a distinguishable pub found in the center of Dundalk Town, Co. Louth, Ireland.

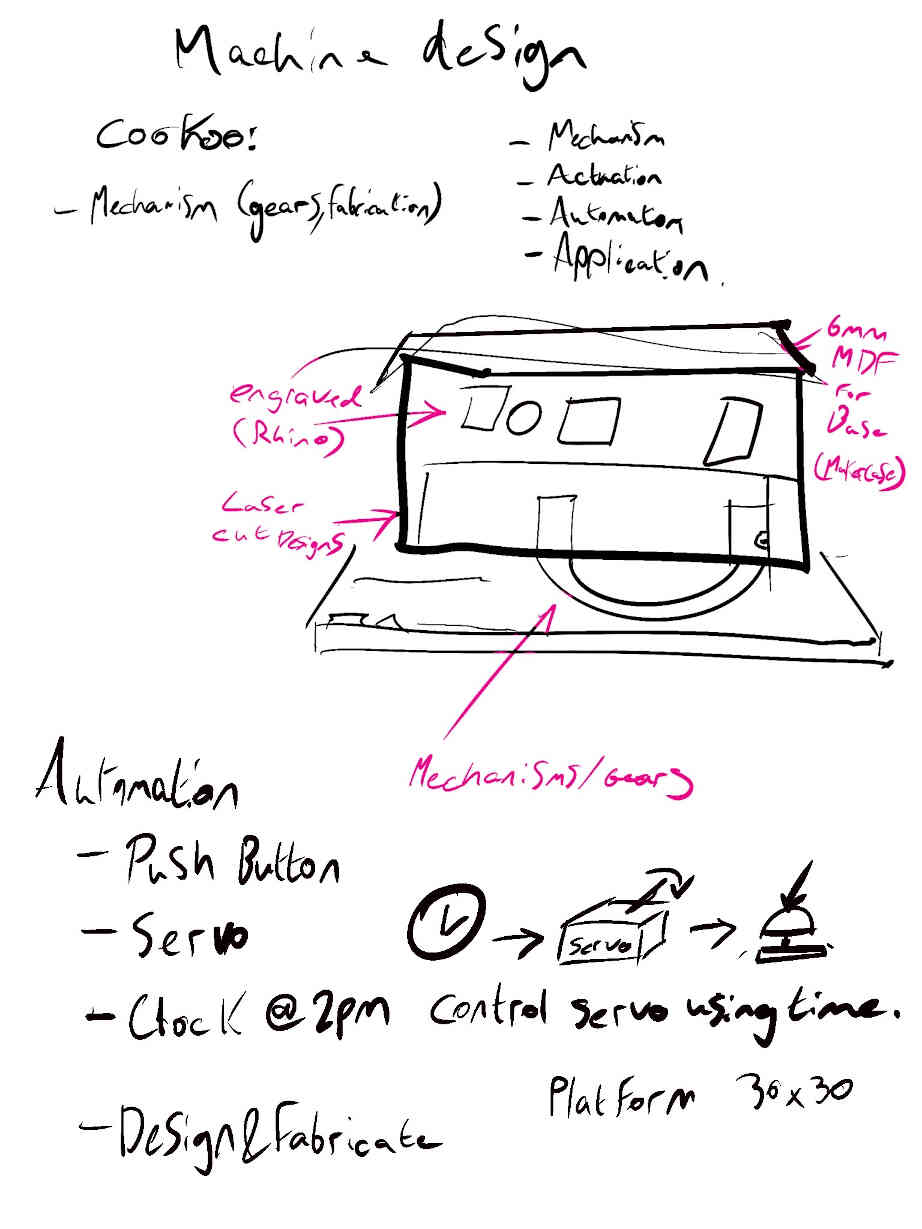

I pitched that we could recreate the pub based on her design using either 3D printing or laser cutting techniques, and design a rotary wheel that has a character with a beer glass coming out. I know I said I wasn’t keen on doing anything stereotypical but I was really into the design process and possibilities, so I pushed it anyway. Oscar also suggested that we set the machine to a timer or dial, then once activated could have the little guy push a button as he comes out, which would activate an online link from Enterprise Fablab to every other Fablab node in Fab Academy through the FMCU Network. We were happy with this concept so we concluded the brainstorming process and broke down the mechanics, parts, circuitry, designs and code needed.

Oscar said he would focus on the programming / electronic side of things while I focus on the design, cutting and assembling. Then we would come together to implement the design and functionality of the machine.

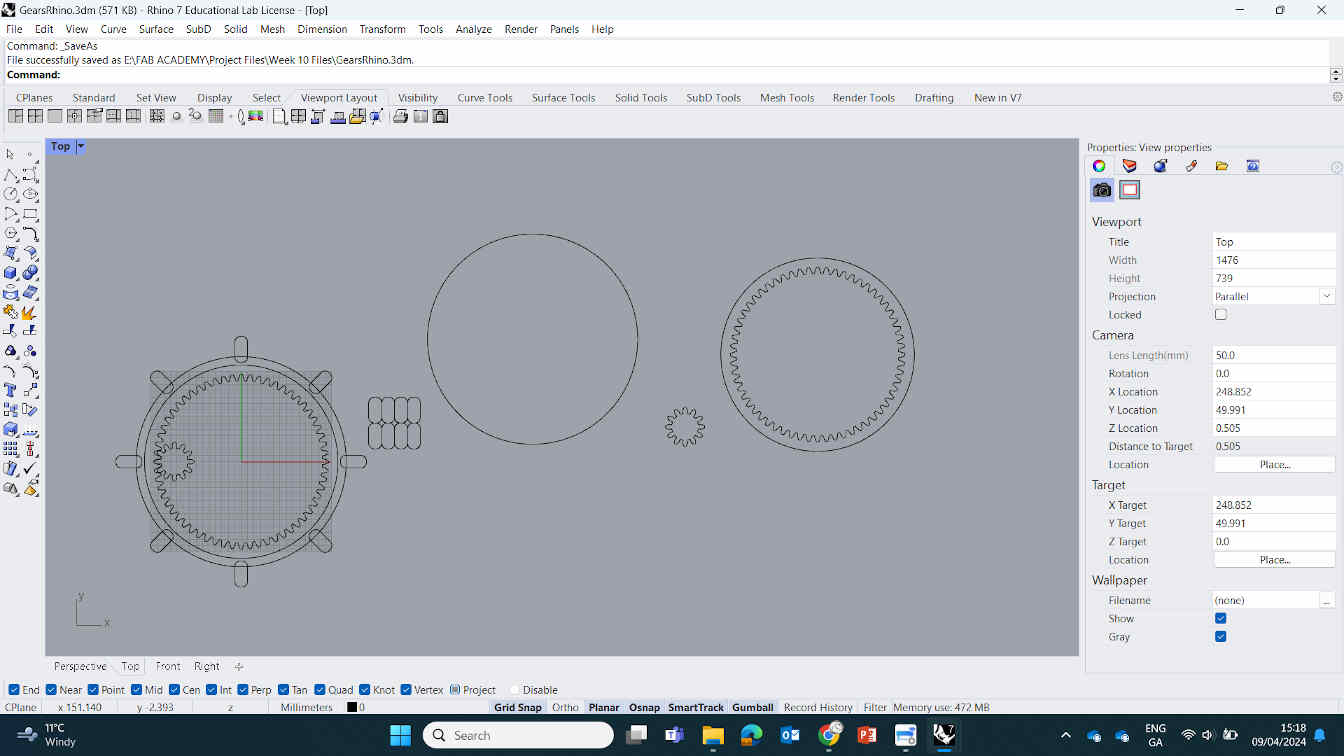

I stuck around Oscar as I started working on the design and he started researching the mechanics and code so I could get an understanding of his side of the process. We found a very cool website named Gear Generator which allows you to design your gears with a visual representation to the side and download the design files. We still needed to design the gears we needed for the assignments but this site would be a great reference point. In case you’re interested, Gear Generator costs money to download the designs but a free alternative is a site named STLgears.com.

____________

Concept Designing

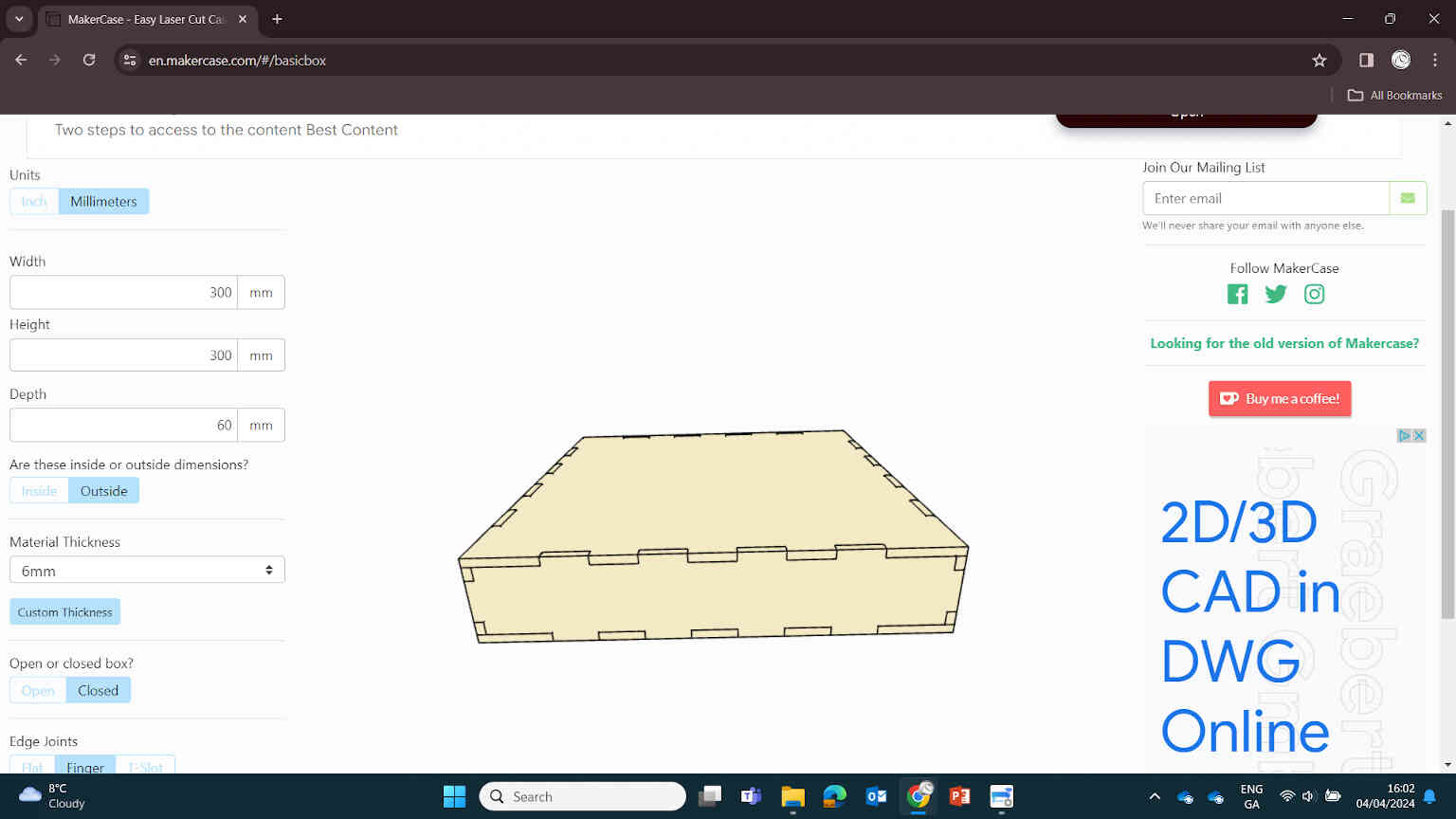

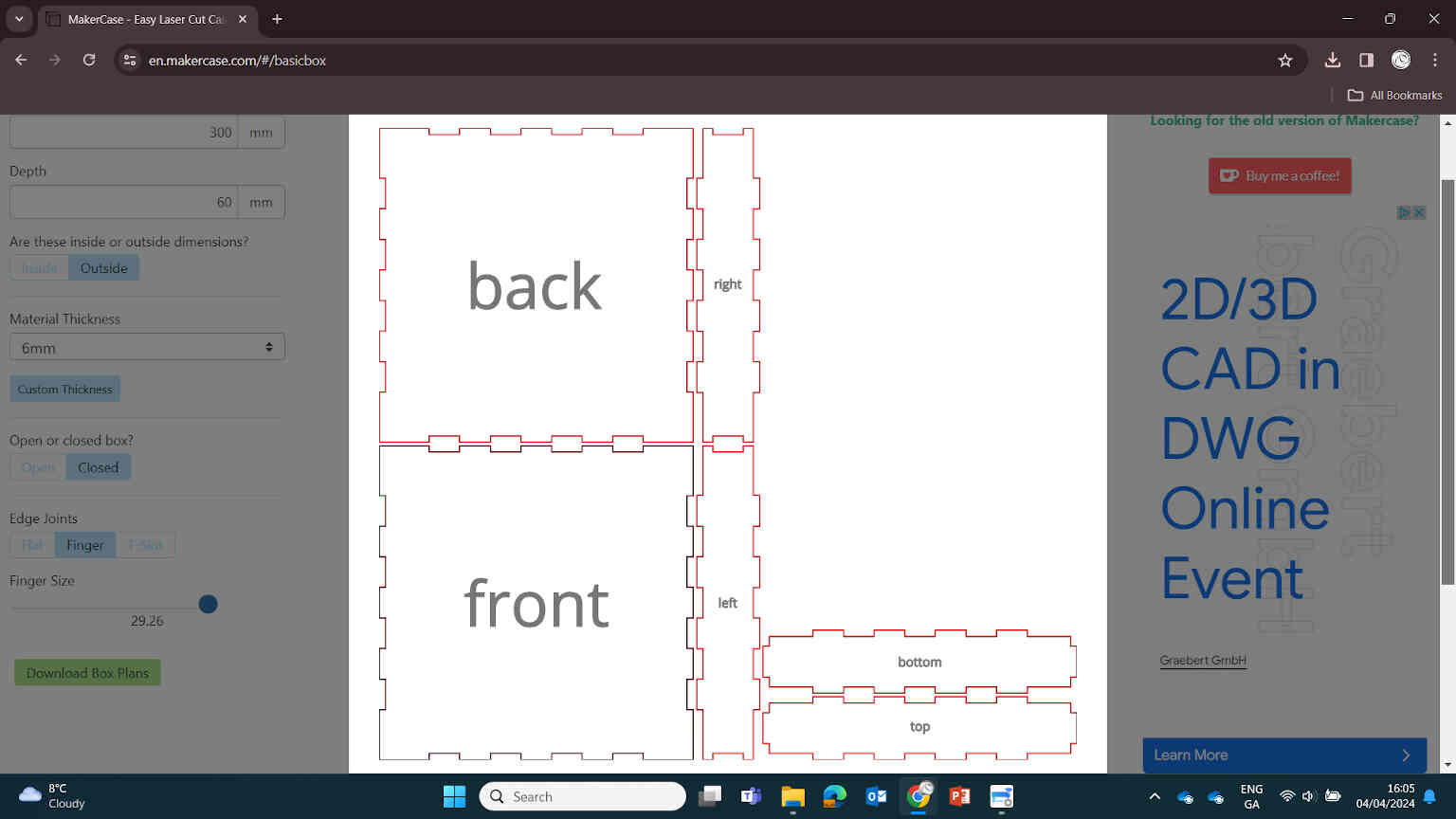

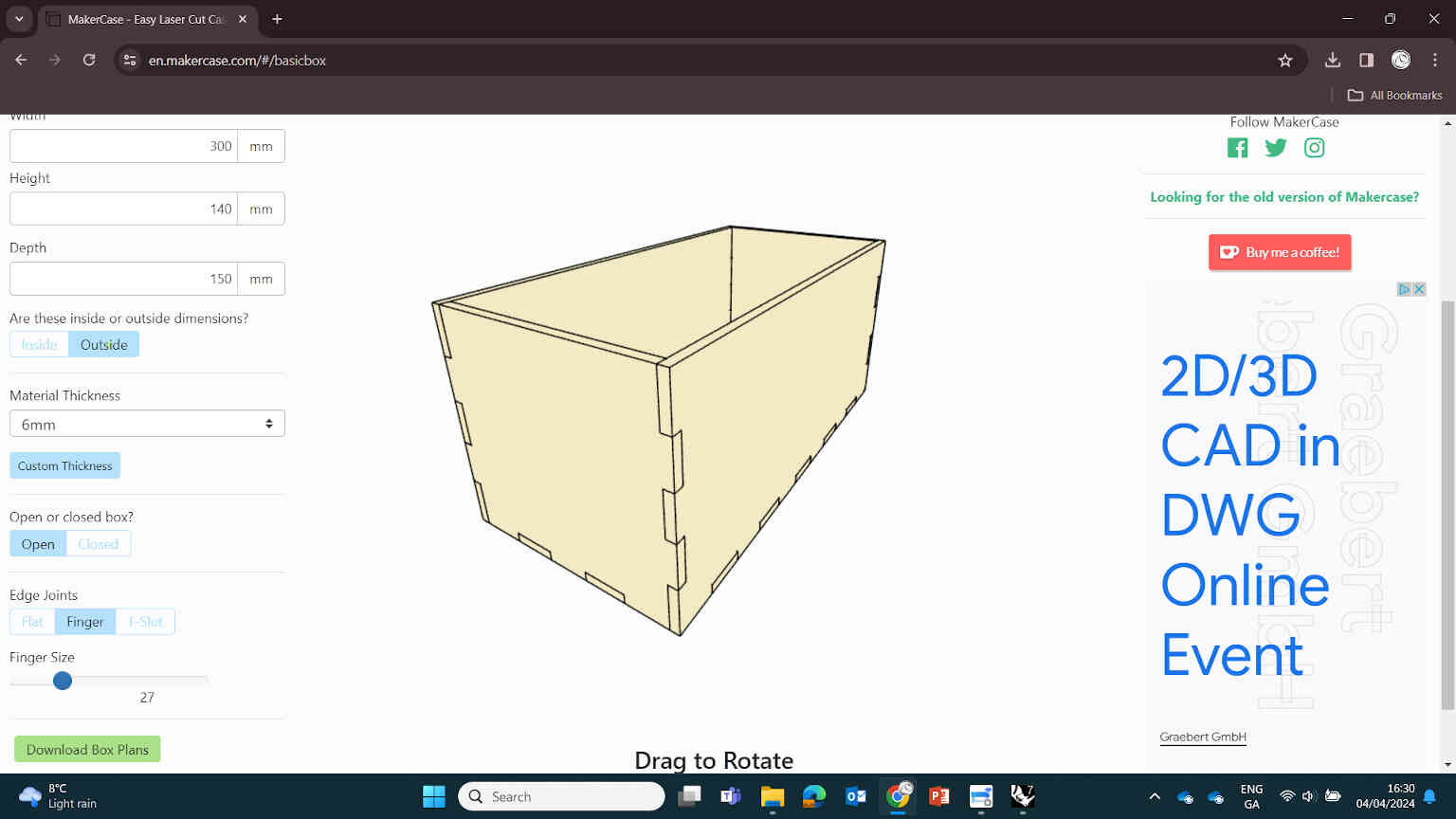

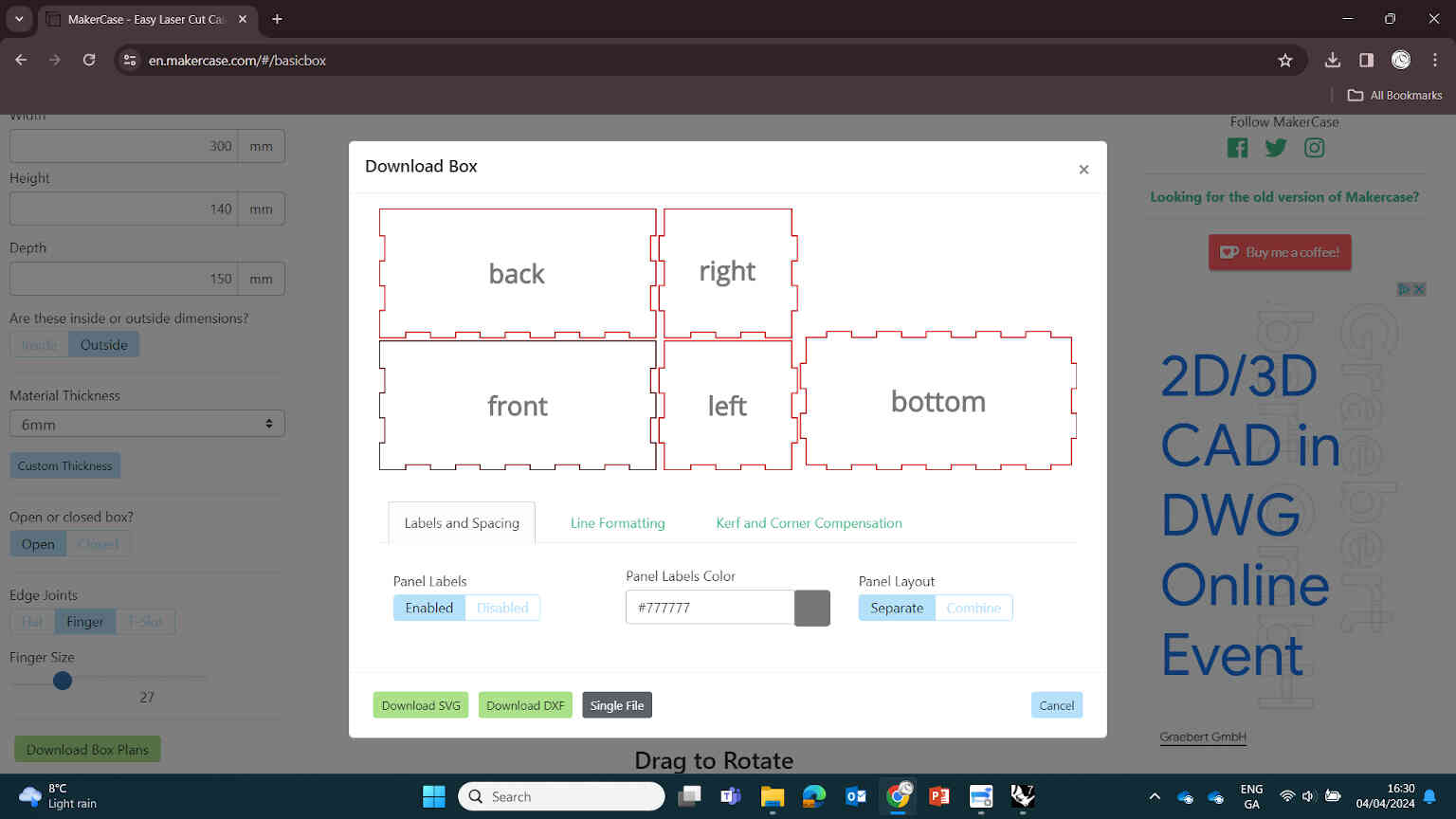

Maker Case Design Process:

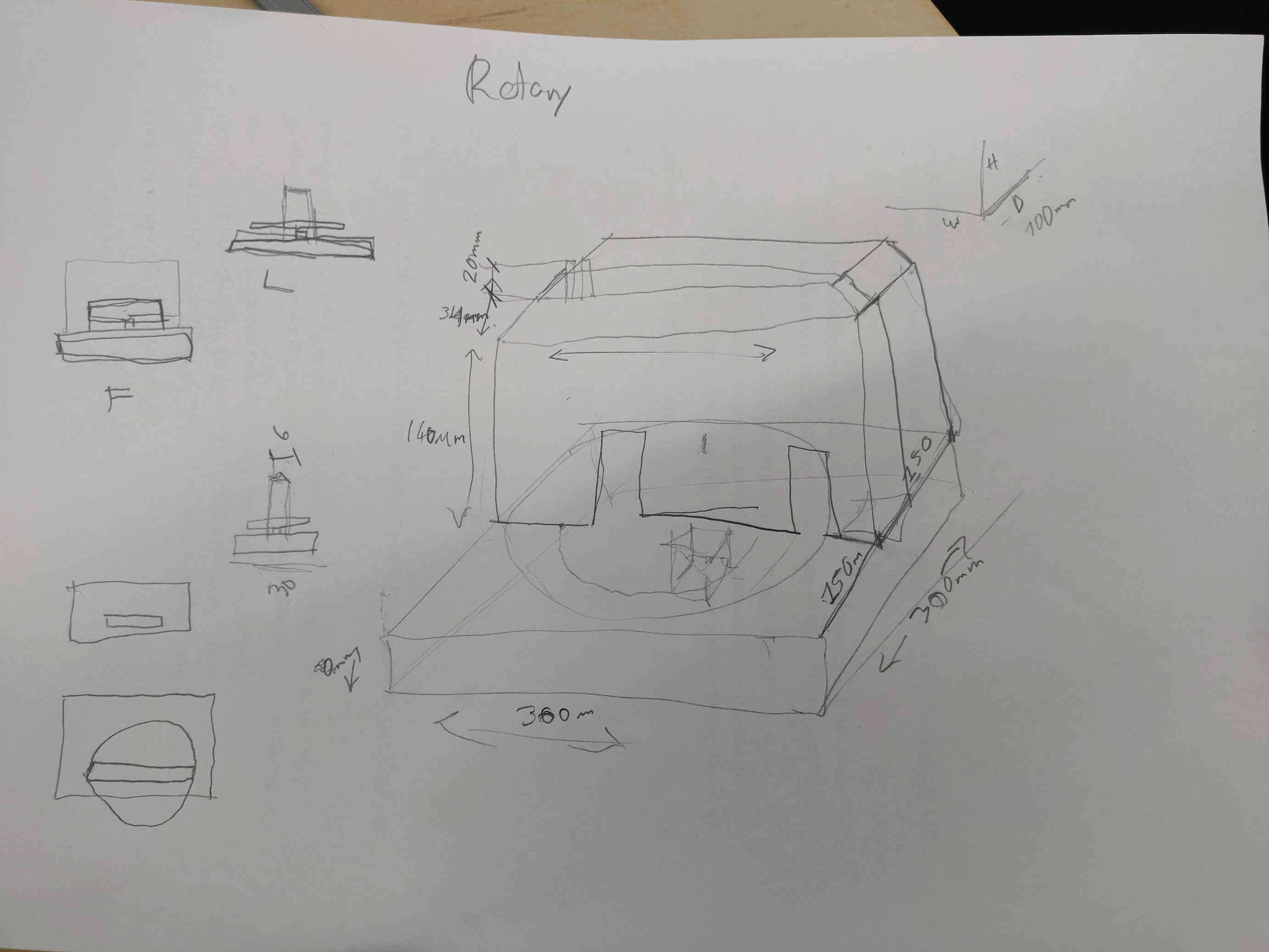

Before starting with the Rhino design, it was important that we drew some measurements to get the correct sizing of both the Bartender Pub itself, and the base that it sits on which would contain the electronics needed for the rotary wheel and the mechanisms needed for connecting to other fablabs. I would then take these measurements and input them into MakerCase.com to download a template dxf file, which can then be edited in Rhino 2D CAD software. This is what I settled on:

Measurements for Makerspace:

Sheet Measurements to hold extension cuts:

____________

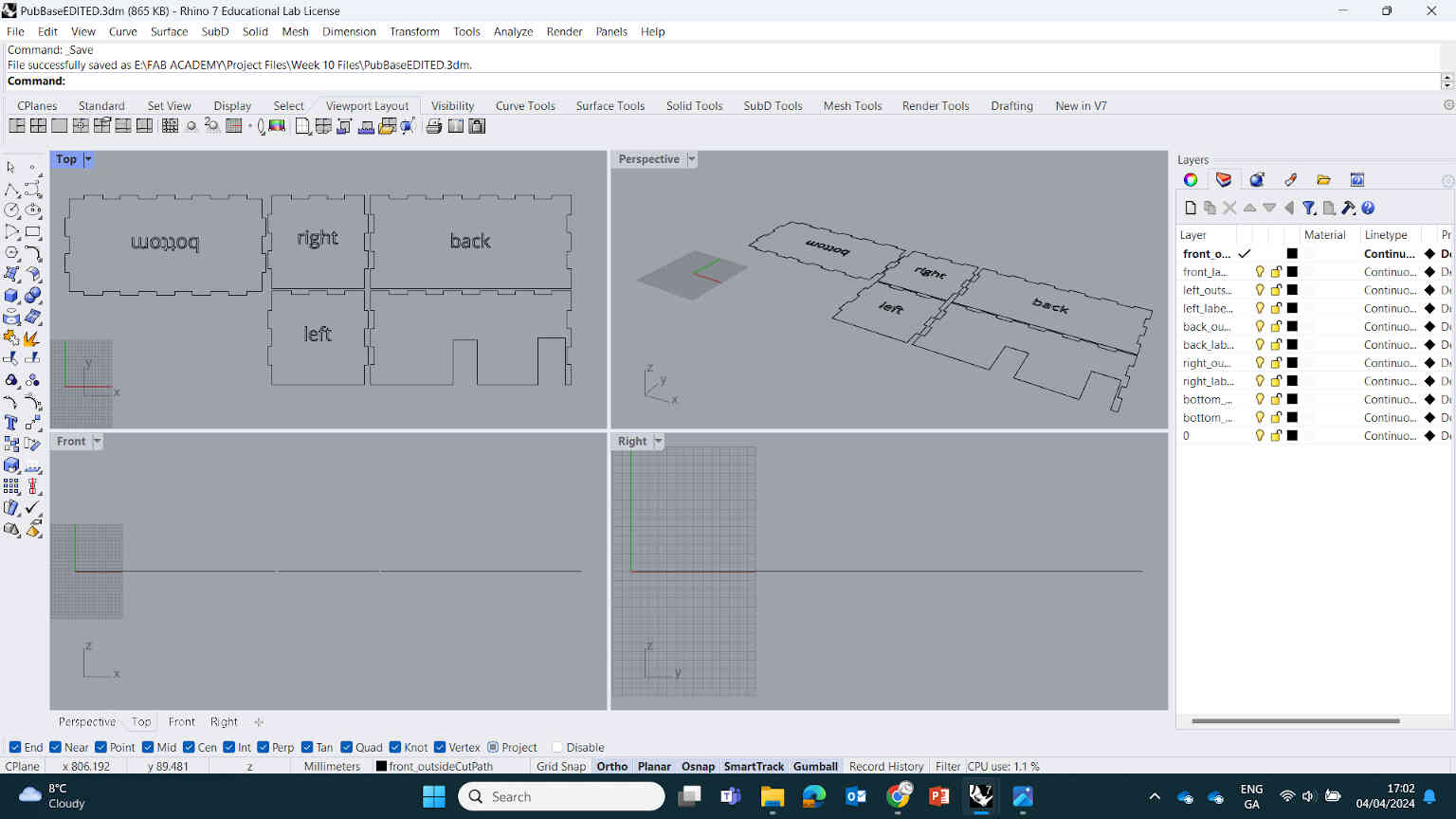

Editing Design in Rhino

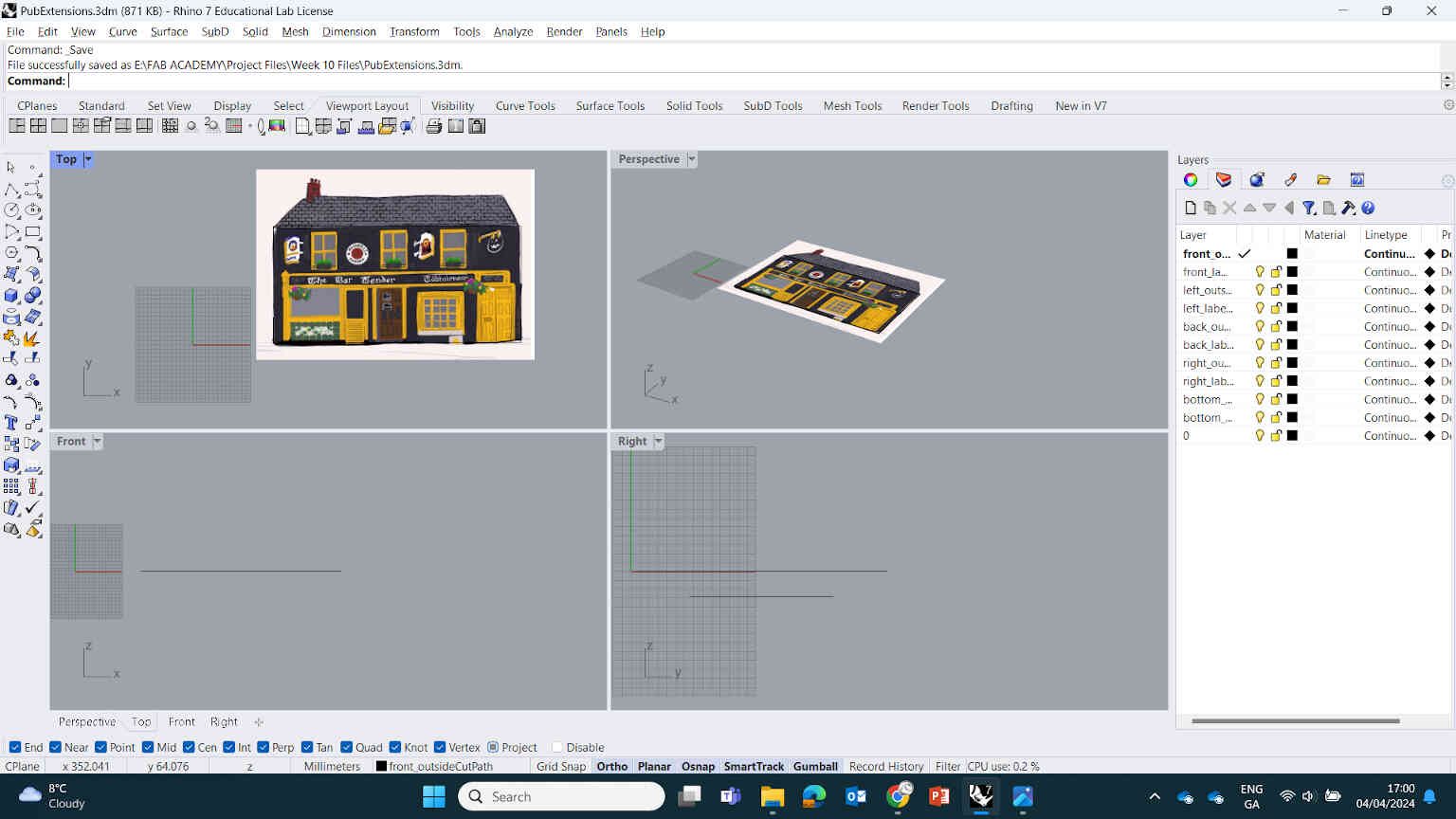

(^ Print Design by Grainne Murphy)

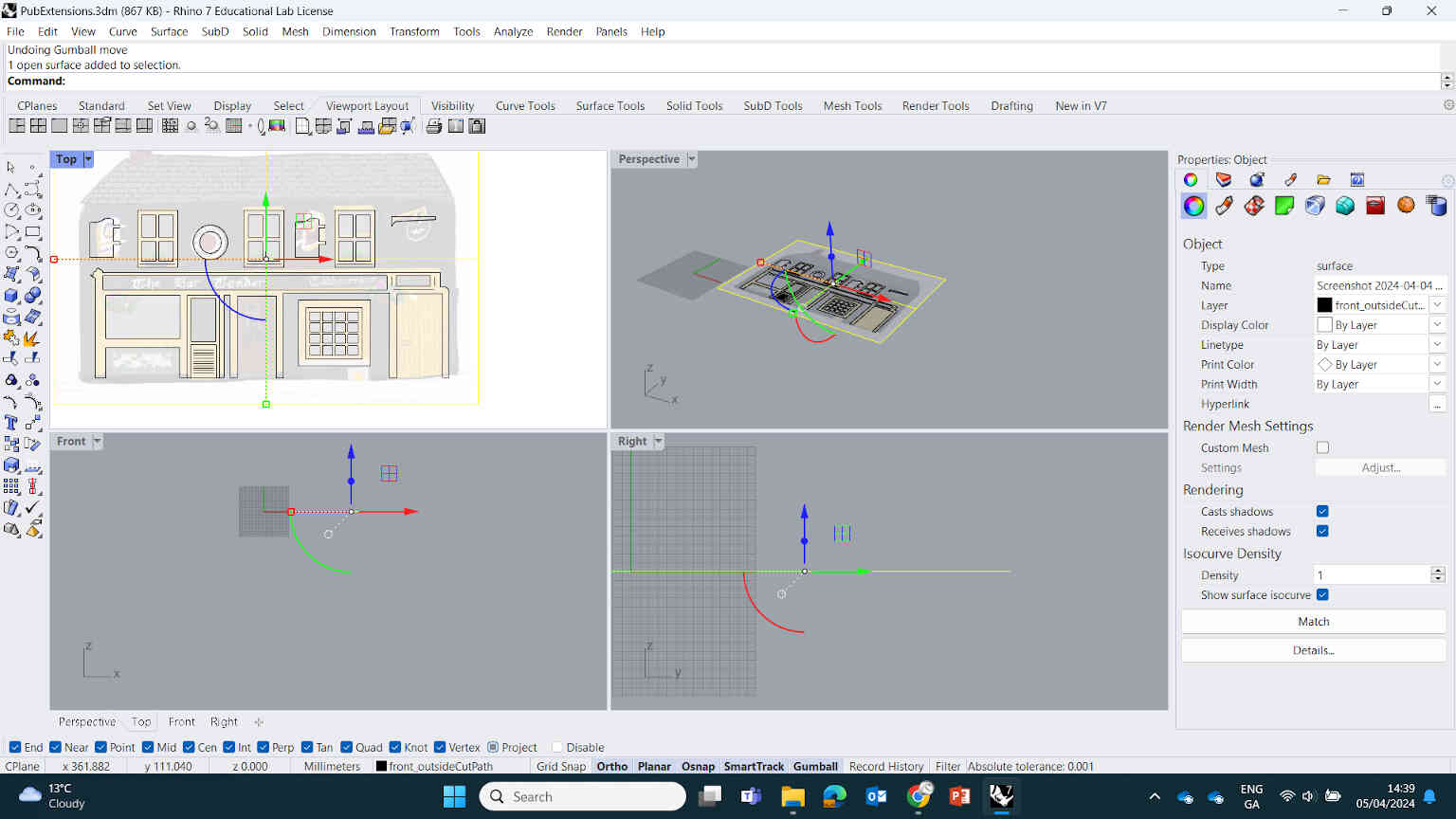

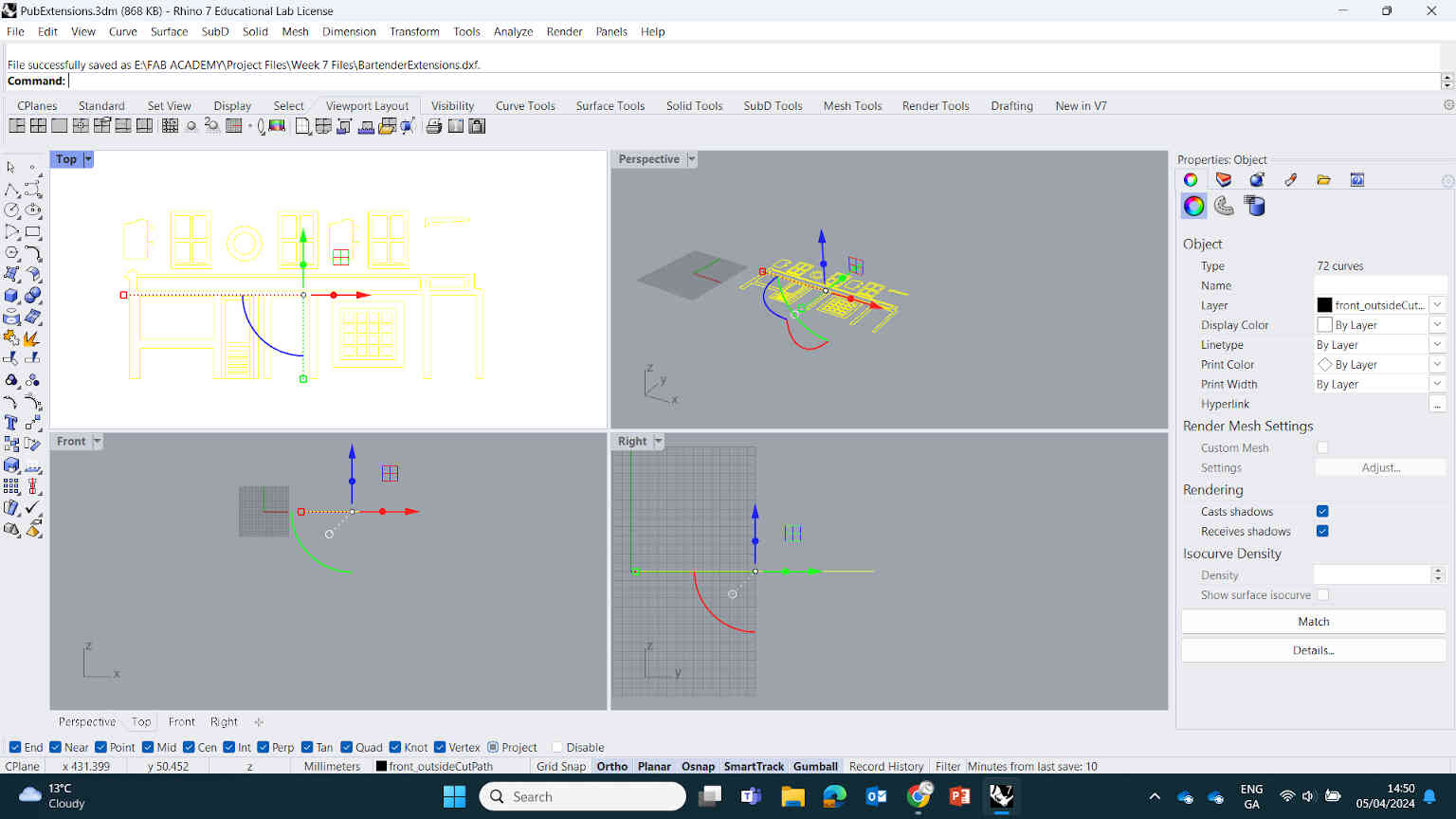

Taking a screen grab of Grainne Murphy’s print of the Bartender found @Grainne’s Instagram, I used it as a reference for my 2D designs in Rhino. I opened the Bartender Pub template dxf file and imported Grainne Murphy’s image and scaled it to our measurements. I didn’t need to change much here, except using the Polyline tool to edit in the cuts on the front panel for where the doors are (where the little man will be coming through on the rotary wheel).

As for the design extensions, I made a duplicate of the Bartender Pub dxf file and removed everything except for the front panel. Within this panel I traced over all the design elements that I would need to cut out. As per Oscar’s instructions, I didn’t go too crazy with the design due to time constraints but I did focus on what makes The Bartender distinguishable from other pubs - one of which being the bold yellow and black colour scheme, but the colour is something I may do after the assignment is complete.

When the time comes for colouring, I’ll be using a white primer paint then an airbrush for overall colour. For now, I just focused on getting the measurement correct for the doors, windows, signs and panels. Once done, I exported the 3 designs as dxf files labeled 1-Base, 2-Building, 3-extensions and brought them into Coral Paint which connects to our laser cut machine.

____________

Laser Cutting and Assembly

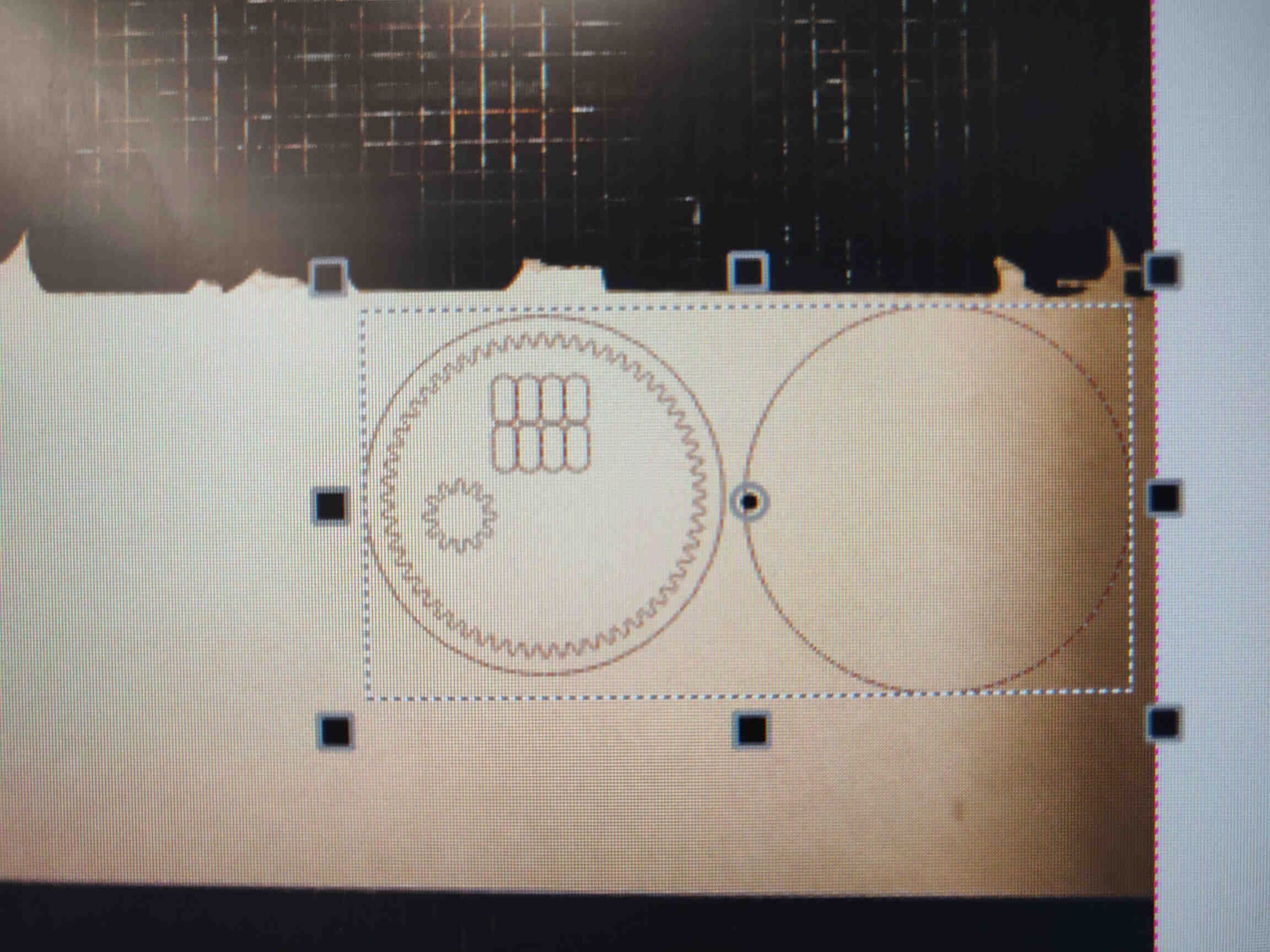

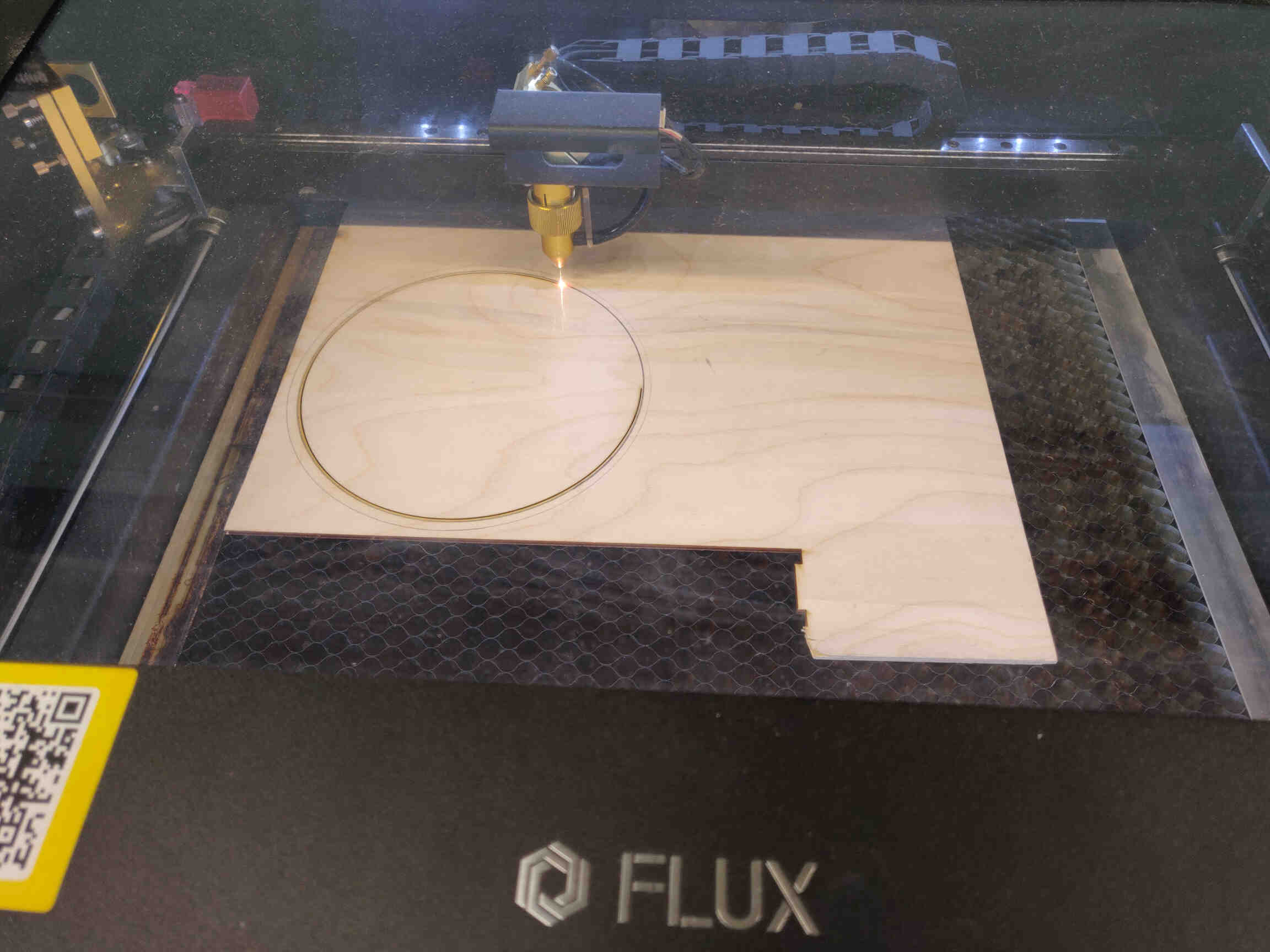

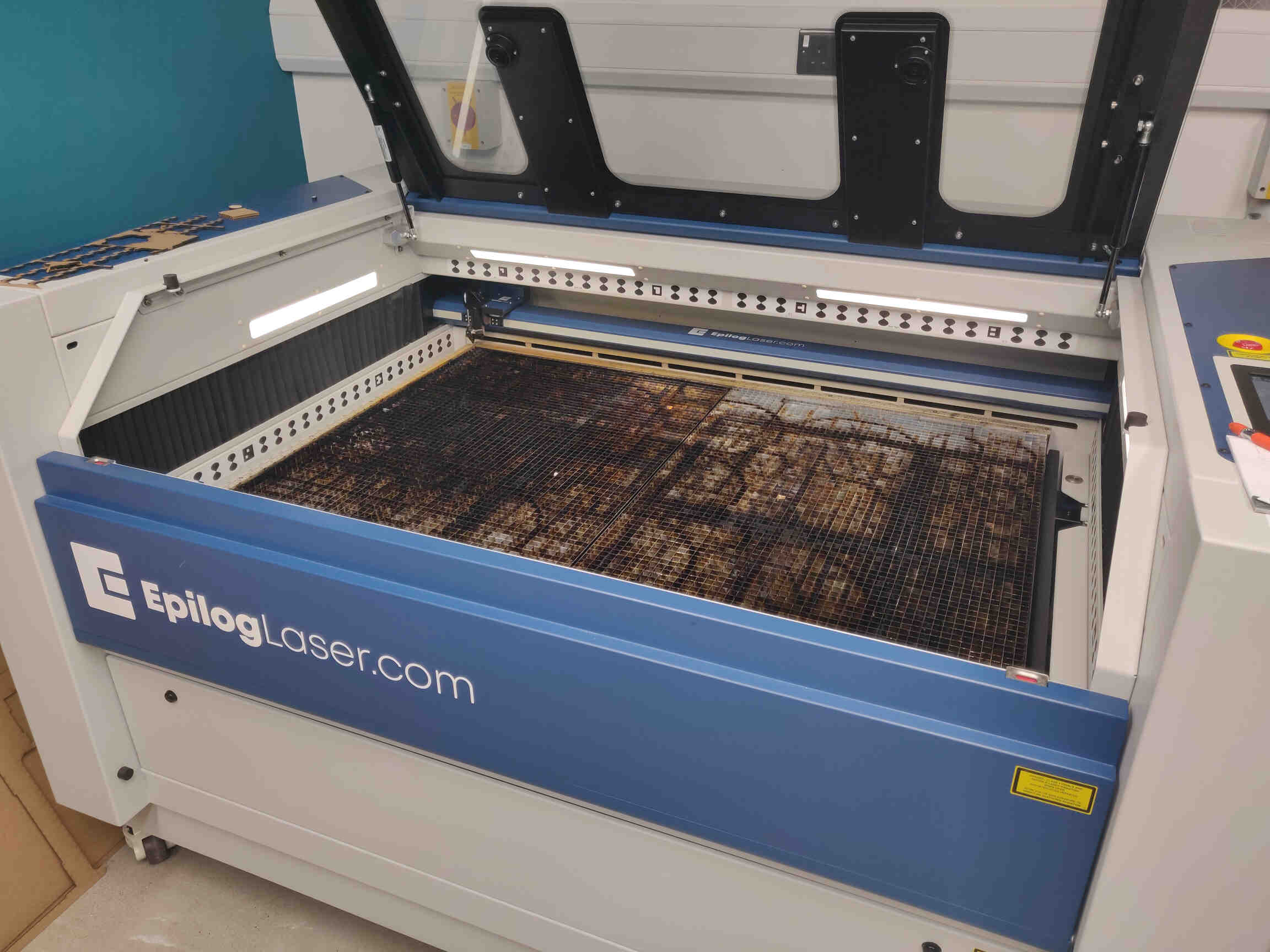

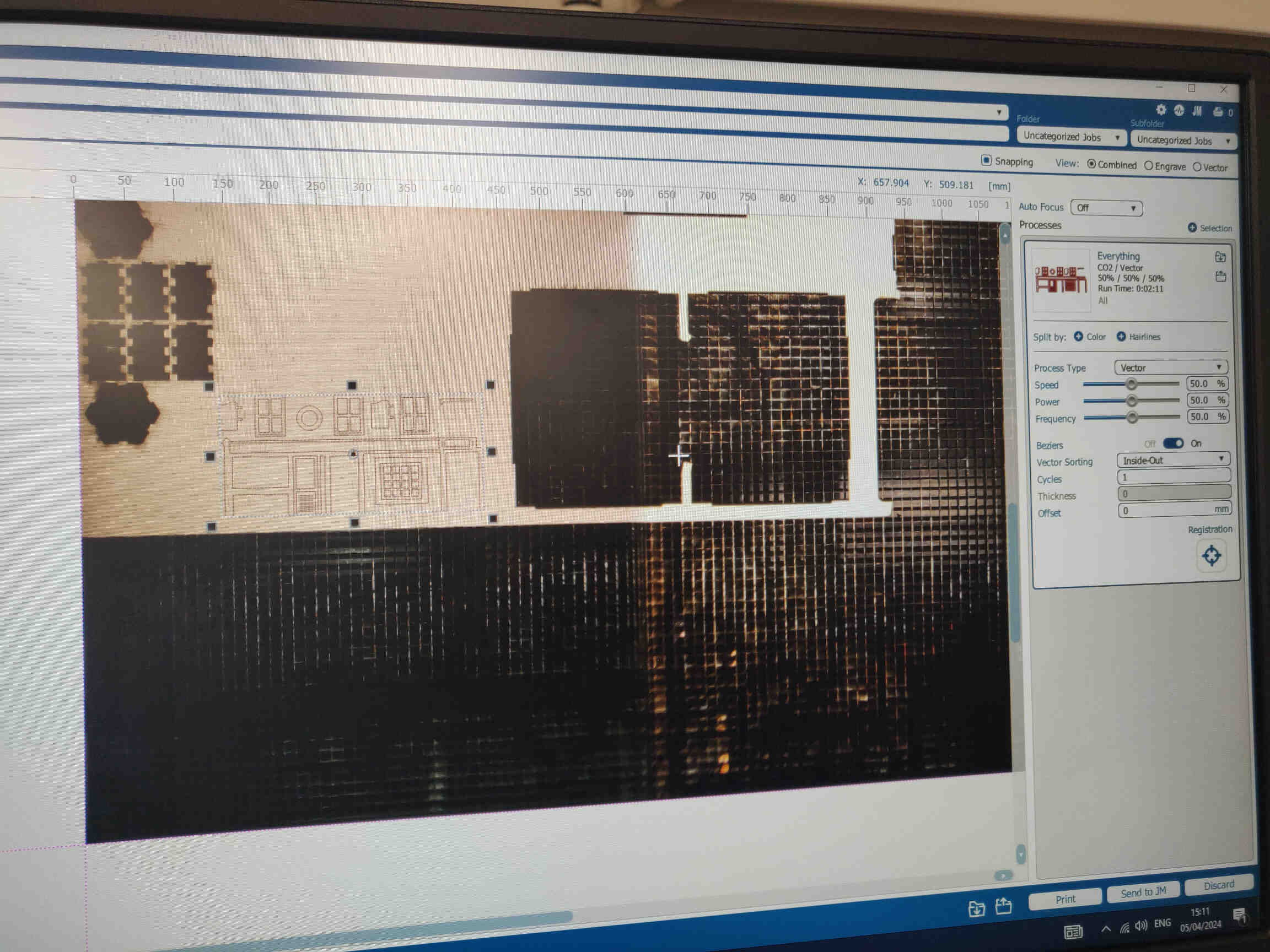

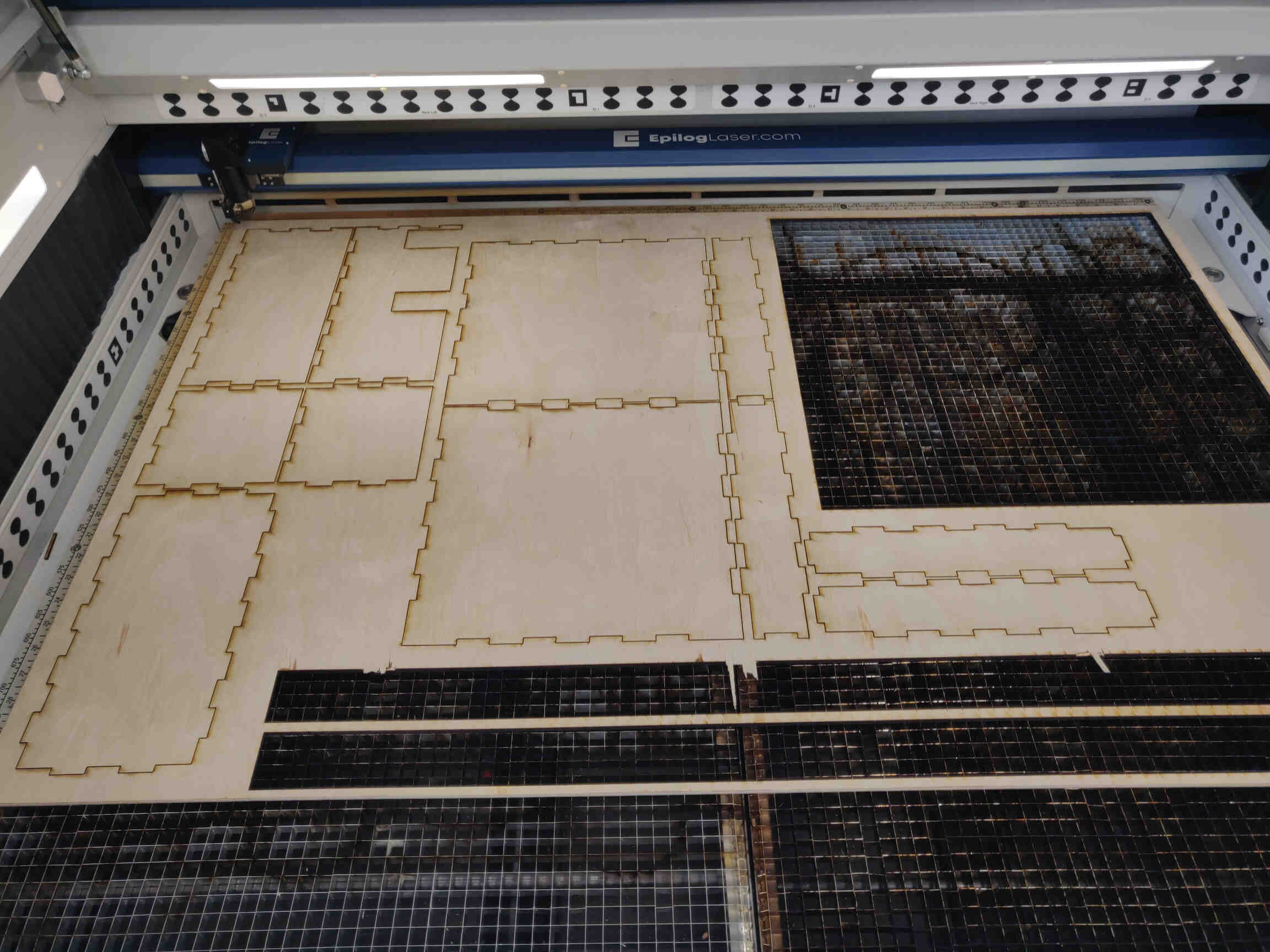

Initially considering the Shopbot for the cutting process, we determined a laser cutter would be what we needed for our product. So instead we brought our designs into Corel Paint which was connected to the fablab’s EpilogLaser laser cut machine. By importing our files into Corel Paint, we can then hitPrint which would then bring us to Epilog’s cutting software.

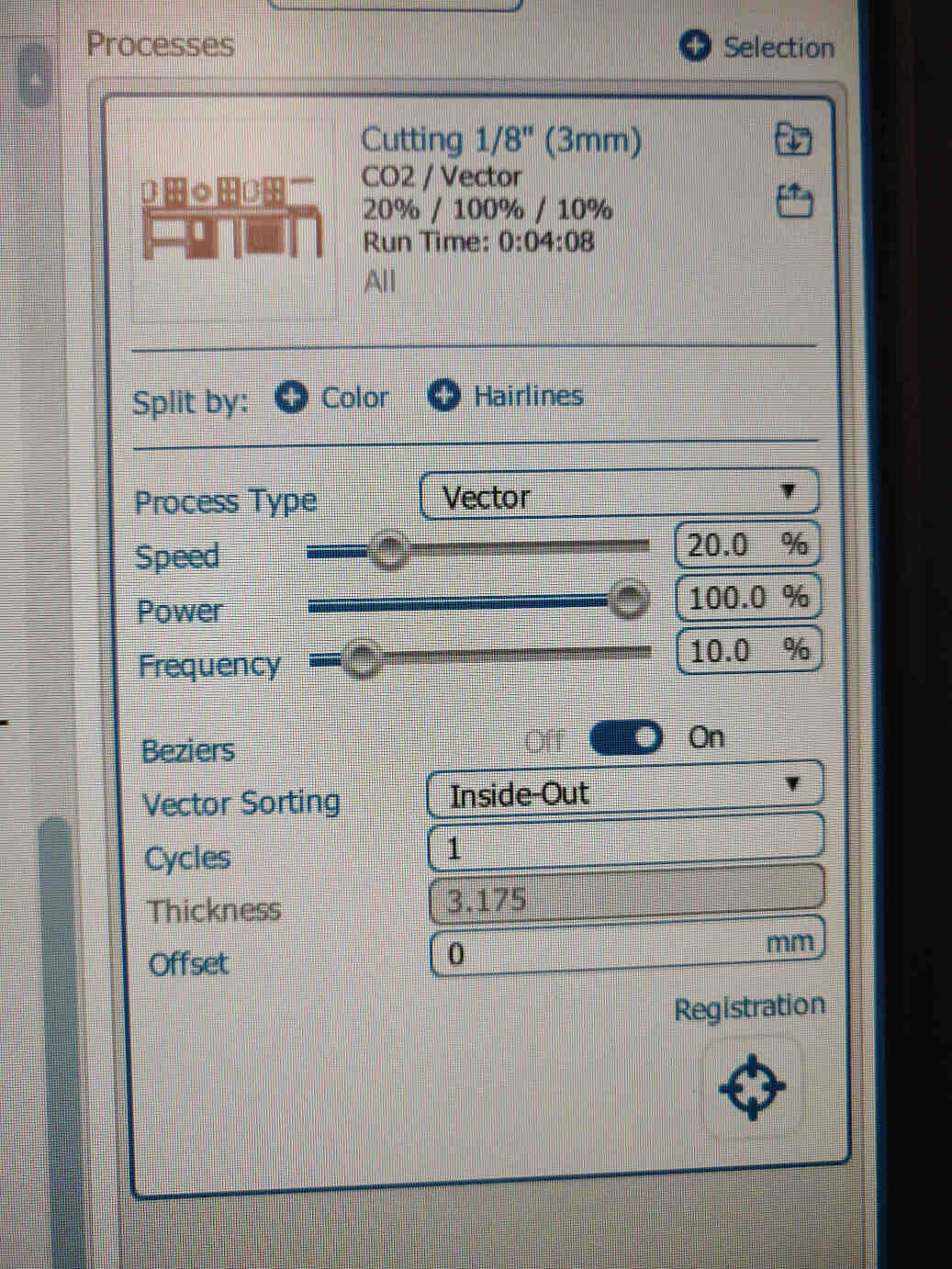

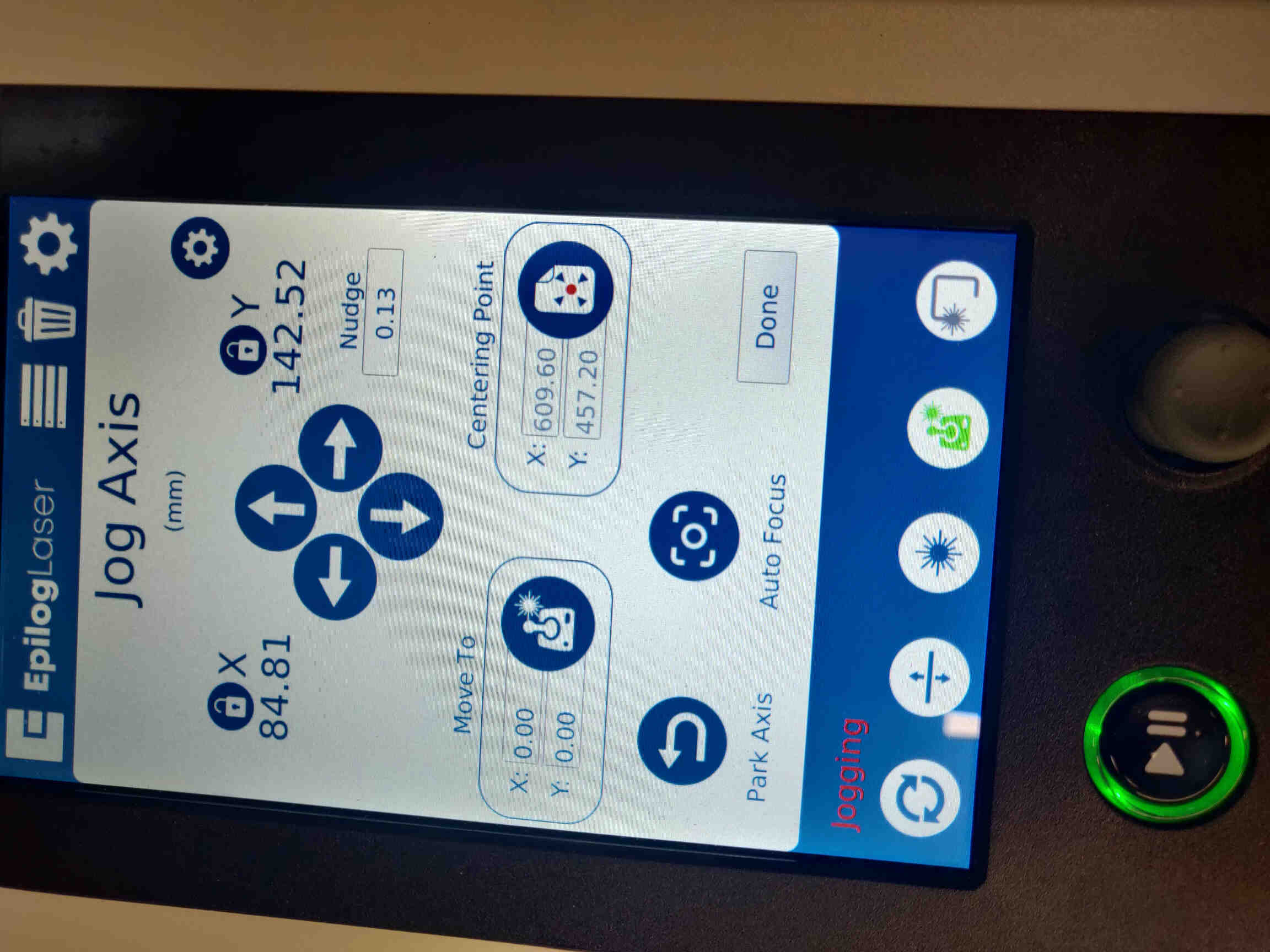

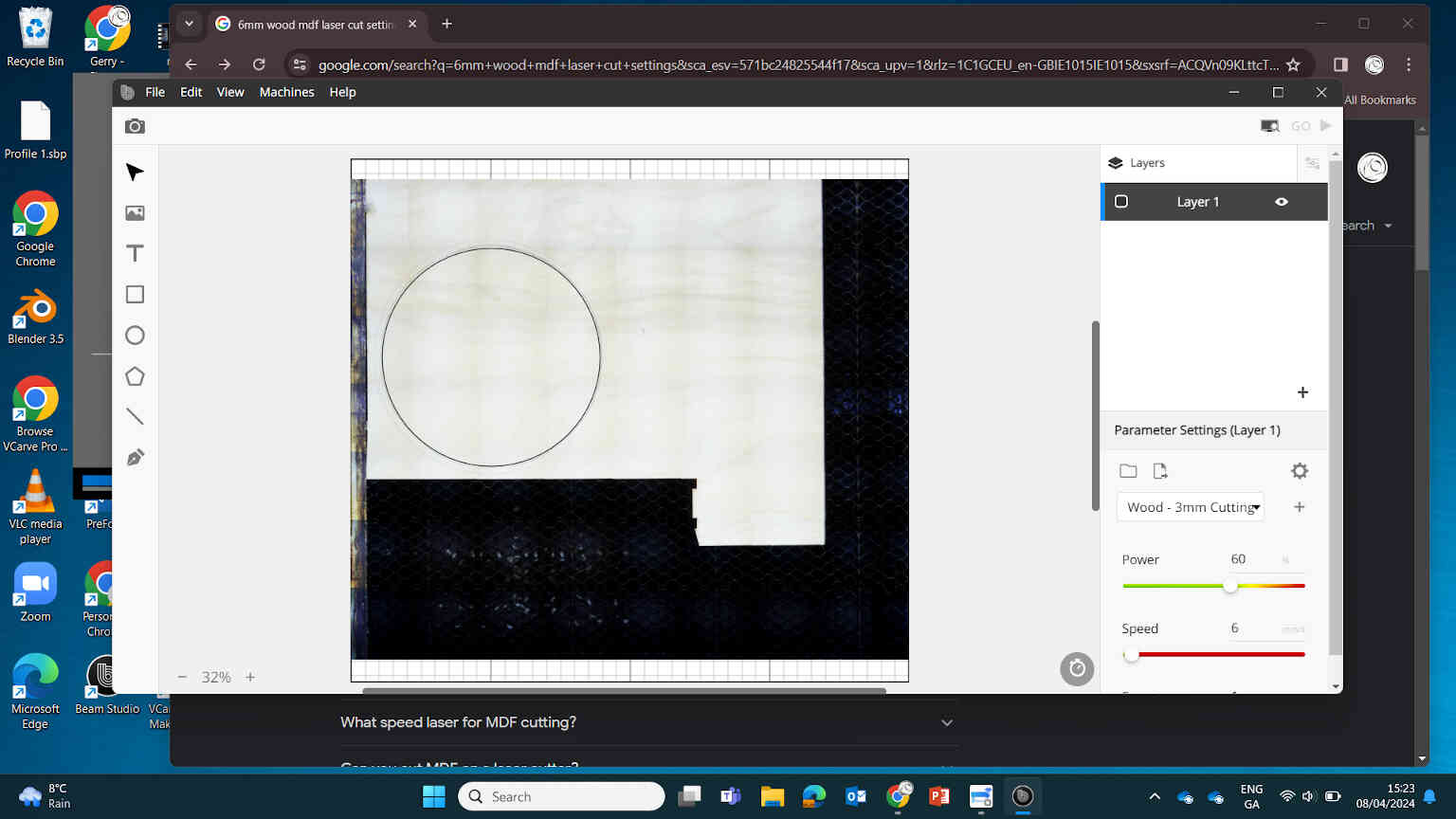

We opened up the Laser cut machine and placed a sheet of 3mm MDF inside, then went back to the cutting software and used the Camera tool to give us a digital view of the inside. With this, we were able to nest and position our designs correctly. Using the panel on the machine, I was able to calibrate the distance between the laser and the sheet of MDF by using the Jog Axis controls and hitting ‘Auto Focus’. In the cutting software, at the panel called ‘Processes’ we were able to import a preset for 3mm wood cutting.

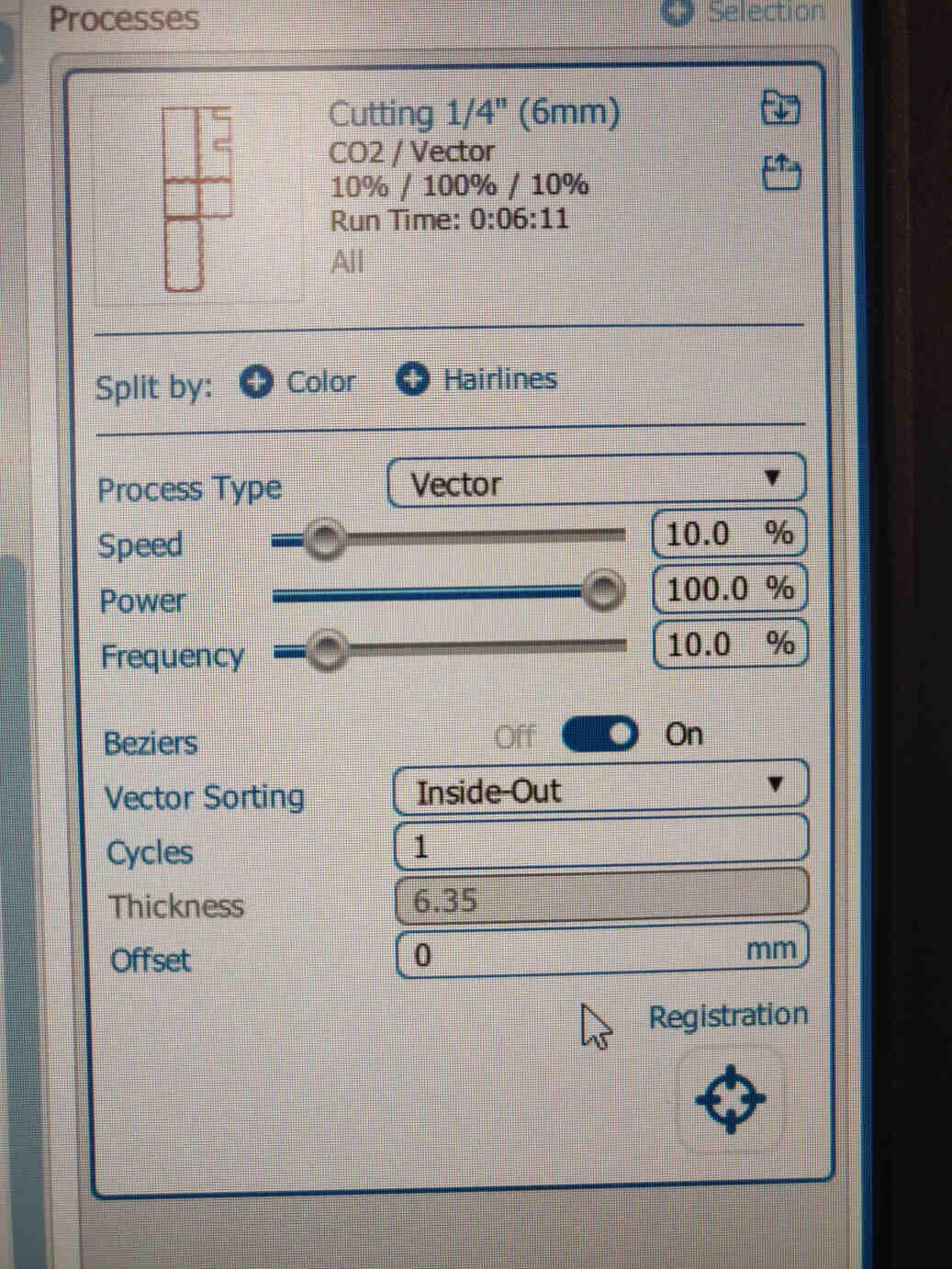

Presets for 3mm and 6mm Wood Laser Cutting

After the 3mm design extensions were complete, we placed a used sheet of 6mm MDF inside the machine and repeated the process for the Base and Pub cuts. We were able to nest both file designs perfectly into 1 previously used sheet of 6mm MDF.

NOTE: The machine needs to be calibrated again once changing material.

____________

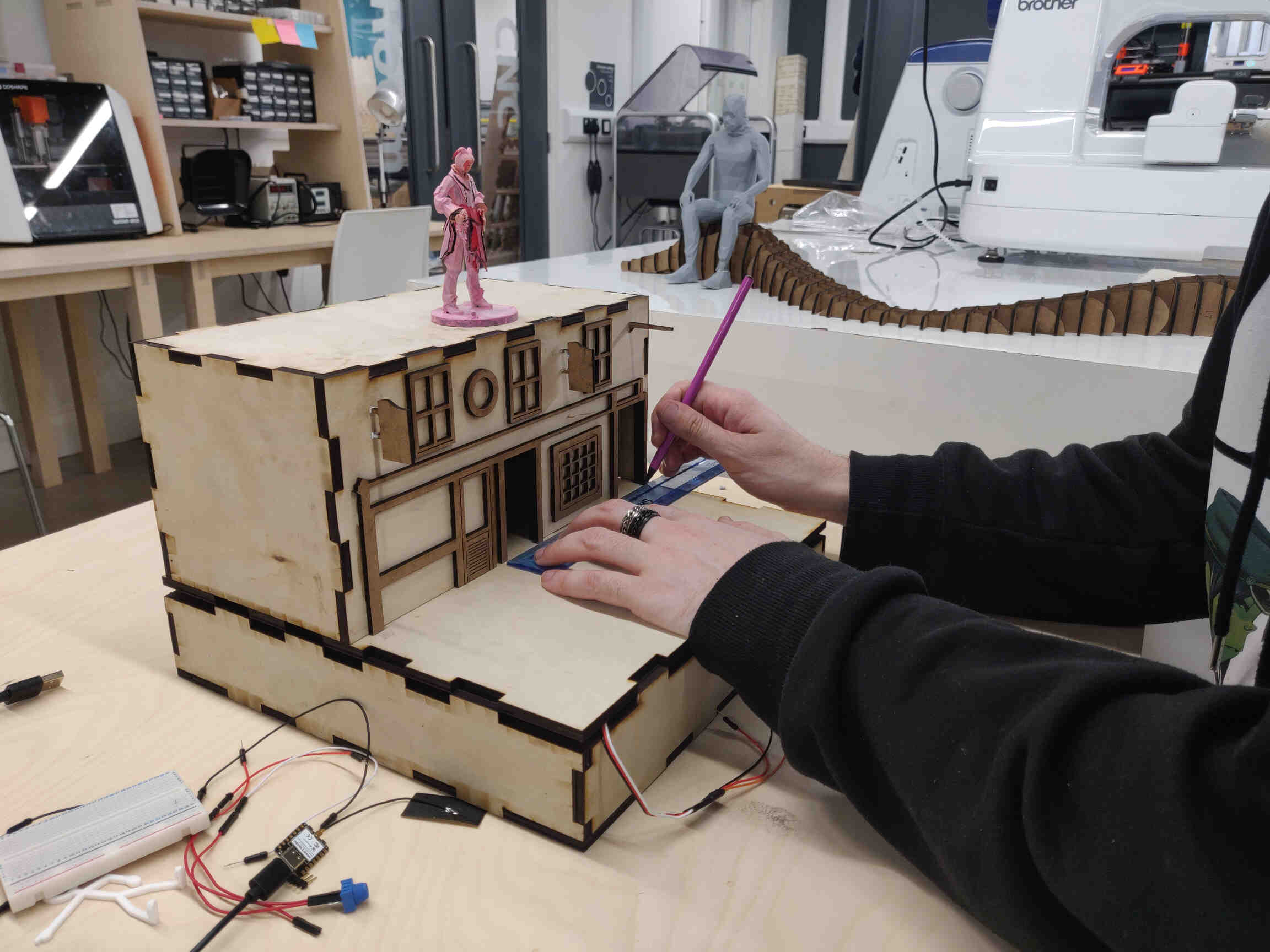

Assembly Process

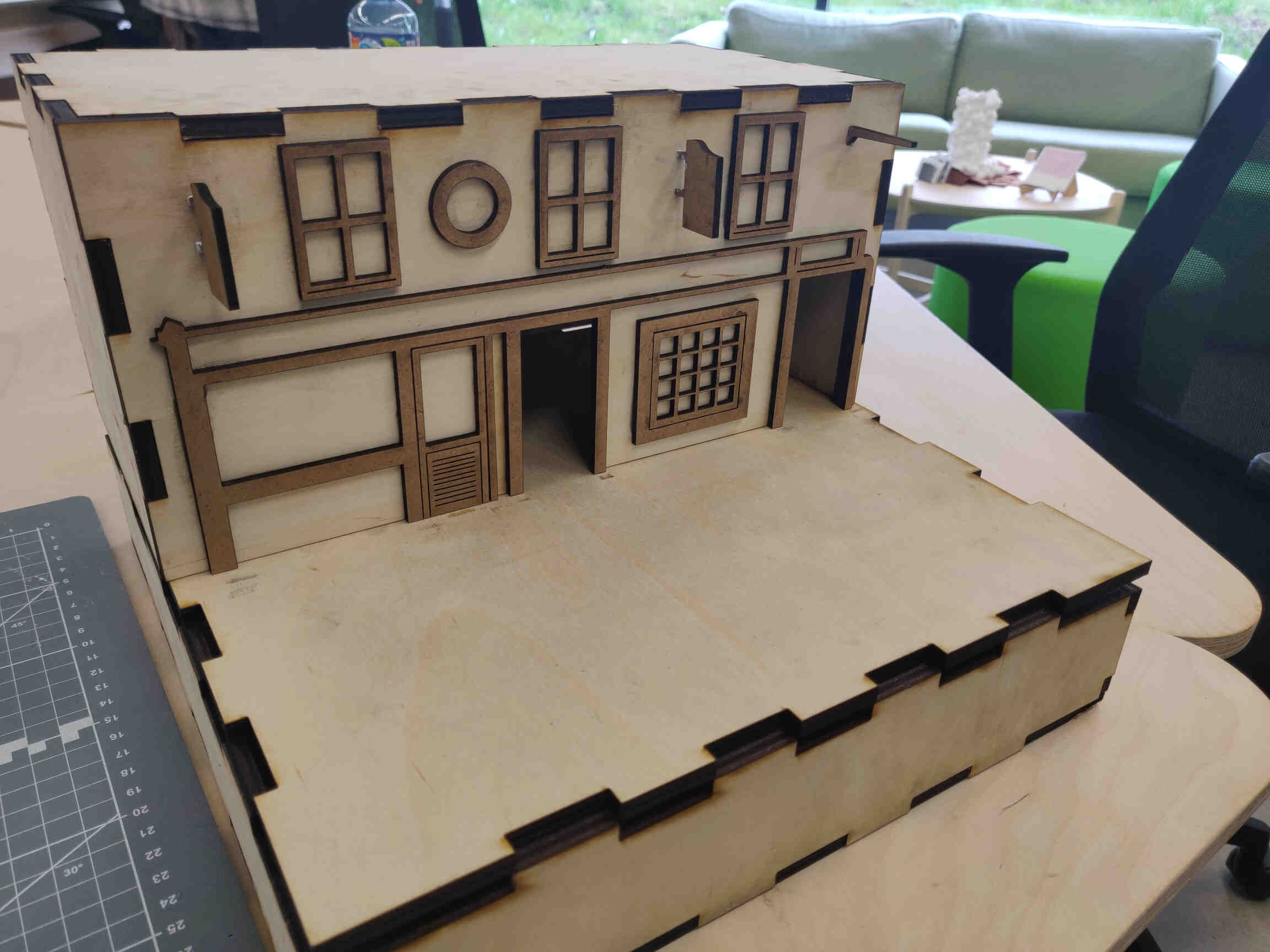

Once the laser cut was finished, I removed the sheets of MDF, placed them on the floor and knocked the designs and panels out of the sheet and placed them on to a cutting mat to position them correctly. Some of the panels still had some wood splintering out, so I used a flat chisel and hammer to cut out any extending pieces. Then I sanded the sharp edges down - though I could have done some more sanding down to ease the assembly process.

As our pieces were cut out with a laser, we didn’t need to add dogbones but the finger joints were still pretty tight. 5 minutes with a hammer later and the Base and Bartender Pub were assembled. For machine building, we were told to avoid glue but focus on fasteners - however I used gorilla glue to stick on the Pub Extensions as they were just extra designs that don’t affect / improve the mechanics or function of the design - they only make the Pub distinguishable. As I mentioned before, I may leave the colouring until after the assignment as I need to be aware of time management.

____________

Cutting for Assembly

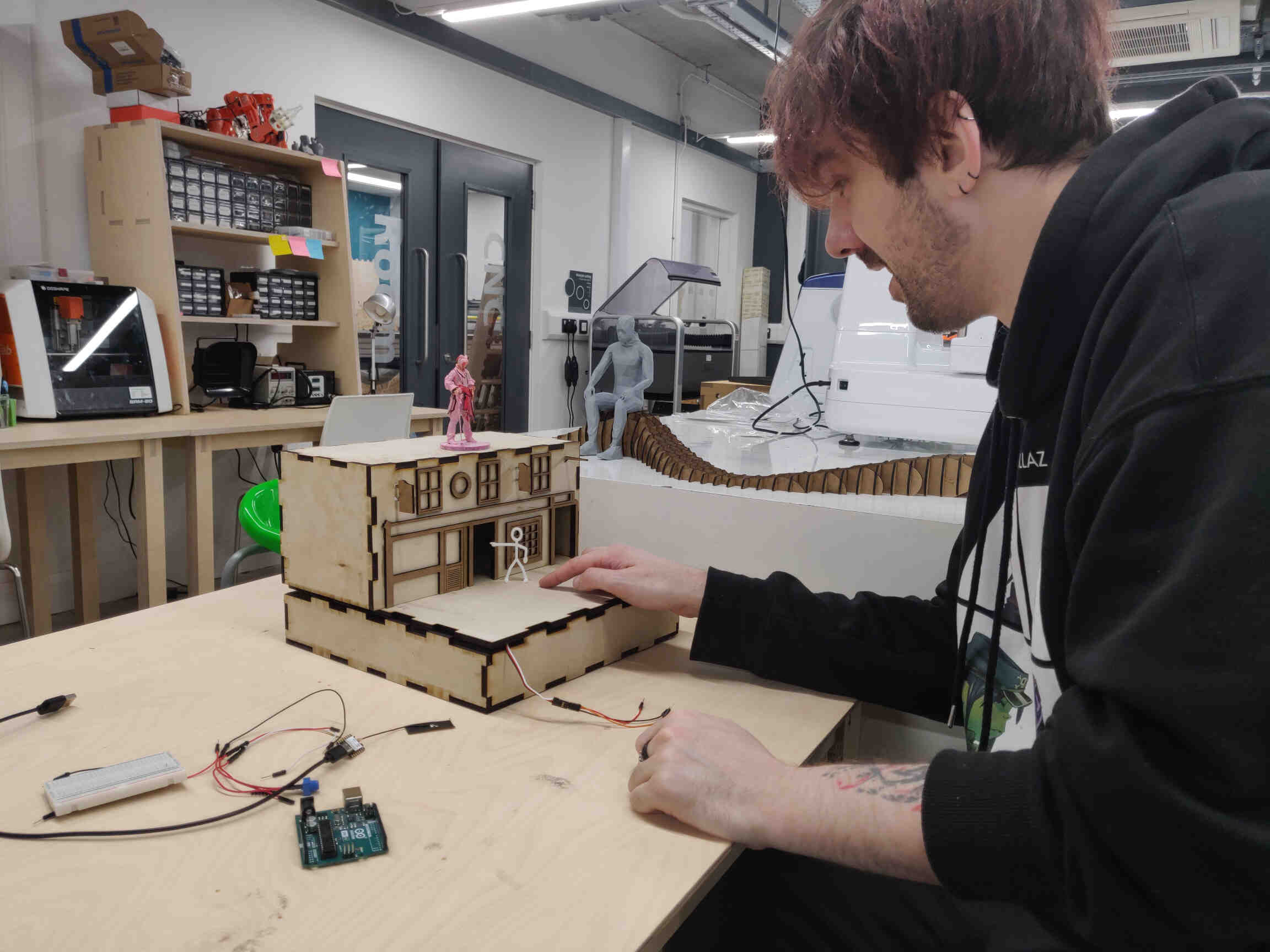

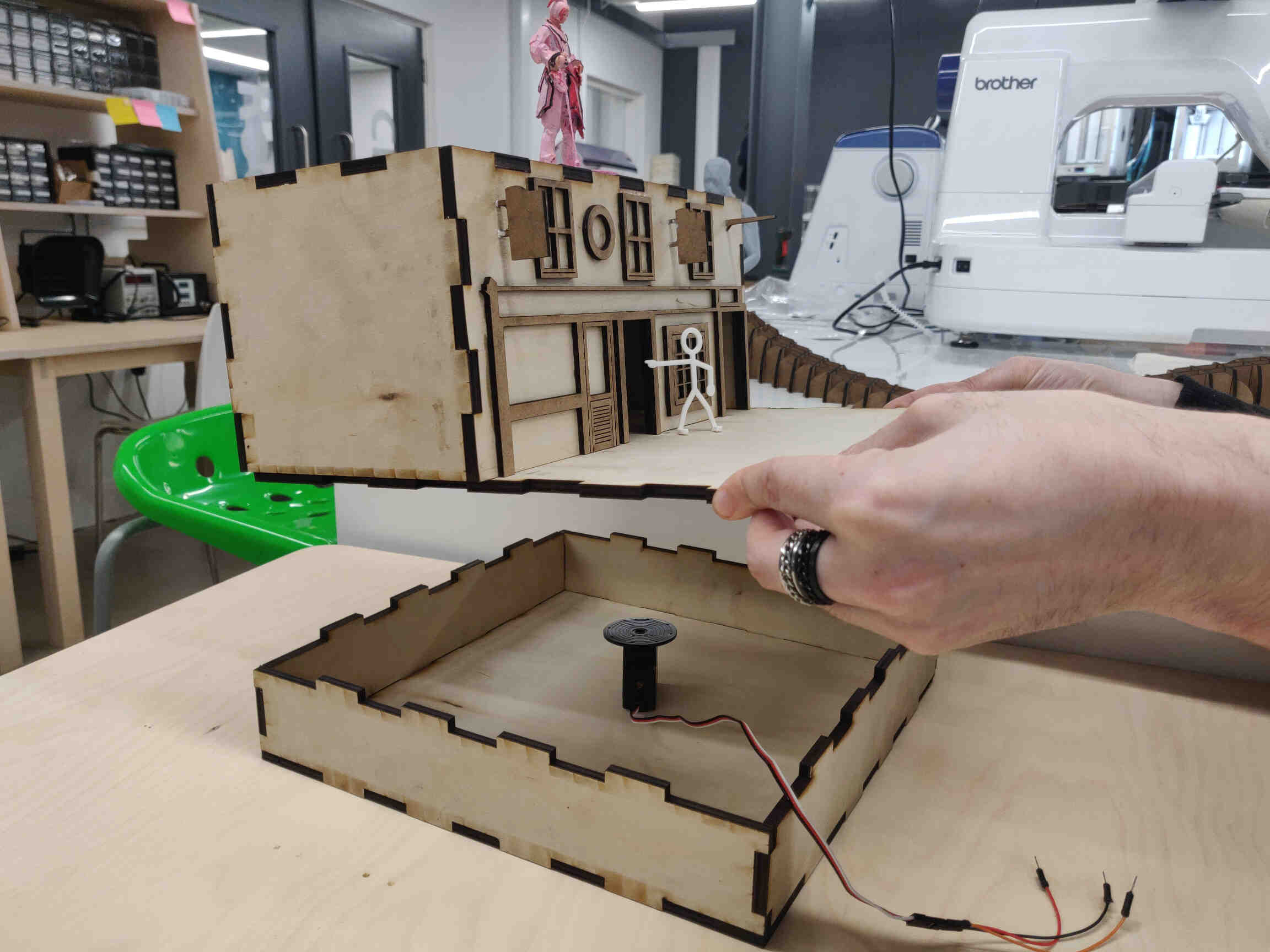

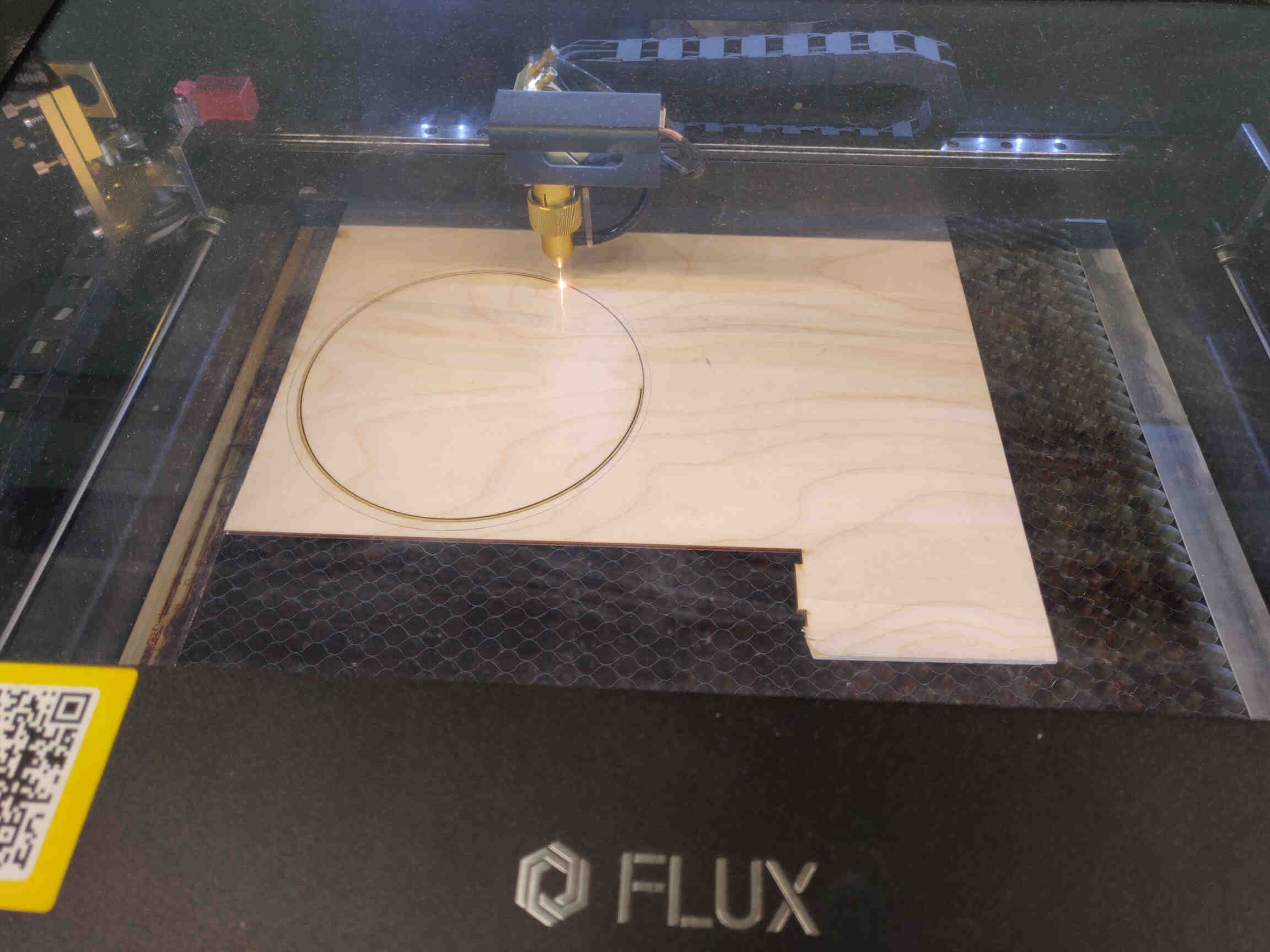

Rotary Wheel Base: We needed to cut a hole in the base for the rotary wheel to slot in underneath the Bartender Pub. So I took the top panel of the base and using a makeshift compass I made the necessary measurements and brought it to our laser cutter to laser cut the hole we needed.

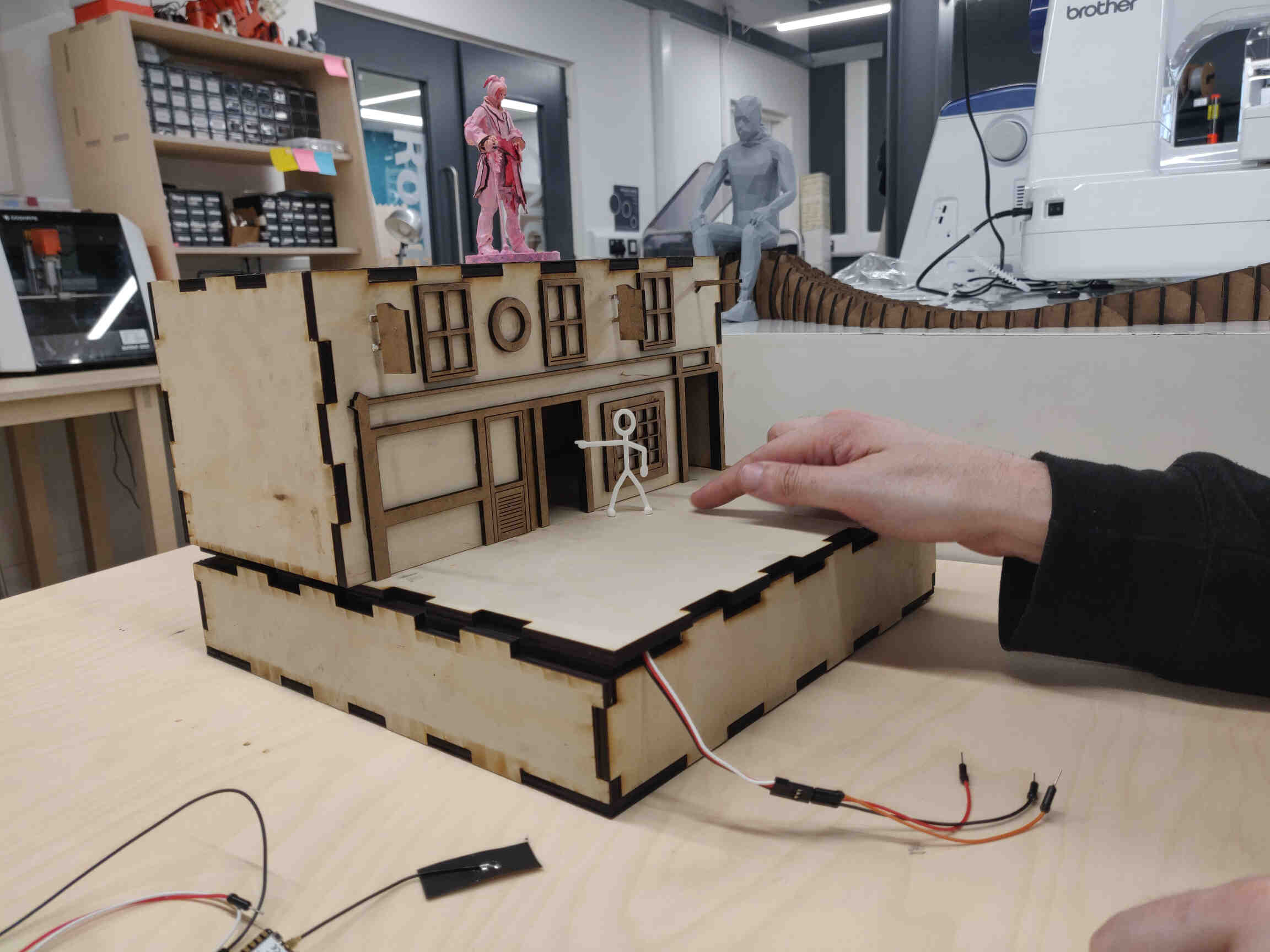

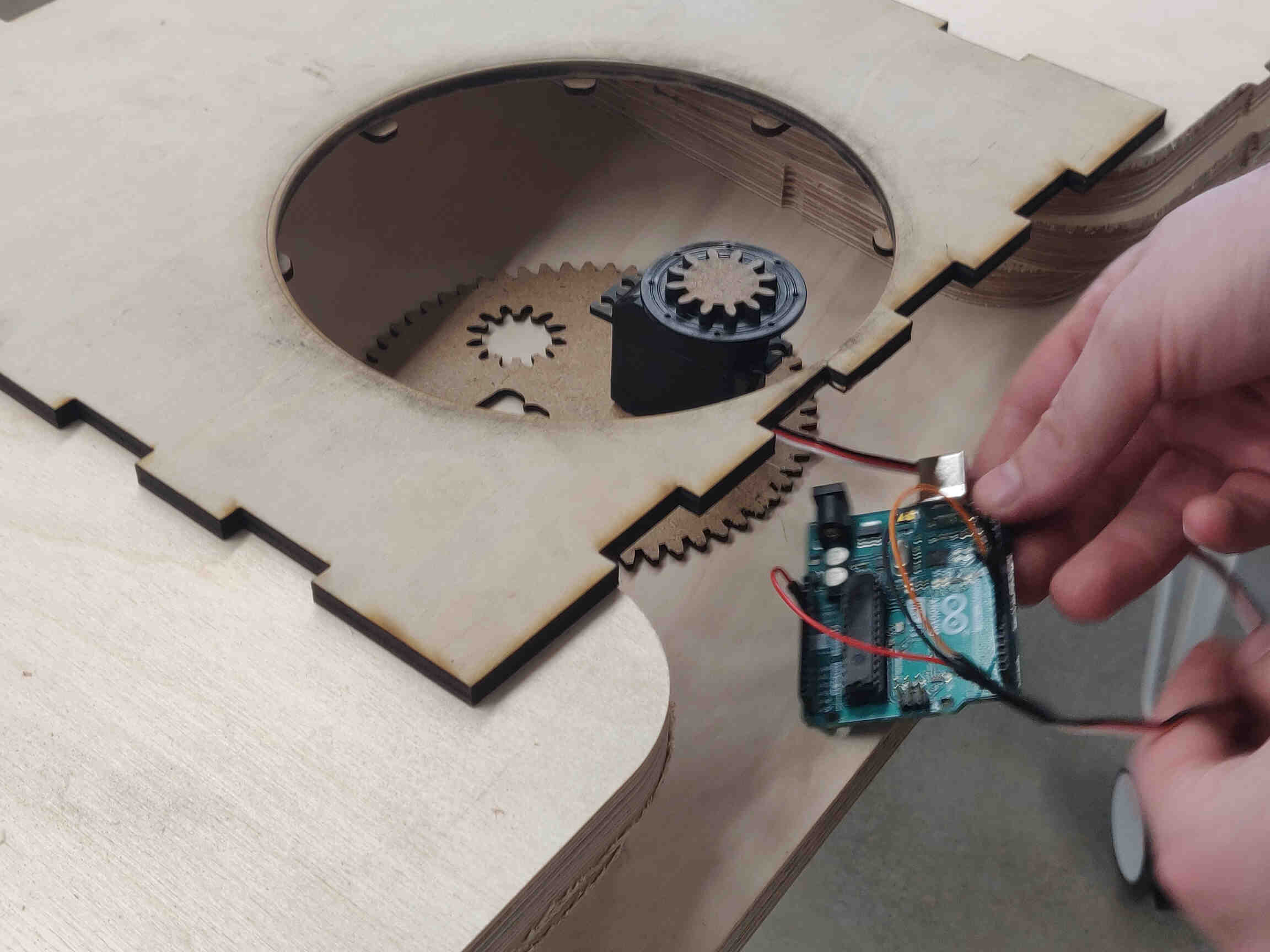

Then I got a 3mm piece of plywood and laser cut a hole 3mm shorter in diameter for clearance. Placing this rotary board on top of our servo wheel, and placing a 3D printed stick figure on top, we were able to test out the mechanics of our machine - it worked perfectly as you can see from the video below.

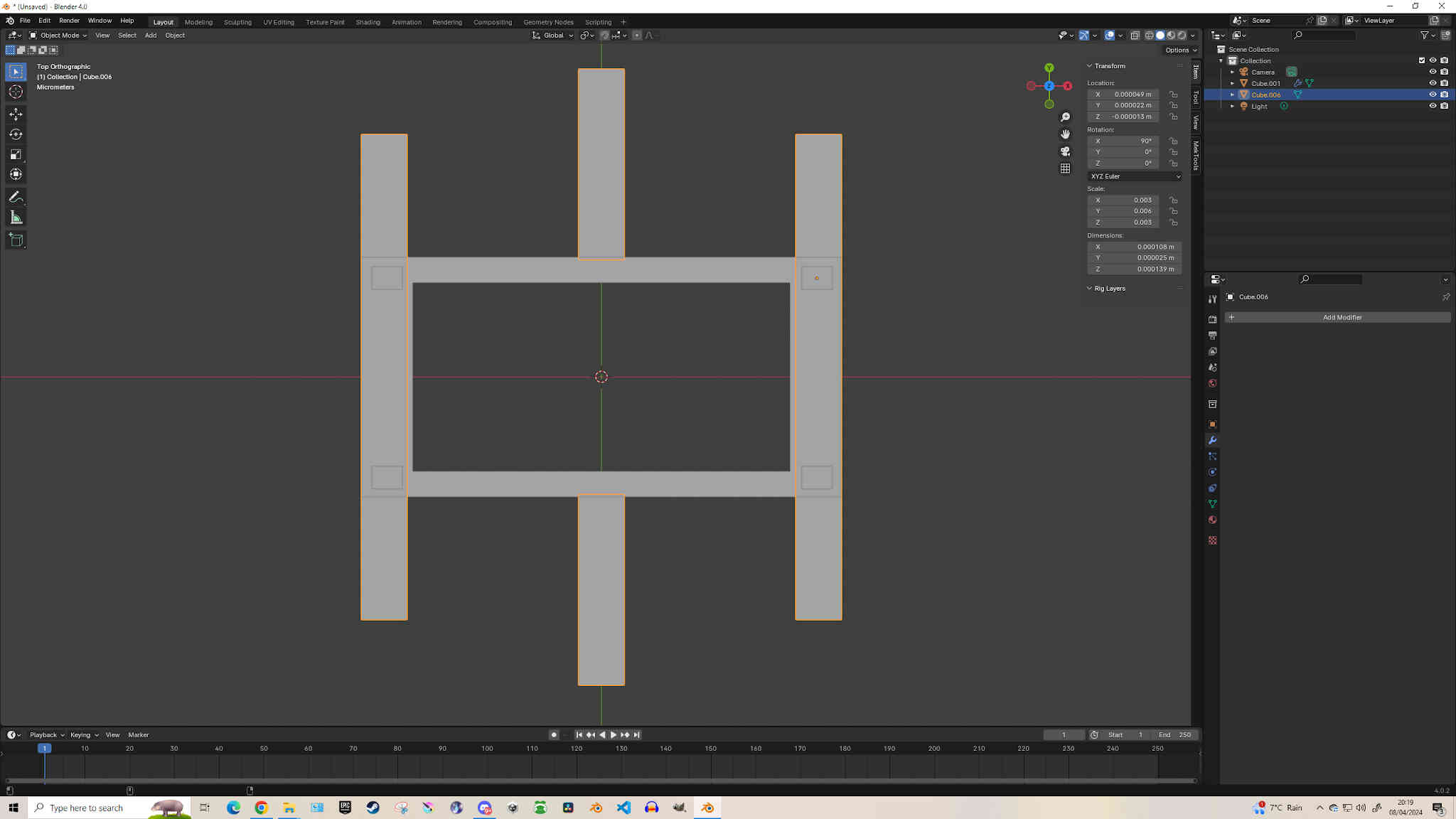

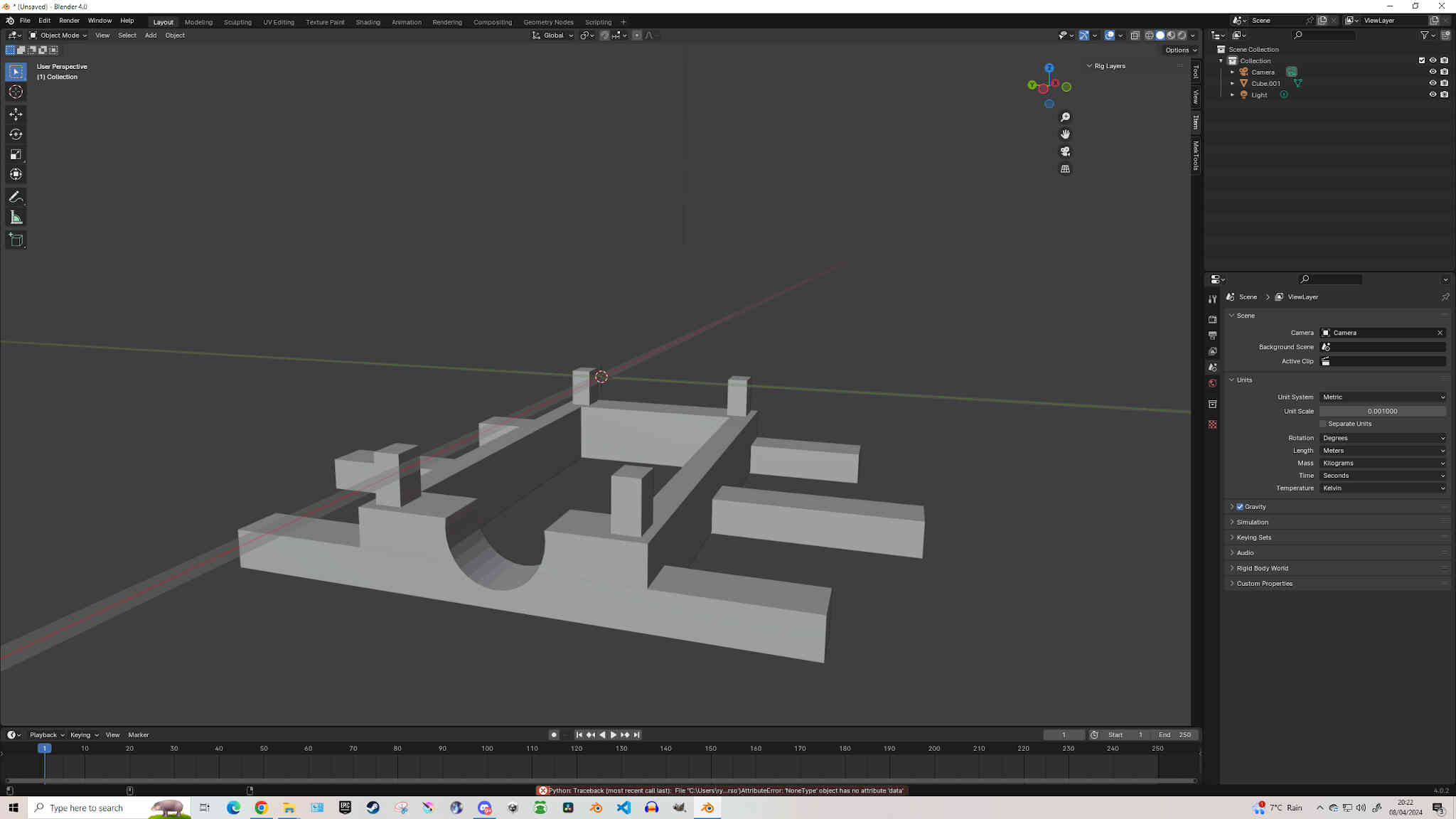

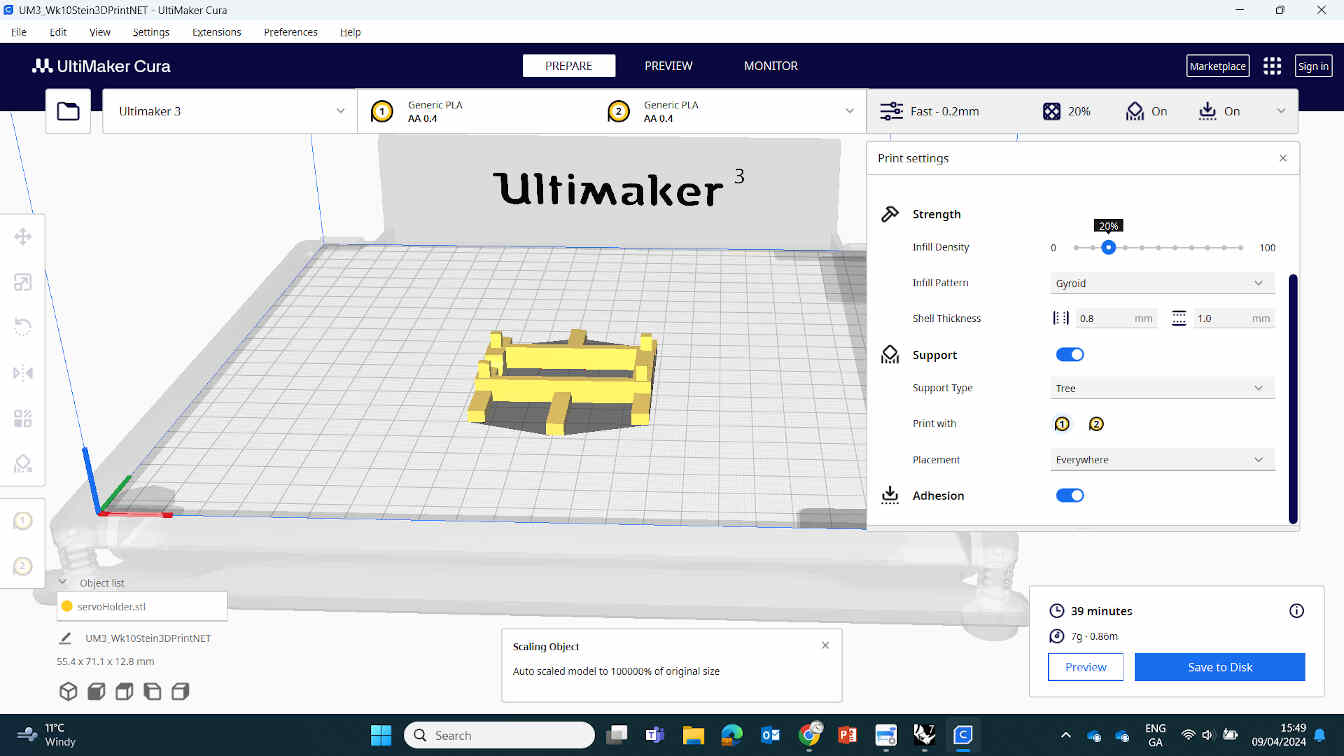

We then needed to make some cuts for the wiring, potentiometer and servo placement. We drilled a hole for the potentiometer and I designed a holder for the servo motor in Blender after taking some measurements, as well as a sign on Inkscape for the machine instructions - which we later engraved onto the left side panel.

____________

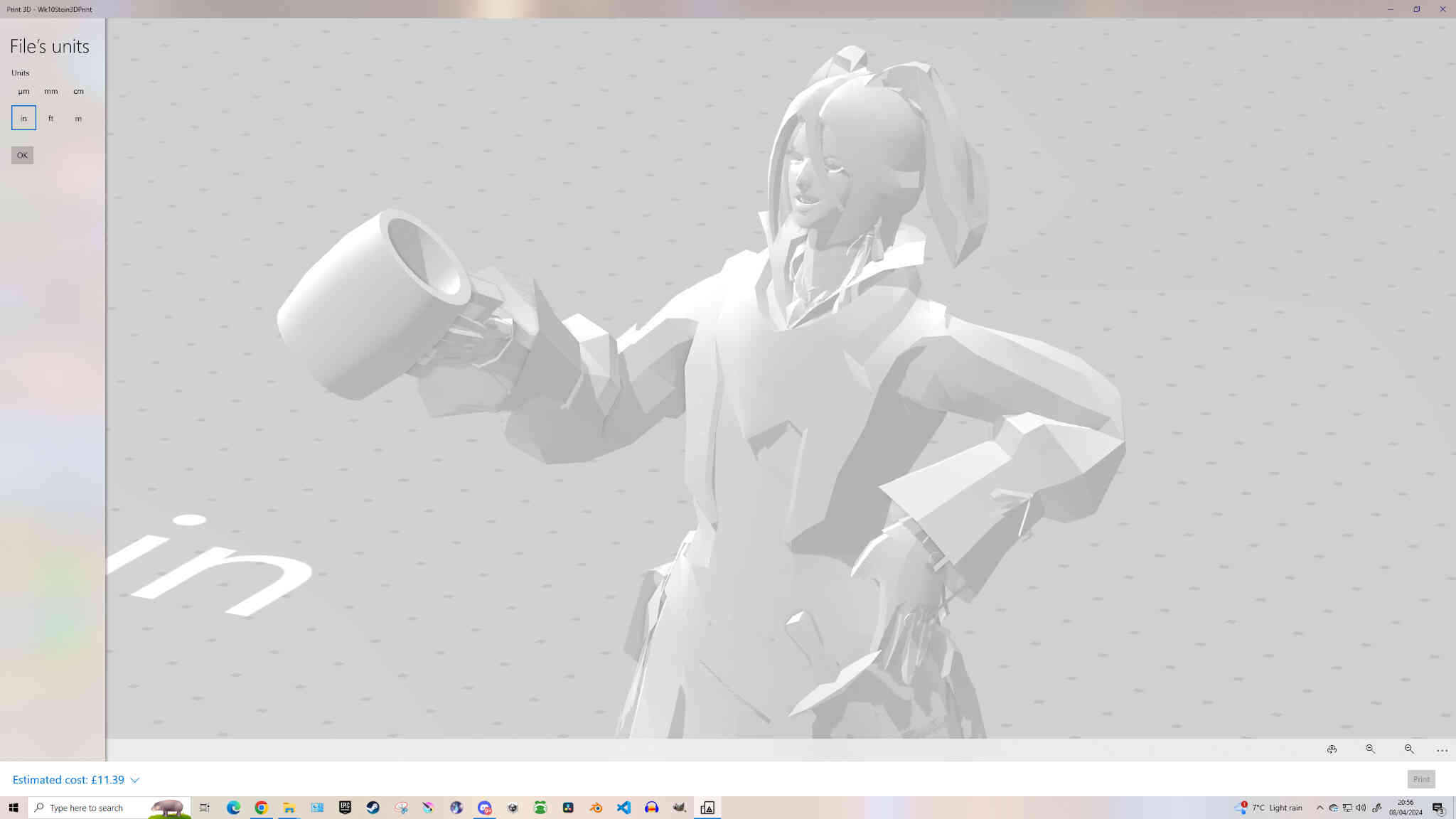

Printing the Little Man

For the Little man design, I used the custom character creator in the video game MMO Final Fantasy XIV and imported the character design into blender, where I posed him correctly and designed a Stein Pint Glass in his hand and used Prusaslicer to 3D print him out.

____________

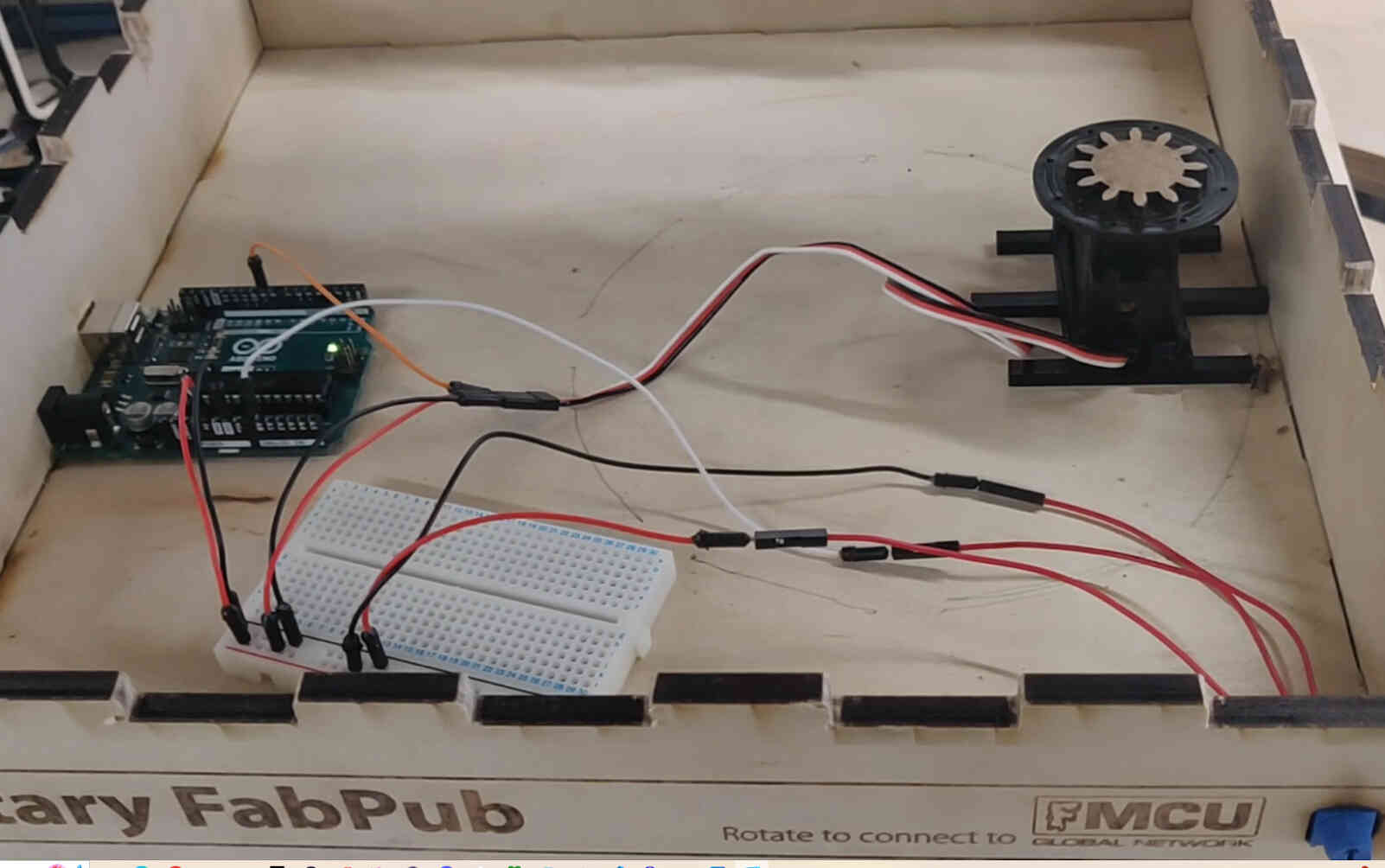

Electronics and Programming

Checking in with Oscar, I saw that he had a servo motor working with a rotary wheel thanks to his electronic assembly and code implementation. These are the tutorials he used to get the motor running:Circuits DIY & Arduino Analog Read Serial.