16. Applications and Implications

Individual assignment:

Propose a final project masterpiece that integrates the range of units covered,answering:

What will it do?

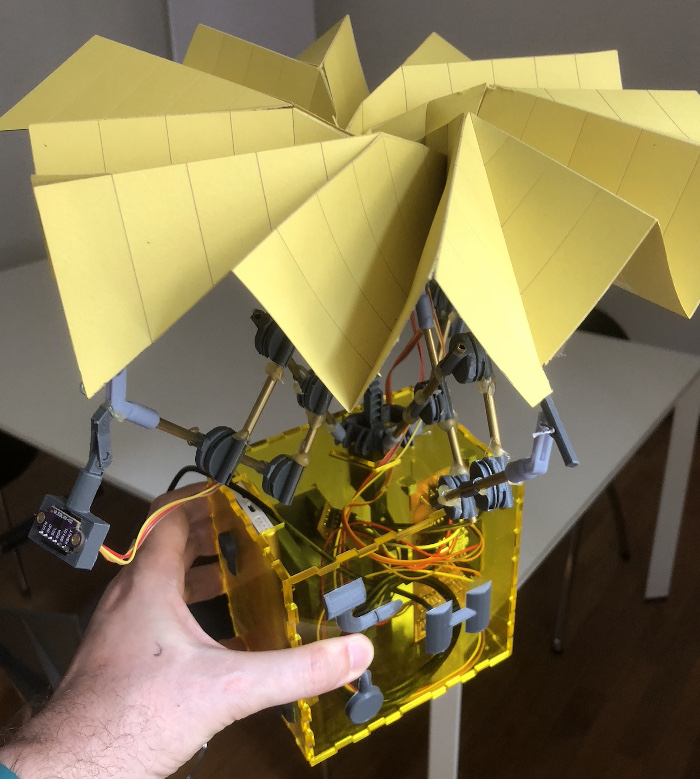

The final project is meant to be a small replication of a satellite with solar panels created with an Origami that will fold and unfold.

The project foresees that the origami solar panels with unfold when enough light is detected.

In case obstacle is detected during the opening of the solar panels, unfolding process will stop immediately and solar panel will start folding.

Who's done what beforehand?

I have not found evidence of similar projects on the public internet, but there's some photos on the Web that proves that space agencies (NASA, ESA) are working on this topic.

What will you design?

Overall solution and components are in scope of the design activities:

What materials and components will be used?

Origami is made of paper in the current project.

Variable geometry structure is made of 3D printed components + lightweight aluminum rods

PCB with electronical components

Enclose in plexiglas for the PCBs, Power bank and motor

3D printed elements:

Where will come from?

Except for the 2 sensors that will be purchased online and the lightweight aluminum rods that will be purchased from a local shop, all the other materials components are available in the FabLab.

How much will they cost?

sensors cost estimate: 20€ to be confirmed

lightweight rods cost: 120€

What parts and systems will be made?

Except for the lightweight rods, motor, 2 sensors and powerbank, all the other elements of the project will be created.

Origami will be made of paper (200grams /m^2 paper)

Mechanical parts: anchors, wheels, kneecap, summit, rack and pignon, enclosure for the sensors, space like decorative elements to stick on the plexiglass

Electronical parts, PCBs: central PCB, PCB for TOF sensor, PCB for photoresistance, PCB for DC motor control

What processes will be used?

3D printing process will be massively used for the preparation of the mechanical components using PLA and resin when higher precision is required

Assembly process Leveraging embedding mechanism of physical elements to avoid glue and screws

Laser cutting of the origami structure (incision and cutting)

milling process to create the required PCBs + soldering of the components

Cabling process: the electric wires will pass inside the tubes of the structure

What questions need to be answered?

One of the questions that I would like to address (not for the current release but for a future phase) is the possibility to replace the paper used for the Origami with a thin plastic material reinforced with thin plastic or plexiglas tiles

This could be the subject for further iteration(s) and tests.

How will it be evaluated?

Your project should incorporate 2D and 3D design

additive and subtractive fabrication processes,

electronics design and production,

embedded microcontroller interfacing and programming,

system integration and packaging

Where possible, you should make rather than buy the parts of your project

Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable