Week 3: Computer Controlled Cutting

Assignment

Group assignment

Characterizing lasercutter's focus, power, speed, rate, width, joint clearance and types

Individual assignment

Design, make, and document a parametric press-fit construction kit, accounting for the laser cutter kerf, which can be assembled in multiple ways. Cut something on the vinylcutter.

- Vinyl cutting machine is a computer-controlled cutting device used for cutting thin sheets of material, such as vinyl, paper, or fabric. These machines use a small blade to cut out intricate shapes and designs in the material based on the digital design files created using computer software.

- The vinyl cutting process involves placing the material on a cutting mat, which is then fed into the machine. The machine's blade follows the paths of the design file, cutting the material with precision and accuracy. Once the design is cut, the excess material is removed, leaving the desired design intact.

- Vinyl cutting machines are commonly used in the production of vinyl graphics, lettering, and decals for a variety of applications, including signage, vehicle graphics, and personalized gifts. They are also used in the garment industry for creating custom apparel, such as t-shirts with heat transfer vinyl designs.

- Overall, vinyl cutting machines provide a versatile and efficient way to create precise and intricate designs, making them a valuable tool for many businesses and individuals in various industries.

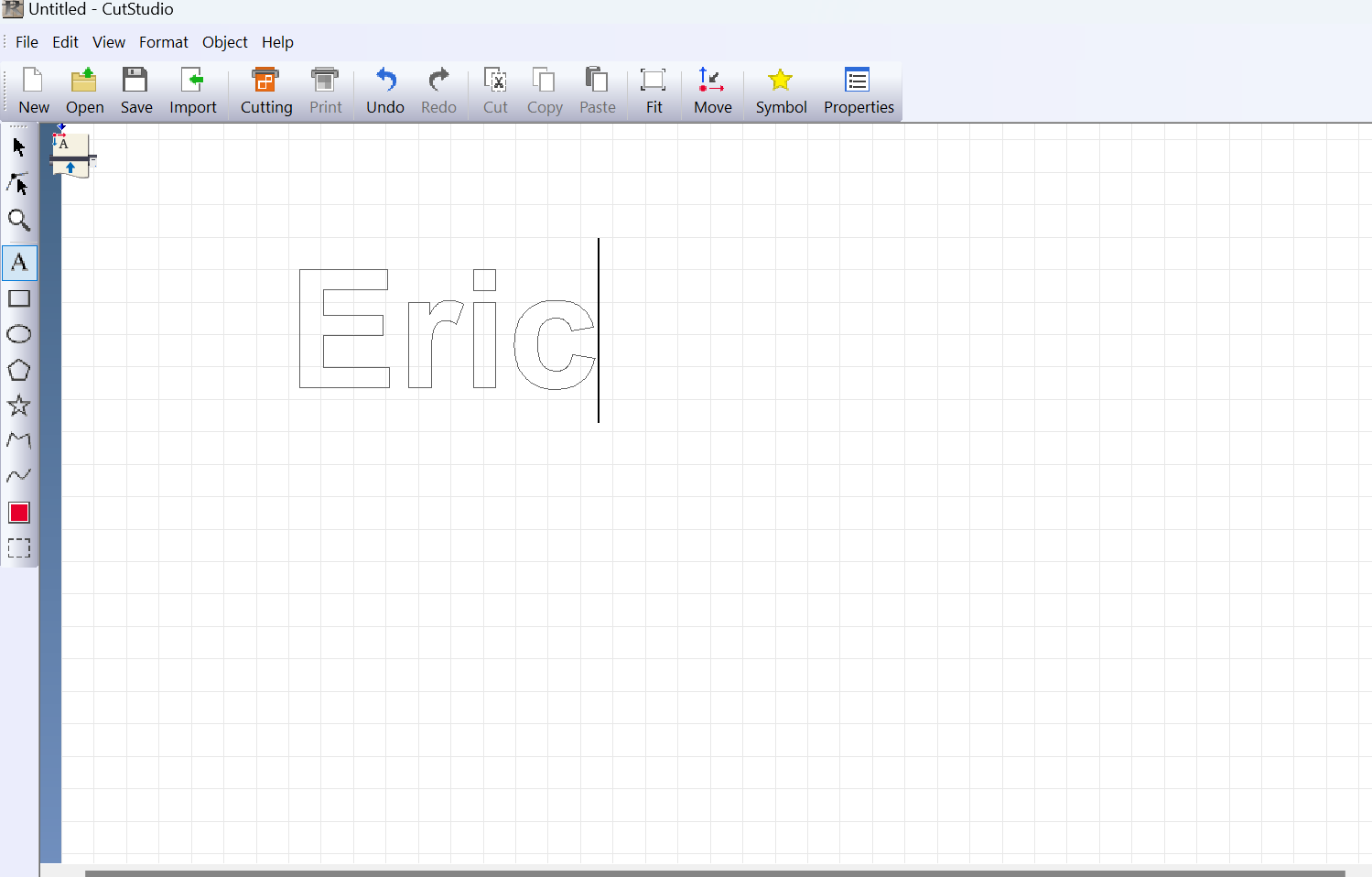

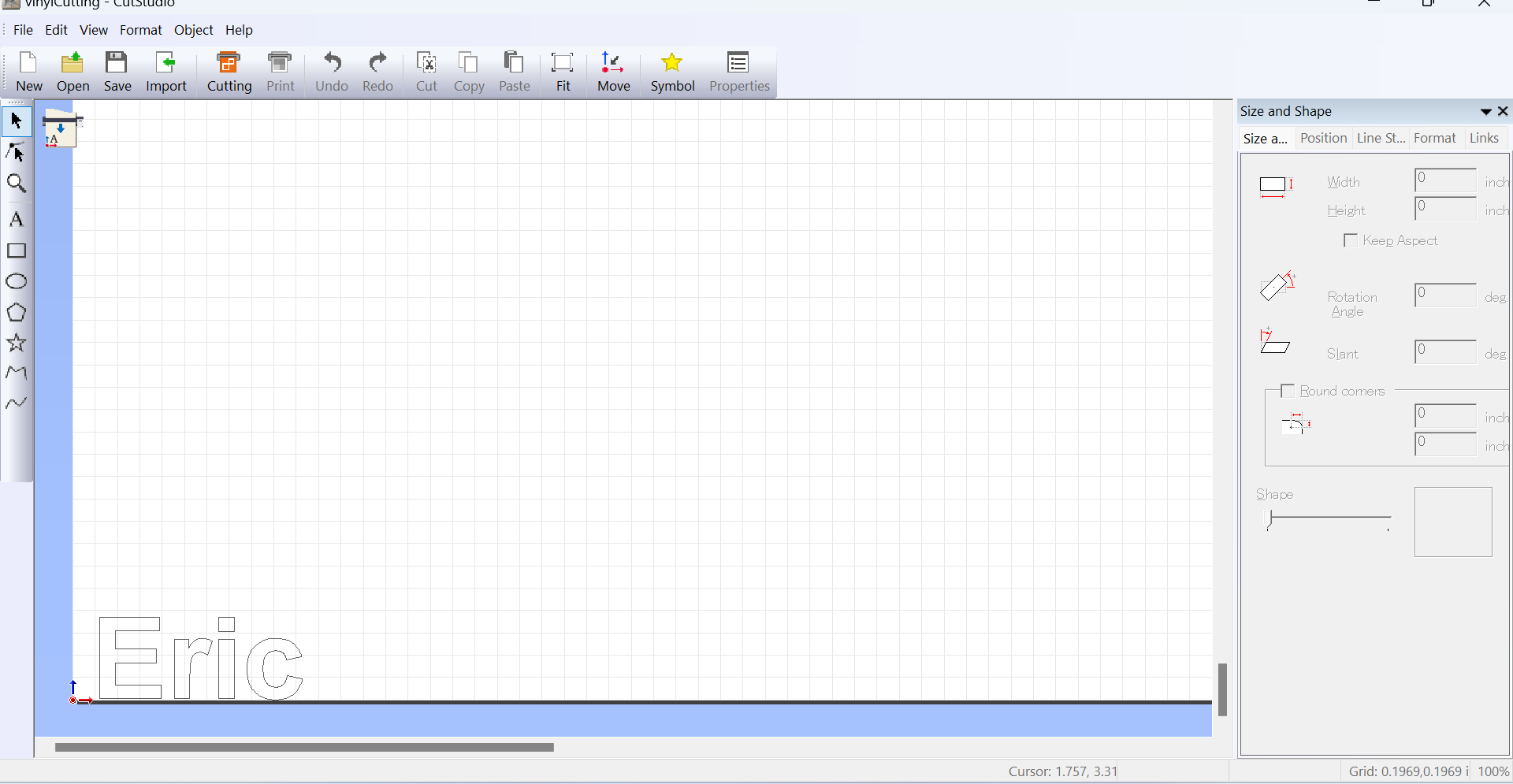

- I am going to write and cut Eric using Roland's powerful CutStudio software, a powerful design and cutting software that is used with Roland's vinyl cutters and digital printers. It allows users to create intricate designs, logos, lettering, and shapes, and then cut them out of various materials such as vinyl, paper, and heat transfer materials.

-

- Opening Roland's CutStudio software and then typing Eric

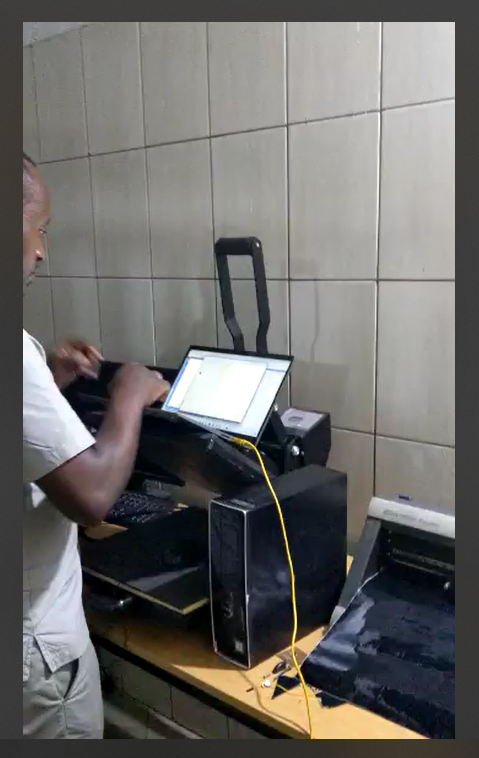

- Inserting and adjusting the vanyl paper

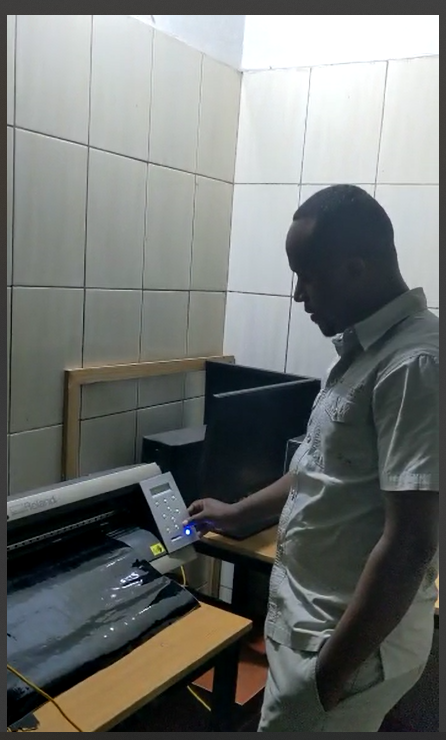

- Starting and cutting in progess

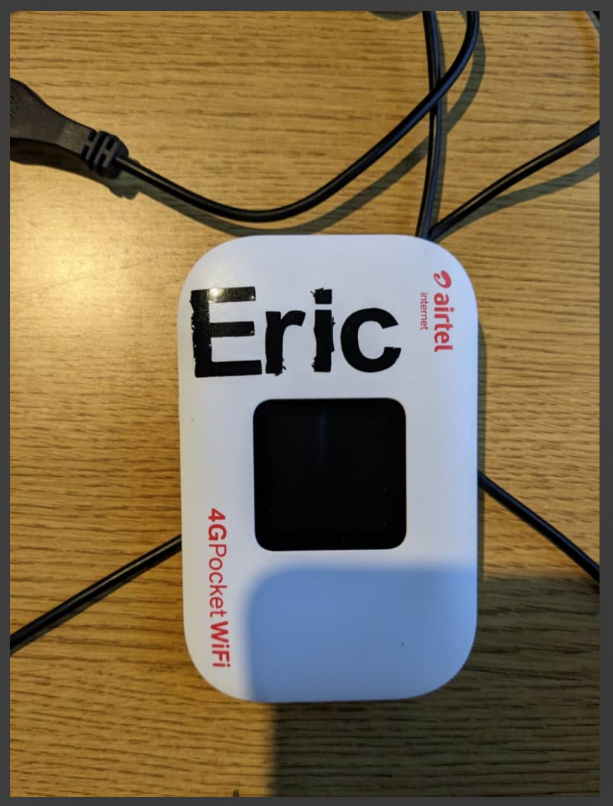

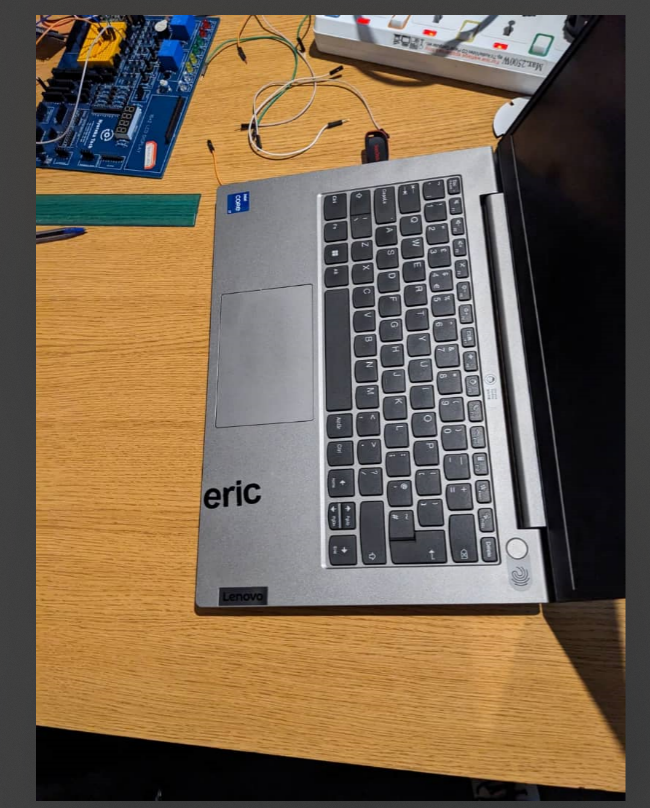

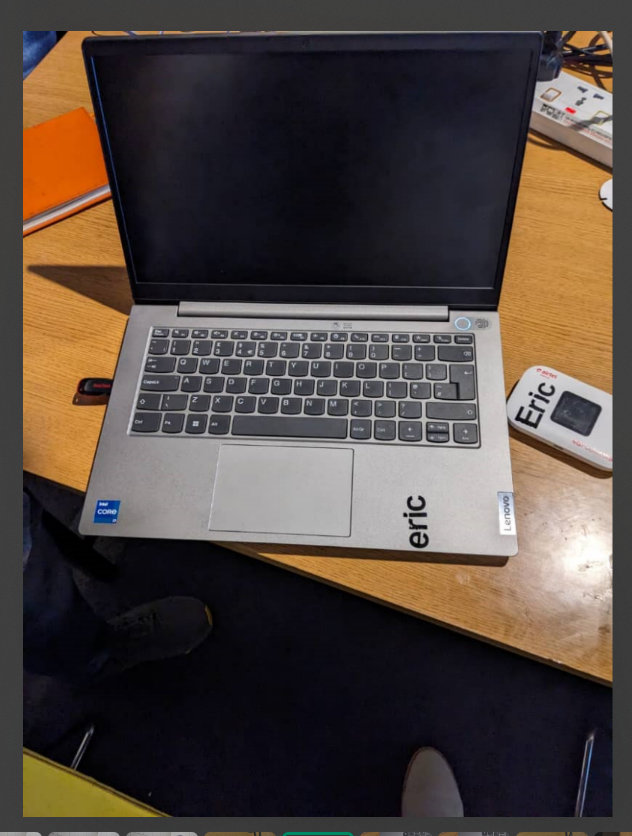

- Sticking vanyl letters E

r i c on my Airtel Pocket WiFi and my computer

Vinyl Cutting:

-

The Laser cutter:

A laser cutter is a type of computer-controlled cutting machine that uses a high-powered laser to cut, engrave, or etch a variety of materials. The laser beam is generated by a laser tube or diode and is directed by mirrors to the cutting bed, where it can be focused on a specific point with extreme precision. The laser beam melts, vaporizes or burns away the material, leaving a clean and precise cut. - Laser cutters can cut a wide range of materials, including wood, plastic, acrylic, fabric, leather, and metal. They are commonly used in a variety of industries, such as industrial manufacturing, architecture, engineering, product design, and art and design.

- The process of using a laser cutter involves designing a digital file or pattern, which is then sent to the machine's software. The laser cutter then reads the file and directs the laser beam to cut or engrave the material according to the design. Laser cutters can produce complex shapes and intricate patterns with high accuracy and speed, making them a versatile tool for a wide range of applications.

-

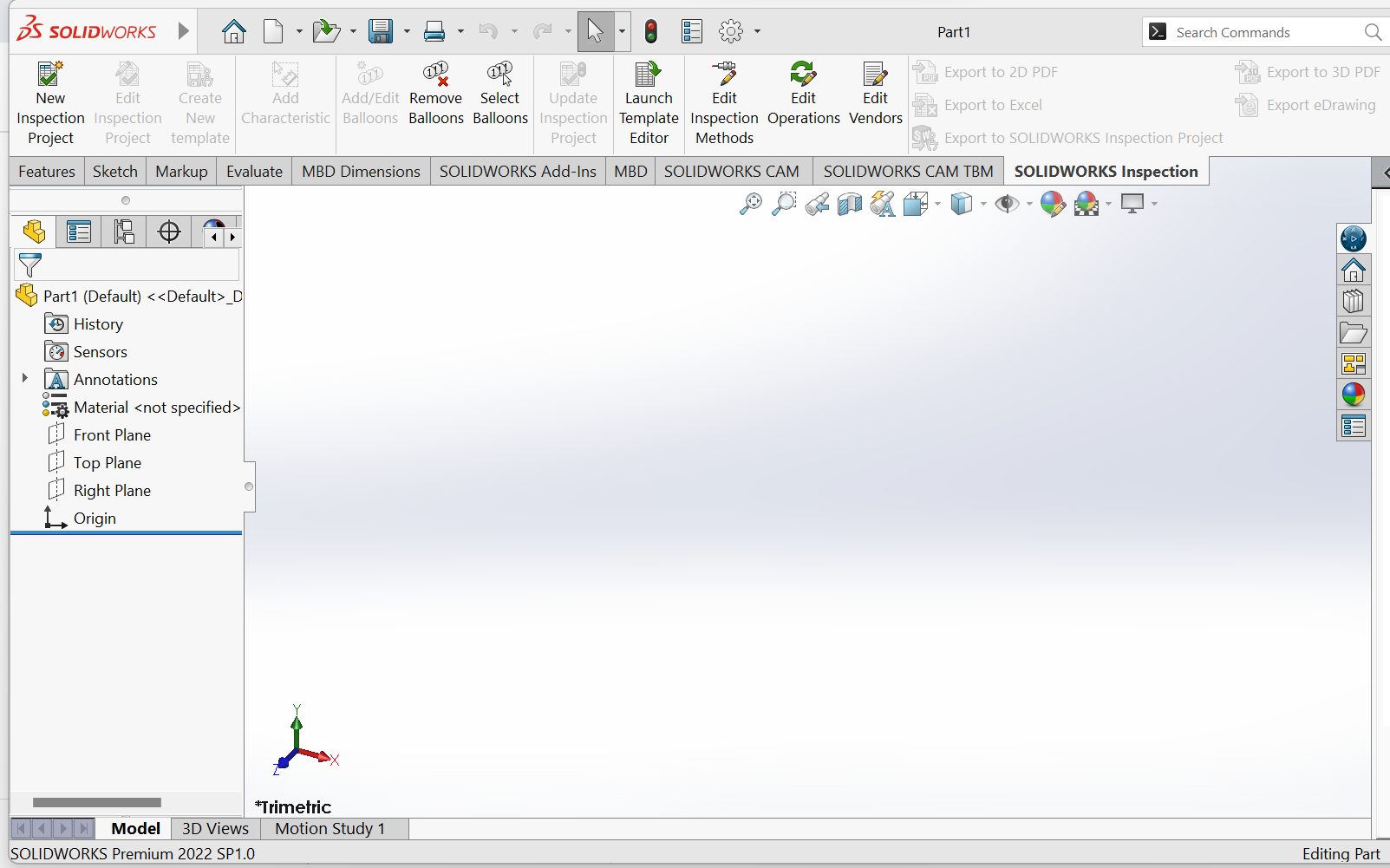

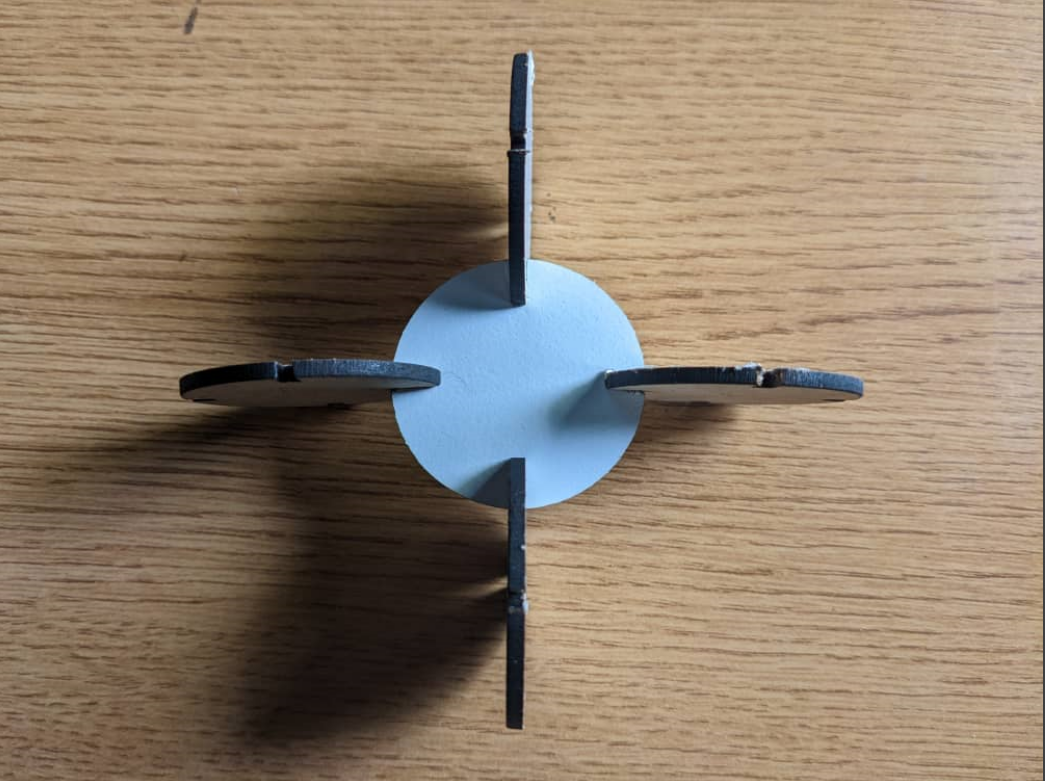

Designing the press fit material in Solidworks

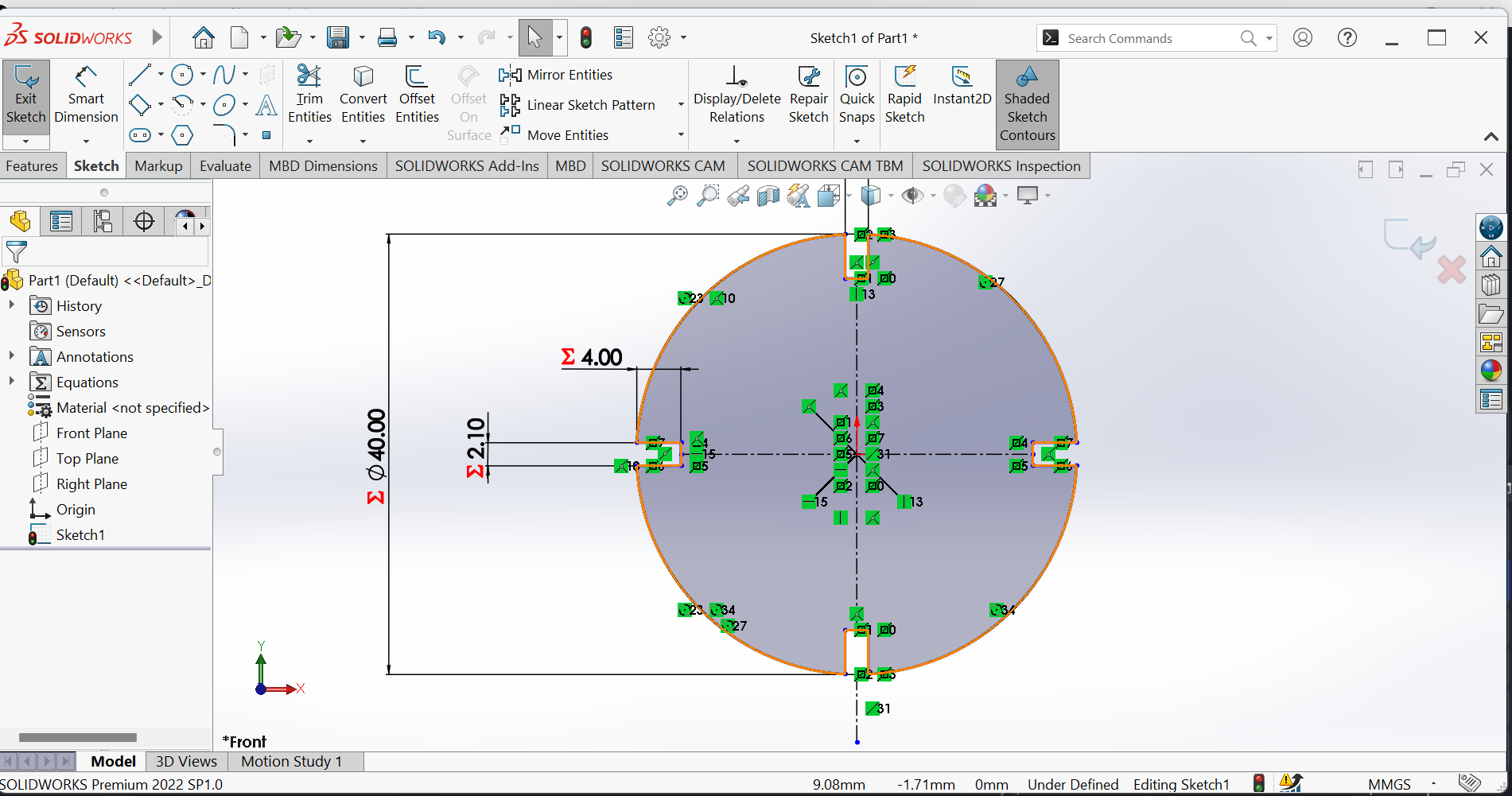

I create a circular form with 4 slots using solidworks. I adjusted the slot's size so that it matched the thickness of the material I intended to use.

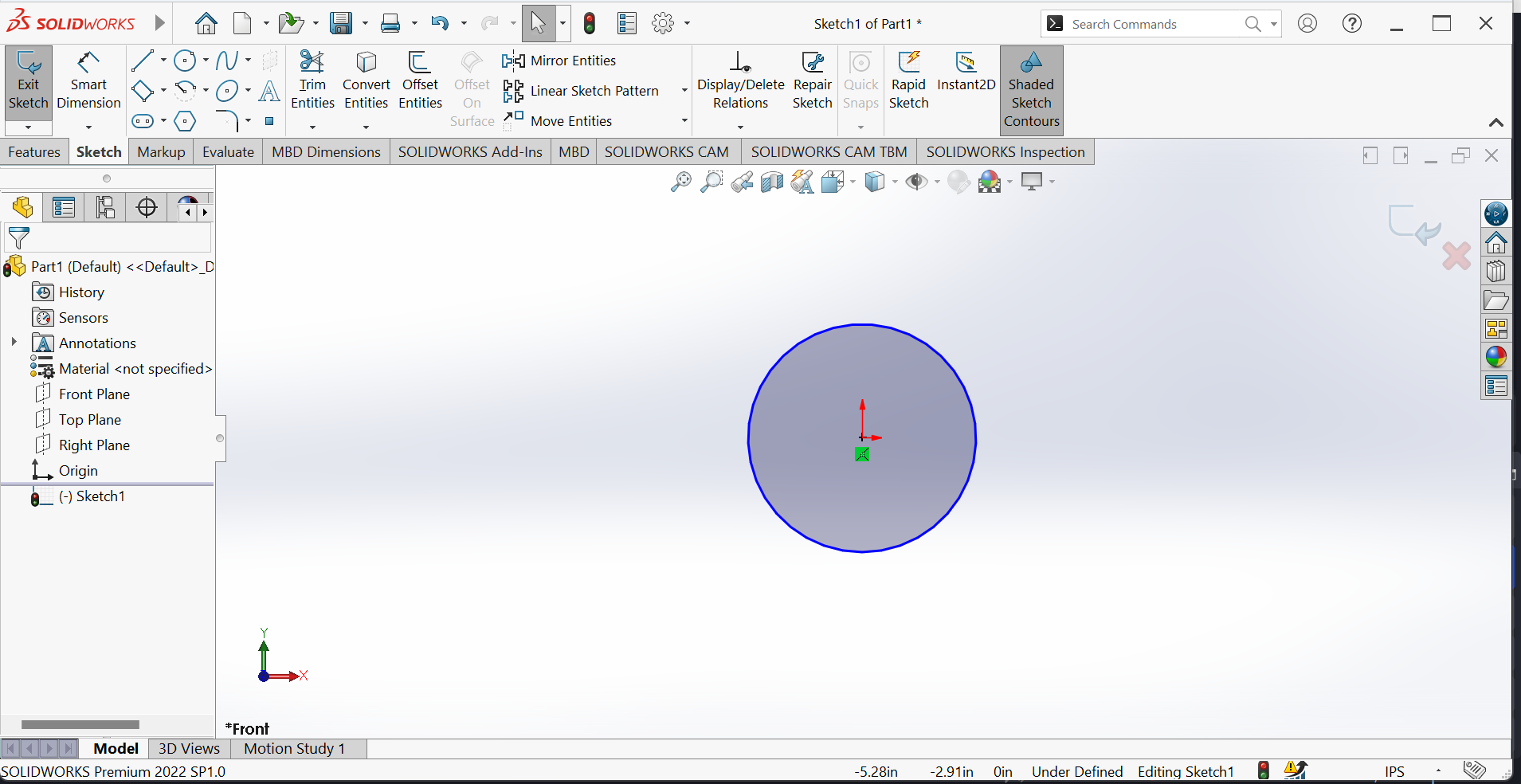

- Opening solidworks

- Drawing a cycle

- Creating a fully-constrained sketch

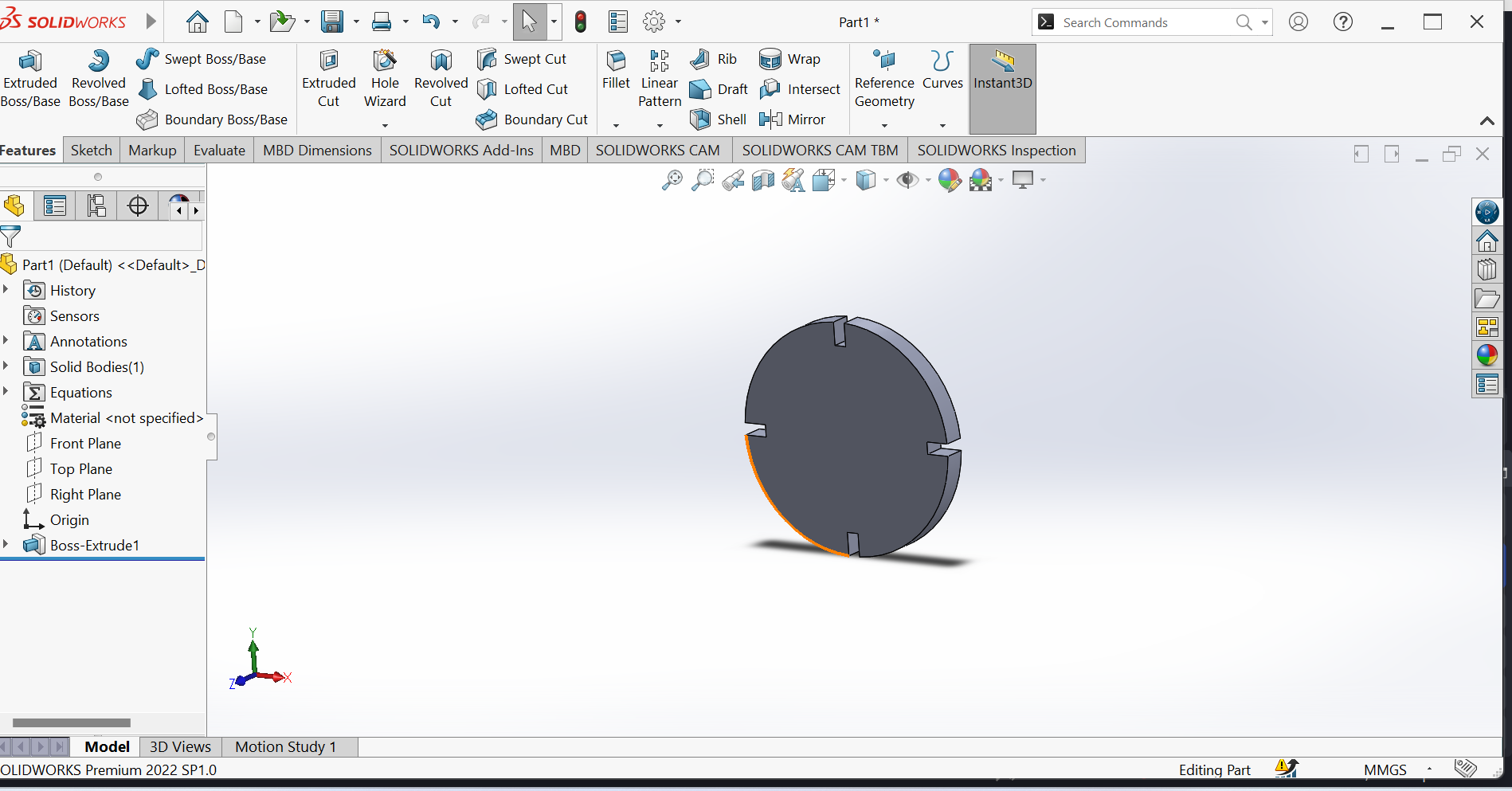

- Extruding the sketch to create the 3D geometry model.

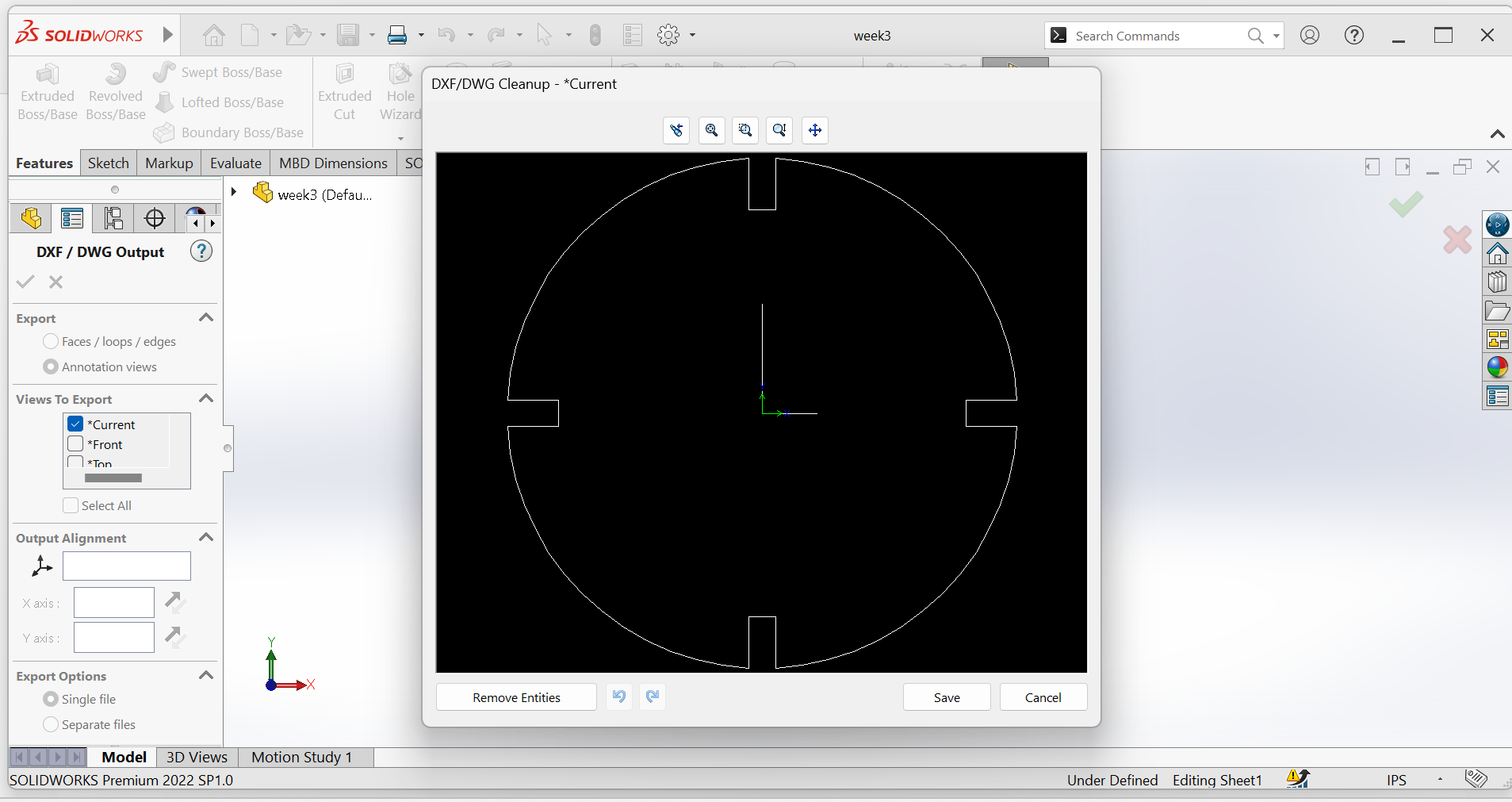

- Saving the file with extension of DXF File compatible with CorelDraw inside the jobing computer

-

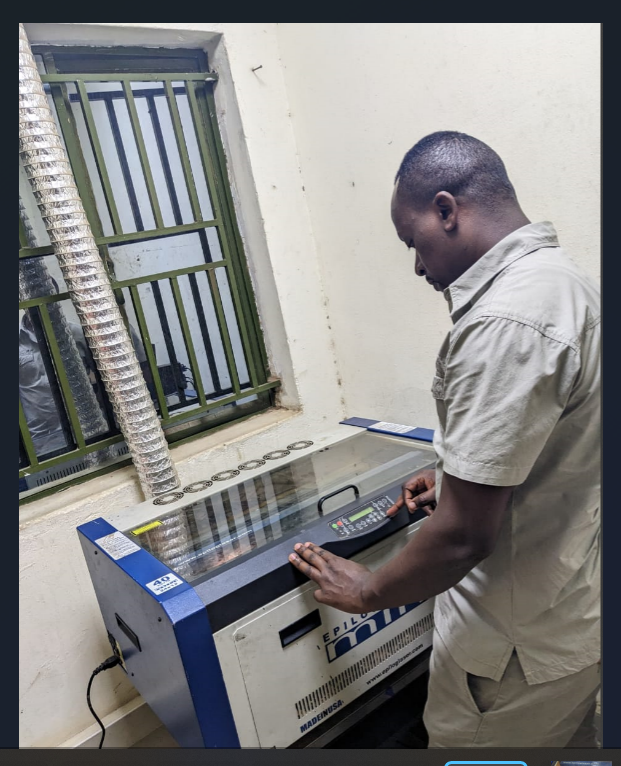

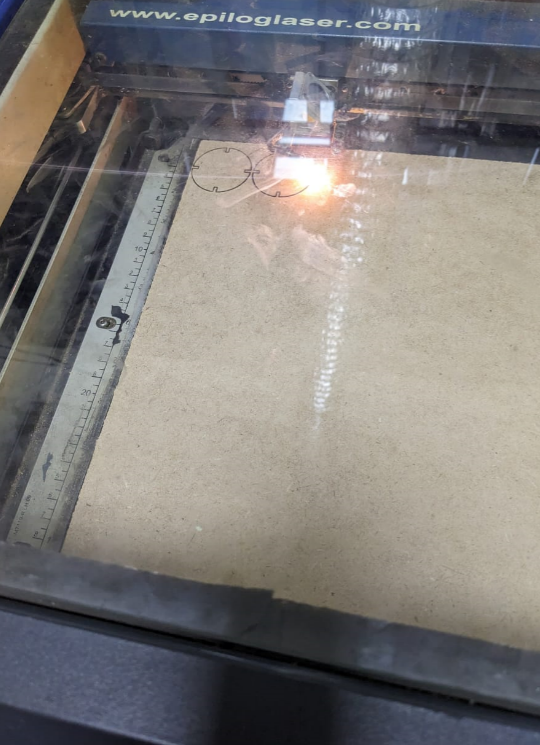

Jobing/ Cutting using Epilog Laser machine

- Duplication of the model from the opened DXF file in the CorelDraw software within the jobing computer

- Switch on the machine using its down Pawer Switch Button

- Turning on the compressor, bringing the pressure via the beam pipe once the job begins

- Turning on the filter that eliminates all smoke and heat exposure

- Applying configurations, Setting and customization

- Setting the Power, the Speed and the rate parameters -

Below I am going to illustrate the molecular formula of methene

| Starting jobing/ laser cutting | |

|---|---|

|

Laser cutting in progress |

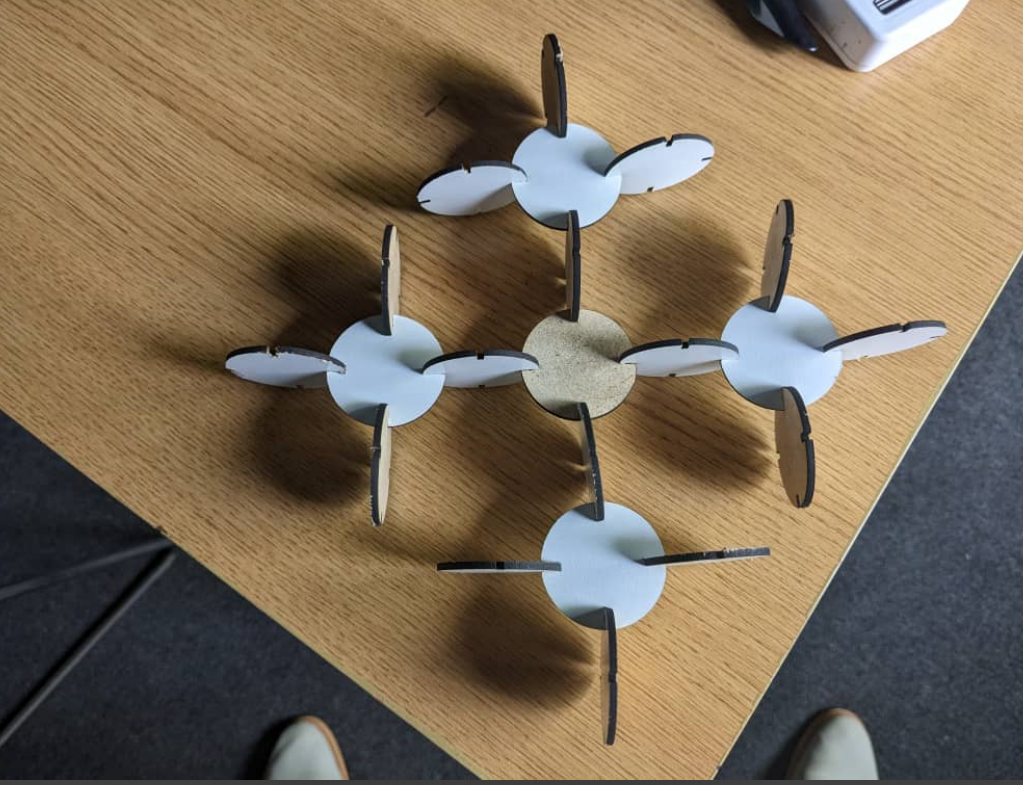

The following is the hero shot of laser cutted part with multiple assembly

- Used file can be found here

© 2023 | Eric NDAYISHIMIYE | All Rights Reserved