Week 12: Molding and Casting

Group assignment

-

* Review the safety data sheets for each of your molding and casting materials

-

* Make and compare test casts with each of them

The group assignment page is here on FabLab Rwanda web page

.Individual assignment:

Design a mold around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

For this assignment I am going to use two types of WAX

Wax is a solid, pliable substance that is derived from natural sources such as plants, animals, or petroleum. It has a low melting point, which allows it to be easily melted and shaped into various forms. Wax is commonly used in candle making, as a protective coating, for sculpting, and in various industries such as cosmetics and polishes.

Blue Ferris File-A-Wax and Yellow Beeswax are the material that I am going to use in molding and casting respectively

Molding

Manufacturing involves moulding malleable raw material using a hard framework or model known as a pattern. A mold is a block that has been hollowed out and is filled with raw materials such as plastic, glass, metal, or ceramic liquid. Inside the mold, the liquid sets or hardens, taking on the shape of the mold. The opposite of a cast is a mold. The term "mold maker" refers to the producer who creates the molds. To remove the hardened/set substance from the mold more easily, a release agent is frequently utilized. Molded plastics are frequently used to make furniture, household items, cases, and structural components.

Here below is the object (like a bar soap) that I am going to make as the result of mold and cast

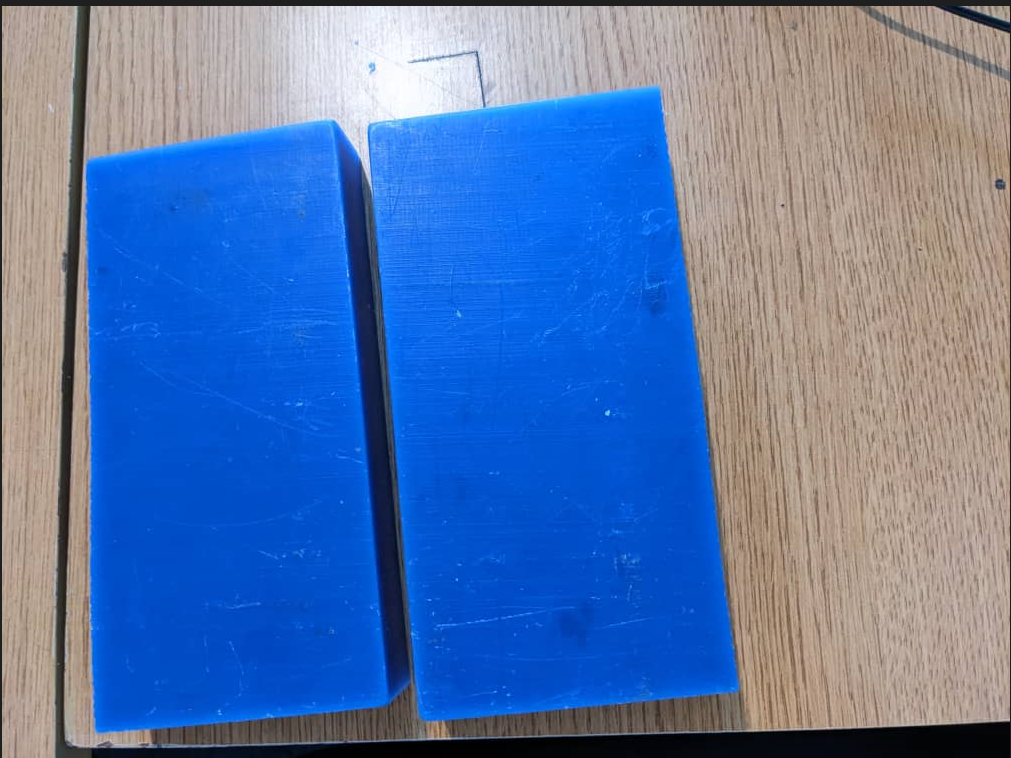

Blue Ferris File-A-Wax is the material I am going to use in molding

Blue Ferris File-A-Wax is a specialized sculpting material used in various artistic and industrial applications. It is a pliable wax-based substance that can be shaped, carved, and molded easily. Its distinctive blue color helps with visibility and accuracy during the sculpting process, making it a popular choice among artists and professionals in need of precise modeling materials.Here below is the Blue Ferris File-A-Wax to be used

To read the Safety Data Sheet of Blue Ferris File-A-Wax, click here

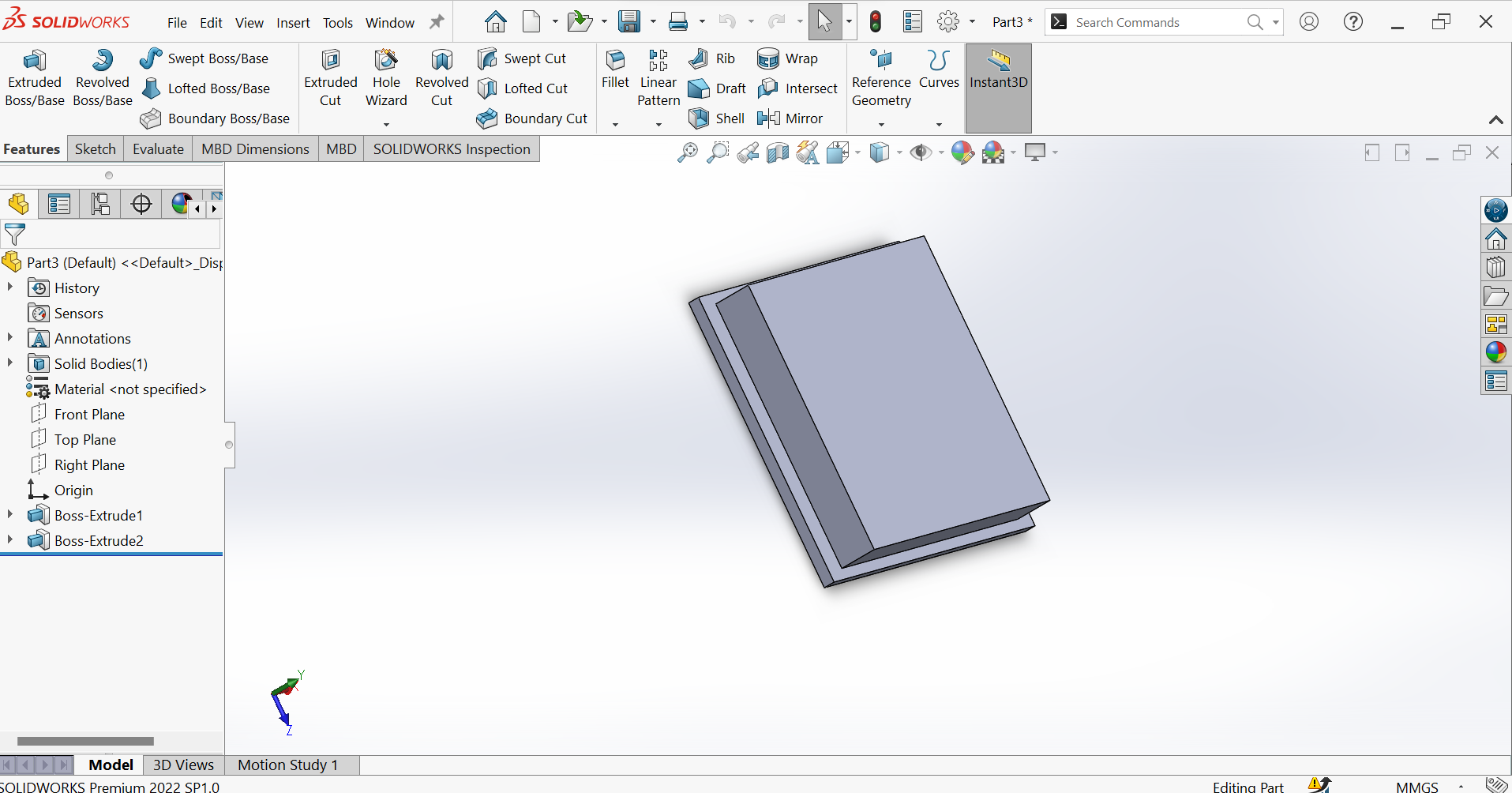

3D design of the mold using SolidWorks

SolidWorks is a computer-aided design (CAD) software that enables the creation of 3D designs and models. With SolidWorks, a 3D mold design can be created by utilizing various tools and features to define the desired shape, dimensions, and details. The software allows for precise modeling of the mold, including the incorporation of intricate patterns, cavities, and draft angles. SolidWorks also offers simulation capabilities to test and optimize the mold design before it is manufactured, ensuring efficiency and accuracy in the molding process.

Using solidworks to design the mold and set parameter measurement as shown below

Inside part of the mold

Here below is the 3D designed mold

This is the simulated video

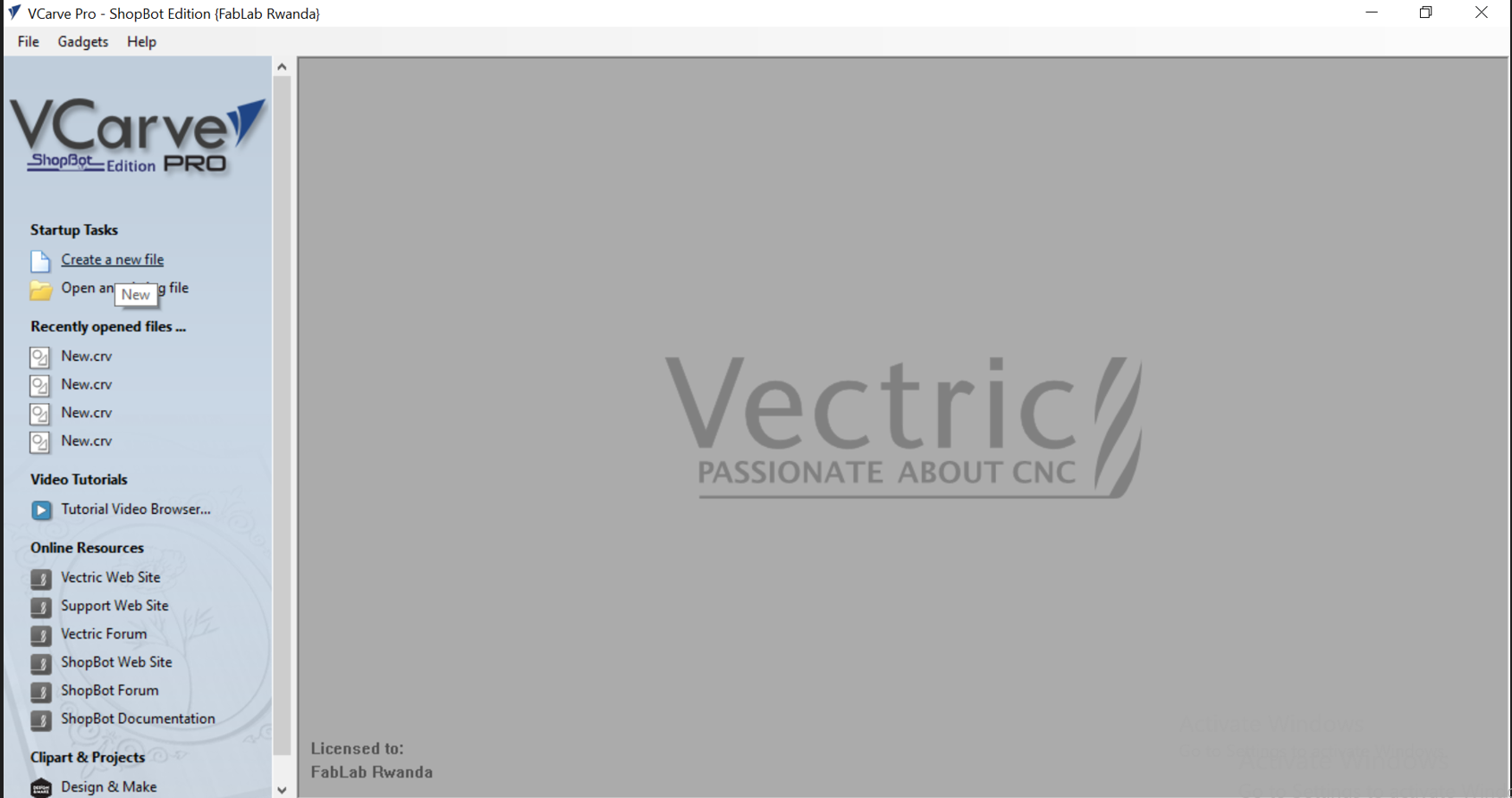

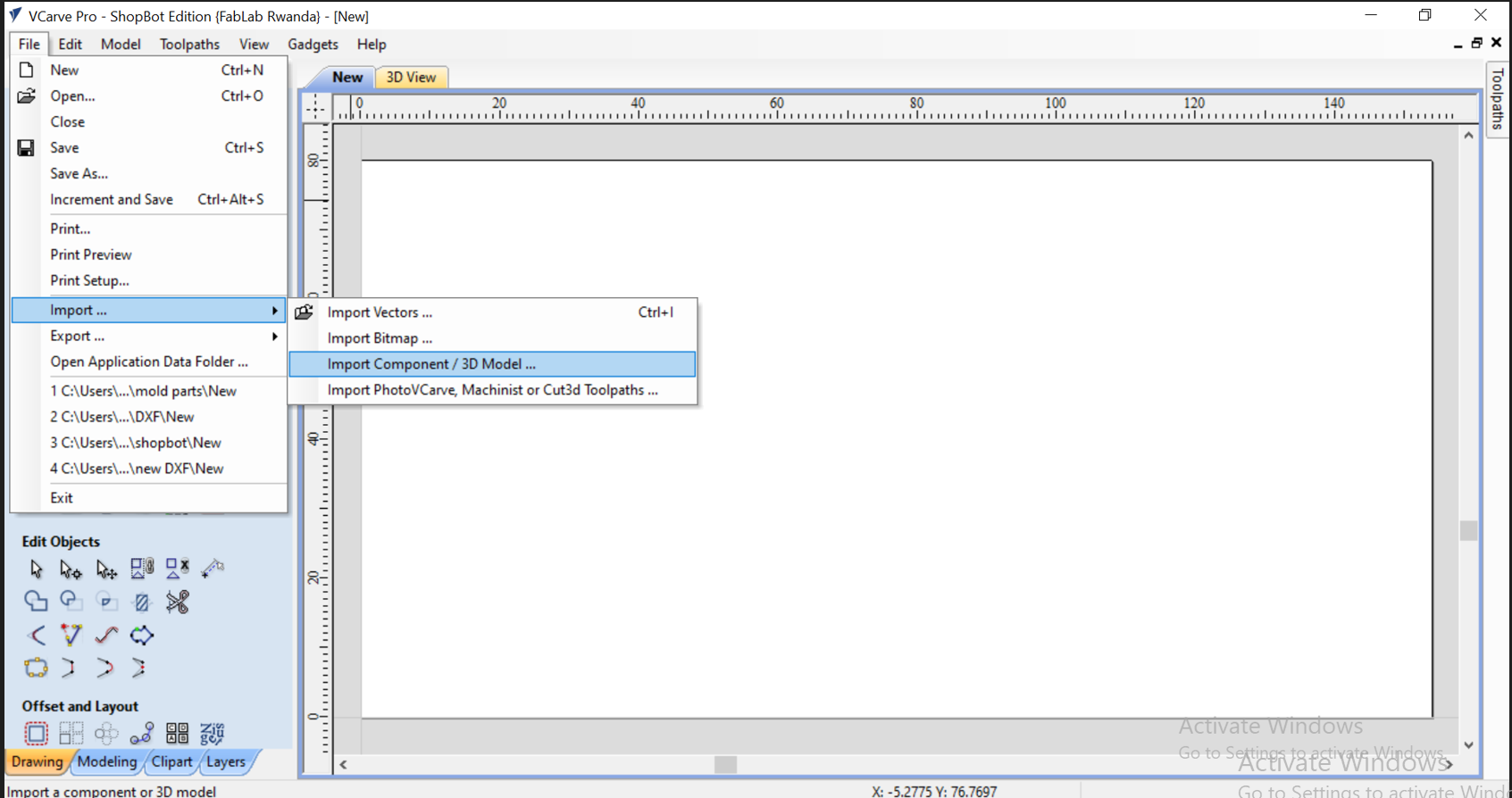

Importing design file into V curve software

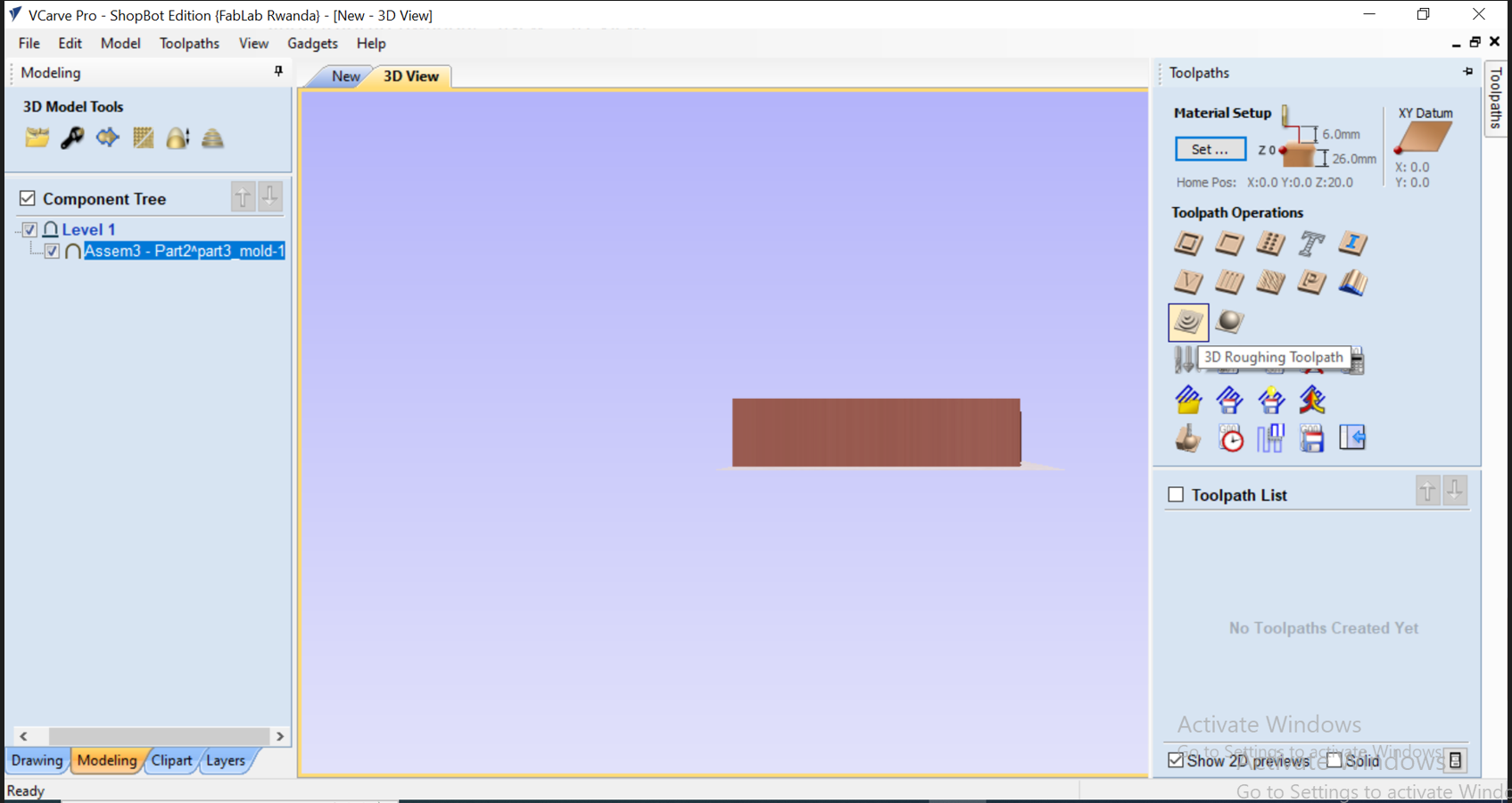

In the CNC machine cutting process, the mold design created in SolidWorks is translated into machine-readable code, which guides the CNC machine to precisely carve out the mold components from a chosen material. Once the cutting is complete, the individual mold components are imported into V curve software, where they are represented as three-dimensional models. This software allows for further analysis, modifications, and simulation of the mold components, aiding in the optimization and finalization of the mold design before proceeding to the manufacturing stage.Afterward, the subsequent action involves importing the individual components of the mold into the V curve as three-dimensional models.

-

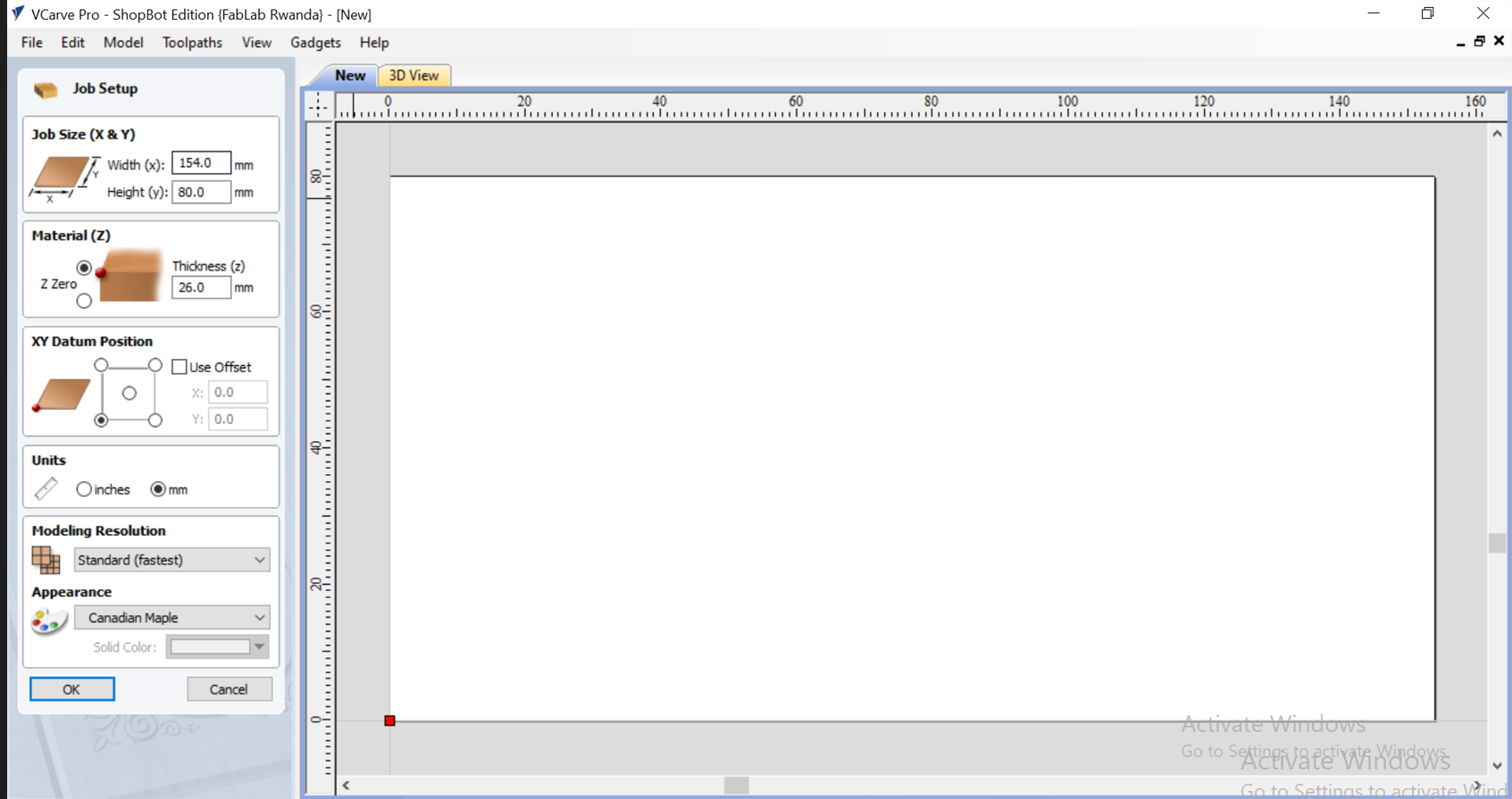

Open V-Curve Pro

-

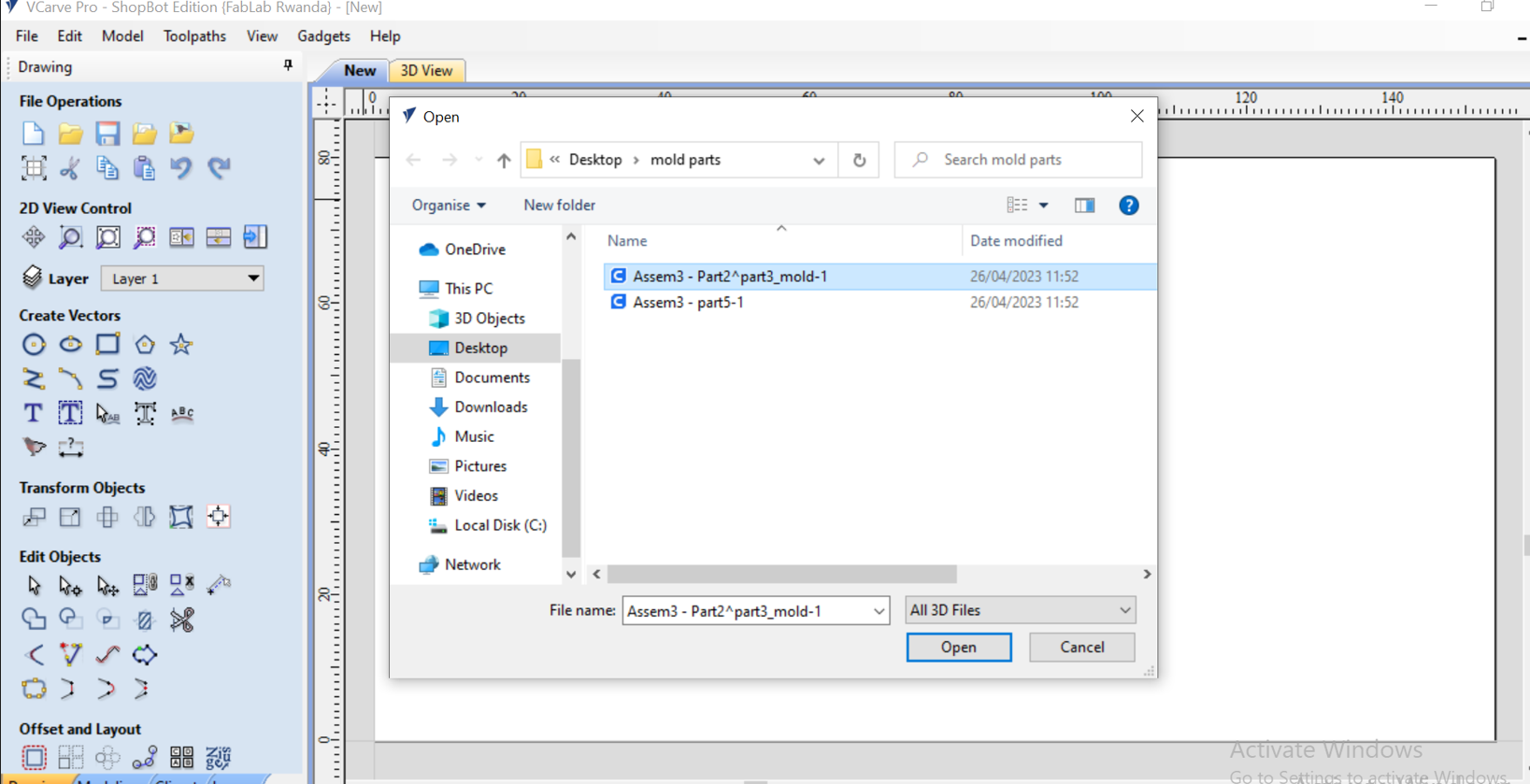

Click on create new file and import the 3D files

-

setting the bed size of the wax to be used

-

Open the STL file with V-Curve Pro

-

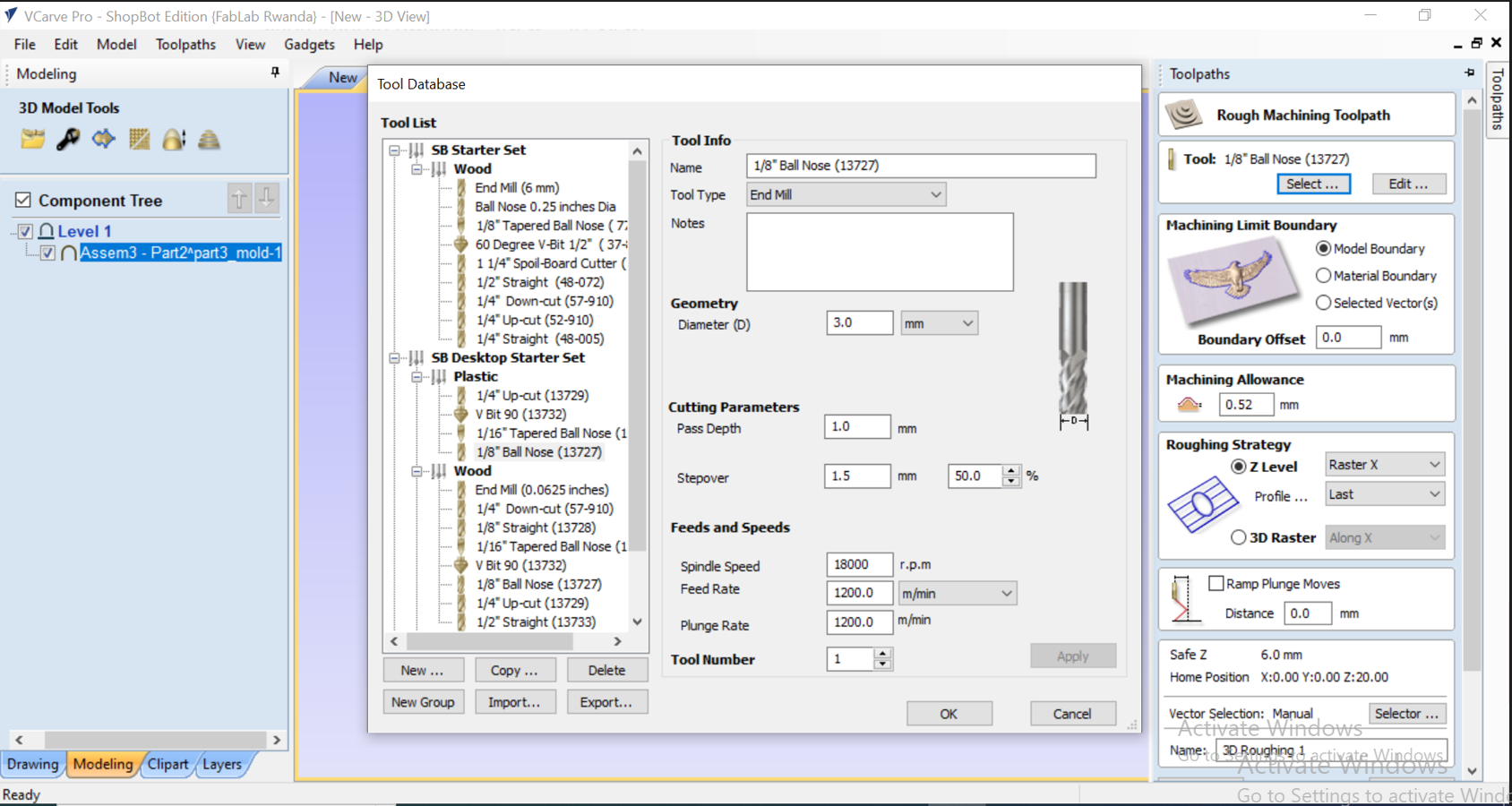

Place the workpiece, and adjust the settings (applying the 3D rough surface).

-

Choose the tool to be used. In this case, a ball nose with a diameter of 3 mm (1/8 ball nose) is used.

Using ShopBot CNC Router to cut and/or make the mold

Cutting the mold on a ShopBot CNC Router machine involves using computer-controlled precision to carve out the desired mold design from a chosen material. The ShopBot CNC Router utilizes various cutting tools and techniques to accurately shape the mold components, ensuring high-quality results. This automated process allows for efficient and consistent production, reducing manual labor and providing precise control over the cutting process.

Starting the software of CNC Shopbot

CNC ShopBot while performing cutting to form/make mold

Here below is the generated mold from the Blue Ferris File-A-Wax material:

Casting

A liquid substance is often poured into a mold that has a hollow chamber in the desired shape during the casting manufacturing process, and the material is then let to harden. A casting, which is the term for the solidified component, is ejected or broken out of the mold to complete the procedure. Common casting materials include metals and a variety of cold-setting substances that harden after being mixed with two or more other substances. These substances include epoxy, concrete, plaster, and clay. Casting is most frequently used to create intricate shapes that would be challenging or expensive to create using alternative techniques.

beeswax: is the material I am going to use in casting

Beeswax is a natural substance produced by honeybees. It is secreted by worker bees to build honeycombs. Beeswax is a yellowish or brownish solid with a waxy texture and a characteristic honey-like scent. It has various applications, including candle making, cosmetics, pharmaceuticals, and as a protective coating for wood and leather.Here below is the picture of beeswax

To read the Safety Data Sheet of beeswax, click here

Here below is the USED COOKING OIL that I am going to use in order to prevent melted beeswax from sticking to the mold

To read the Safety Data Sheet of used cooking oil, click here

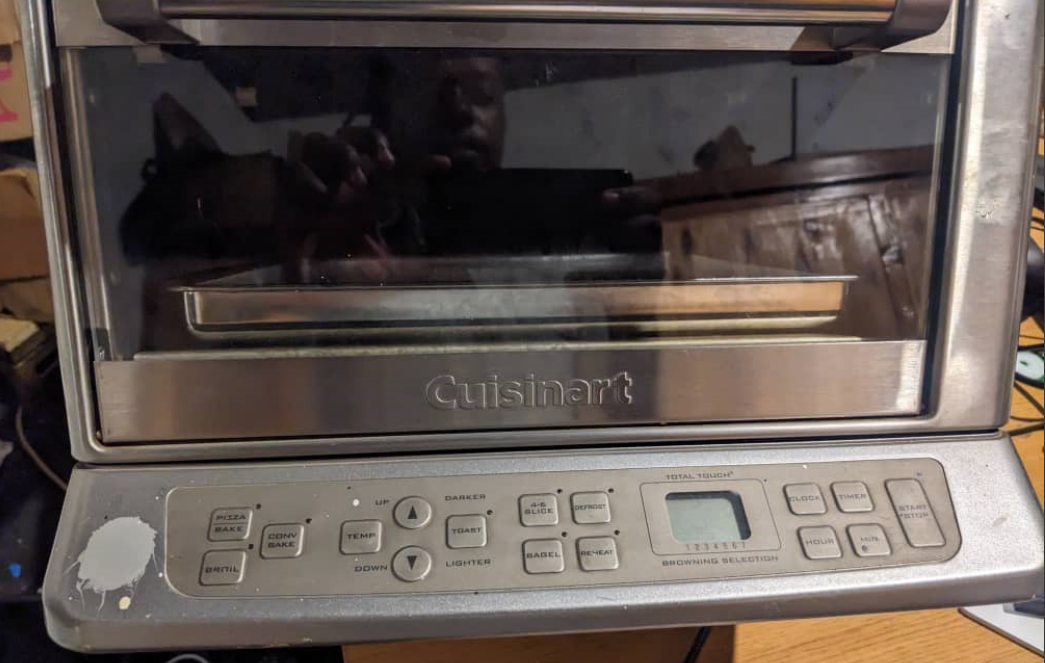

I am going to use the cuisinart to heat the beeswax in order to get it in liquid form

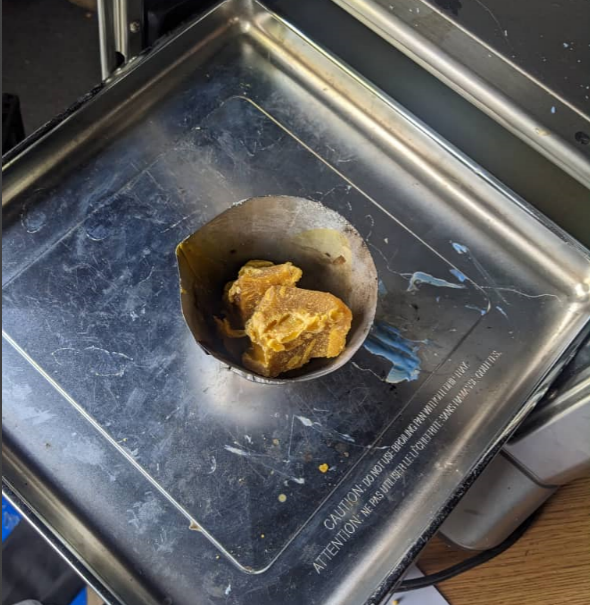

Here below is the beeswax ready for being heated in the cuisinart

Here below is the resulting beeswax in liquid form

Here below I am using the injection molding technique for pour the melted beeswax into the mold

Here below is the hero shot video to express what I did as molding and casting

Challenges that I faced:

Regrettably, the casting didn't achieve the desired outcome due to the absence of a mold-release agent. Despite my efforts in the FabLab Rwanda, I was unable to locate any lubricant suitable for this purpose. Consequently, after an extensive and unsuccessful search for a substance to prevent the melted beeswax from sticking to the mold, I resorted to utilizing easily accessible used cooking oil obtained from chicken as an alternative solution.

However, as evident in the video preceding this one, the utilization of used cooking oil proved to be ineffective. It was a challenging endeavor to extract the casting product, which resulted in the melted bar soap not attaining a desired shape.

-

Click here to download all the files that I used for molding and casting.

© 2023 | Eric NDAYISHIMIYE | All Rights Reserved