MACHINE DESIGN

Group Assignment

-+1.Design a machine that includes mechanism + actuation + automation + application

2.Build the mechanical parts and operate it manually.

3.Document the group project

4.Actuate and automate your machine.

5.Document the group project.

Group Assignment

This week group assignment was to design and make machine. our group i made by 9 participants and we have selected two machine types : one is Arm robot and other one is laser cutter machine.the group work is documented

Individual Assignment

#Document your individual contribution.

My Contribution

My task was to do assembling of our machine robotic arm and laser to complete our assignment.

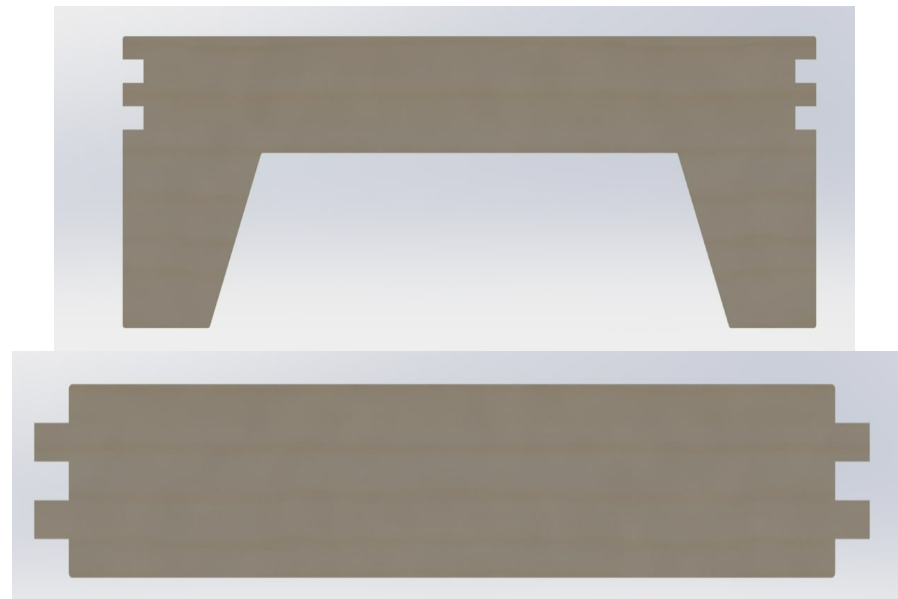

Our Design for lazer machine

For Y axix , we decided to use NEMA17 becuse the laser Head is not heavier

Tools used on our laser machine:

NEMA17 STEPPER MOTOR

NEMA23 STEPPER MOTOR

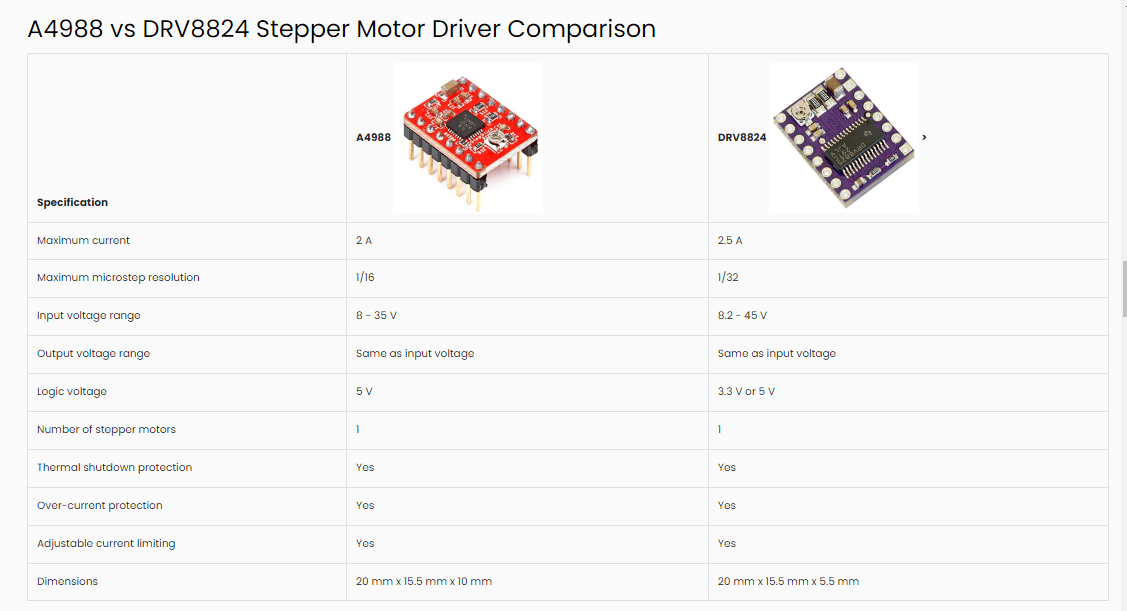

From the power perspective, both A4988 and drv8824 , produce current lower that 2.5 A where NMA 23 CONSUMES 2.7 a PER PAHSE. here we have used NEMA17 for A4988 because it is what we have .

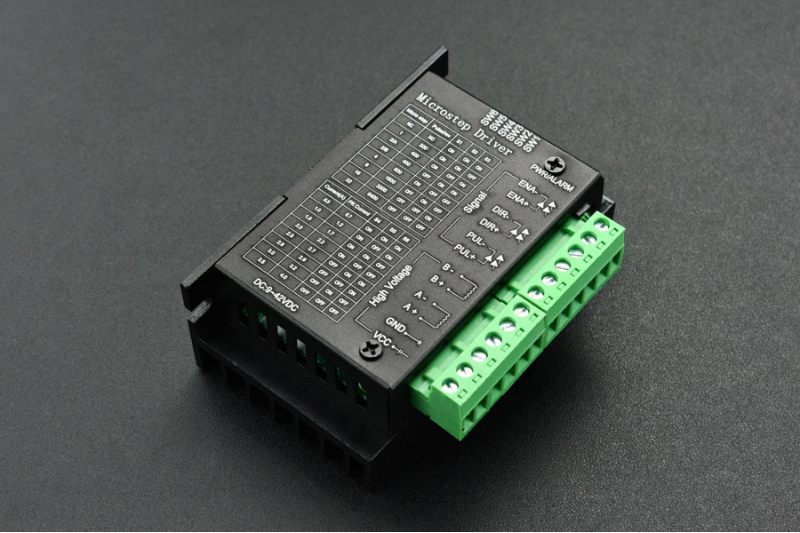

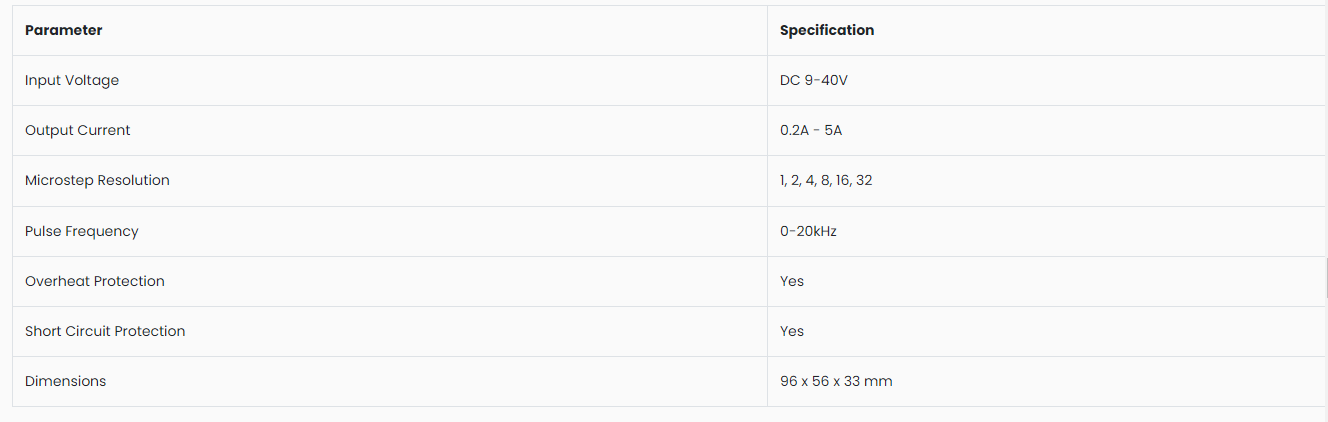

TB600 Stepper motor driver

Most thing to know about this driver is tha it can provide up to 5A which is adequate current for our NEMA23 stepper driver

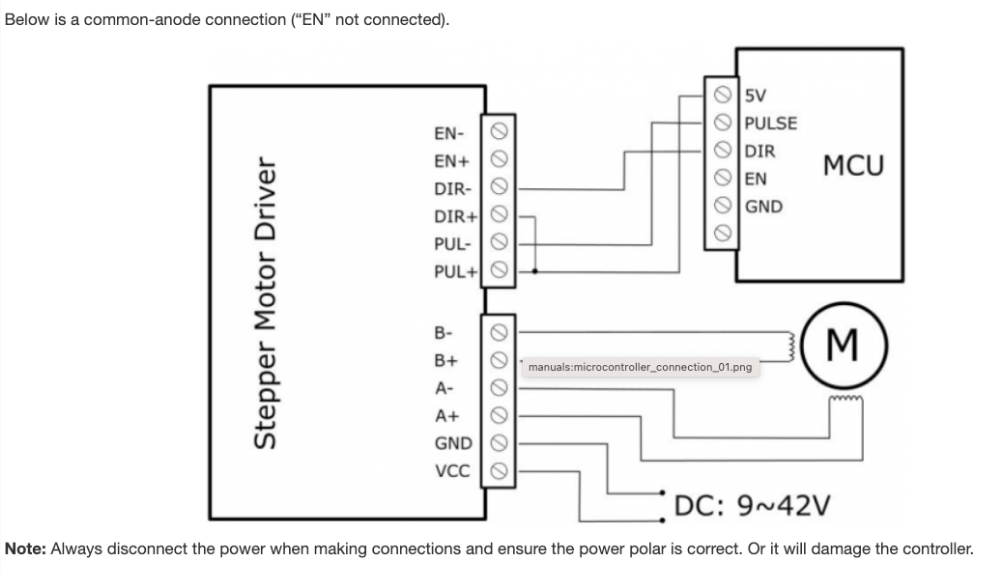

Microcontroller Connection For TB6600 STEPPER MOTOR DRIVER

The source of the image

Team member working on different tasks

Robotic Arm

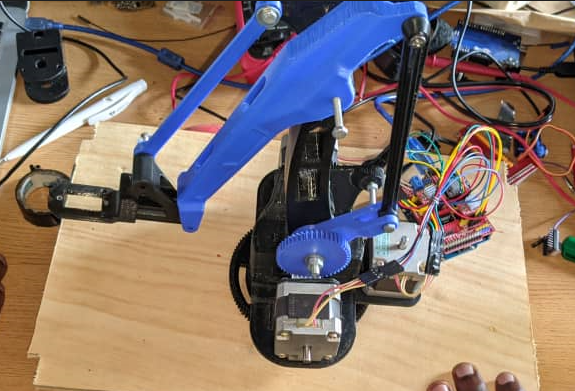

As my contribution to do assembling on our assignment here is the assembling robotic arm

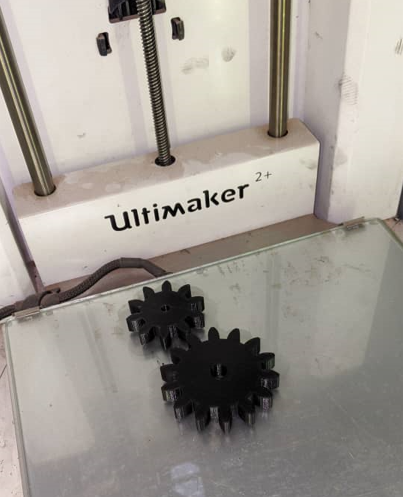

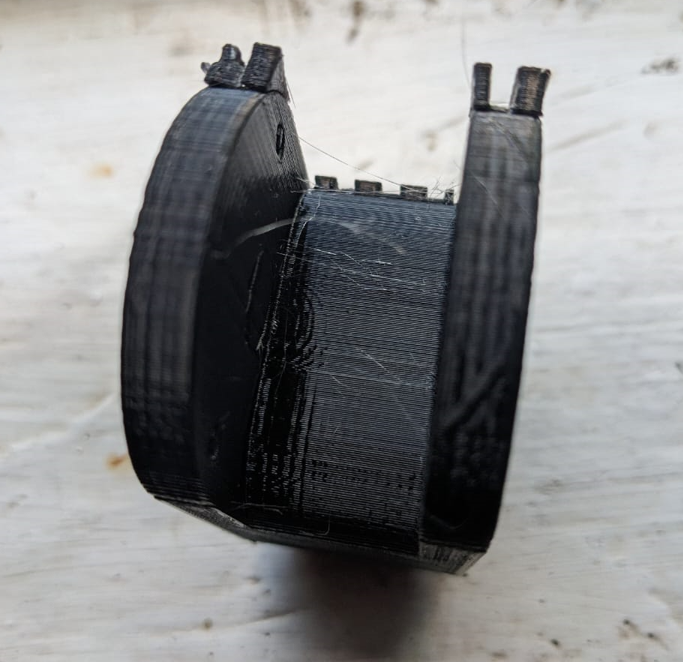

Here are same parts of our robotic after being printed

Starting assembling

After assembling and our arm robot is ready to be used

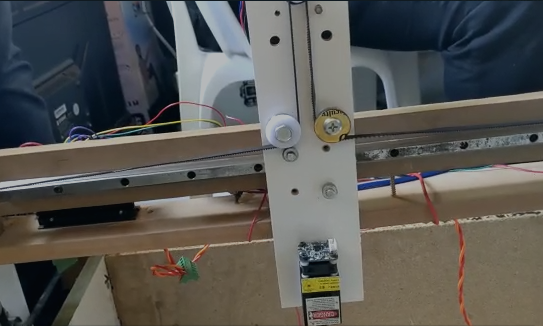

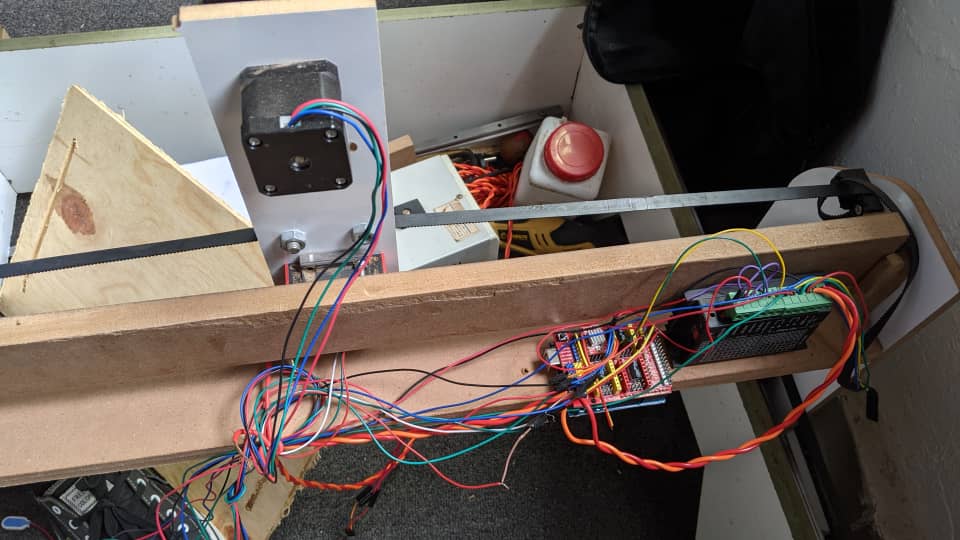

Assembling for Lazer machine

As i said before my contribution in this week assignement is to do assembling sofar

My contribution to this work was assembly in order to get the final product and down here there are all procedures I passed through toward the complete and working machine.

Here are the steps by steps of assembling laser machine:

1.Here are same image of Design for laser in software

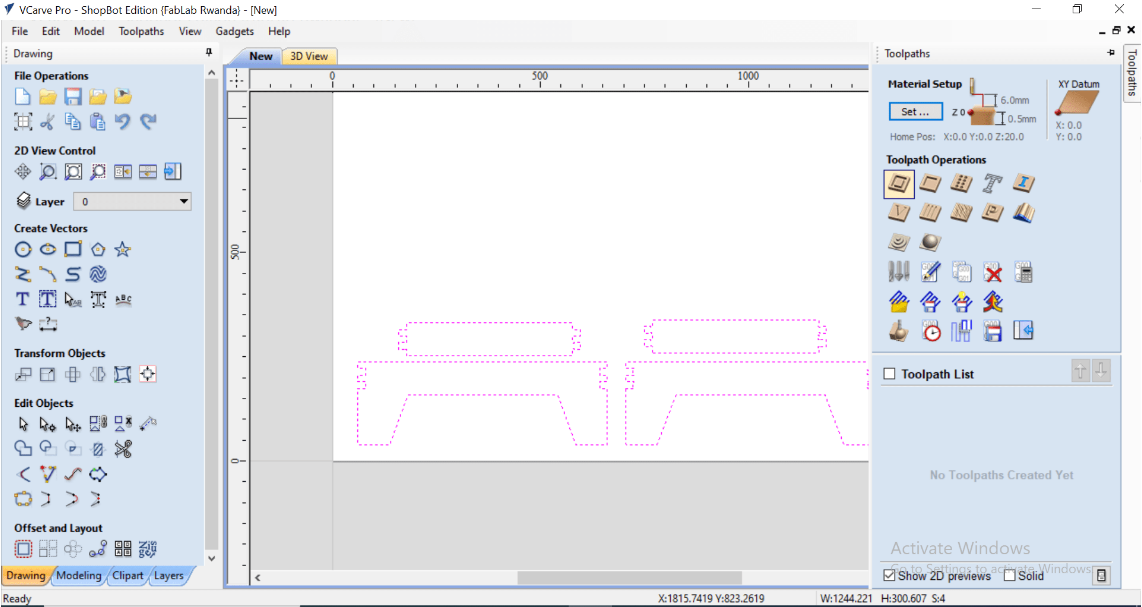

2.Next here is setting the toolpath:Setting the tool path for a CNC machine is important because it determines the path that the cutting tool will take to machine a part or component. The tool path is a set of instructions that tell the CNC machine how to move the cutting tool in three-dimensional space to produce the desired shape and dimensions of the part. Next step was to import our design of laser in cnc machine software

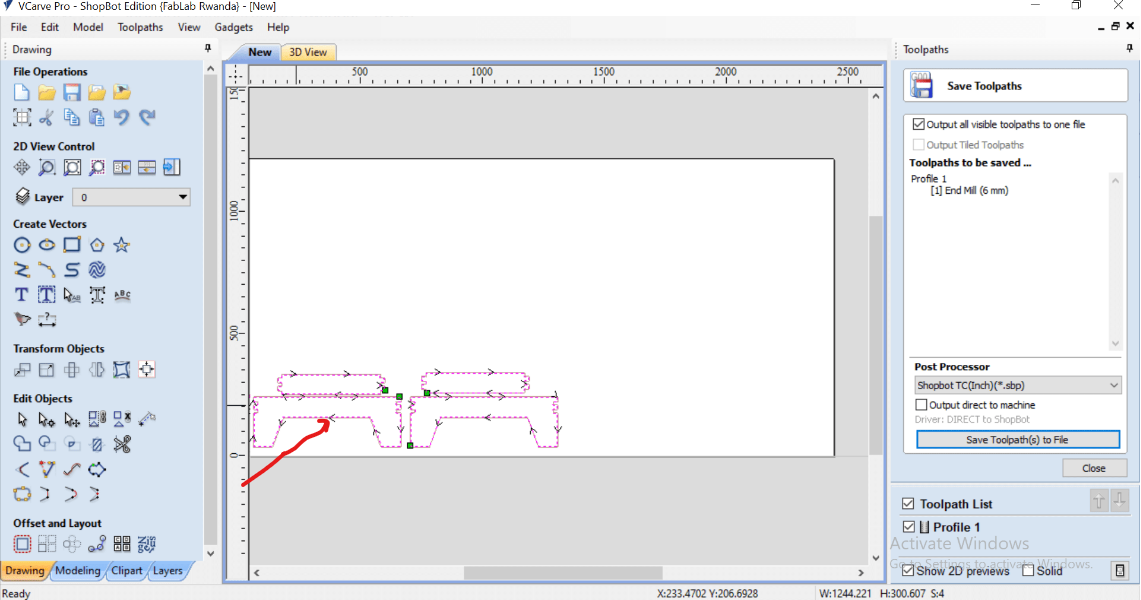

3.Here the next step was to check were the tool of cnc machine will pass the Image below shows how the tool will move when cutting

4.The next step was cutting

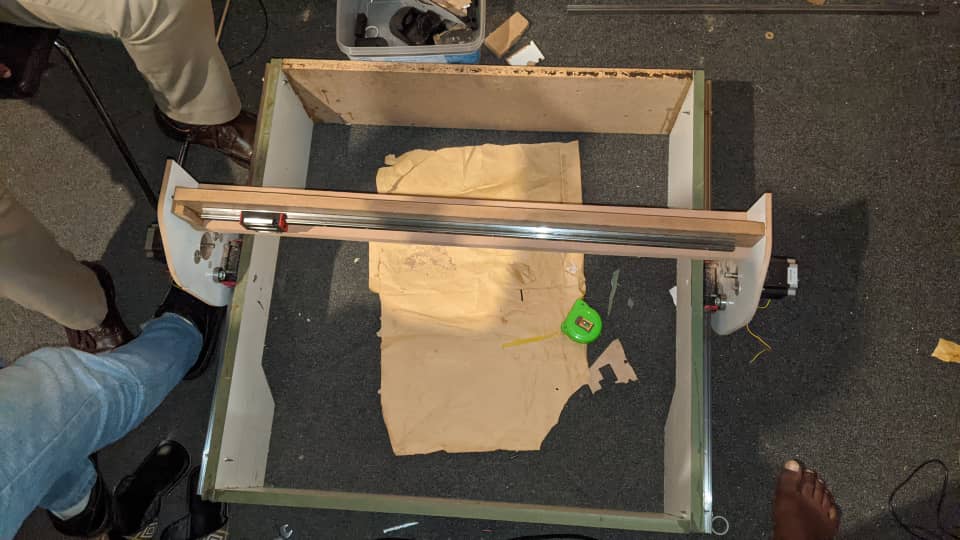

5.Assembling process

#Then assembling the cutted pieces

6.Assembling mechanical parts

#Assembling electronics parts

7.Connecting mechanical parts with electronic parts

Connecting laser eye as shown in the image below

.jpeg)

Connecting to the controller

After assembling the next step is to program and text the way it works