concept

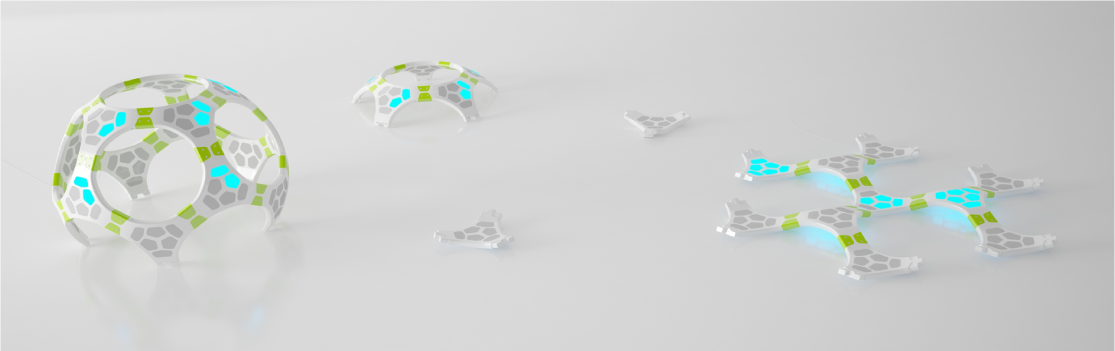

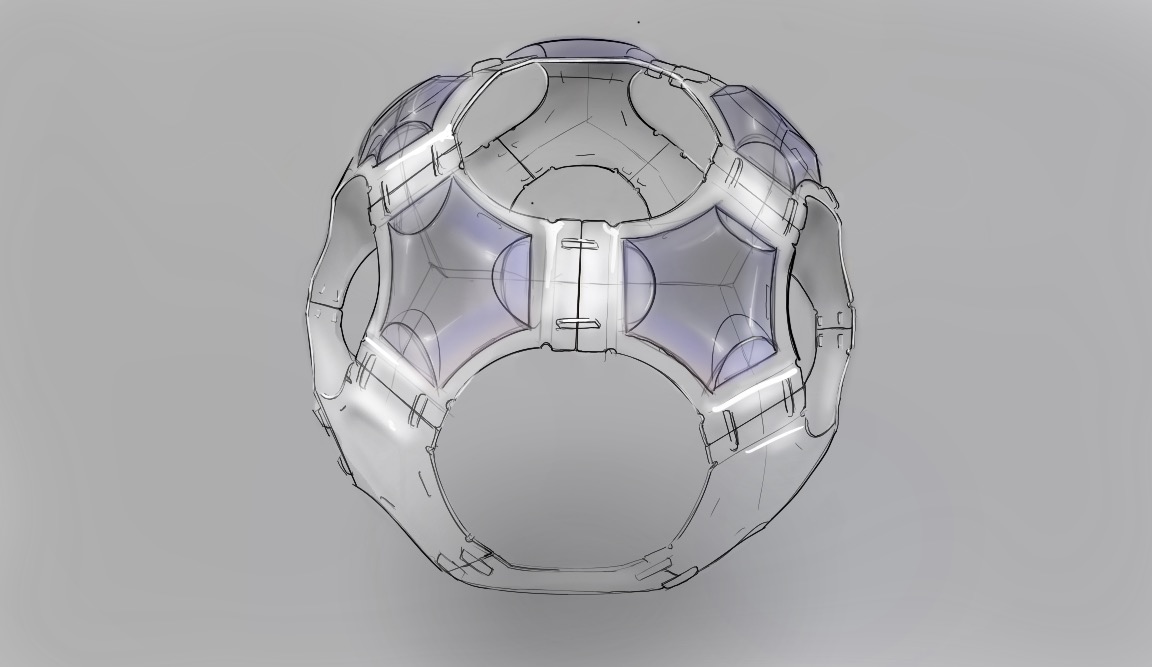

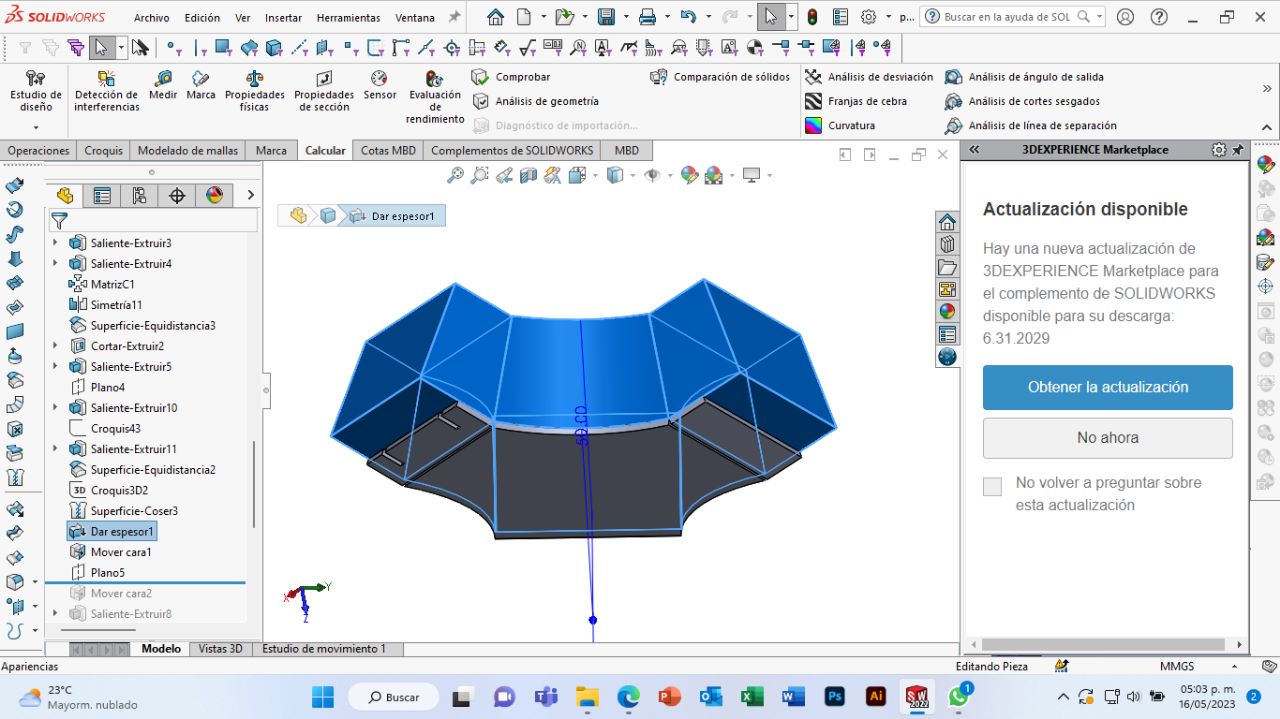

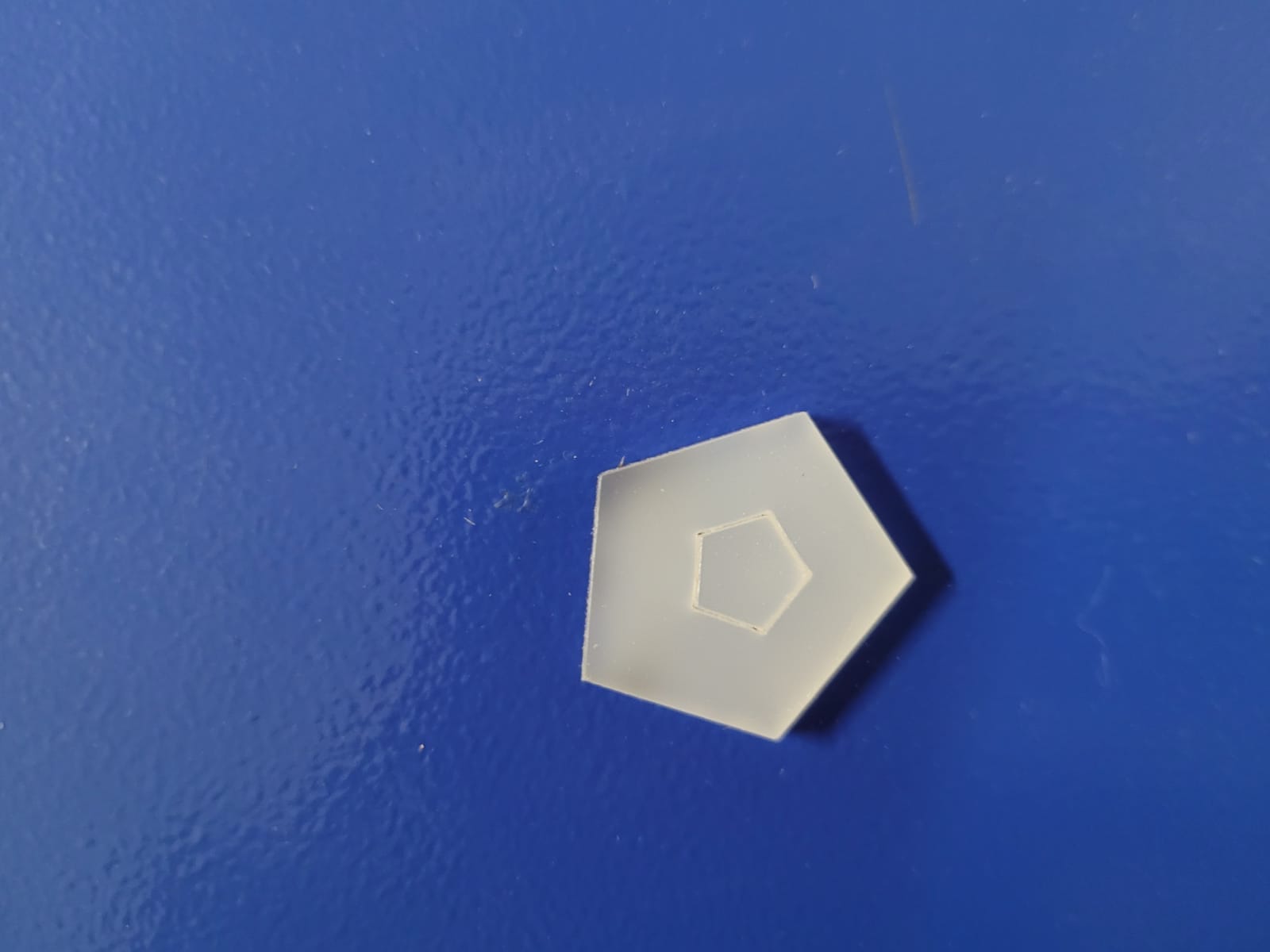

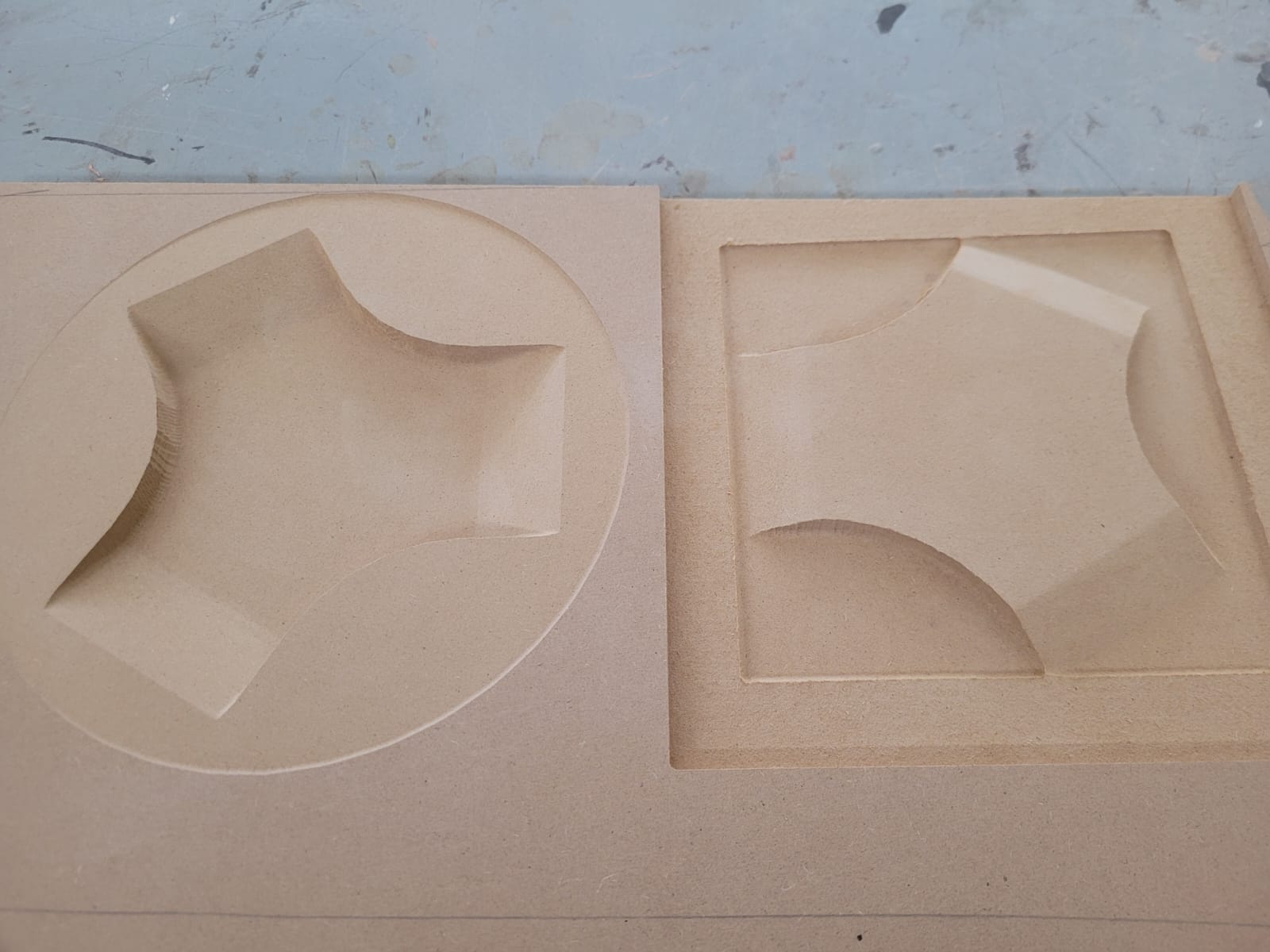

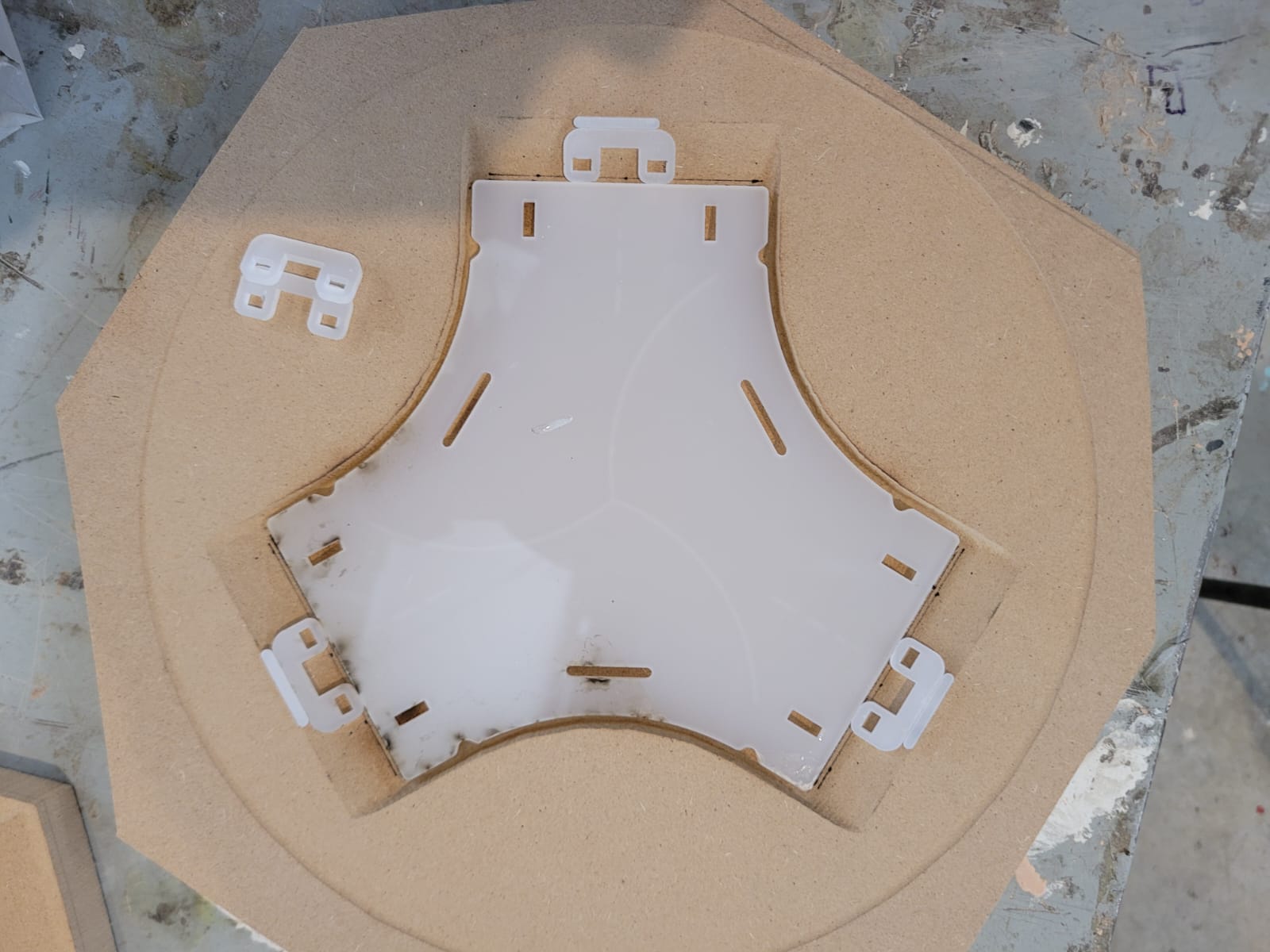

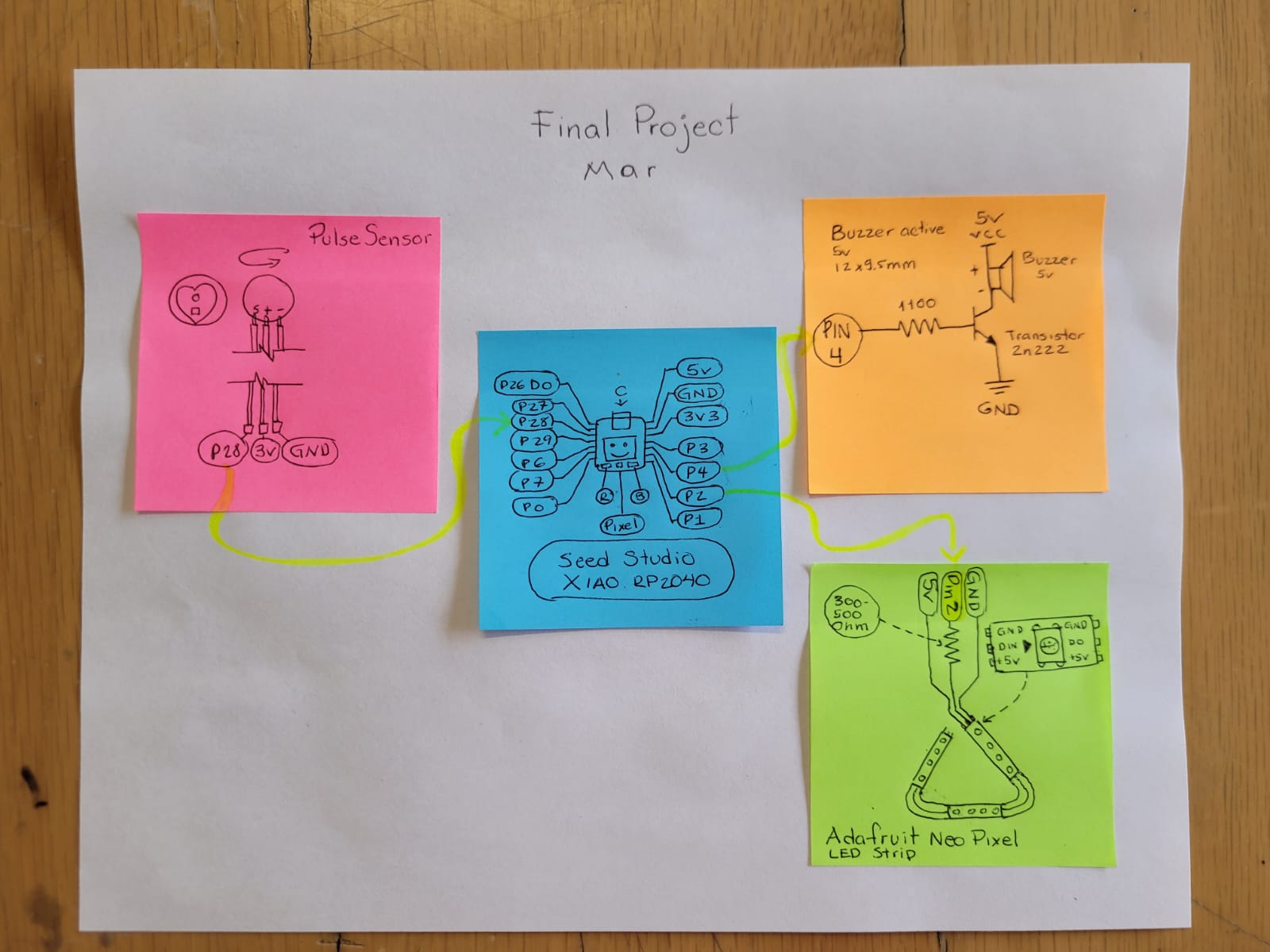

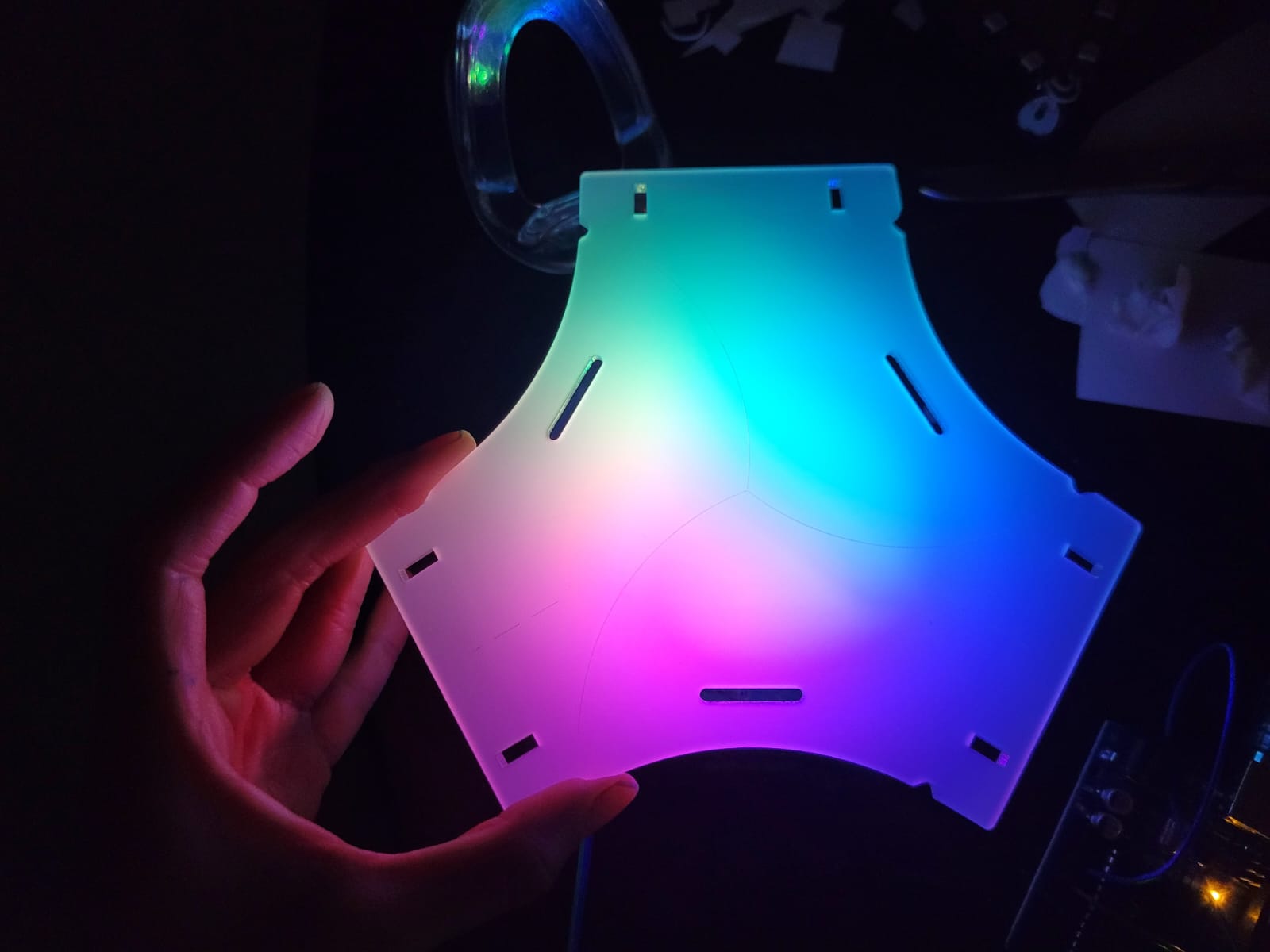

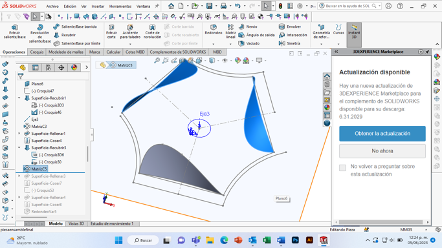

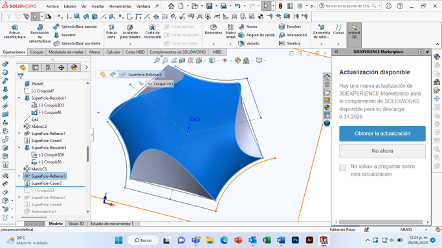

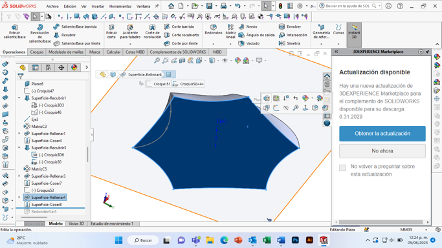

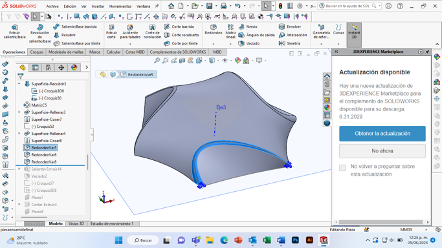

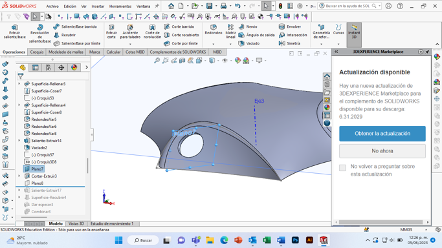

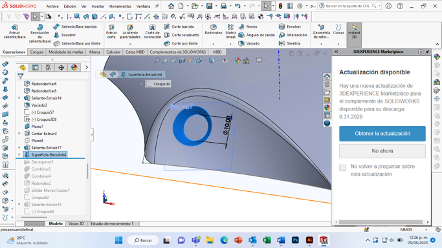

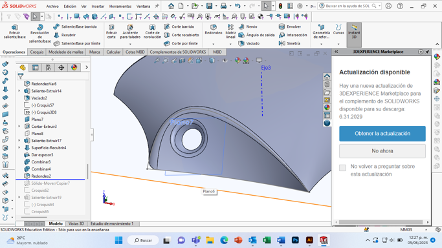

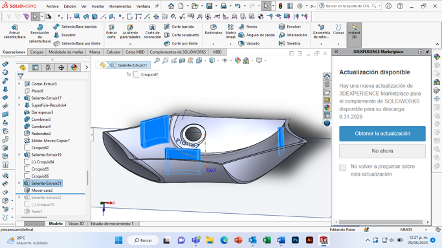

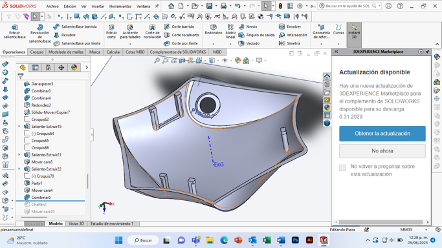

The concept borns from a bubble, which is the interpretation of a safe place for many children with hypersensitivity. The idea is to use this bubble to interact with his users and break itself to create other spaces in order to encourage outside interaction safely.

It is system, a multifunctional space to positively motivate interaction with the physical environment, in a child (10-12 years). with Autism (TEA).

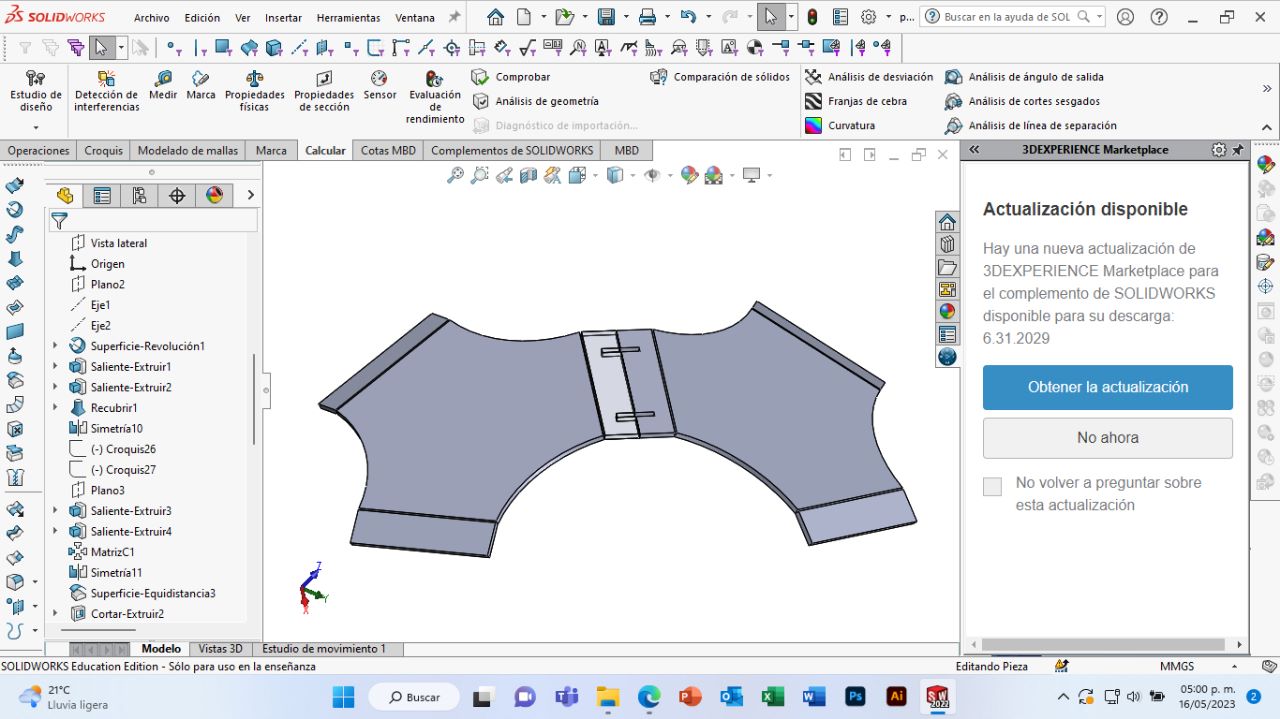

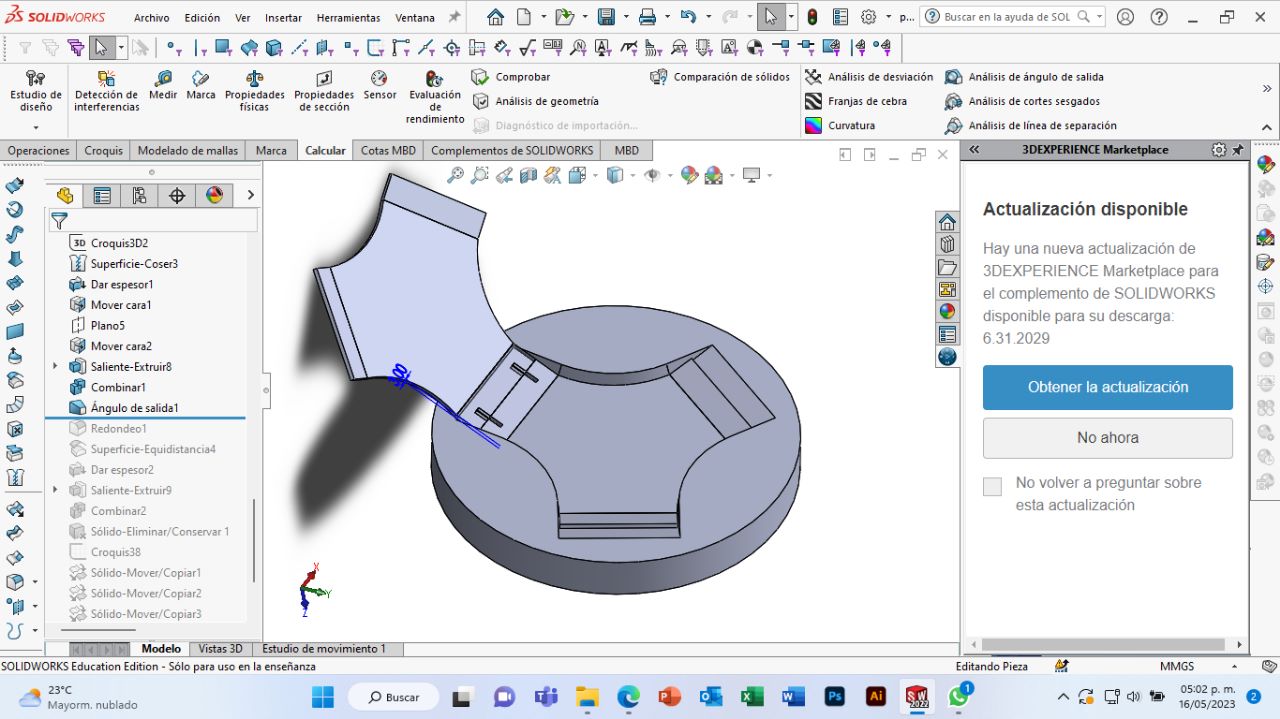

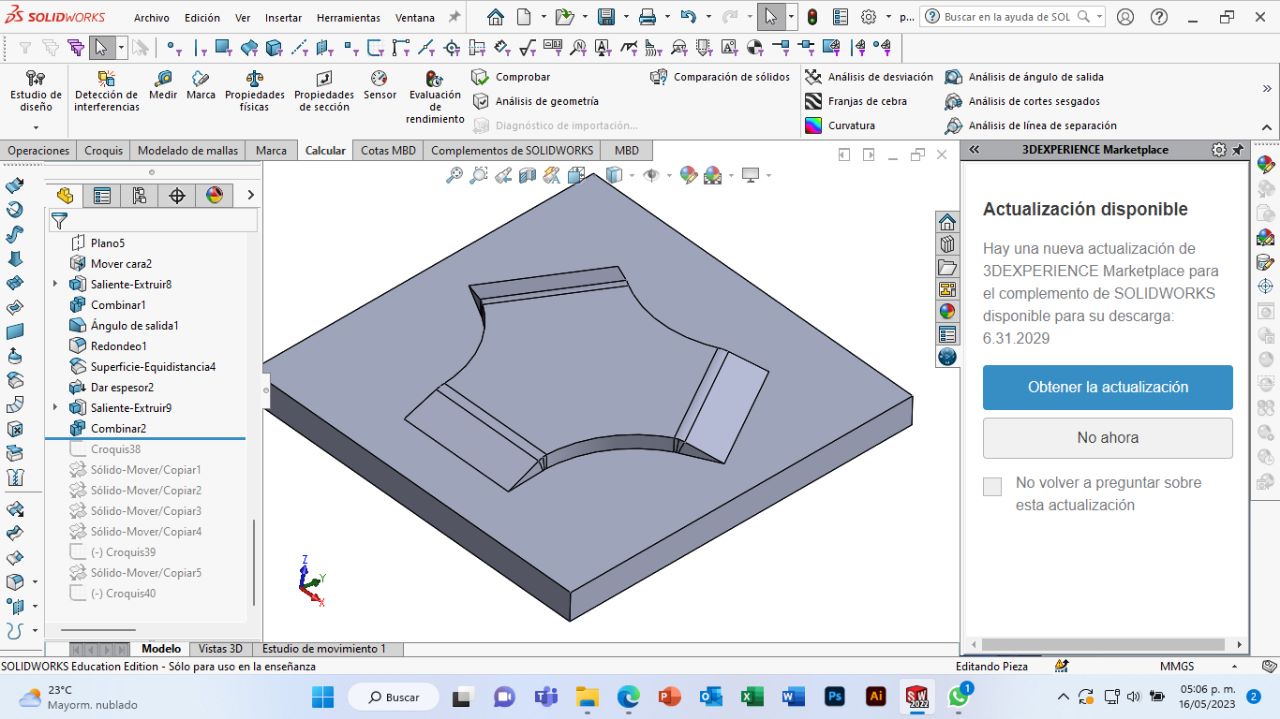

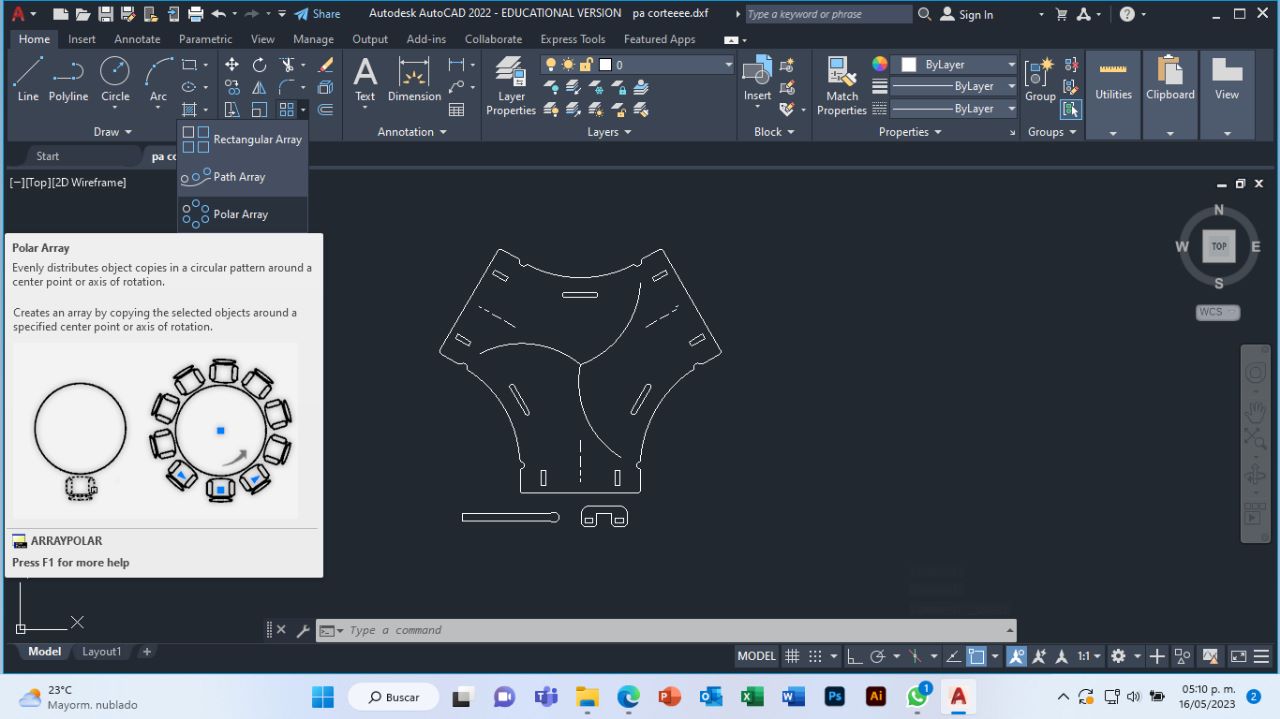

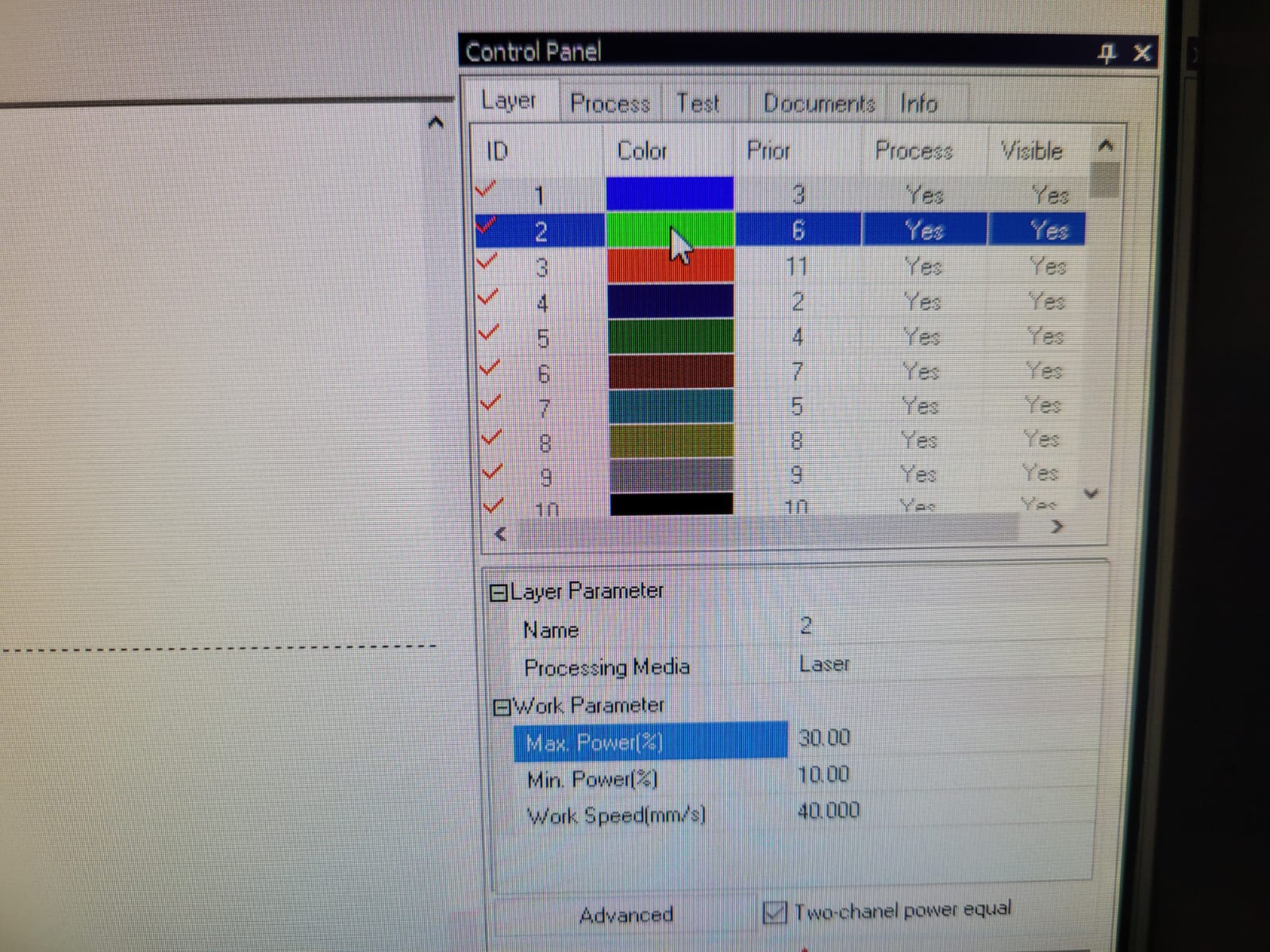

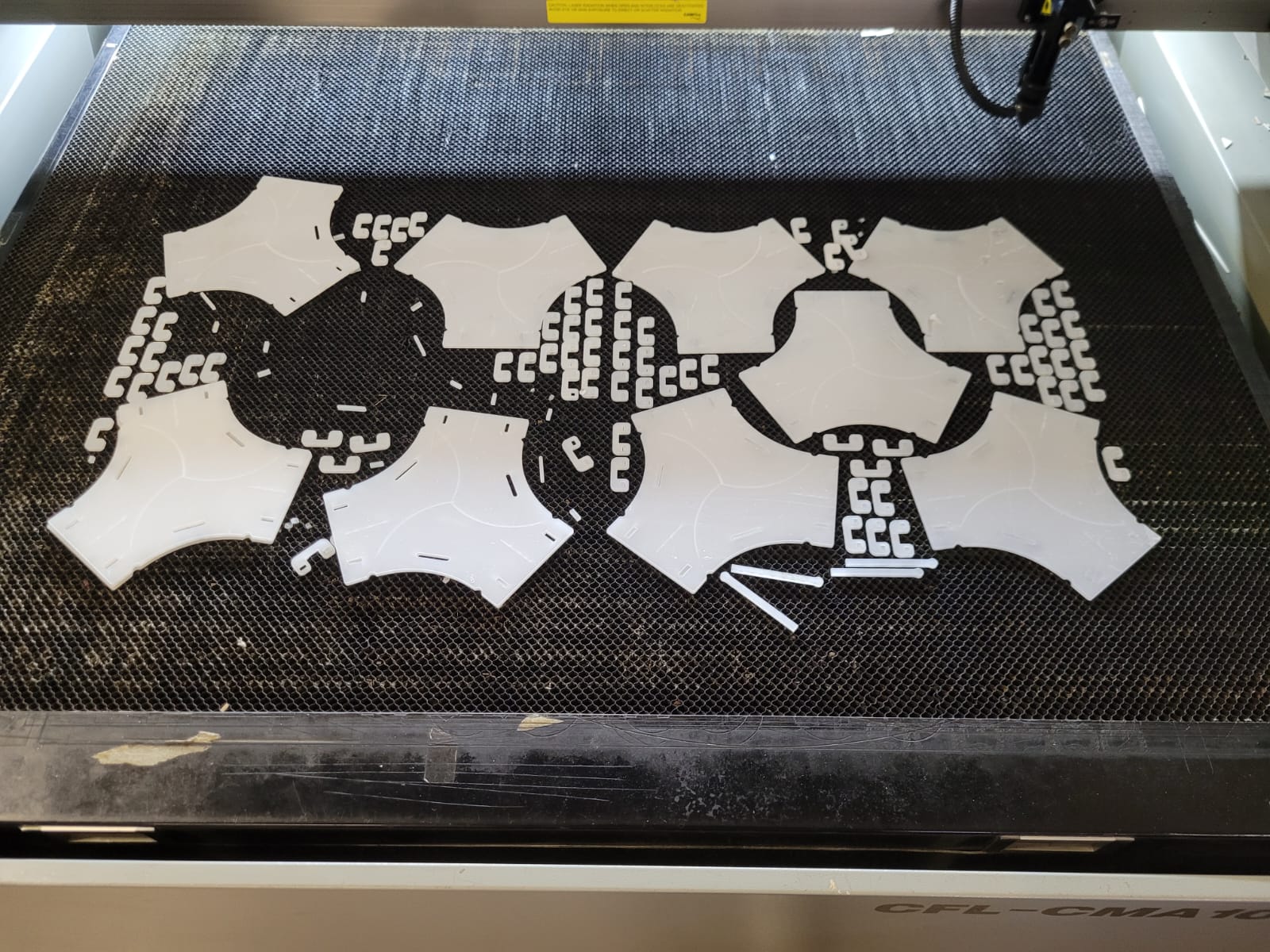

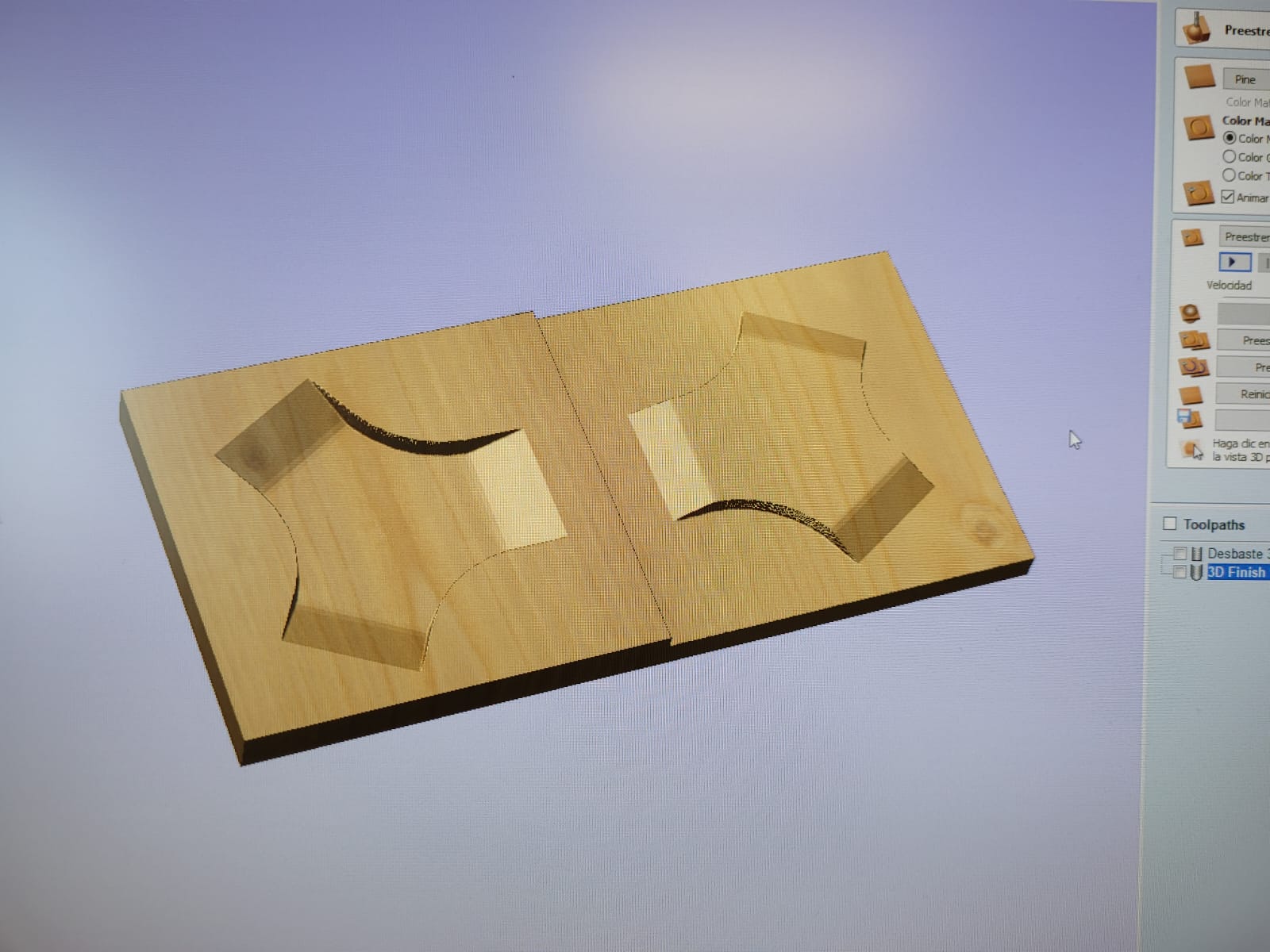

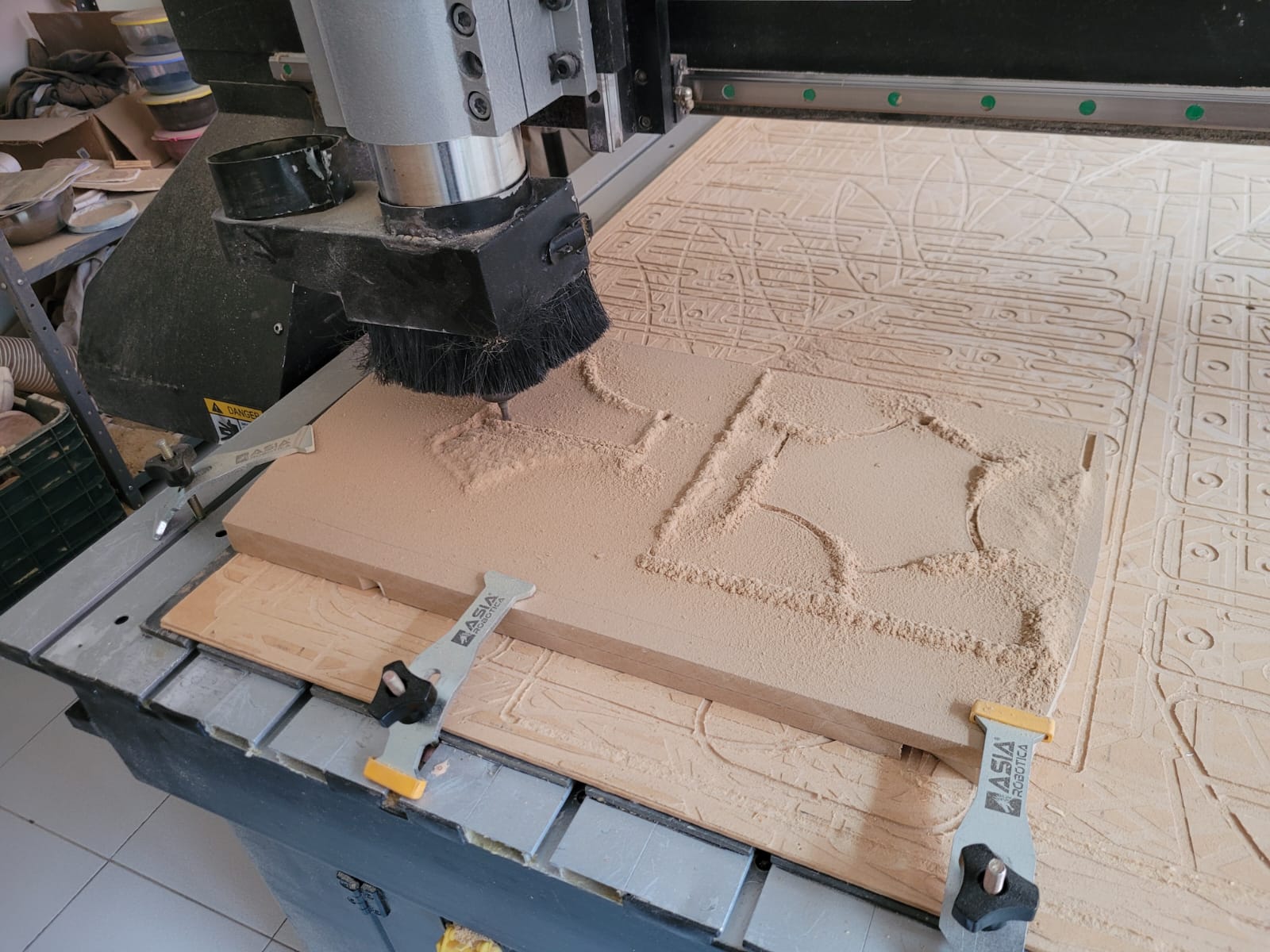

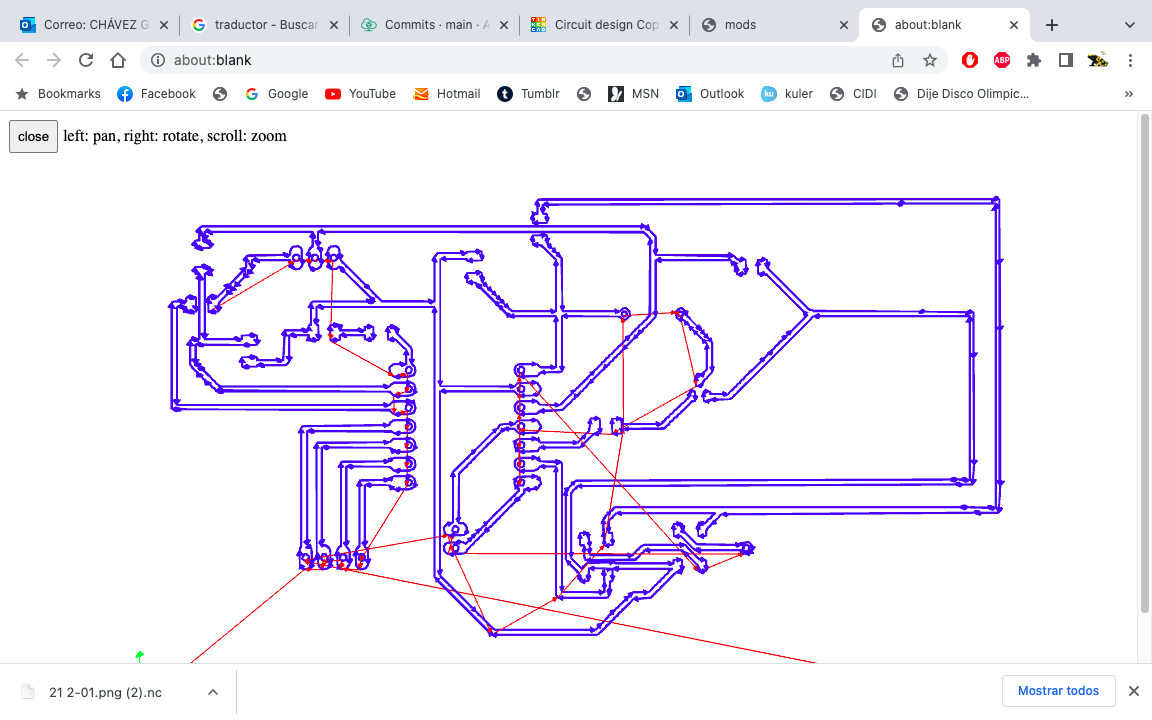

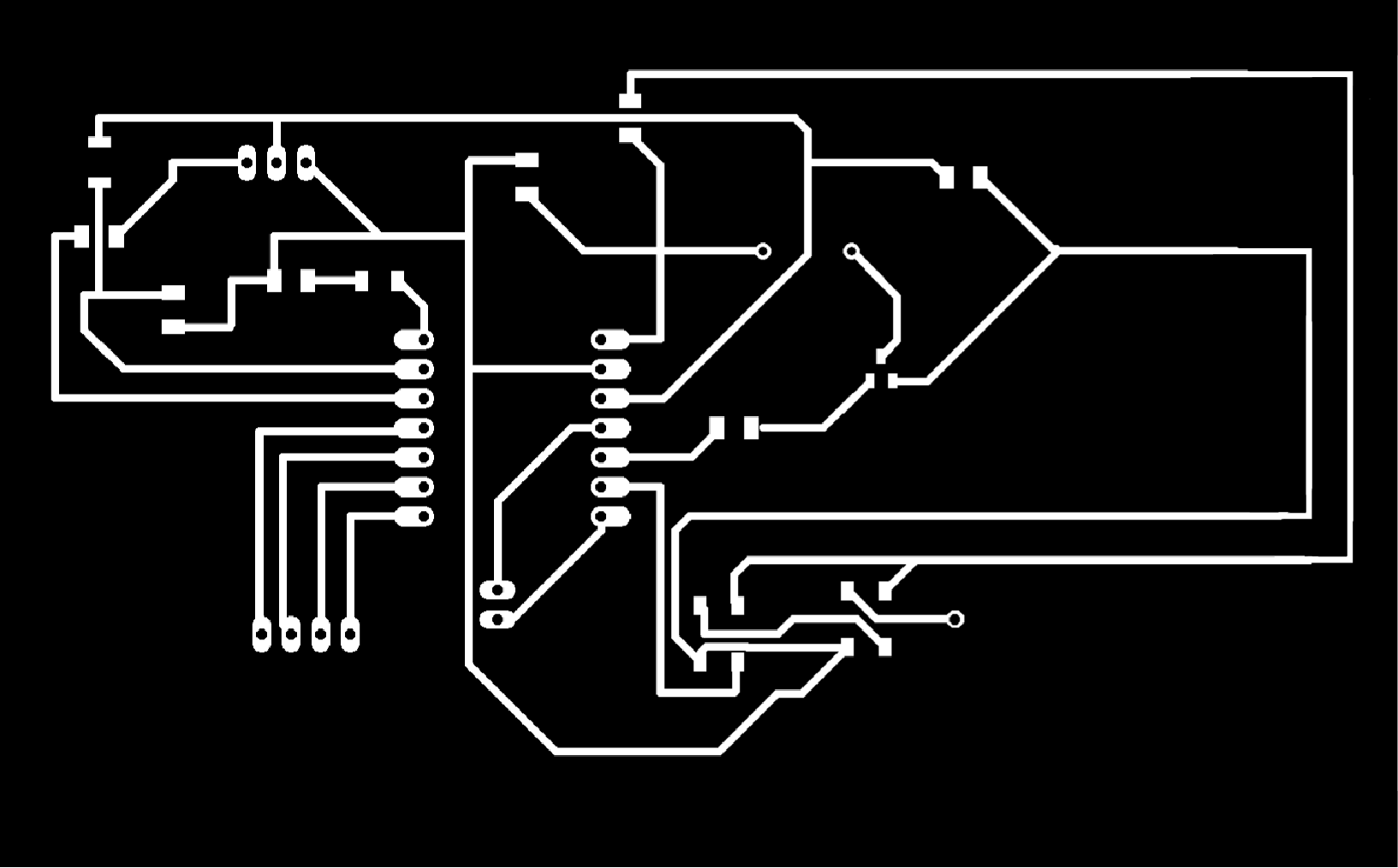

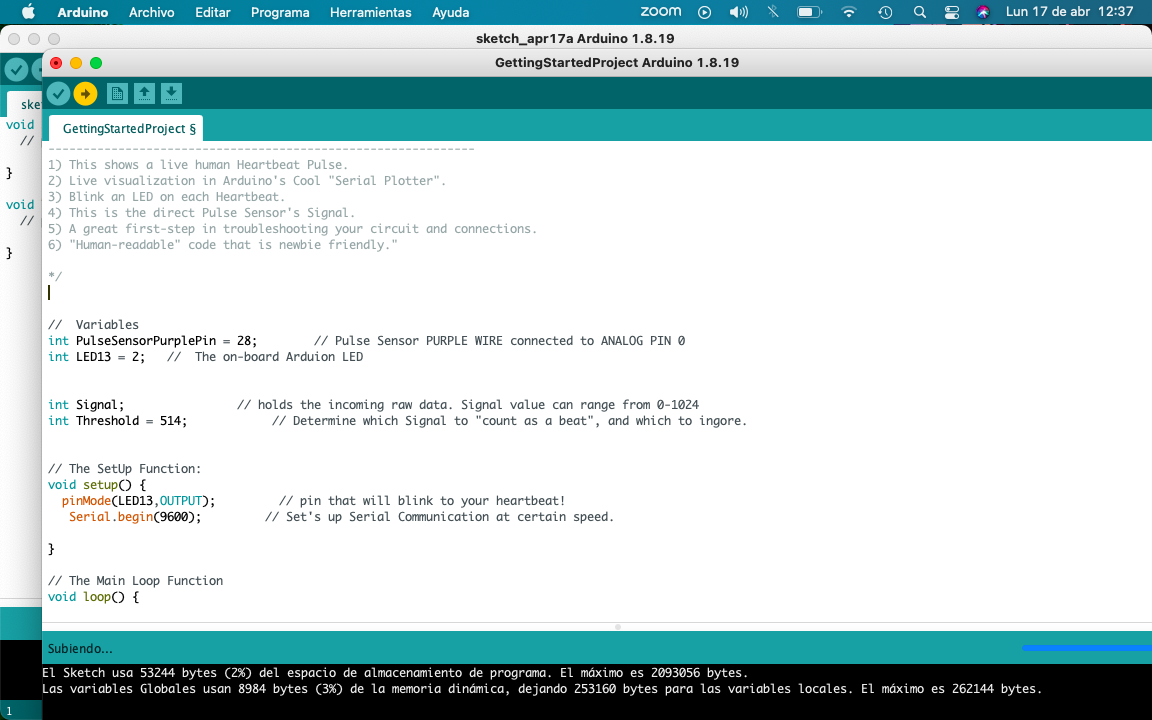

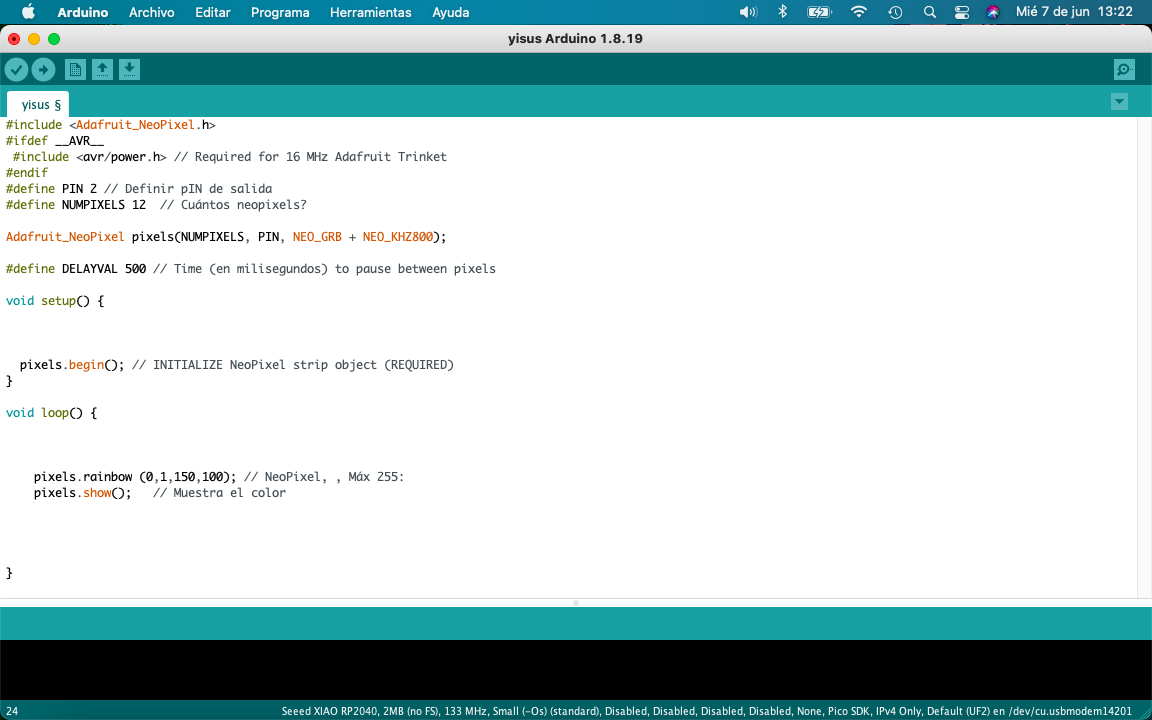

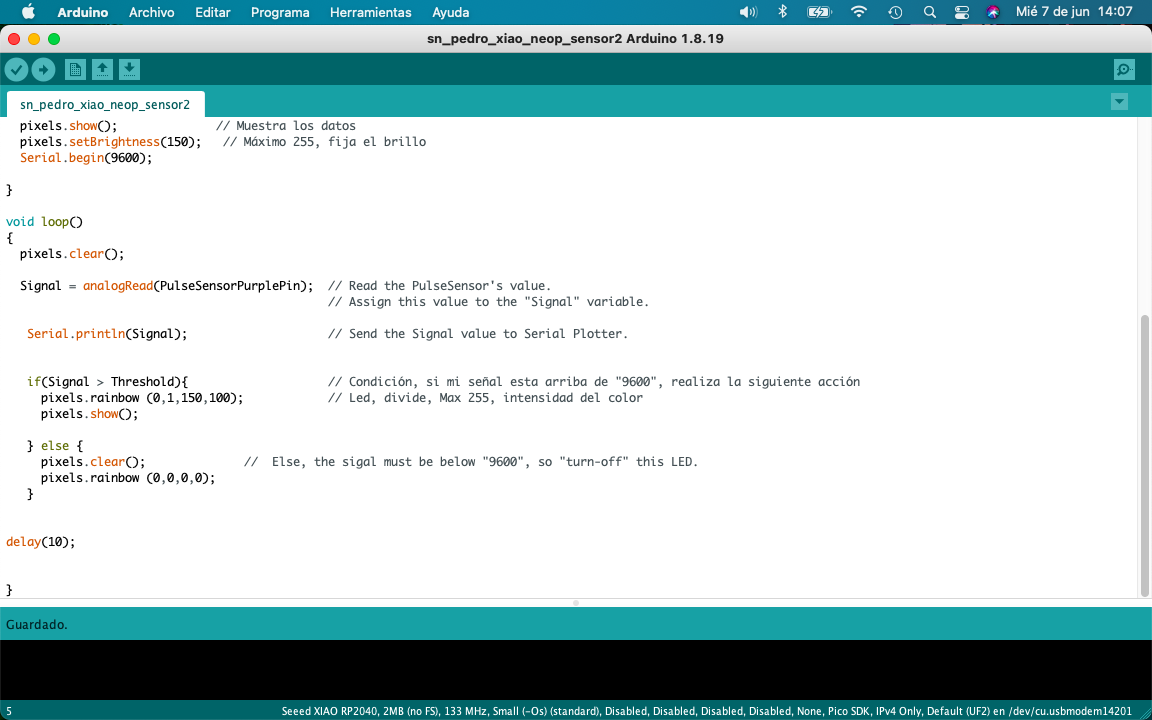

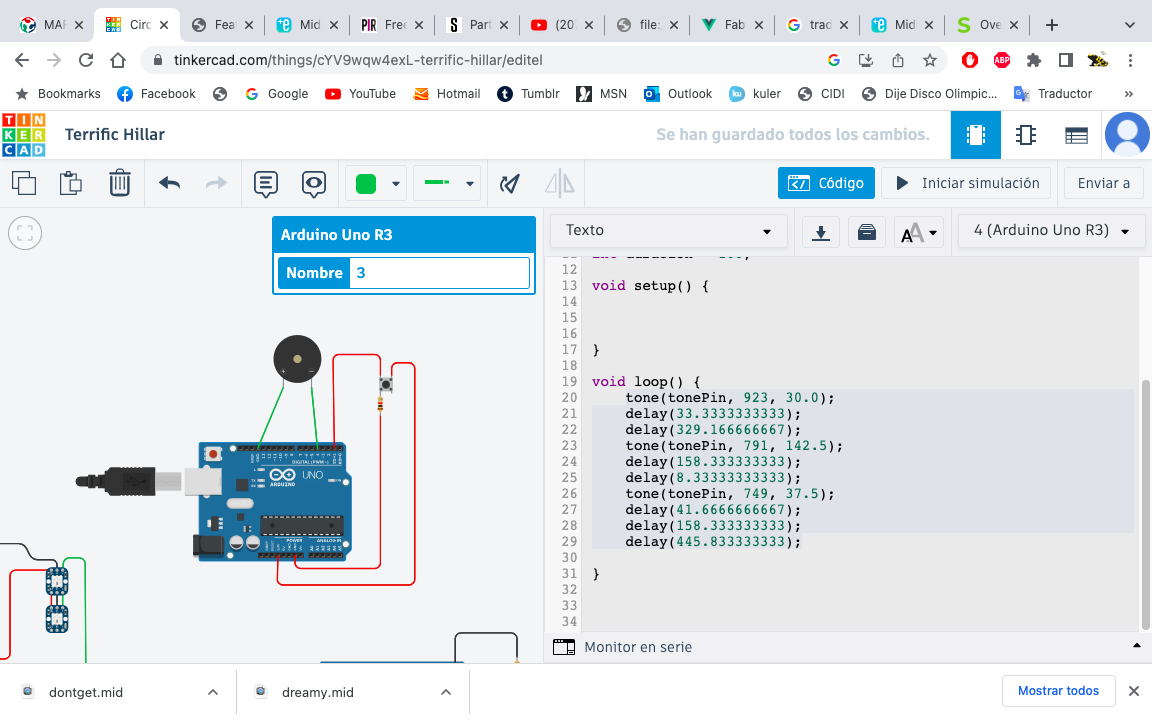

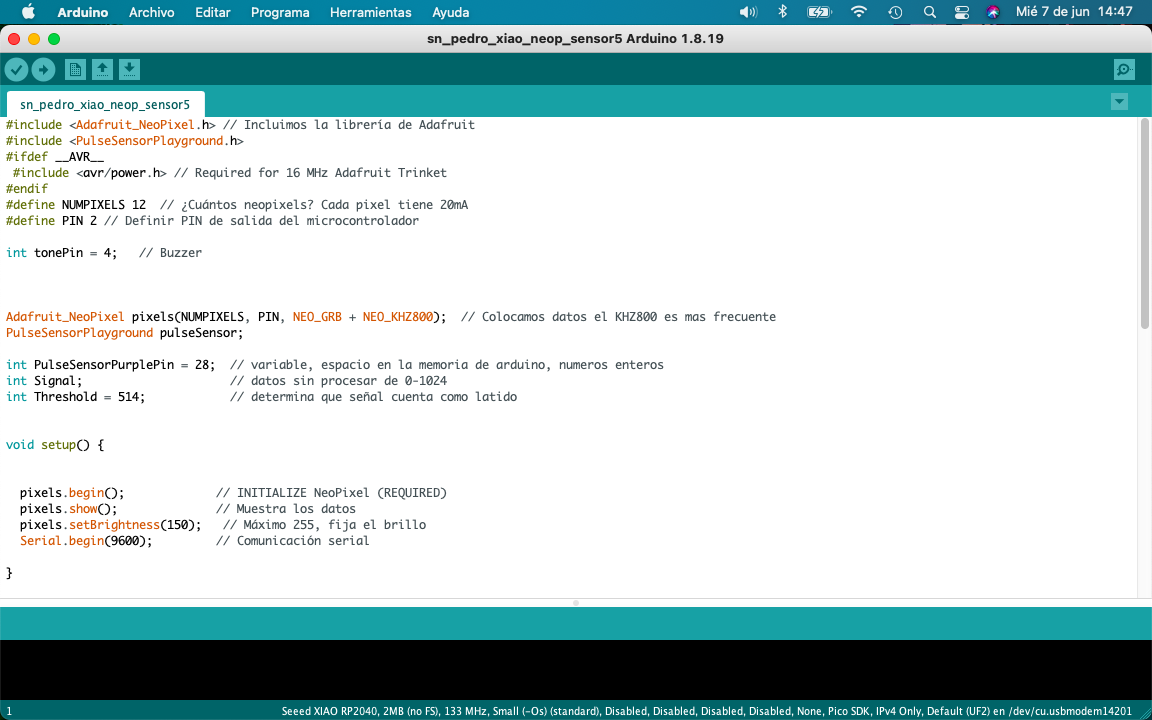

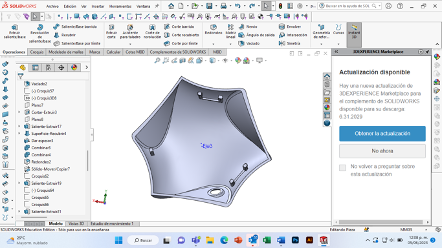

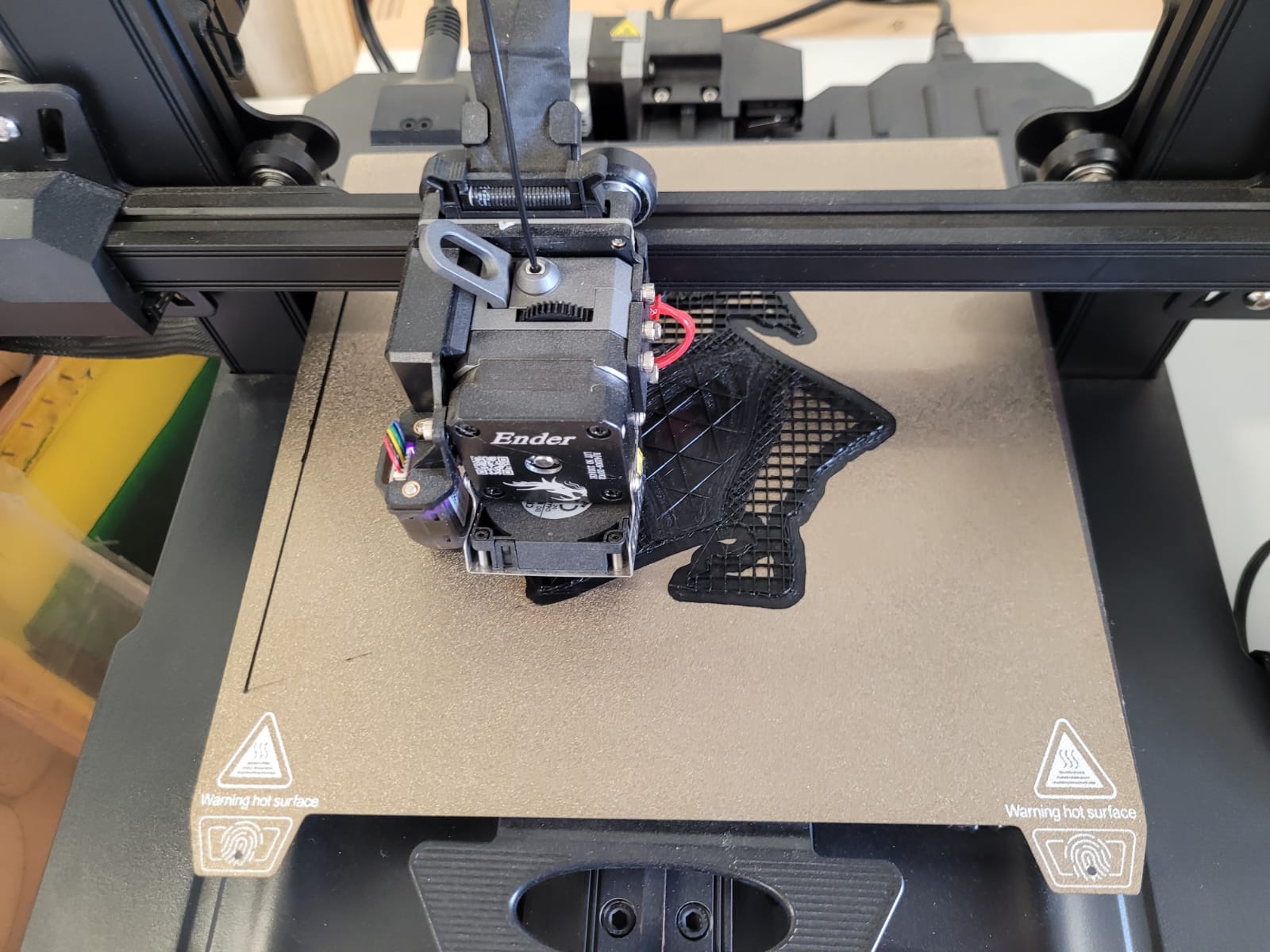

This is a modular system with multifunctional spaces in order to motivate positively physical interaction, it also improves interaction with the enviroment for one children and many other. Childrens practice their socialization abilities through a game with light patterns.

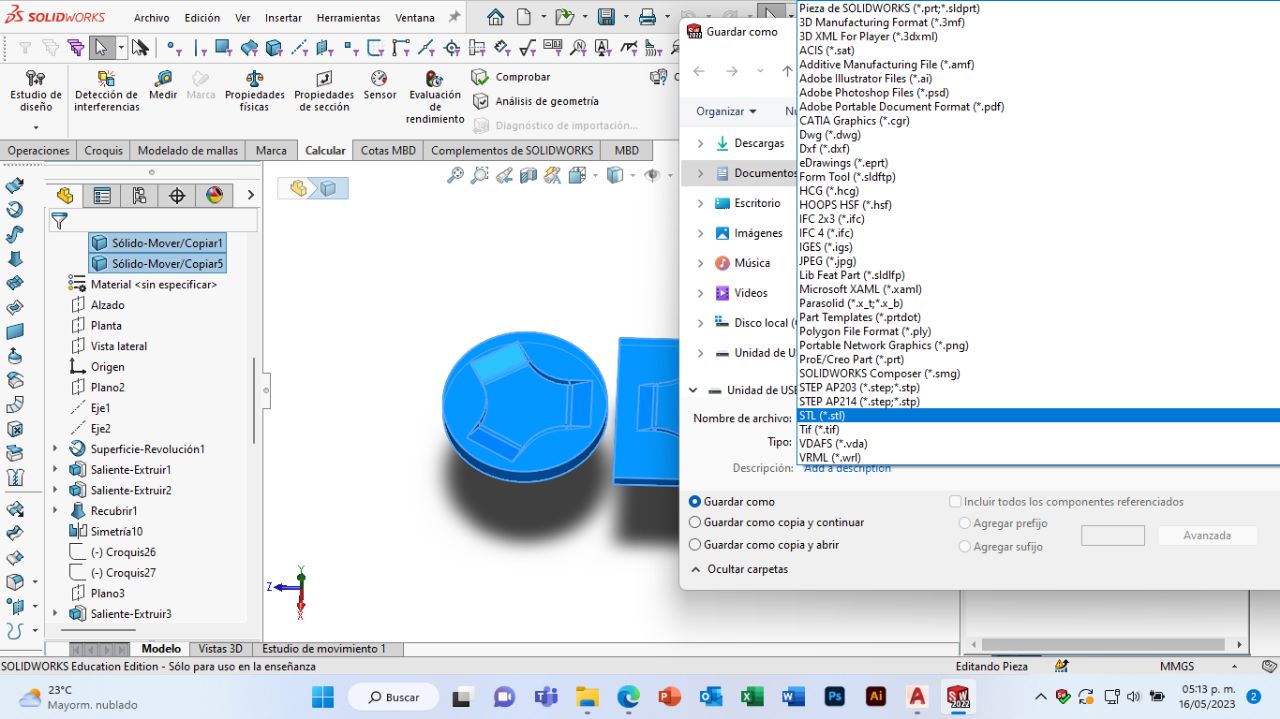

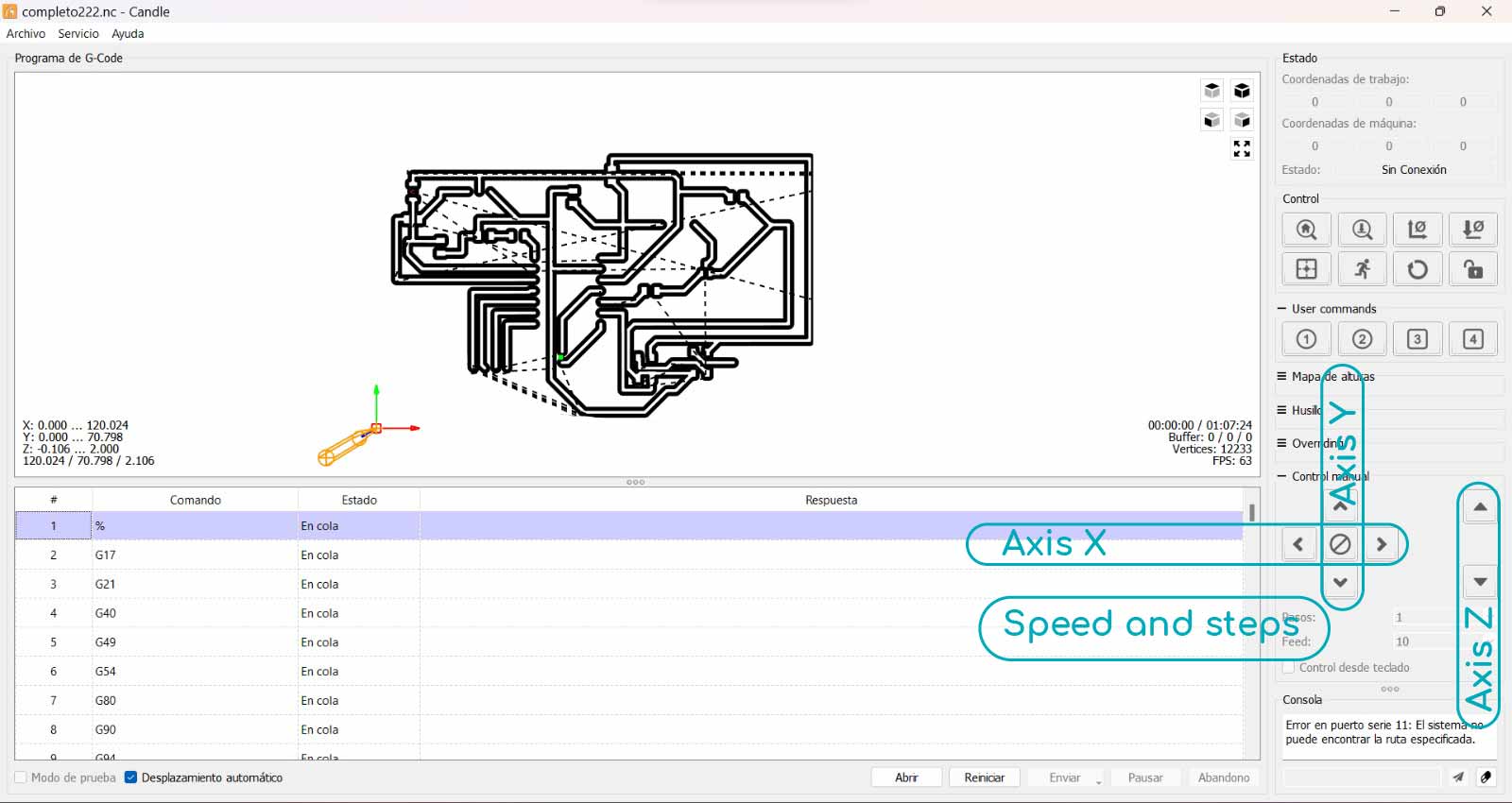

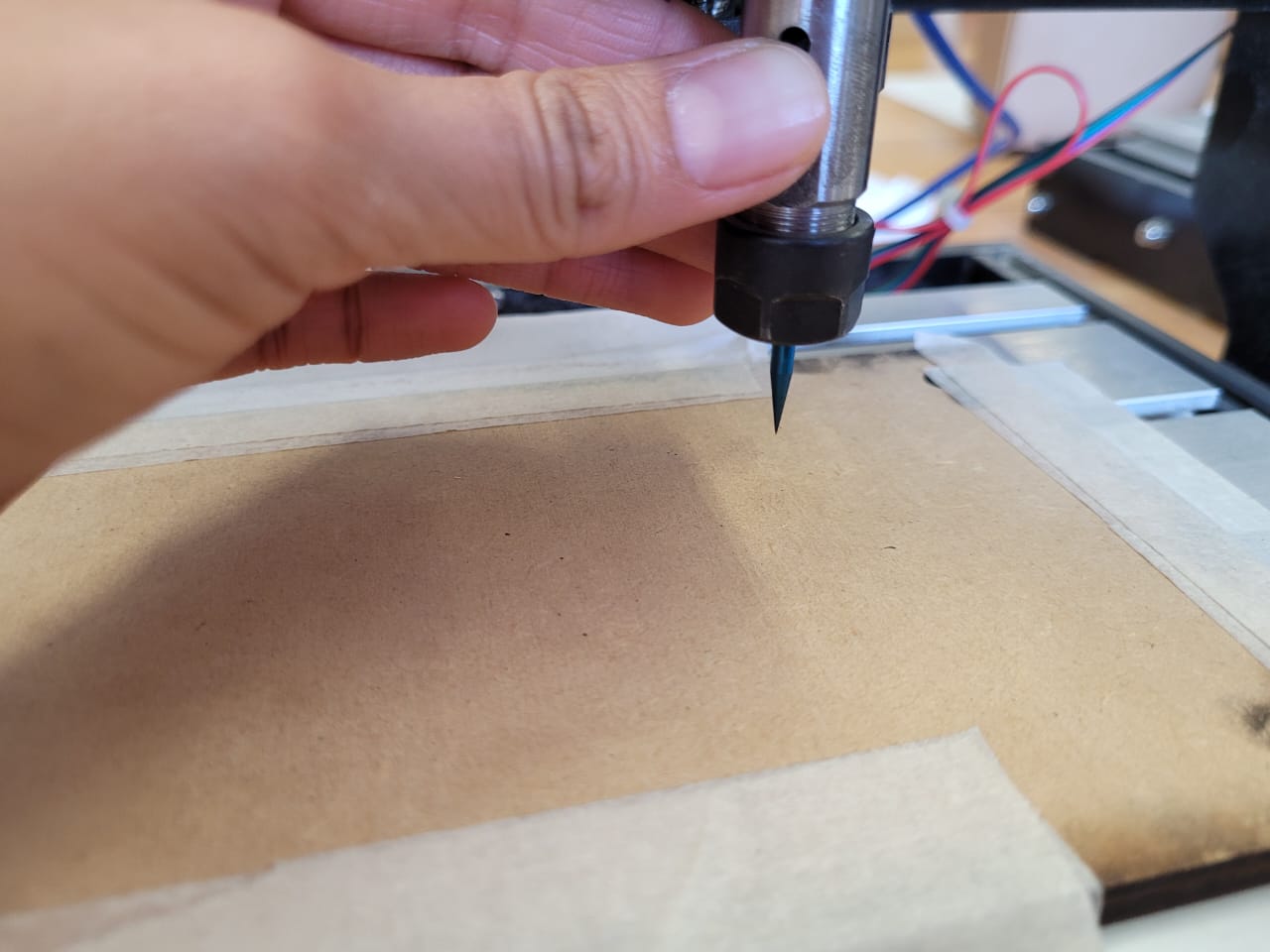

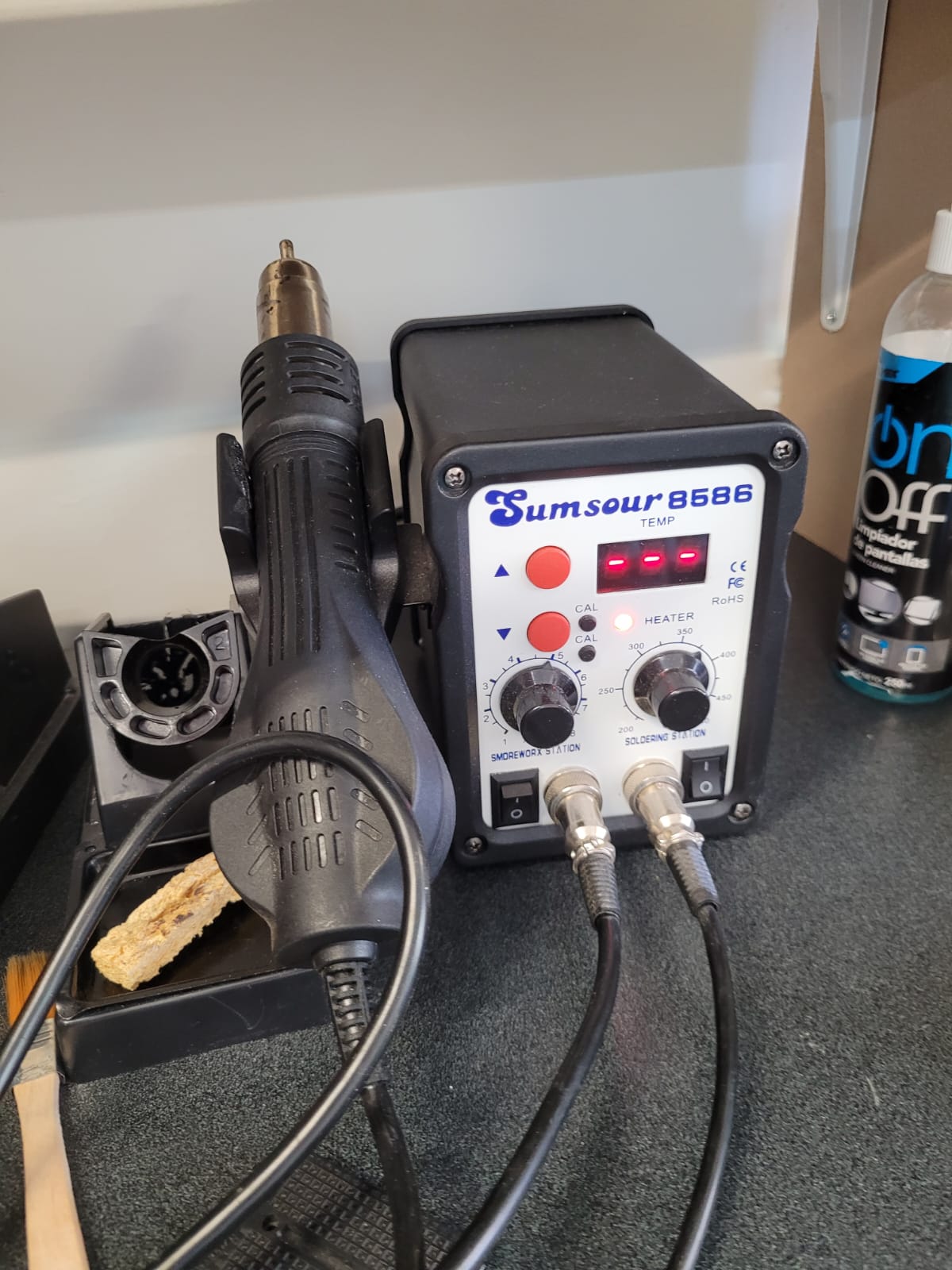

This is a project of mine that I would like to resume to improve it, because I created this system as part of my final thesis project at UNAM, in the scope of production I was not able at that time to explore and closely test its versatility, which is why I am interested in retaking the system for my final project.