WEEK 16: Applications & Implications

The home stretch is approaching. This week is dedicated to the organisation and description of the final project where I will describe step by step. Maybe later on I will make some changes if I have some problems or if I decide to change something.

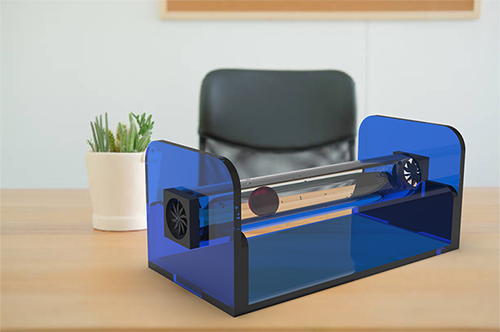

My final project is an educational project for teaching and research. A control platform D.O.F Degrees of freedom "horizontal x". The degree of freedom can be thought of as the number of independent ways an object can move horizontally, from left to right or from front to back. It is ideal for introducing students to the fundamental and intermediate principles of controls. The university asked me to, so I can teach everything I learned to the students.

WHO HAS DONE WHAT BEFOREHAND?

I have been researching on the internet to see if there is anything similar to what I am going to do and I have not found anything.

The only thing I have found is a student project that does it vertically. Click here

So it will be good to have a first example of a machine with these characteristics and to be able to teach what I have learnt to the students.

CONSIST OF:

DESINGN TO BE REALISED

The first problem I encountered was that: I have to attach the methacrylate tube to the structure of the machine with a piece to be able to hold it better. So I will design a suitable piece for it.

TECHNOLOGY TO BE USED:

LIST OF MATERIALS

| NUMBER | MATERIAL | DESCRIPTION | WHERE TO GET IT? | COST |

| 1 | Bluethoot SP32-C3 | |||

| 1 | Pantalla OLED | Deusto FabLab | ||

| 1 | Microcontrolador | Deusto FabLab | ||

| 2 | Fan | More Info | 13€ | |

| 1 | Had of Methacrilate | More Info | 14,99€ | |

| 1 | Distance Sensor VL53L1CXV0FY/1 | More Info | 11,59€ | |

| 1 | Ping- Pong Ball | 1€ | ||

| ? | Cables | Deusto FabLab |

HOW WILL IT BE EVALUATED?

A suitable code must be entered into the microcontroller for the fans to move and move the ball on the X axis with a sensor that identifies where the ball is located and a screen where we will see the values of the distance of the ball. The information is evaluated by sending information to the microcontroller and should move the fans. Knowing at all times where the ball is located.