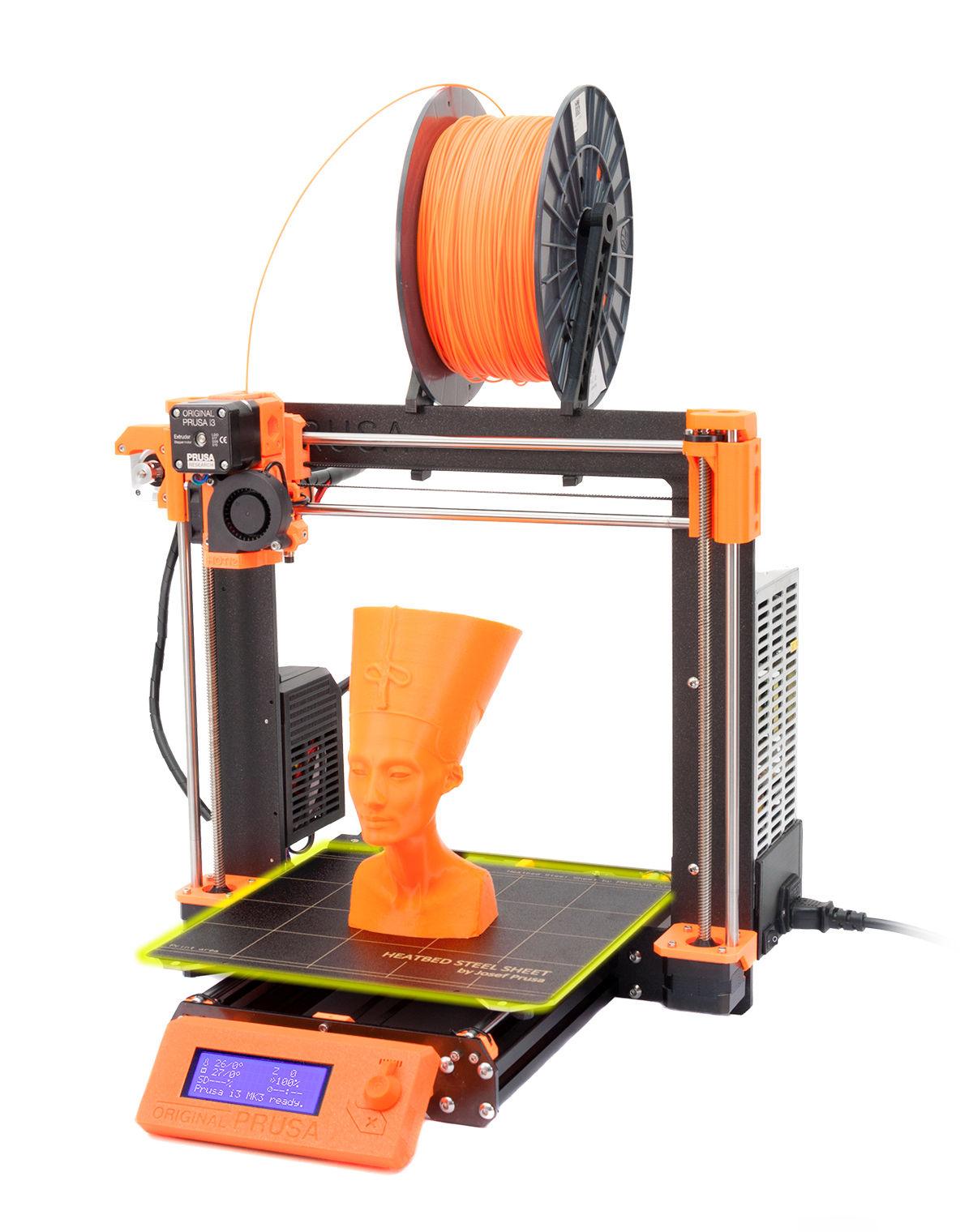

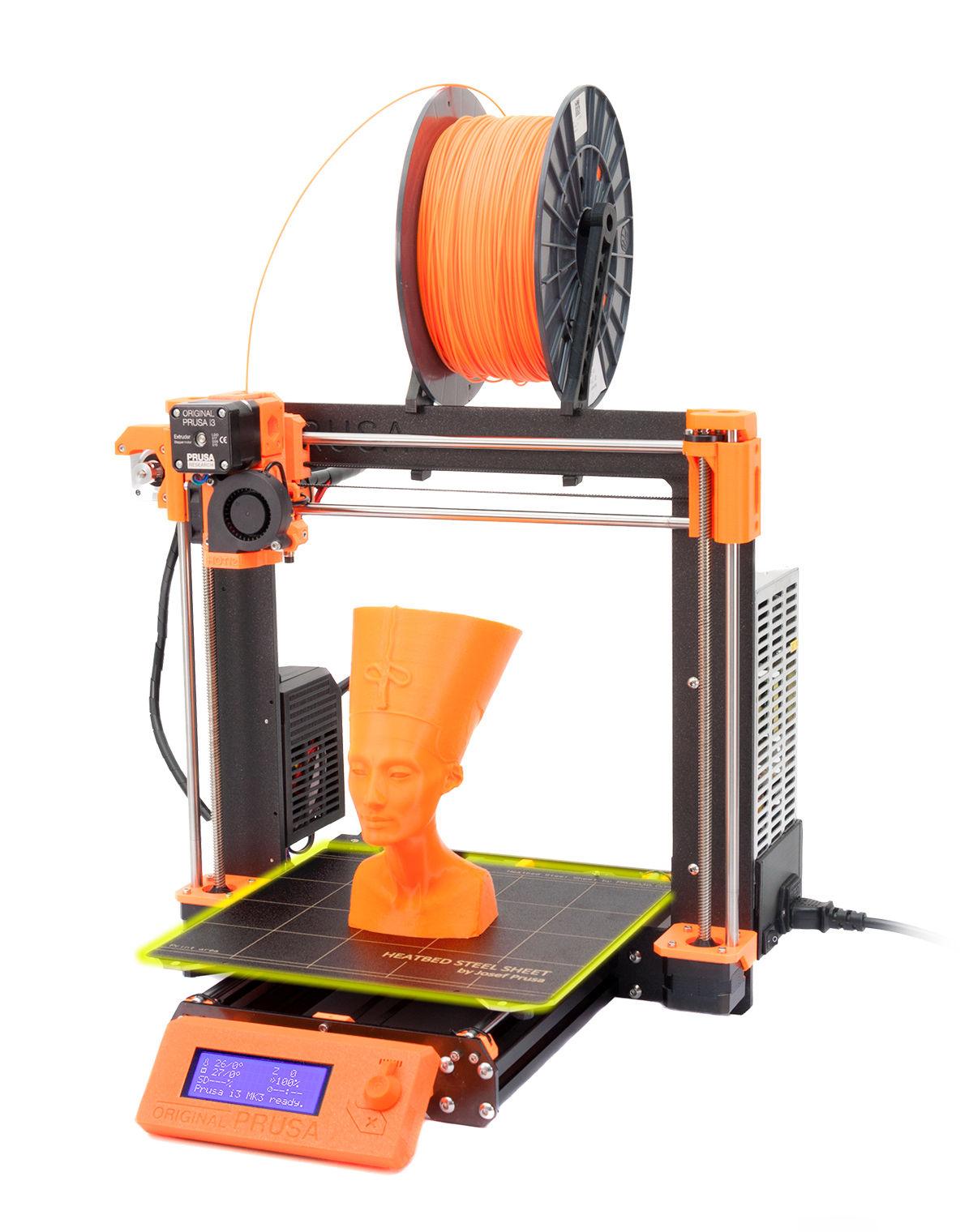

Prusa 3D Printer MK3+ technical description

The Prusa MK3+ is known for its reliability, high print quality, and user-friendly design. Key features include:

- High Precision: Offers layer resolutions from 50 to 200 microns, ensuring detailed,

high-quality prints.

- Generous Build Volume: 250 x 210 x 210 mm, allowing for larger projects or batch printing.

- Auto Bed Leveling & Filament Sensor: SuperPINDA probe for automated leveling and a sensor to

detect low filament, preventing failed prints.

- Power Recovery Mode: Resumes prints after power interruptions, reducing material waste.

- Quiet Operation: Equipped with silent Trinamic drivers, making it ideal for home use.

- Flexible Filament Compatibility: Supports PLA, ABS, PETG, and more for various applications.

- PEI-Coated Print Bed: Magnetic, removable bed for easy print removal and strong adhesion

during prints.

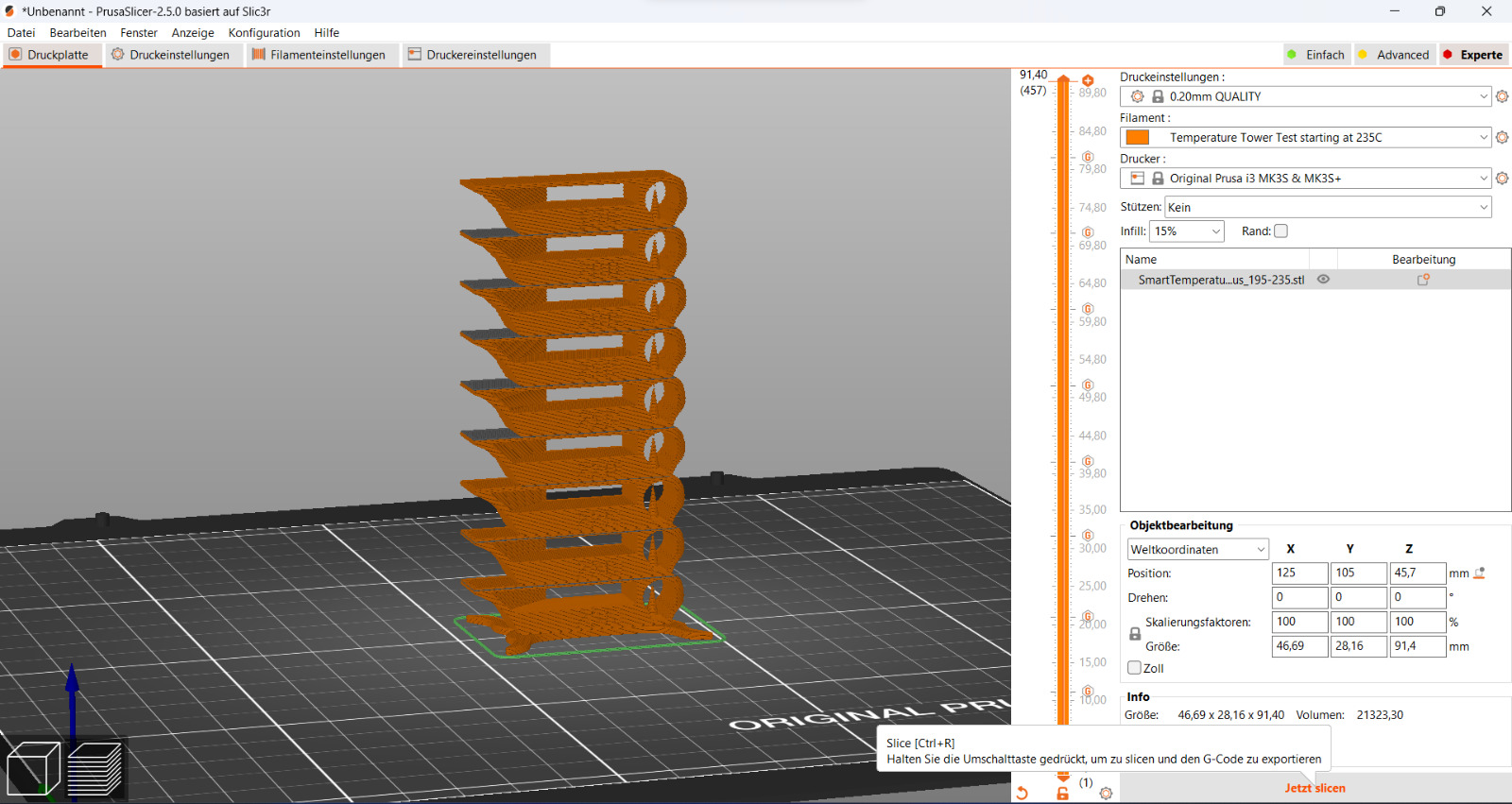

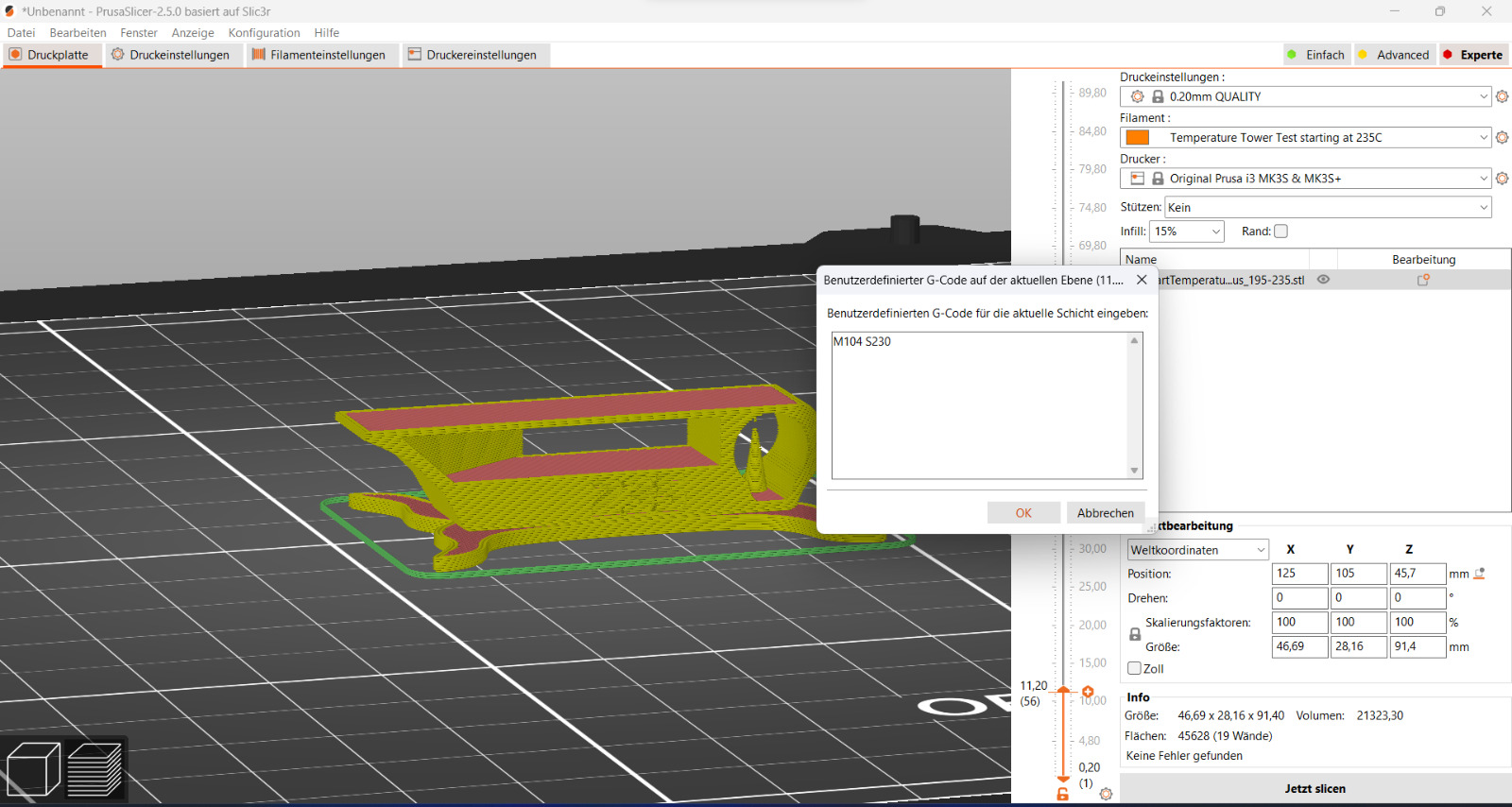

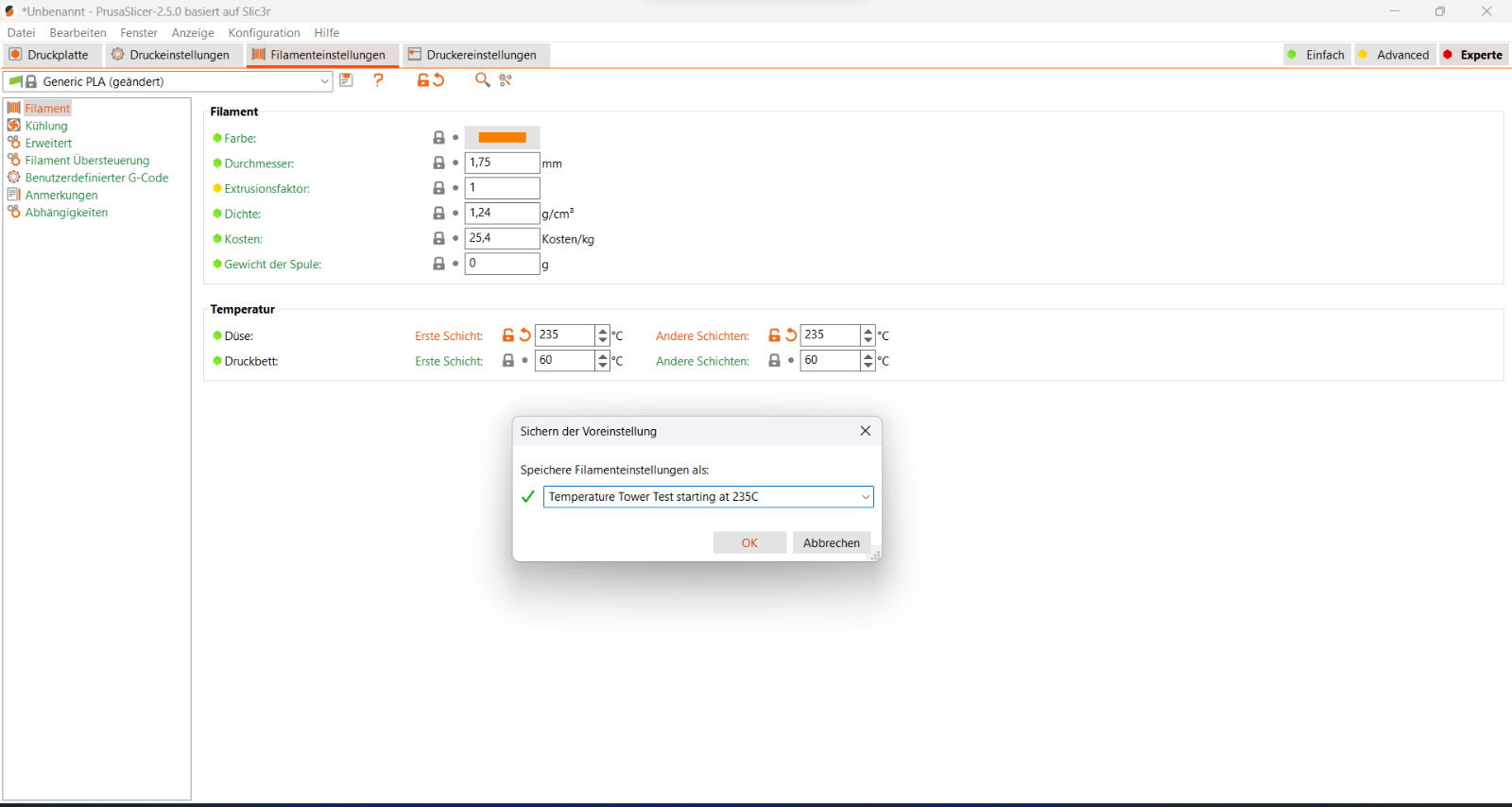

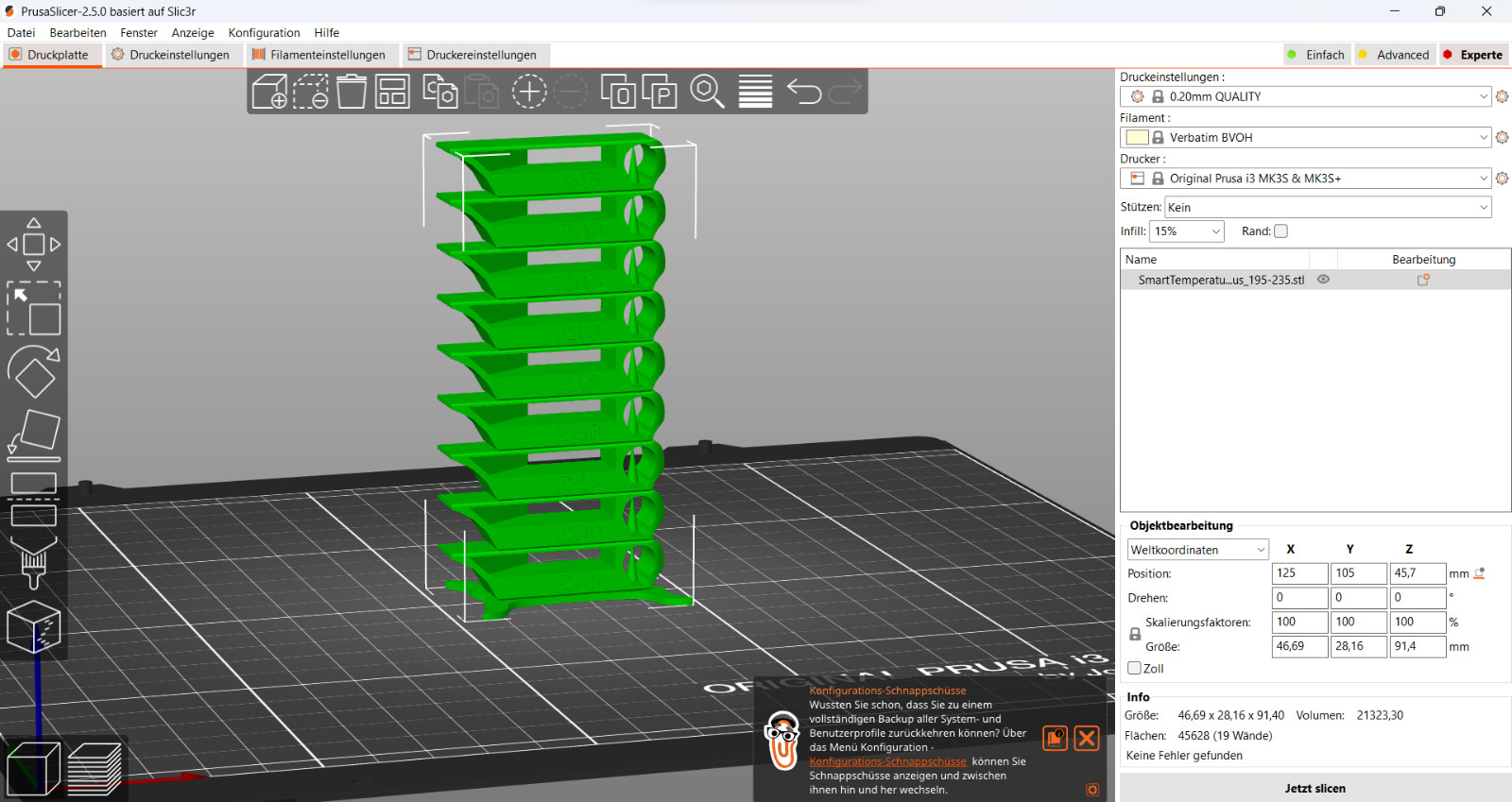

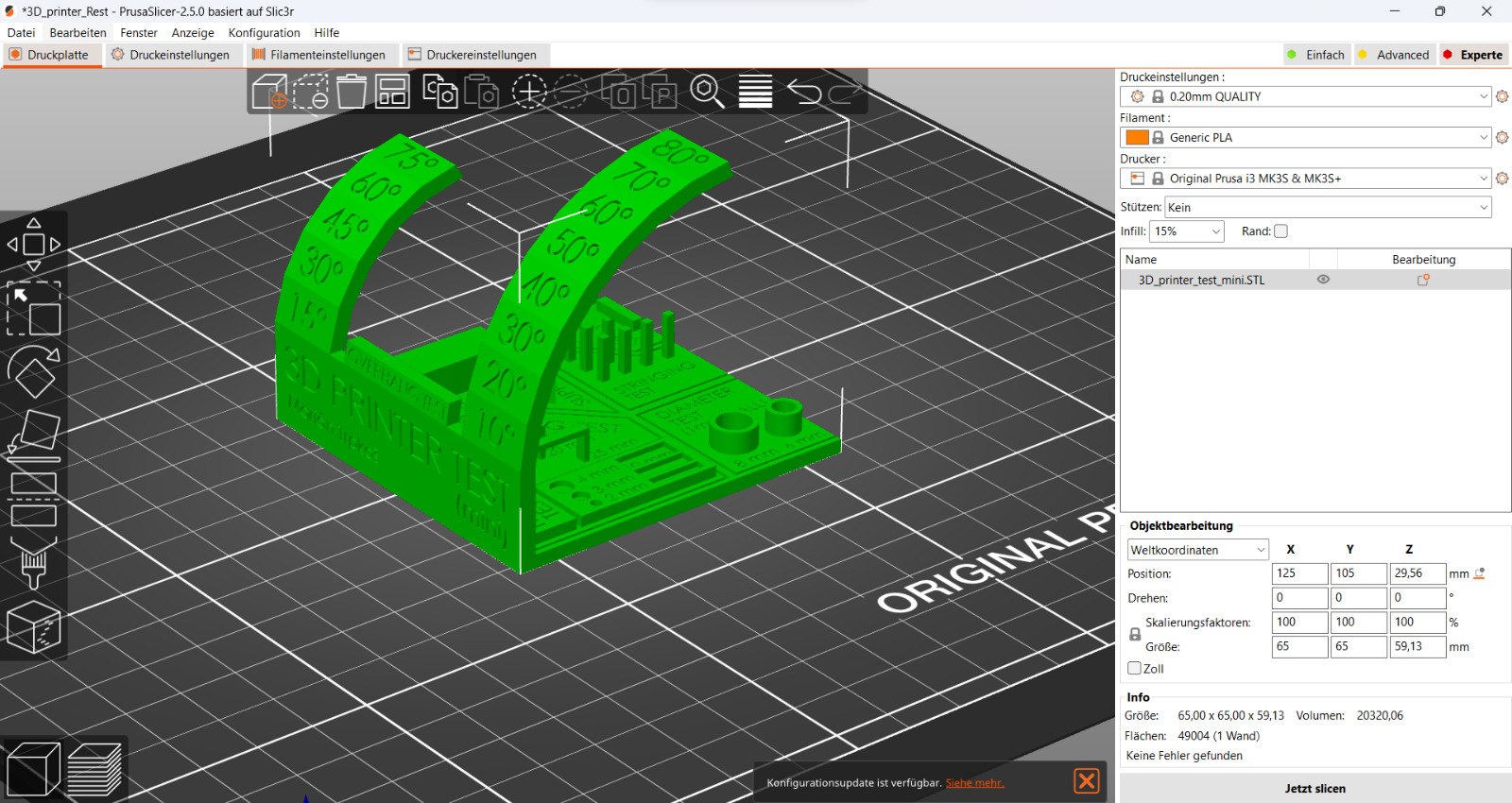

- PrusaSlicer Software: Comes with PrusaSlicer for advanced slicing options tailored to Prusa

printers.

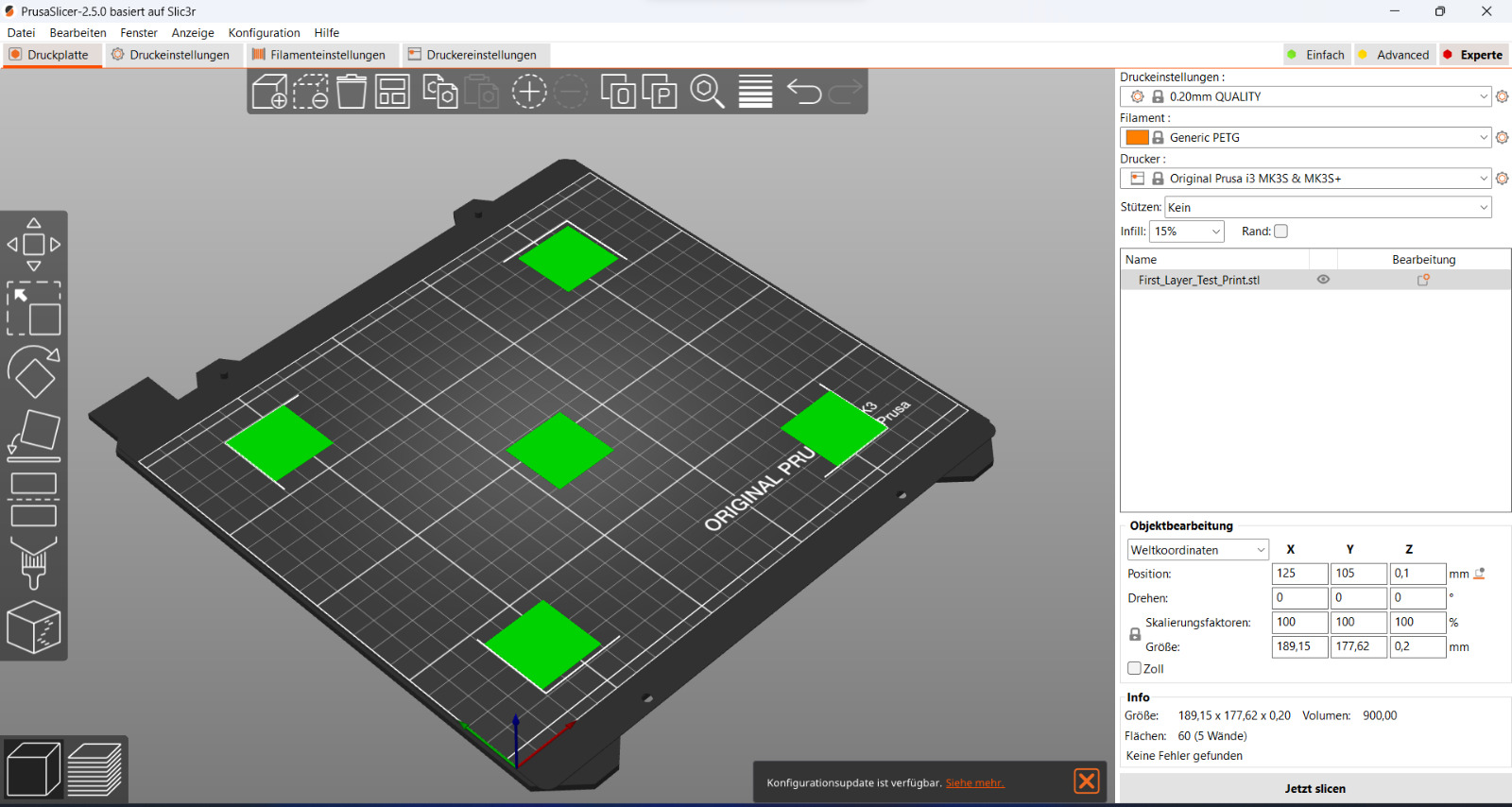

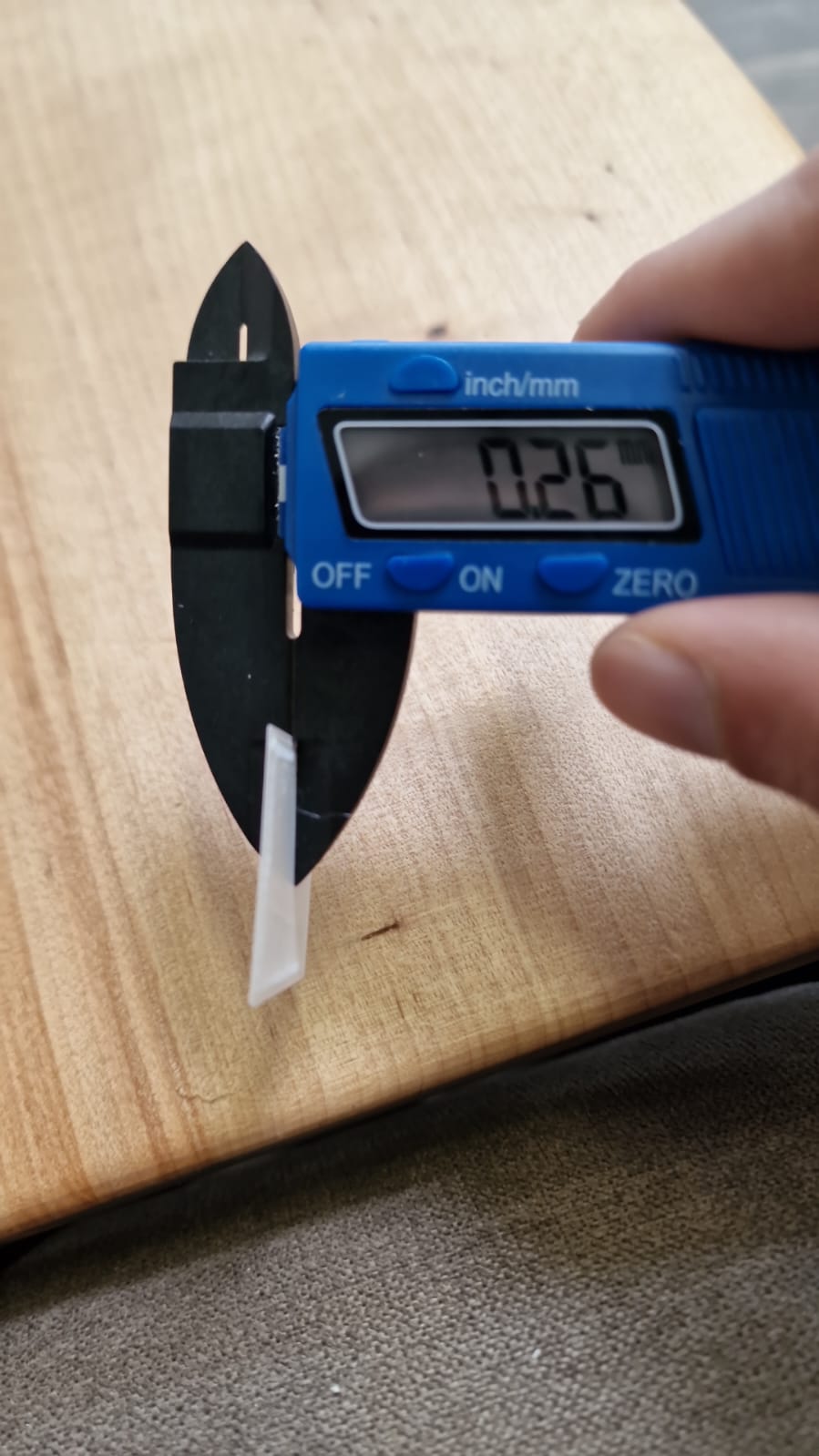

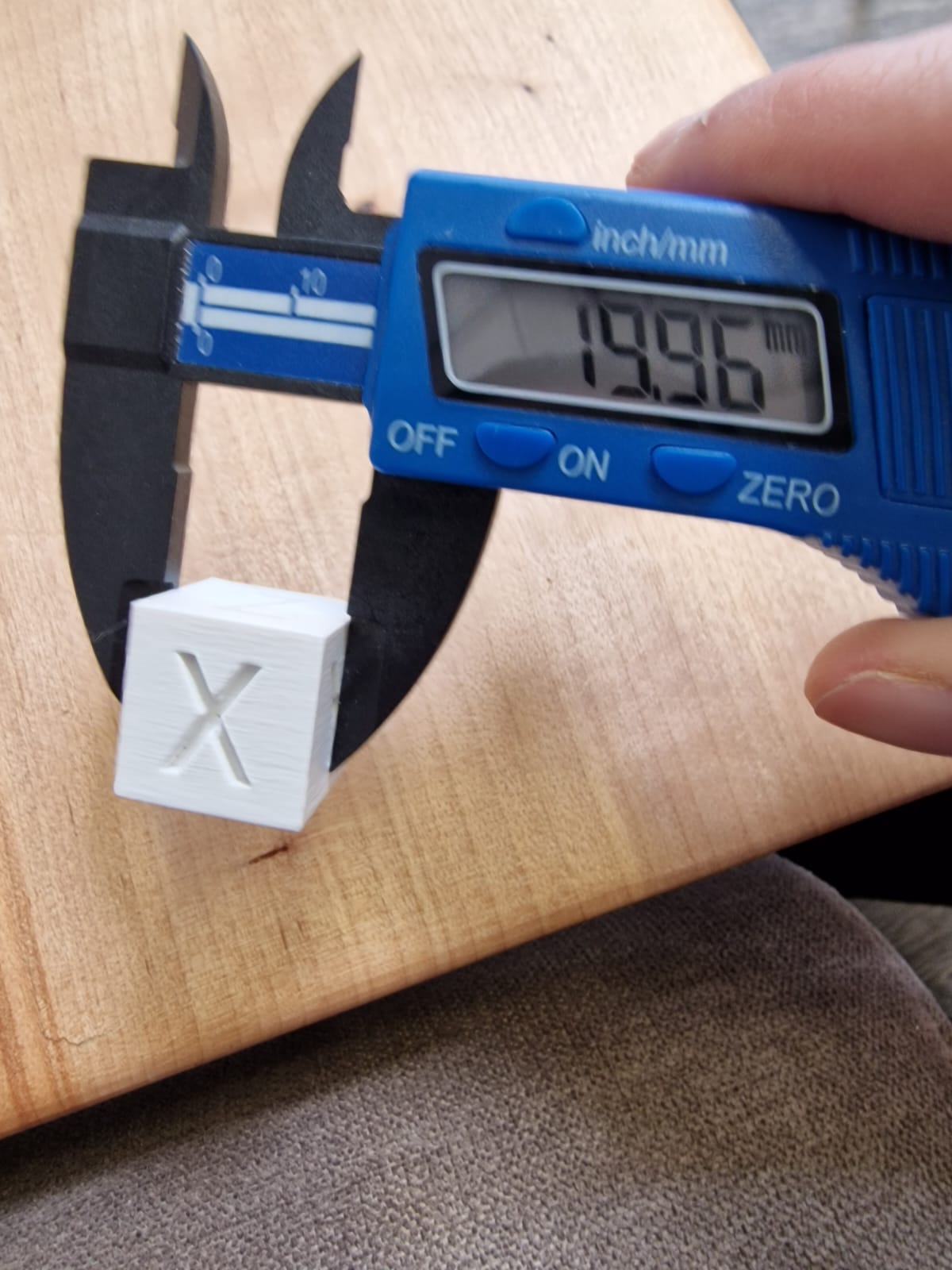

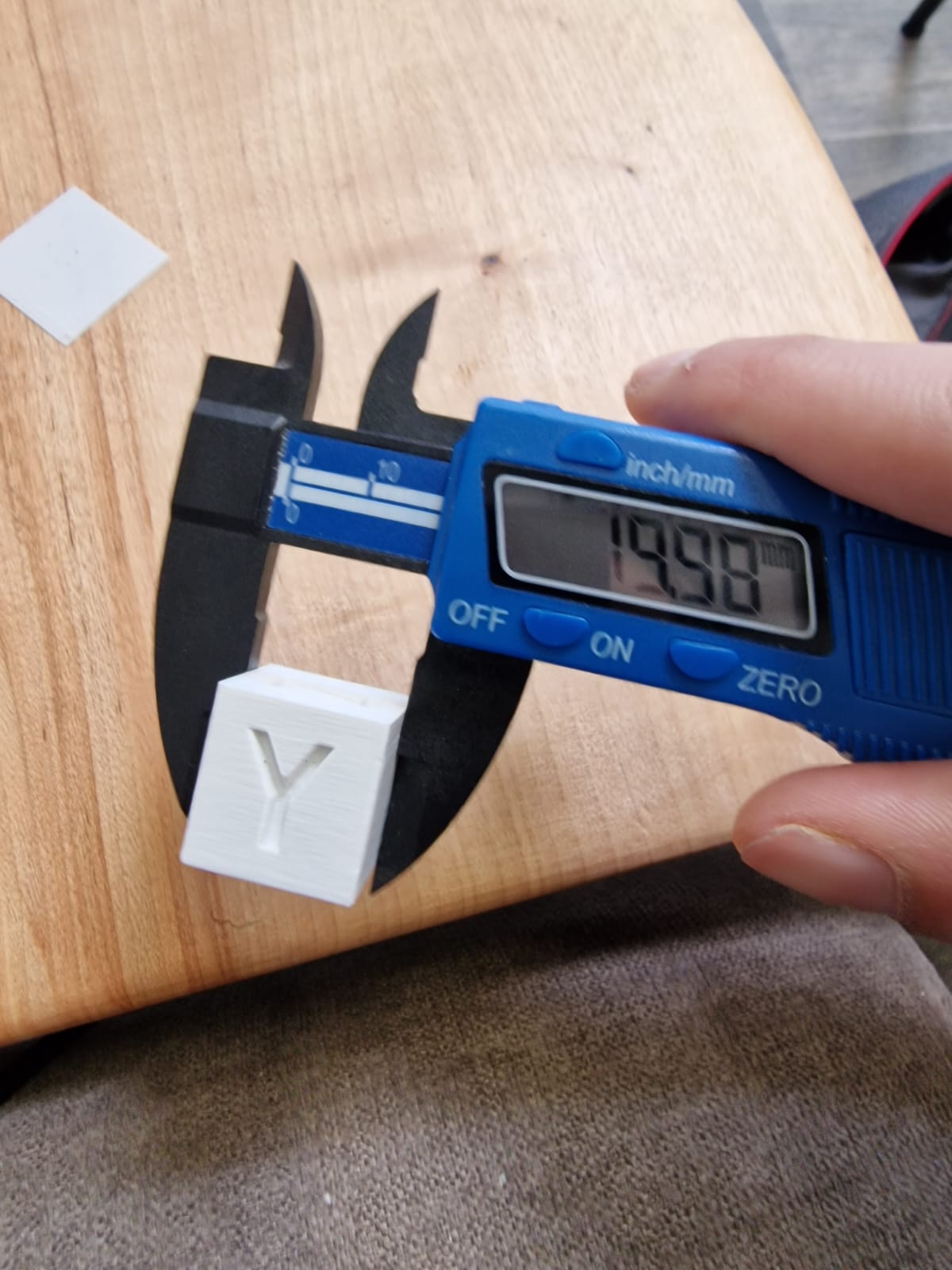

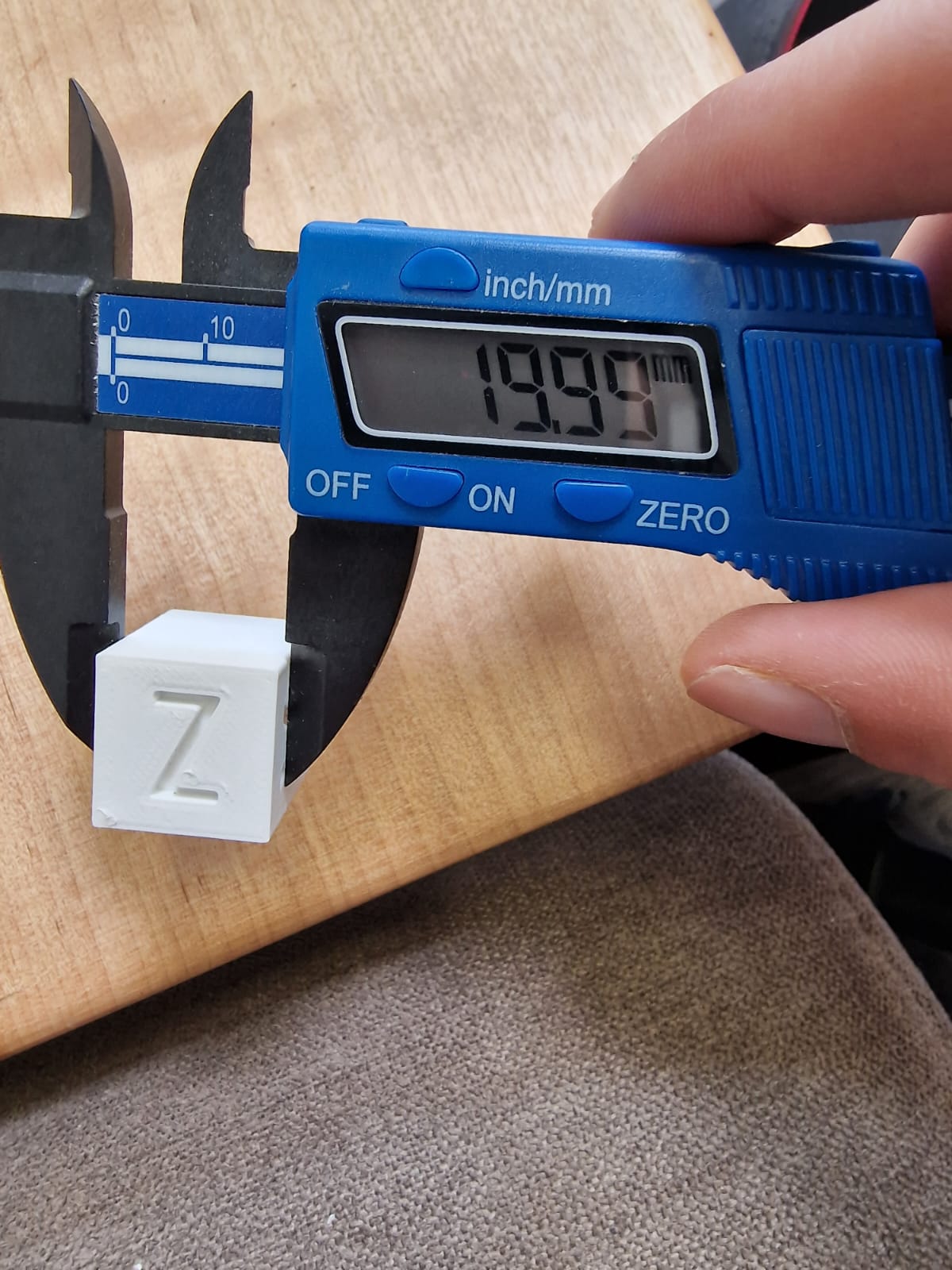

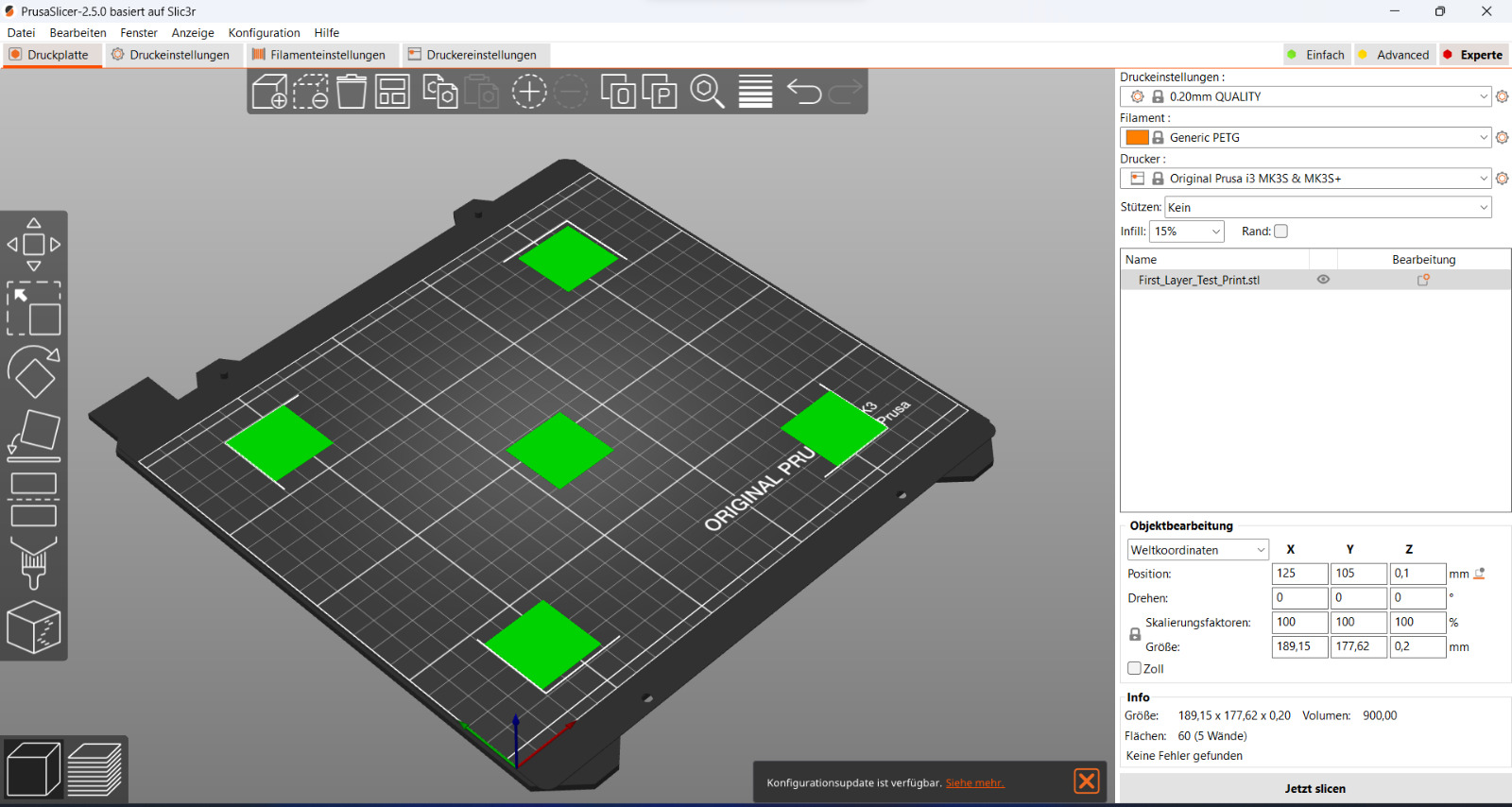

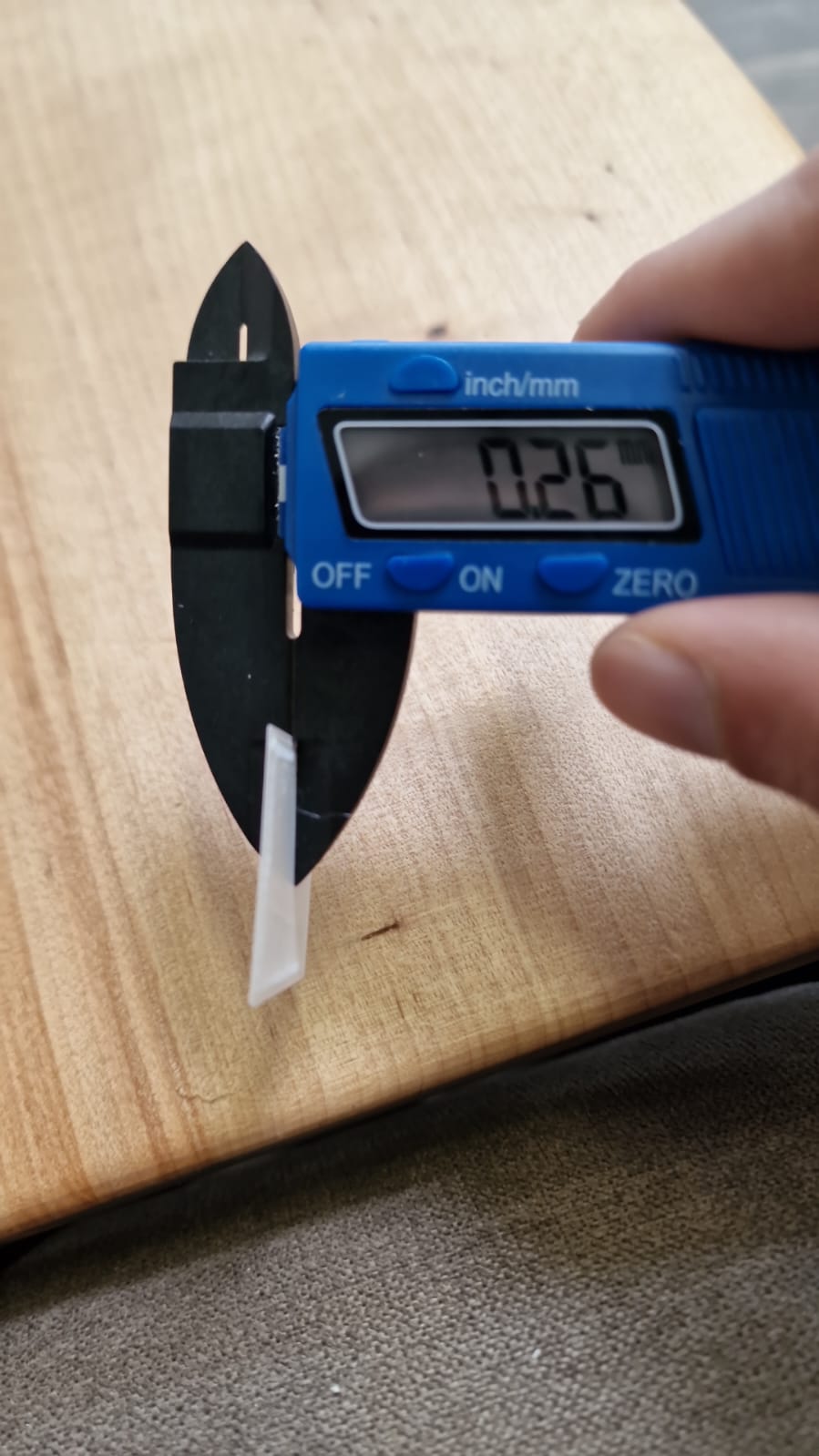

Group Assignment: First Layer Test

For this critical assessment, I printed a small 20mm x 20mm square with a generously thick initial layer. By

meticulously adjusting the Live-Z setting in PrusaSlicer, I fine-tuned the bed level. The outcome consistently met

expectations across five distinct points on the bed.

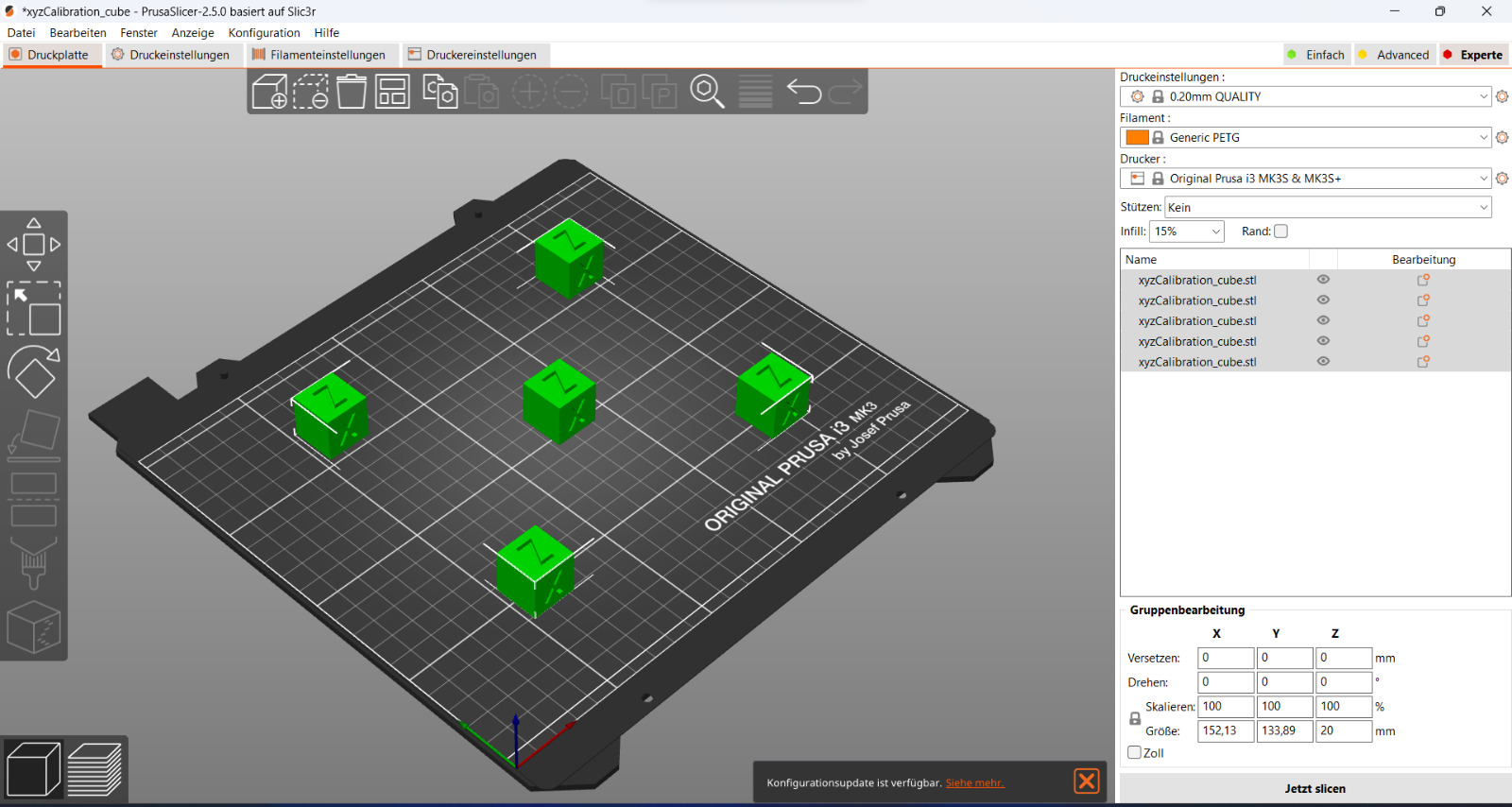

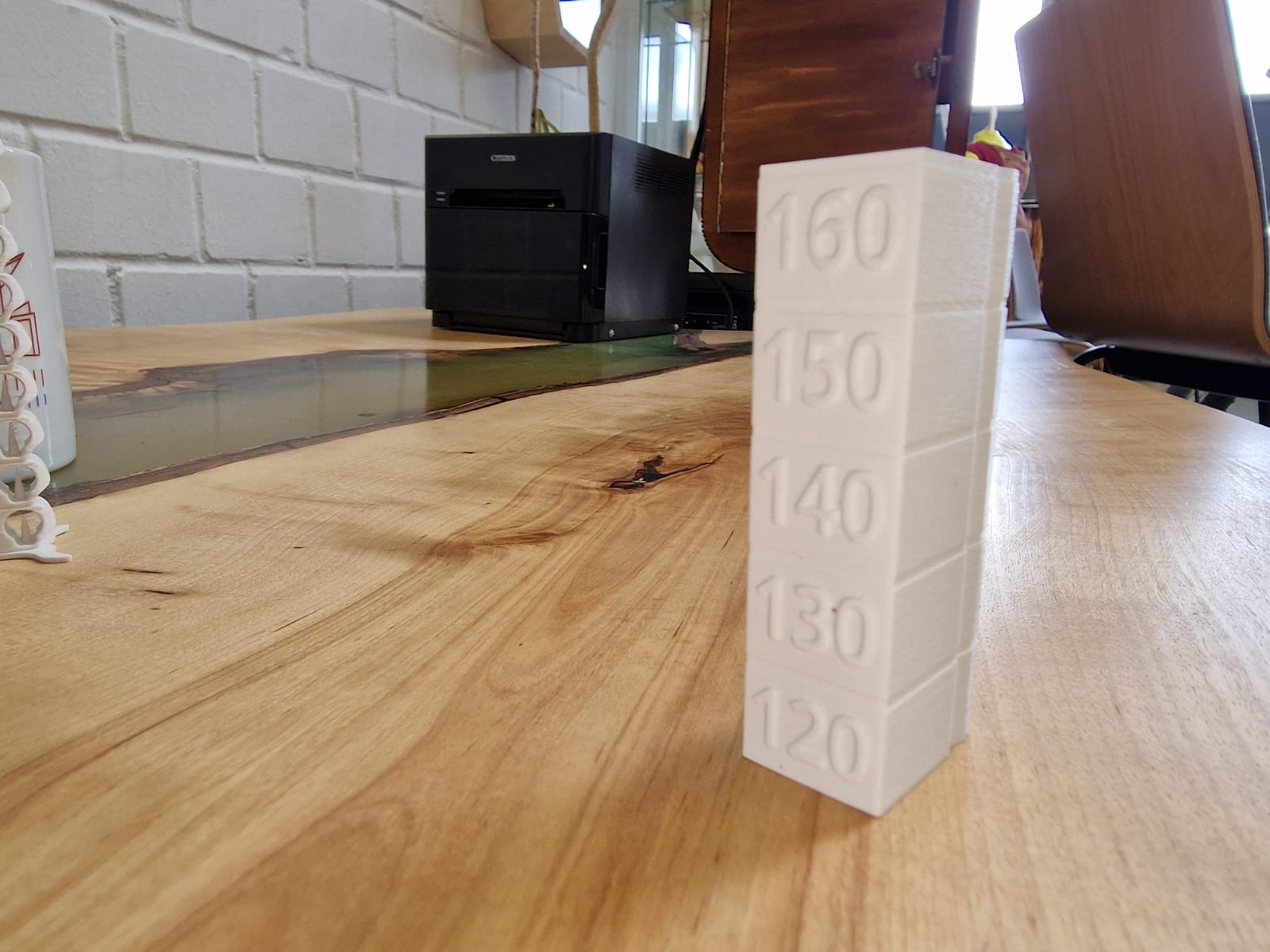

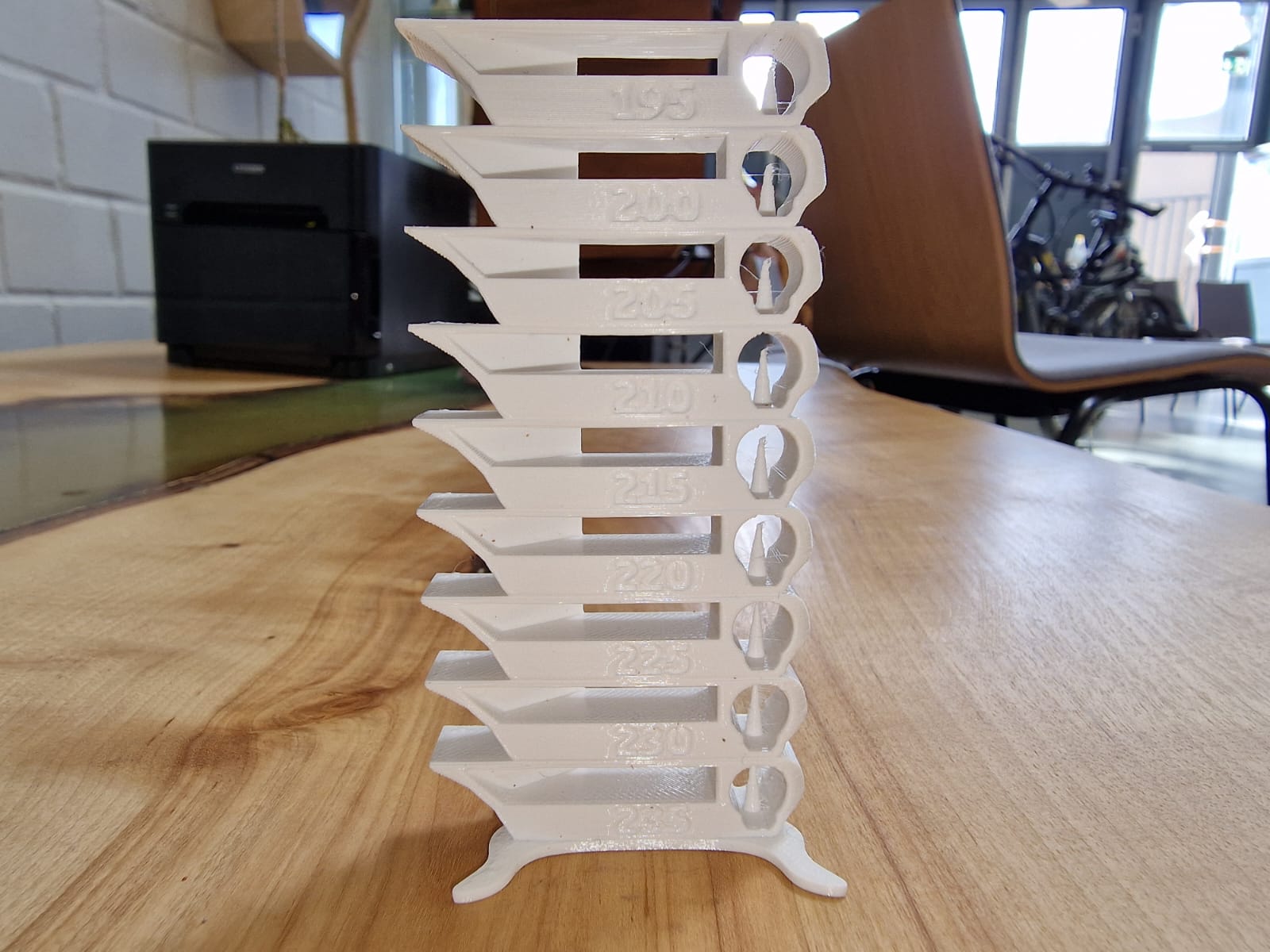

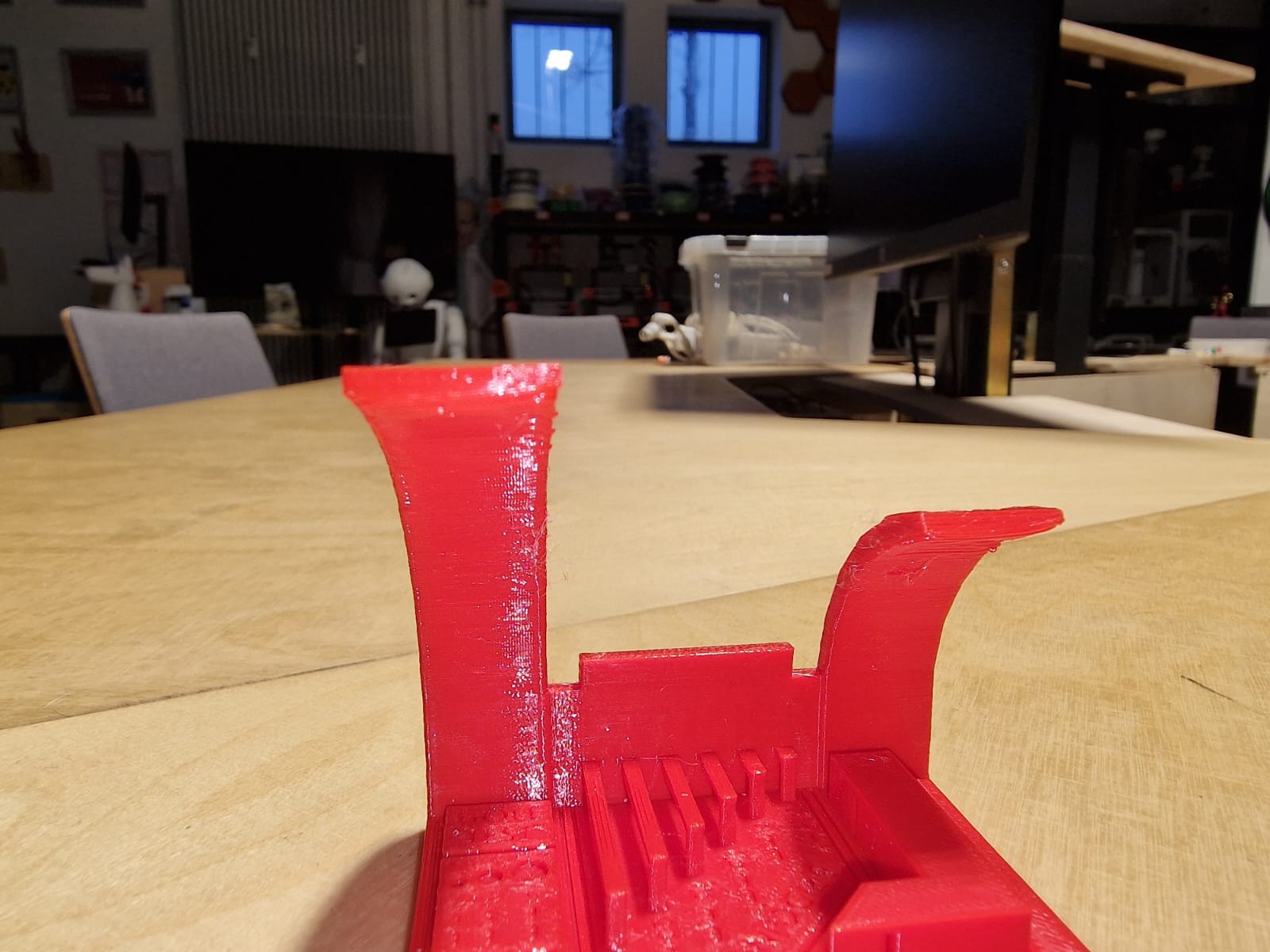

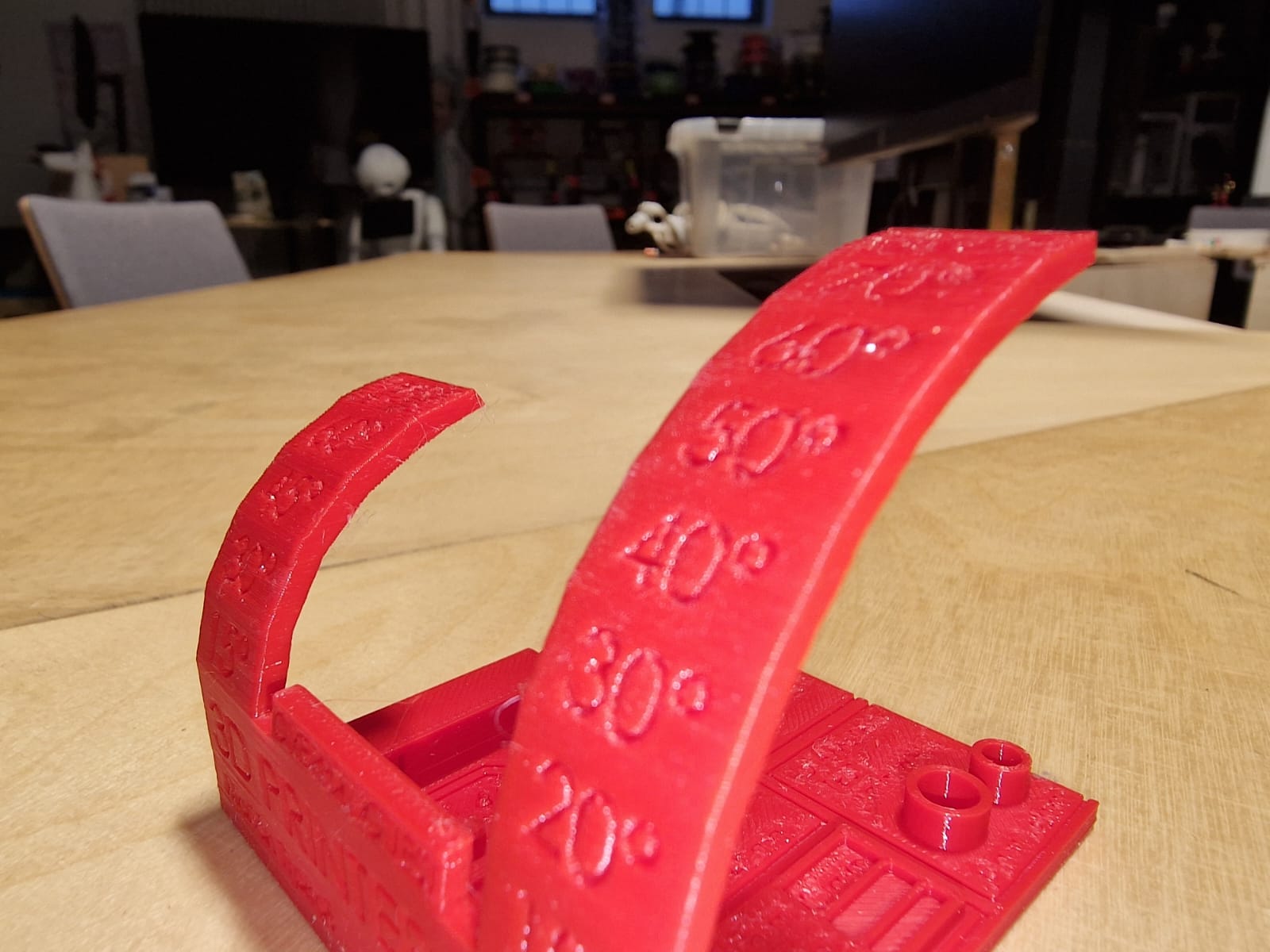

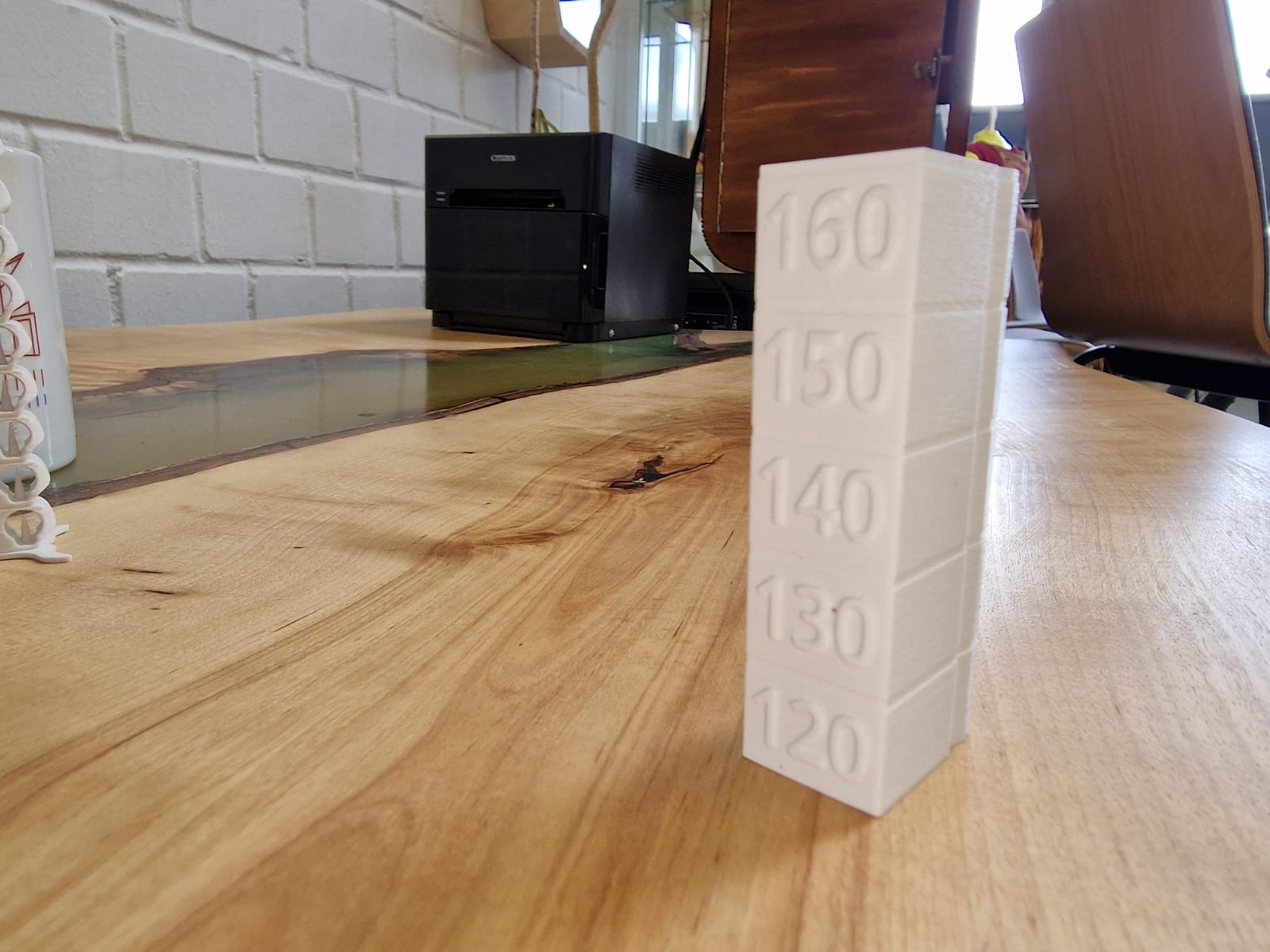

Group Assignment: Speed Tower Test

In this test, I meticulously programmed the slicer to employ varying speeds on each layer, ranging from

120 to 160 mm/s. Notably, we observed that increasing the speed led to a perceptibly rougher surface finish.

What I've Learned from 3D Printing

3D printing, also known as additive manufacturing, has revolutionized how we create objects. Key takeaways

include:

- Layer-by-Layer Fabrication: 3D printing builds objects layer by layer, allowing intricate

designs and customization.

- Material Variety: 3D printers work with diverse materials, impacting the final object's

performance.

- Design Freedom and Complexity: 3D printing enables complex geometries and lightweight

structures.

Challenges of Subtractive Methods for Lattice Structures

Creating volumetric lattice structures using subtractive methods faces hurdles:

- Material Removal Limitations: Achieving intricate internal voids is challenging.

- Internal Complexity: Subtractive methods struggle to access hidden areas within lattices.

- Wasted Material and Time: Subtractive processes generate waste during removal.

- Structural Integrity: Removing material weakens lattice connections.