Molding and casting

Introduction

Individual Assignment

In this individual assignment, the objective is to design a mold using computer-aided design (CAD) software

around the stock and tooling that will be used. The mold will then be milled using a CNC machine with a

rough cut followed by a three-axis finish cut to achieve a precise shape and smooth finish. Once the mold is

complete, it will be used to cast parts using a suitable casting material.

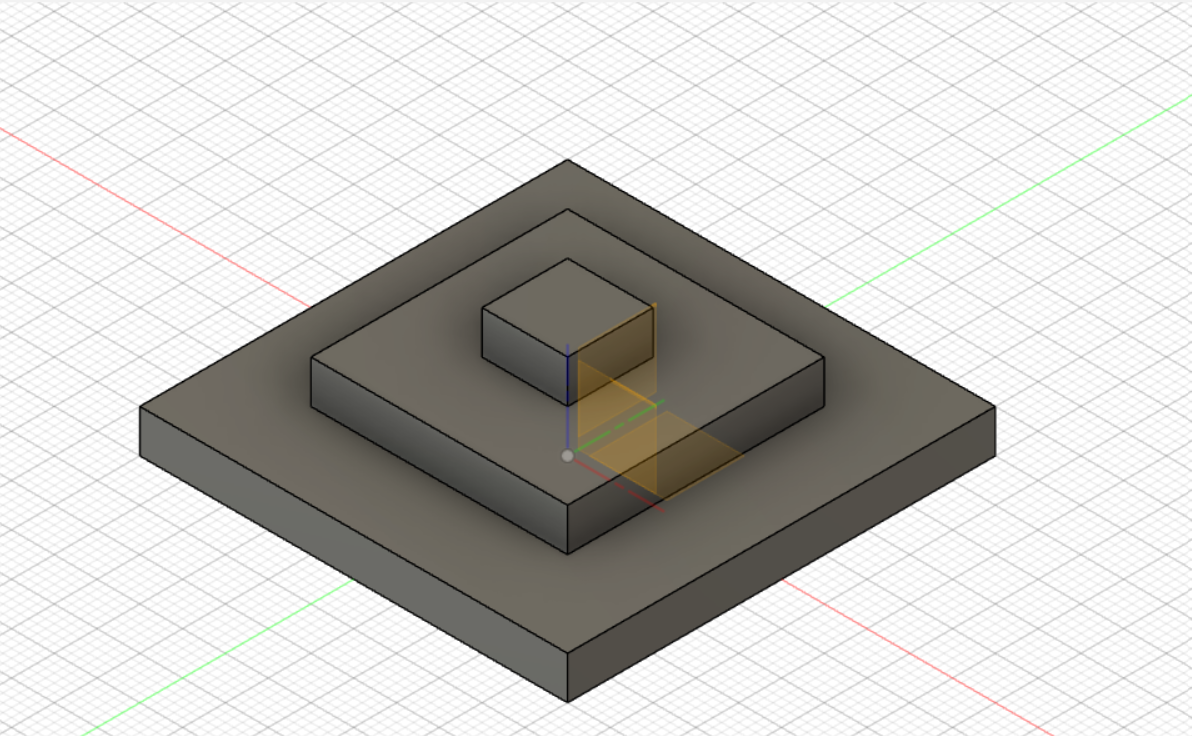

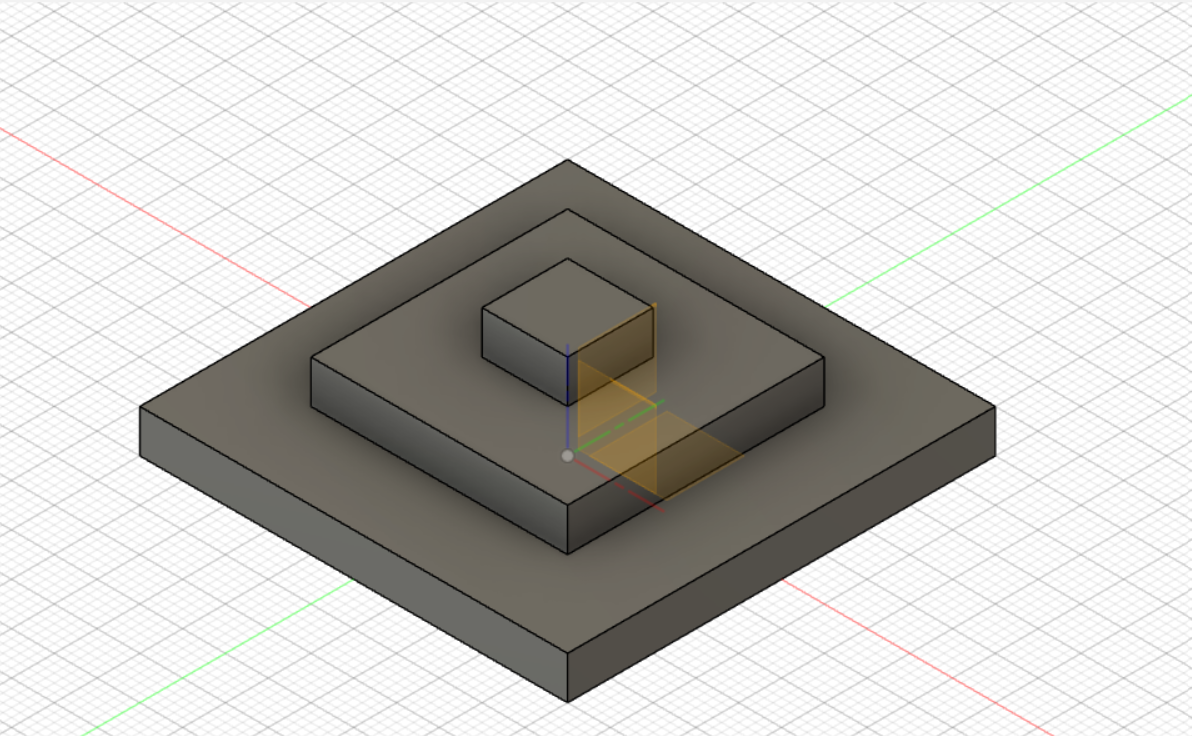

Step 1: Designing the Pyramid with Steps in Fusion 360

The first step in this assignment is to design a 3D model of a pyramid with steps using Fusion 360 software.

This design will serve as the mold for casting chocolate. The pyramid should have a base of 50mm x 50mm and

be composed of multiple steps, increasing in size as they reach the top. The design must be precise and

accurate to ensure the quality of the final product.

Step 2: Manufacturing the Wax Body using a CNC Machine

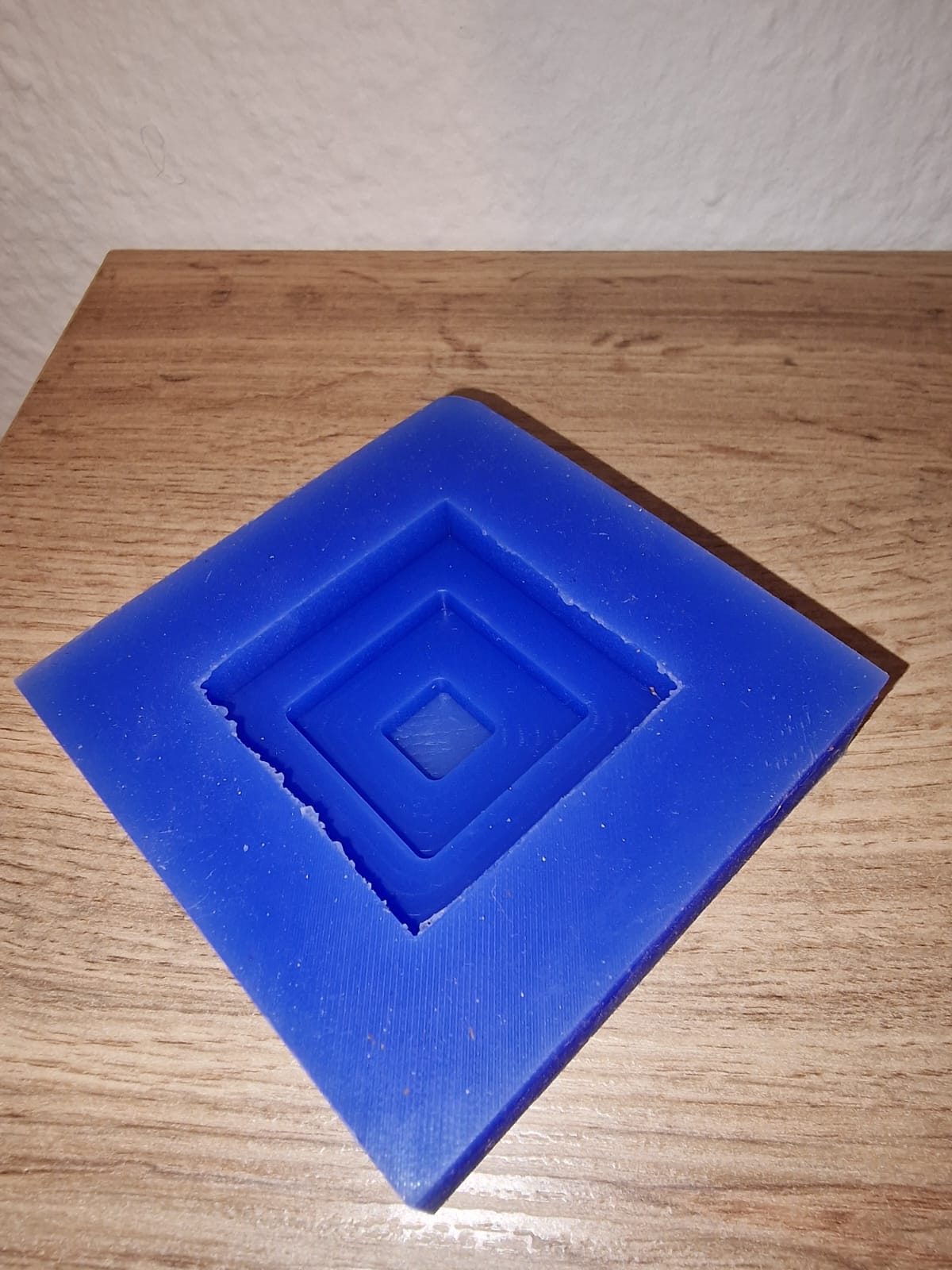

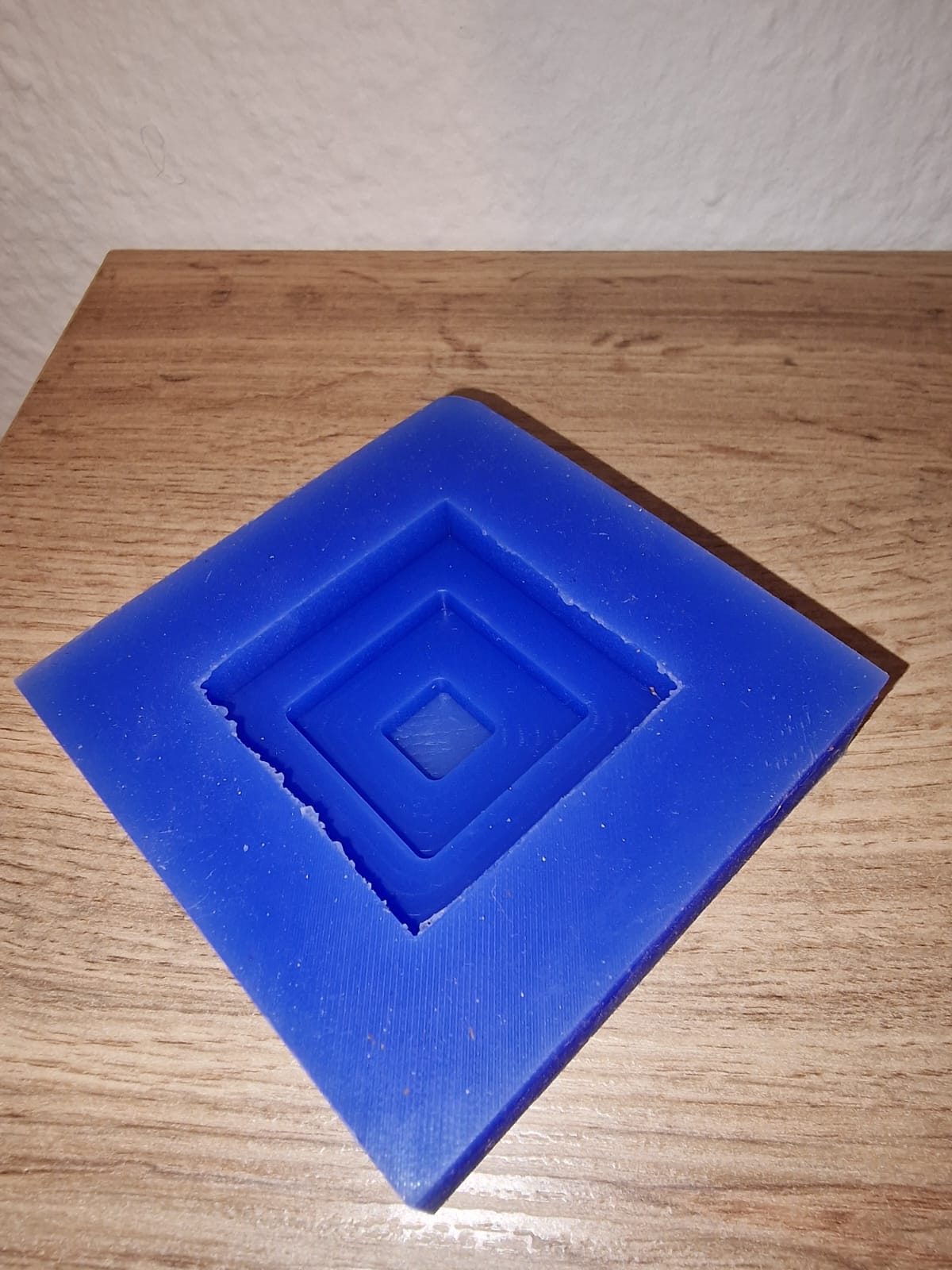

Once the design is complete, the next step is to manufacture the mold from a raw body made of wax. Using a

CNC milling and cutting machine such as the Stepcraft, the wax body will be cut to the exact shape and

dimensions of the pyramid with steps design. The machine will perform a rough cut, followed by a three-axis

finish cut to achieve the desired level of precision and smoothness.

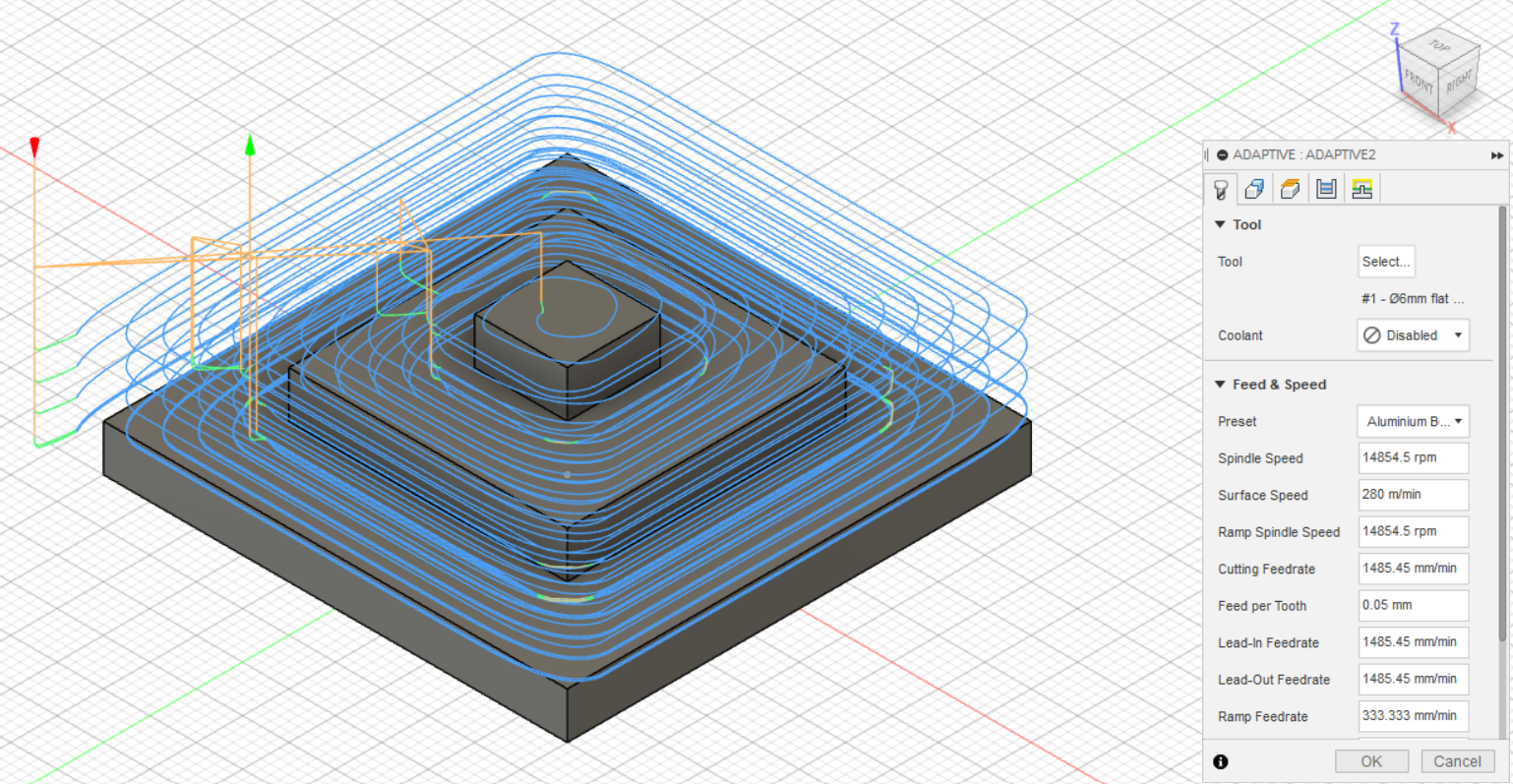

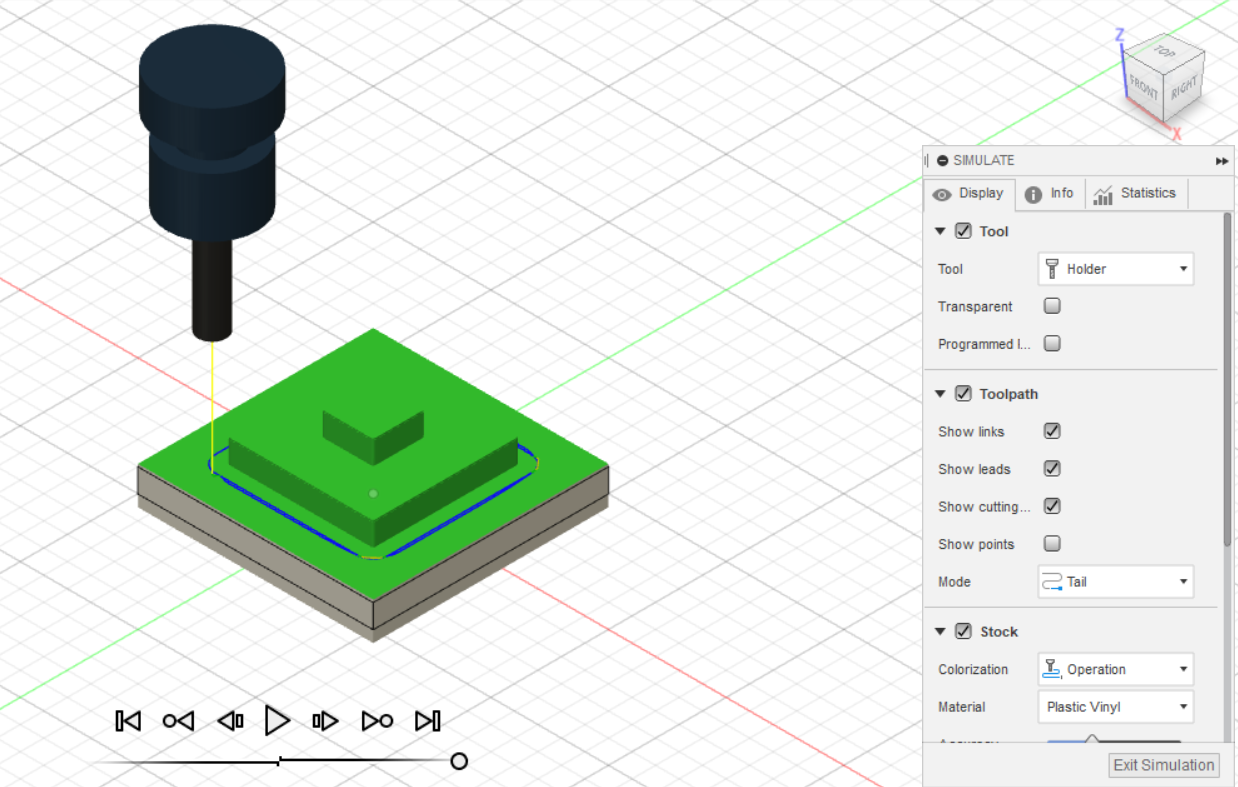

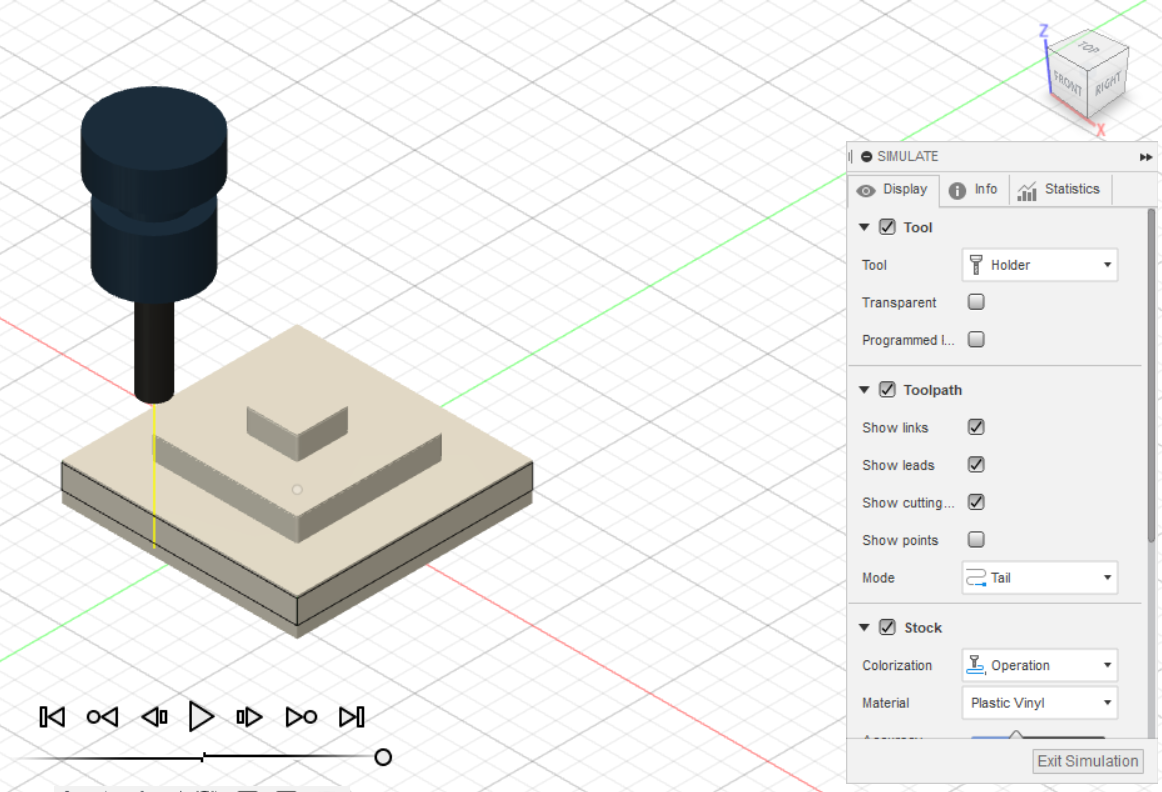

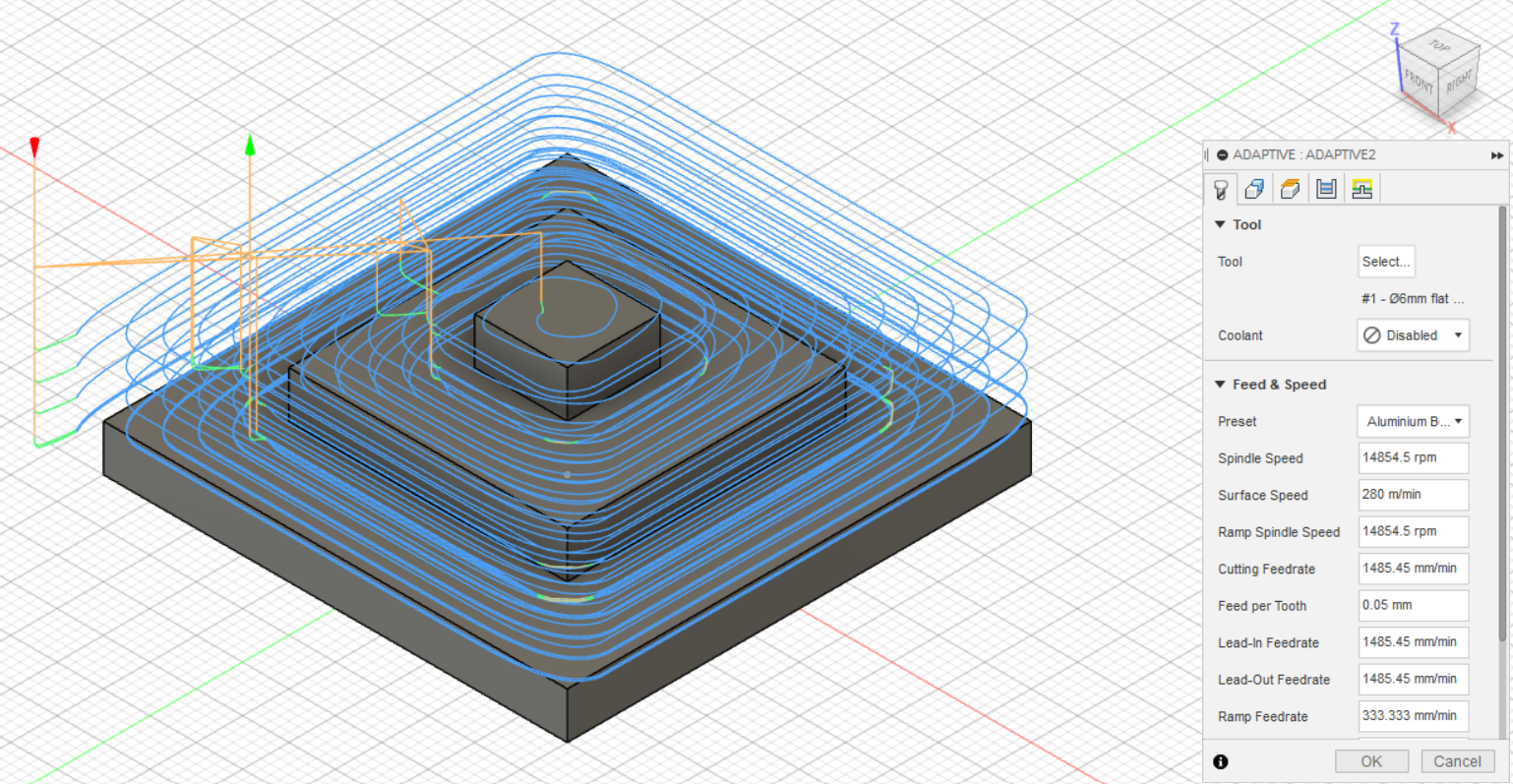

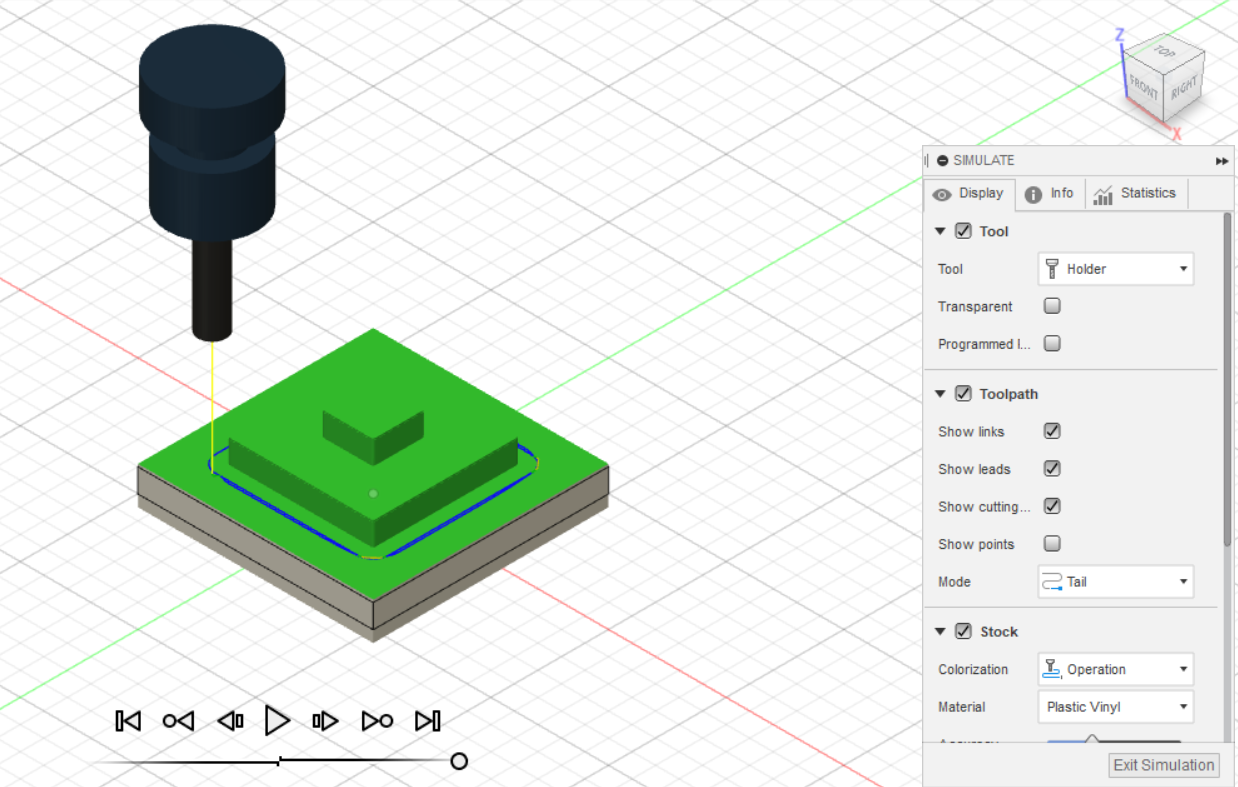

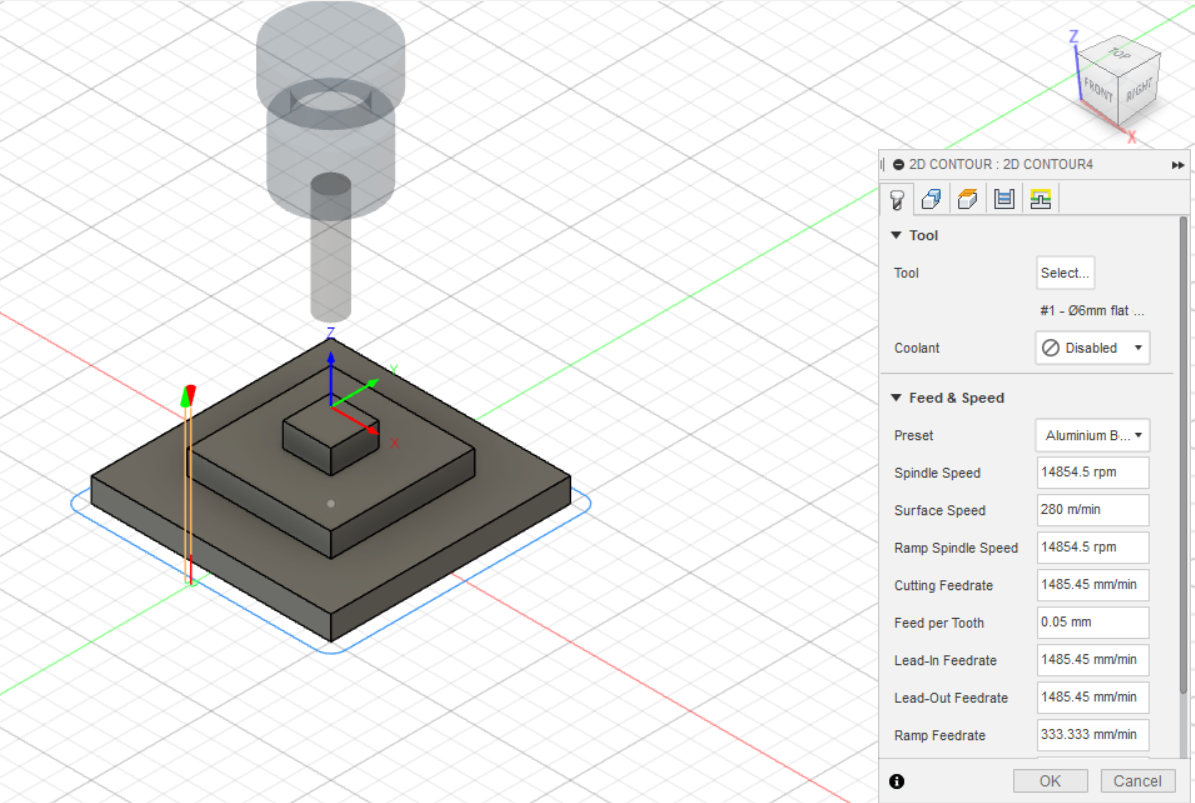

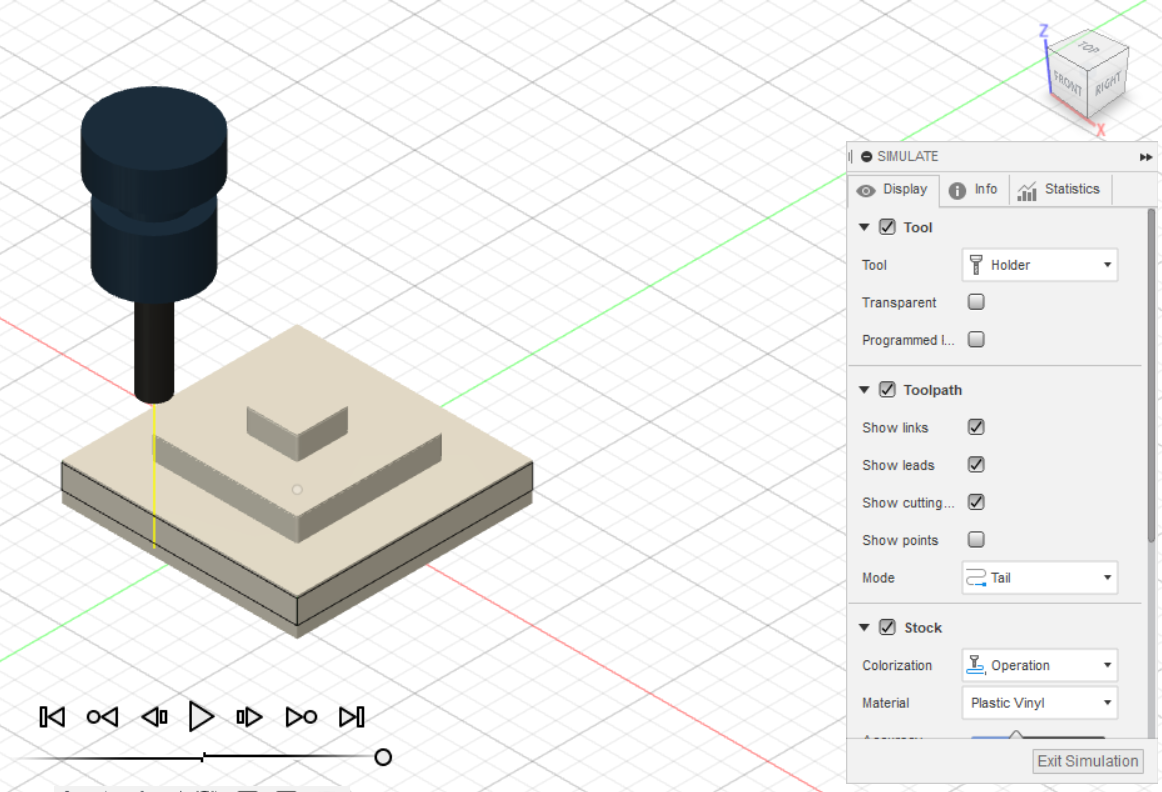

The raw body made of wax was manufactured using a CNC milling and cutting machine, such as the Stepcraft. The

manufacturing process began by using Fusion 360 software's manufacturing feature to select suitable CNC

tools. Initially, an adaptive clearing toolpath was used to remove the bulk material quickly, followed by 2D

contour cutting to smooth the external contours of the pyramid with steps.

Adaptive clearing is a toolpath strategy that optimizes the machining process by removing as much material as

possible using the cutting tool's entire flute length. This is achieved by removing large amounts of

material quickly, and as the cutting tool progresses, it removes smaller amounts of material, which reduces

the stress on the cutting tool and extends its lifespan.

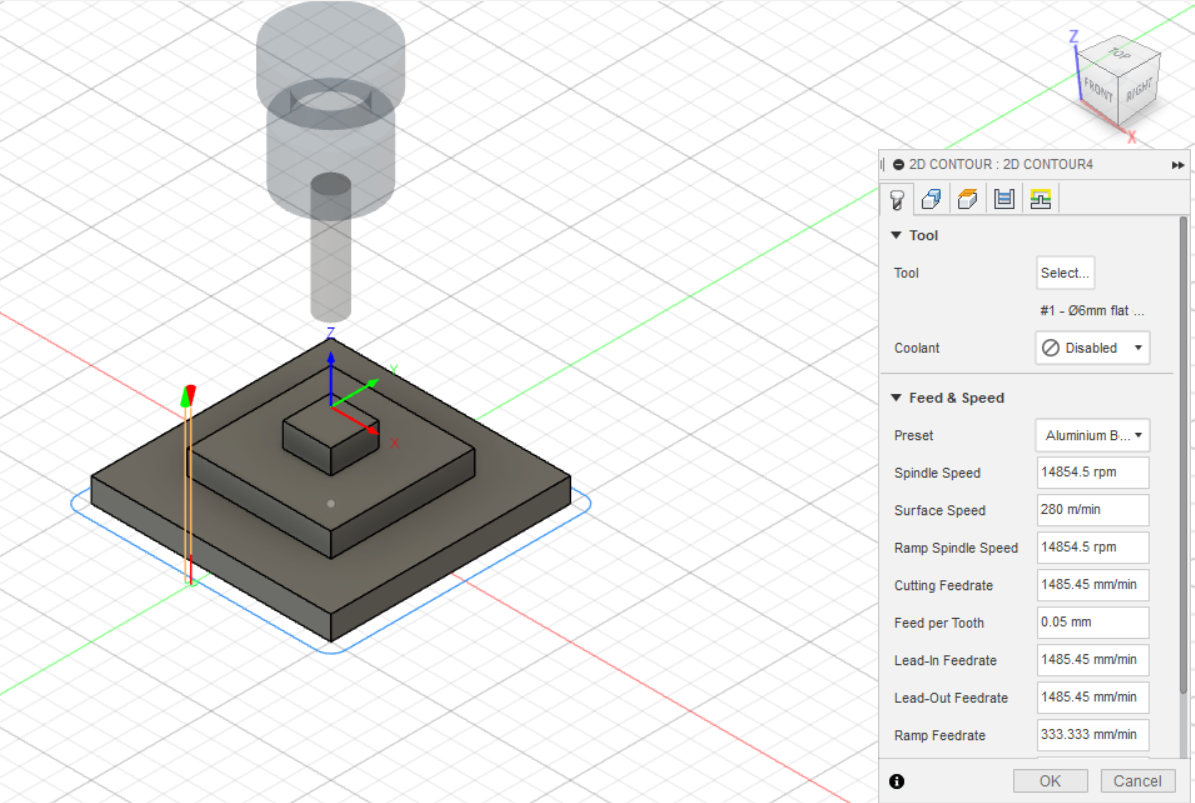

After the rough cut was completed, a 2D contour cutting toolpath was used to smooth the external contours of

the pyramid with steps. This toolpath strategy allowed for precise control of the cutting tool's movement

along the contours of the design to create a smooth finish.

By utilizing both the adaptive clearing and 2D contour cutting toolpaths in Fusion 360, the wax body was

precisely cut to the desired shape and dimensions of the pyramid with steps design

Step 3: Creating the Silicon Mold

The first step in creating the silicon mold is to place the wax mold in the center of a box designed in

Fusion 360 and 3D printed. The box must be large enough to accommodate the wax mold with sufficient space

around it for the silicon material to be poured. The box should also have a flat base to ensure that the

silicon mold is level and uniform.

Once the box is ready, the next step is to mix the silicon material according to the manufacturer's

instructions. The mixture typically consists of two parts: a base and a catalyst. The two parts must be

mixed thoroughly in a ratio specified by the manufacturer to ensure that the silicon cures correctly and

produces a mold with the desired properties.

After the silicon mixture is ready, it is poured into the box, covering the wax mold completely. The silicon

will fill all the crevices and contours of the wax mold, capturing its precise shape and dimensions. The box

is then left undisturbed for the silicon to harden over time. The curing time for silicon varies depending

on the brand and type of silicon used, but it typically ranges from a few hours to overnight.

Once the silicon mold has cured completely, it is carefully removed from the box. The wax mold is then

extracted from the silicon mold by gently peeling it away. This process leaves behind a perfect negative

impression of the wax mold in the silicon material, creating a reusable mold that precisely replicates the

shape and dimensions of the pyramid with steps.

Step 4: Casting Chocolate in the Silicon Mold

The final step in this process is to use the silicon mold to cast chocolate. The mold is carefully removed

from the 3D printed box, and hot chocolate is poured into the cavity of the mold. After the chocolate has

cooled and solidified, the silicon mold is carefully peeled away, revealing a perfect pyramid with steps

made of chocolate.