Wild Card Week

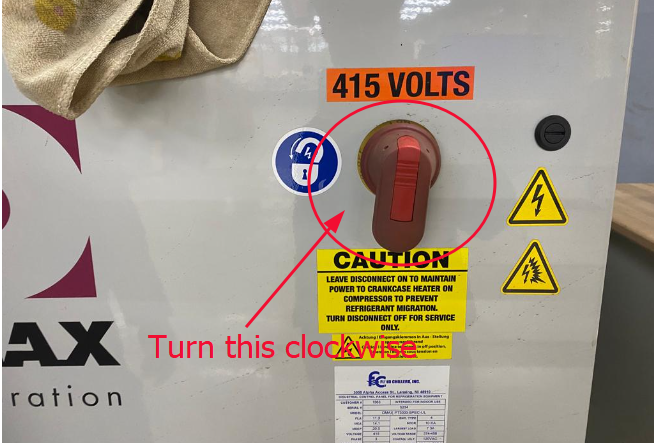

Wild card week was fun because we got to choose what we wanted to work on however on other manufacturing process that were not covered in other weeks. Therefore, I wanted to work on water jet machine particularly because the machine was available in the Lab and in addition I always wanted to learn about using the machine. Of course there were other heavy machines like Wire EDM and Zund but water jet machine had relevance in my passion for learning. The image of the machine is given below:

Wildcard Week Assignment

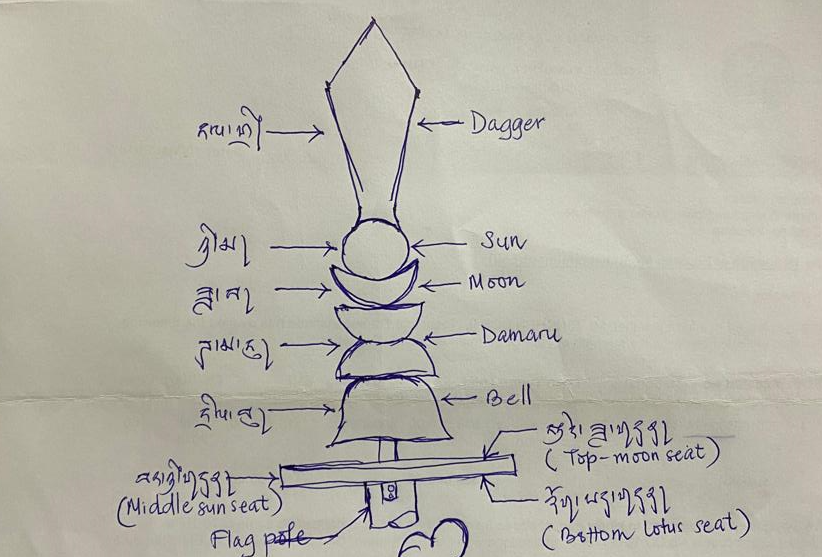

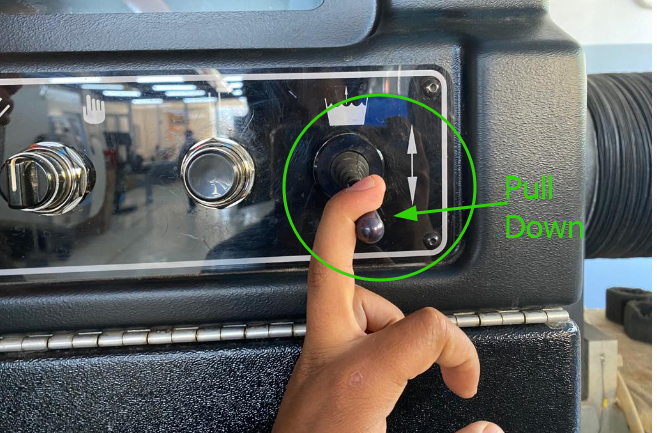

For this week, I was to design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it as per assessment guide. Hence, I wanted to make something that can be incorporated to my final project initially, however the idea could not materialize as my project actually was small in volume. Consequently, I thought of making something real application product in Bhutanese context which means producing Bhutanese traditional flag top with metal sheet. It is widely known as RELDRI-(dagger) in our national language. The free hand sketch with description in Dzongkha-National language and as well as in English is shown below:

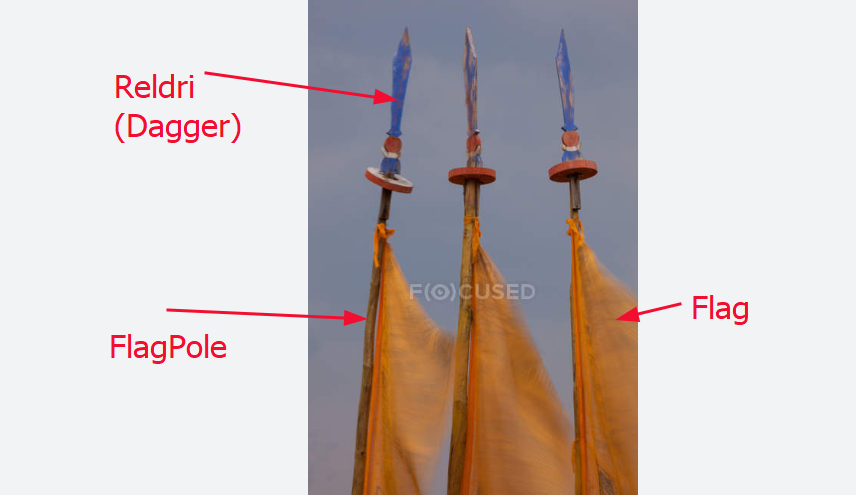

The image below is how my product after fabrication would look on top of prayer flags. Image is taken from GOOGLE and I have added description.

Water Jet Machine

Despite seeing the machine on daily basis, I could not manage time to get familiar with this machine ultimately it demanded prior hands on experience and expertise to use it. Fortunately, I could contact Mr. Lungten from JNWSFL who was in-charge and expert of the water jet machine to learn from as a part of this week's program . They assisted me with walking around the basics of machine and constantly supervised me when I was operating.

Basic Water Jet Machine Components

There were components to be known prior to working with the machine, and some of them are described below.

1. High Pressure Pump:The pump generates a flow of pressurized water for the cutting process.

2. Nozzle:The Pressurized water passes through a small-diameter orifice inside the nozzle and forms a coherent jet of water. The jet then passes through a venturi section where a metered amount of granular abrasive is drawn into the water stream. The mixture of water and abrasive particles passes through a special ceramic mixing tube and the resulting abrasive/water slurry exits the nozzle as a coherent cutting stream of abrasive particles travelling at very high speed.

3. Catcher Tank:The water-filled catcher tank dissipates the energy of the abrasive jet after it has cut through the material being machined.

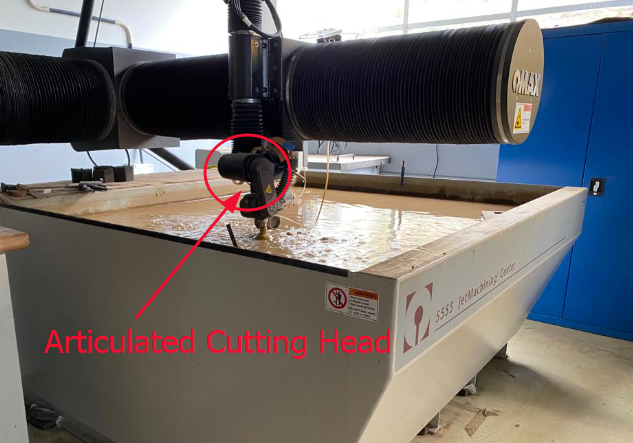

4. Abrasive Hopper:The abrasive hopper and associated abrasive flow control system provide a metered flow of granular abrasive to the nozzle. Articulated Cutting Head.

5. Articulated Cutting Head(Optional):As an add-on option to OMAX waterjets, this computer-controlled multi-axis cutting head permits angled cuts and can be used to automatically minimize taper for precise vertical cuts.

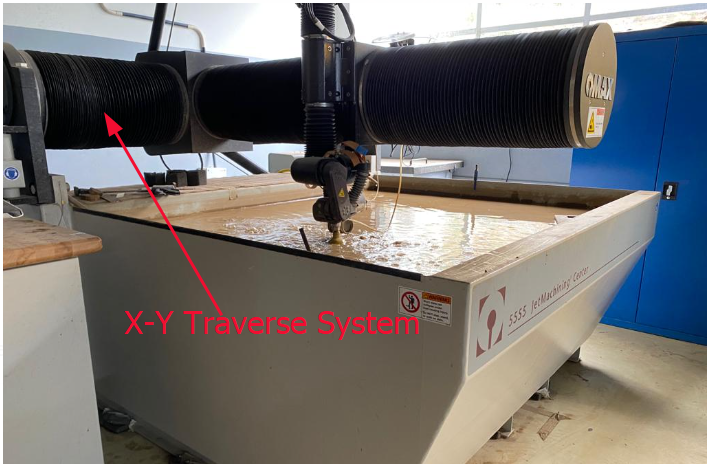

6. X-Y Traverse System:A precision X-Y motion system is used to accurately move the nozzle to create the desired cutting path.

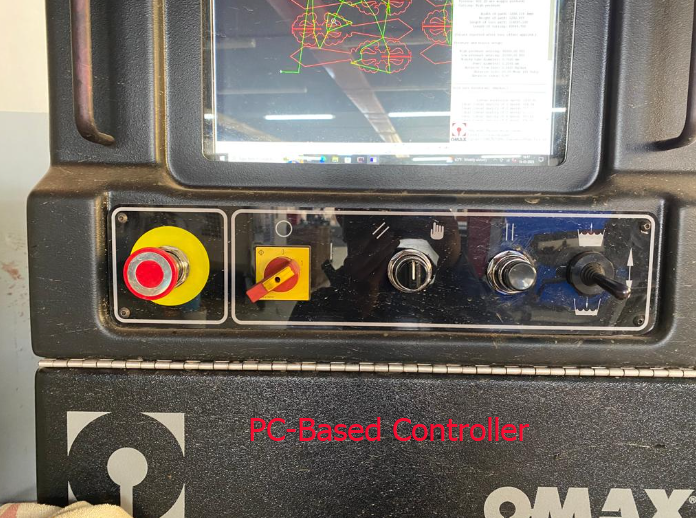

7. PC-Based Controller:Advanced motion controllers for abrasive waterjet systems are PC-based and permit production of accurate parts with minimal operator experience.

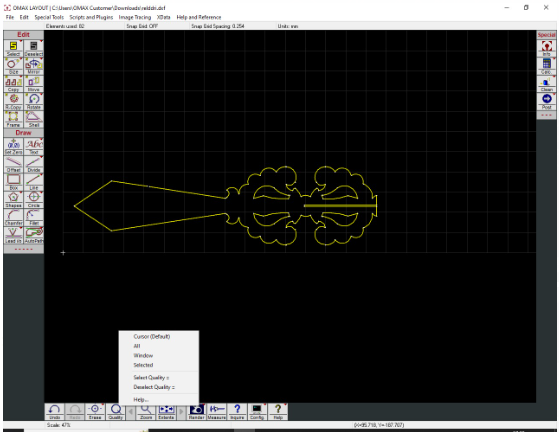

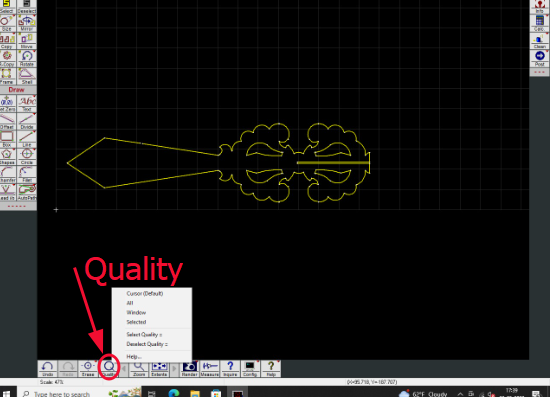

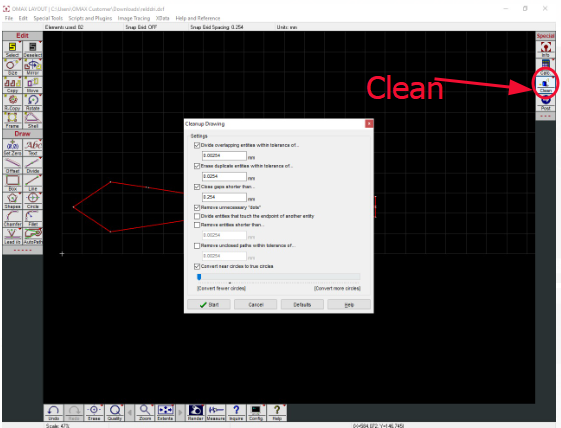

Design in Fusion 360

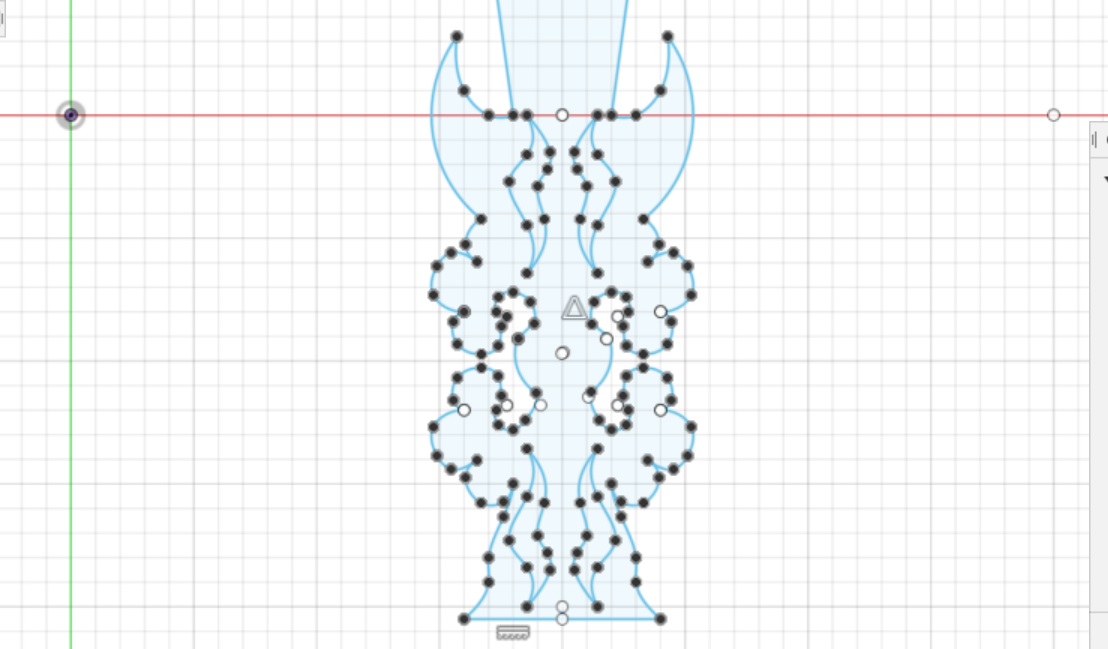

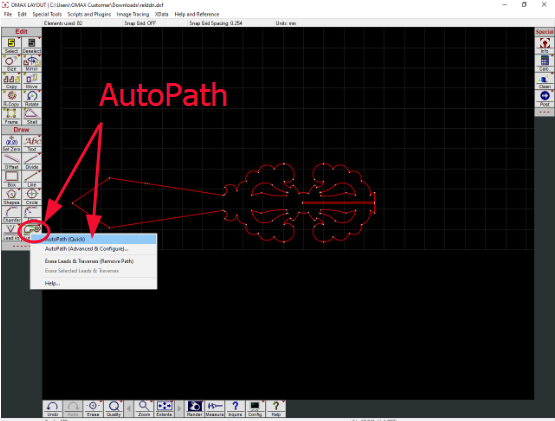

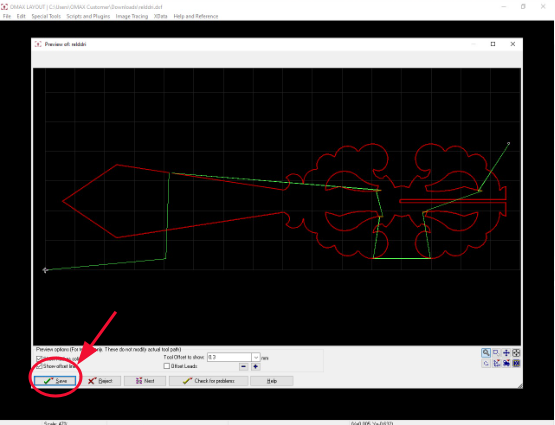

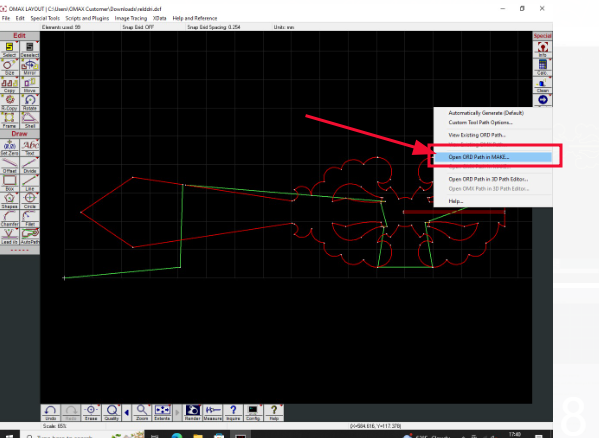

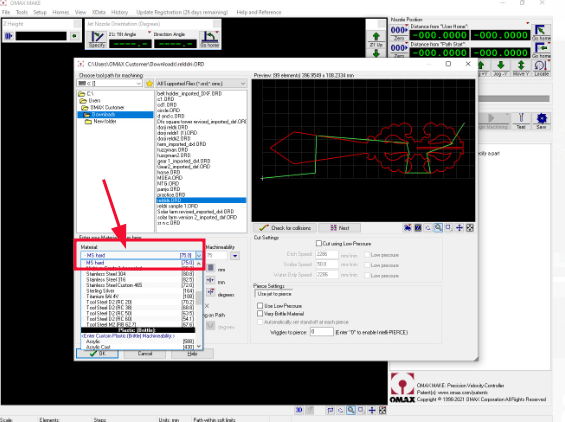

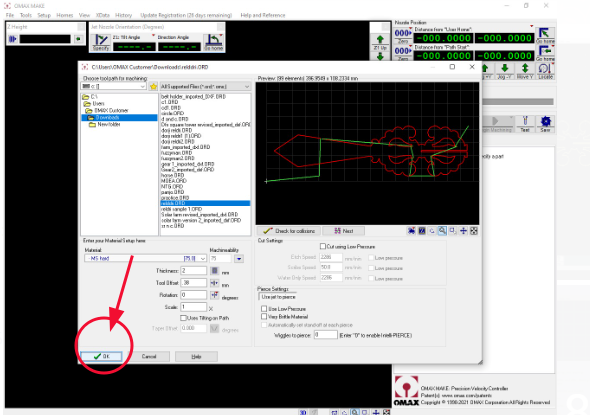

Design of 2D sketch has to be exported in the form of .DXF so that it can be read in the Omax of water jet cutter. Otherwise you can also directly draw in the omax software of the machine PC. But I have designed in the fusion and then exported in .DXF format. Design file attached in the bottom of the page for reference.

Work Flows

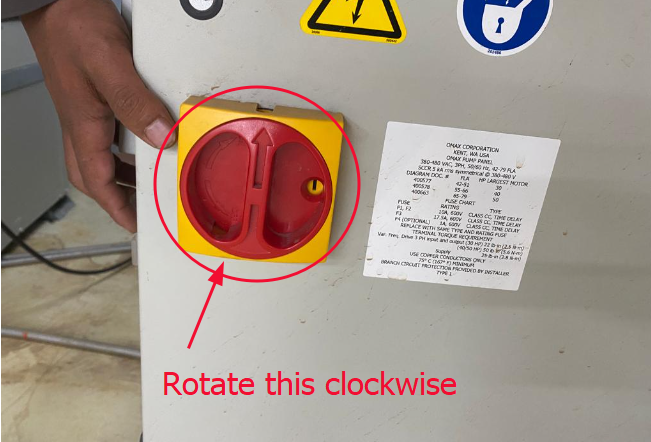

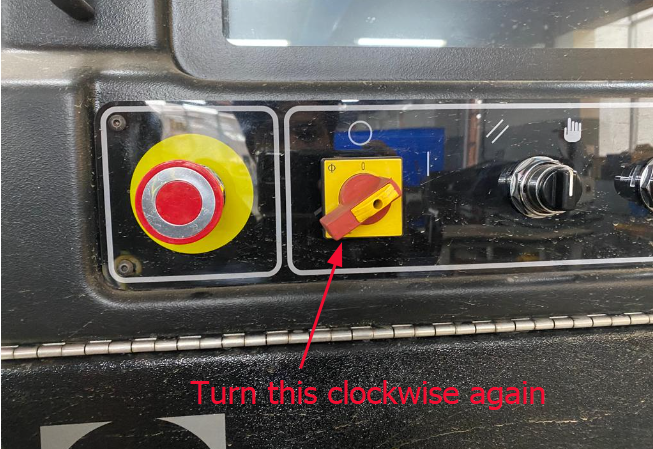

There were certain steps specificcally on using water jet machine to cut the job after the design is ready and these are as follows:

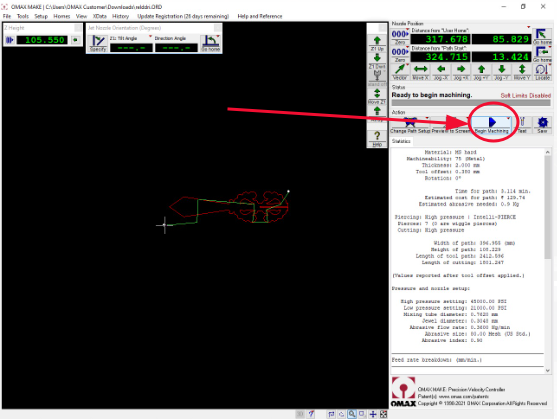

Job Setting and Clamping

After setting everything and before step 13, you need to do the job setting on bed. That is clamp the job piece on the bed with clamp as shown: The clamp is of both side.

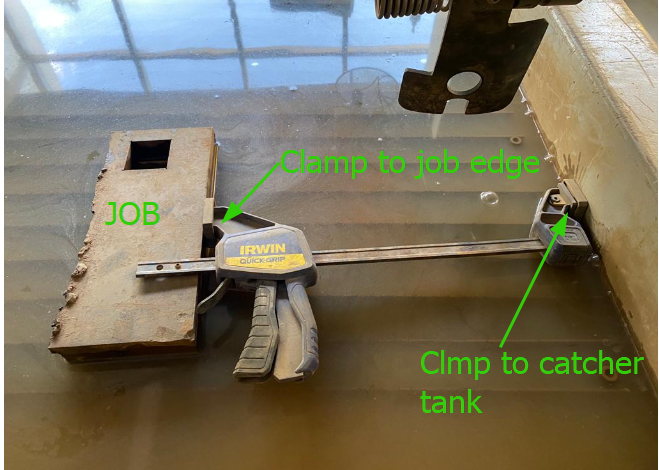

Then after step 13, pull down the know under PC to level up the water on bed to cover the job completely. Then the machine will begin to operate.

The capture from the work of the week. This video shows how the machine cuts your design file.

Hero Shot of the week and the product made for Wildcard Week by water jet cutter as shown below.

Design File

2D Sketch of Reldri