Wildcard Week

Task for Week 15

- Individual Assignment

- Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to):

Waterjet OMAX 5555

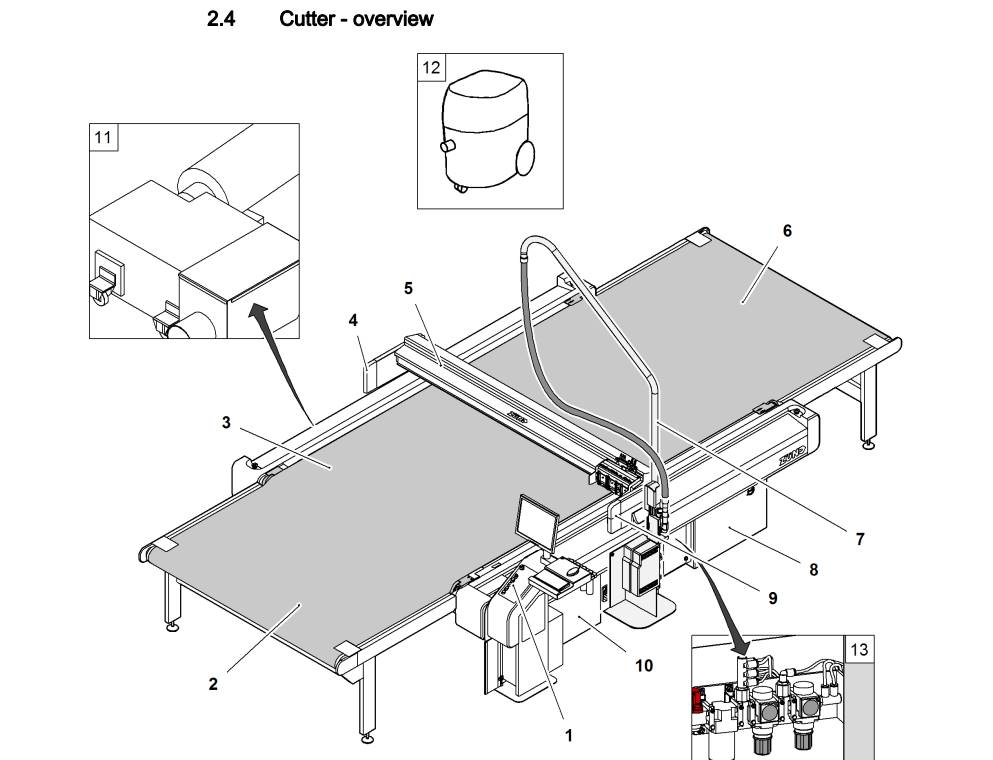

The waterjet in the lab was under maintenance so couldn't work on the machine. So I decided to use the Zund. To be honest, I found the machine quite attractive because the cutting surface is carpeted, unlike any other machine. Zund offers a variety of machines for different applications, including the G3, D3, S3, and L3. Each series has several models with different sizes and features to suit different needs. The JNWSFL has the G3-L2500 model.

Zund G3-L2500

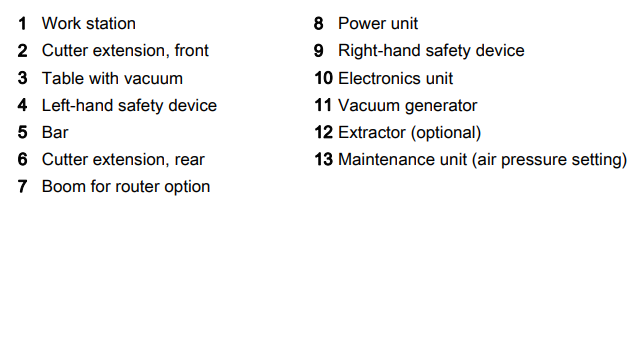

- The Zund G3-L2500 is a digital cutting system that is designed for high-speed, precision cutting system that is designated for high-speed, precision cutting for a wide range of materials. It features a modular design, which allows it to be configured to meet the specific needs of different industries and applications.

- The cutting surface is 2.5 meters wide, which makes it ideal for handling large sheets of material.

- The cutting head is equipped with a variety of tools, such as blades, routers, and creasing wheels, which can be quickly and easily changed to accommodate different materials and cutting equipments.

- The system is controlled by a powerful software suite, which allows users to create and manage cutting jobs with ease.

- Overall, the Zund G3-L2500 is a versatile and reliable cutting system that is widely used in Industries such as graphics, packaging, and textiles.

Cutter- Overview

Modules

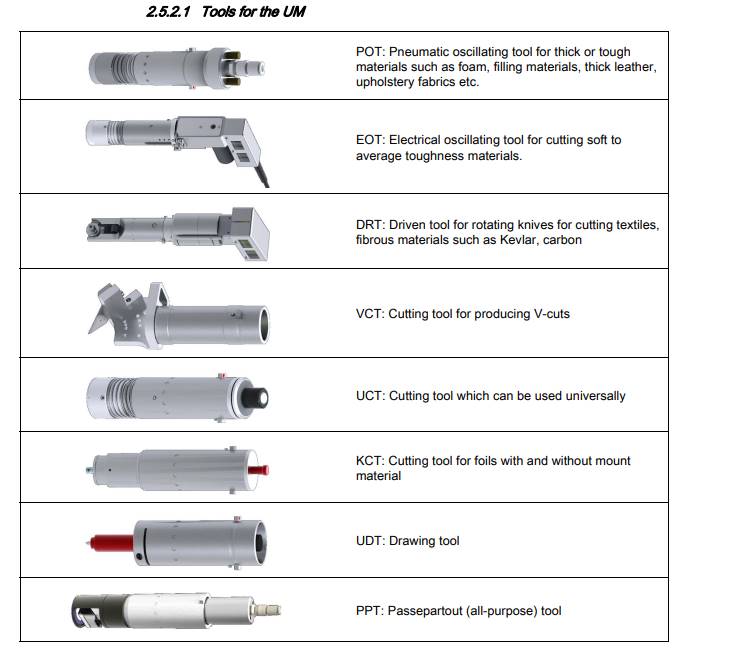

Tools

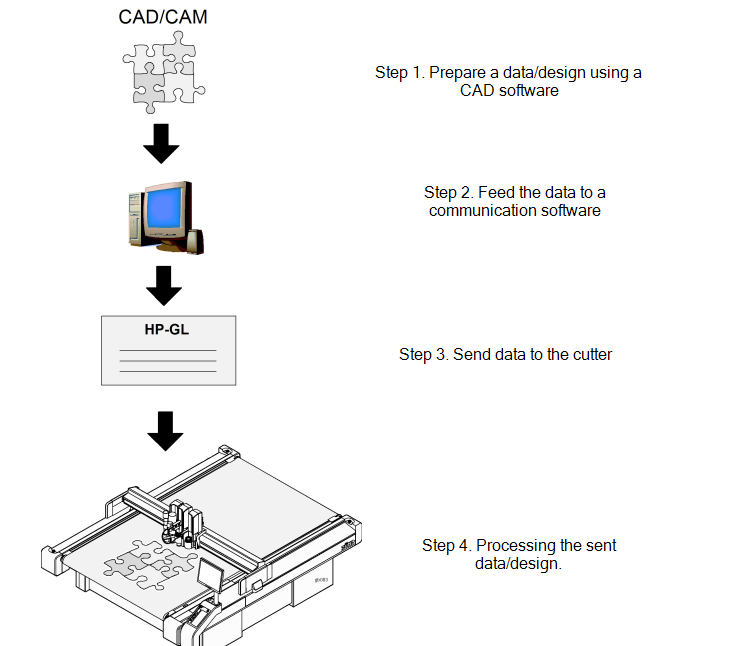

How does the machine work?

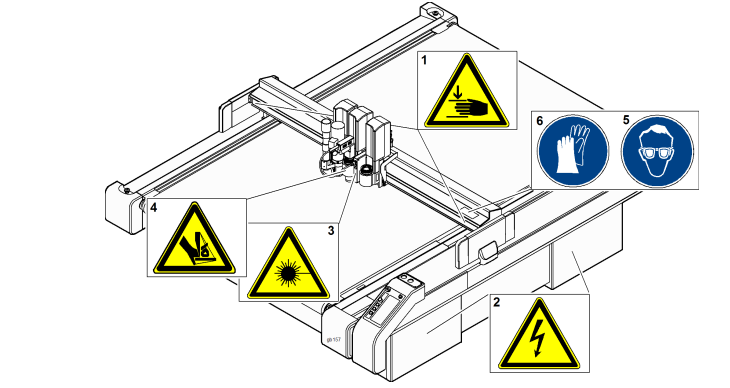

Safety Measures

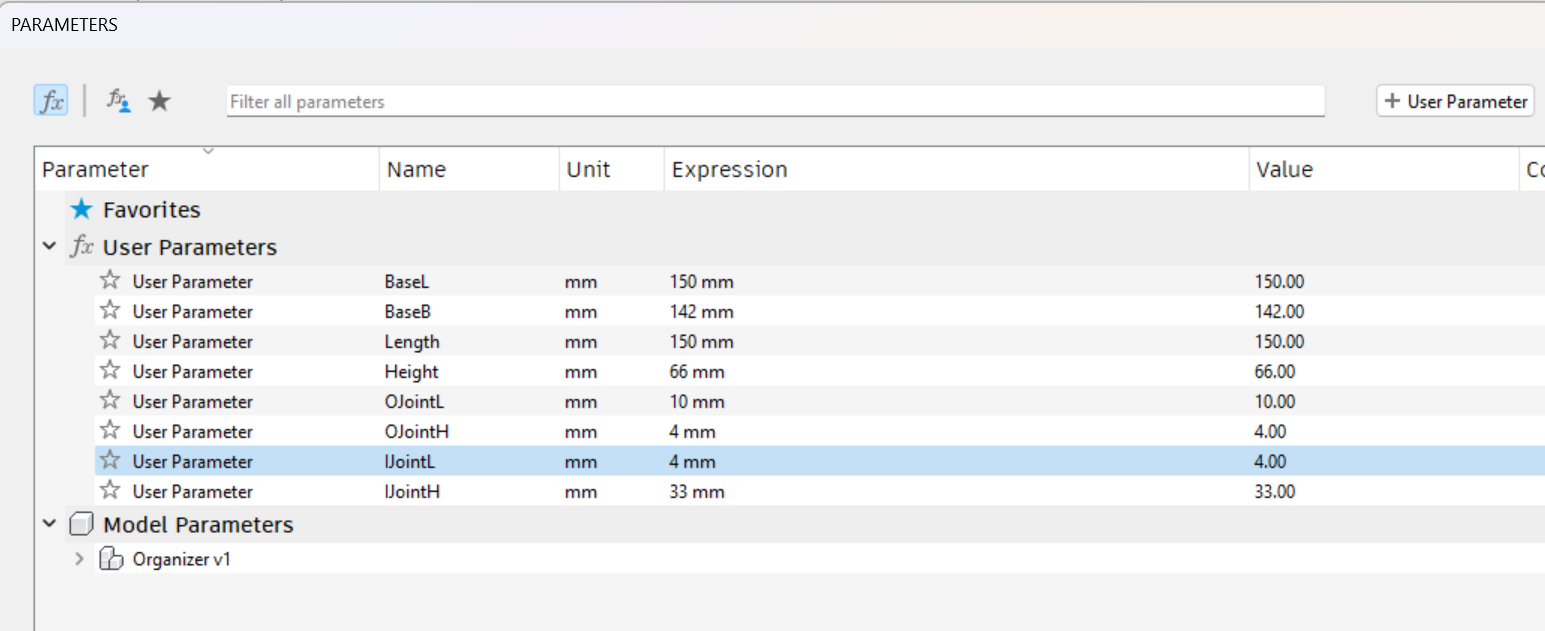

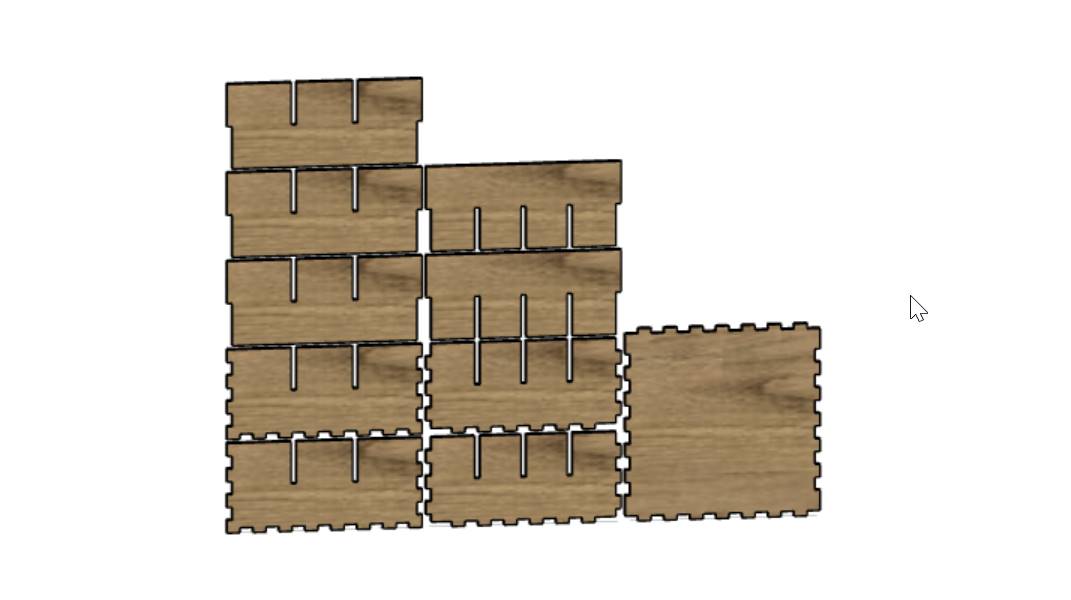

Design of the Organizer

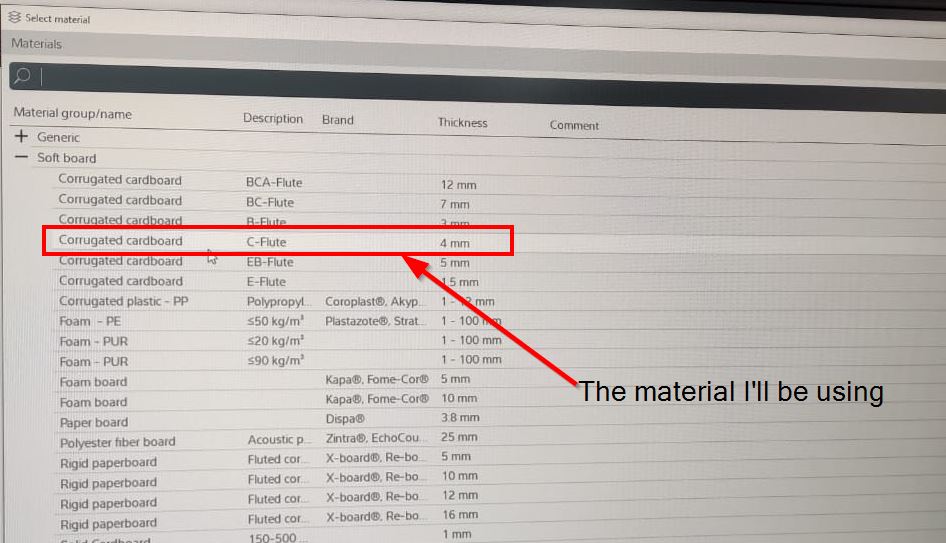

For this week, I've decided to cut a Organizer for my electronic components. I actually planned to cut the organizer using Acrylic sheets but the compressor of the Machine isn't working as of now so went ahead with Cardboard.

- I've designed using the Fusion 360. These are the parameters I used.

- The organizer design.

Zund Workflow

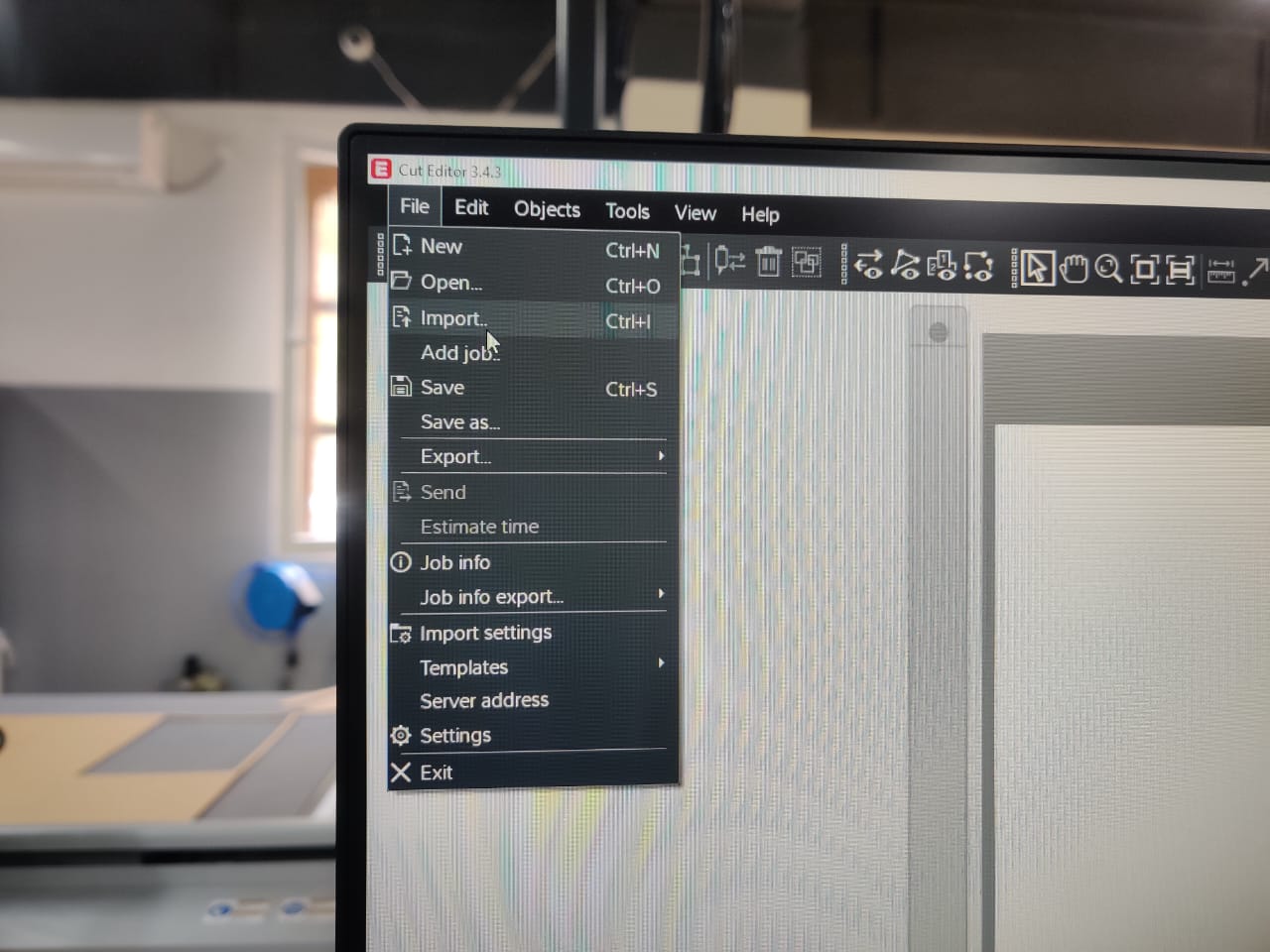

- Out of 4 Zund Apps, Click on "Cut Editor"

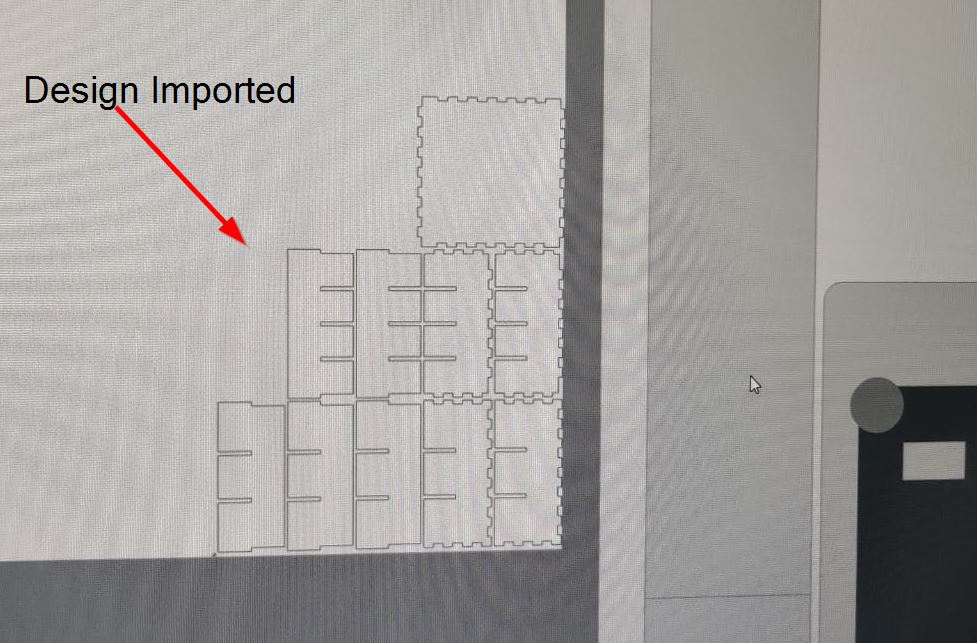

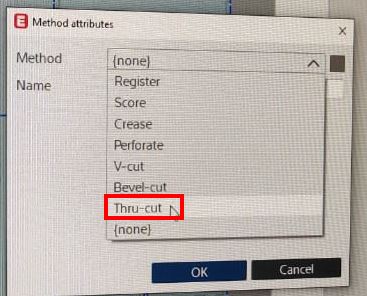

- Once the design is completed, transfer the design to the communication software in either dxf or Svg format by clicking on Import from file

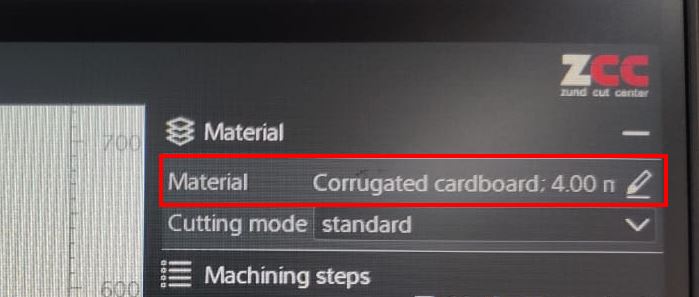

- After the design file is imported, change the material type that you will cut the design on. To do so, Click on the Material on the top right panel as shown below.

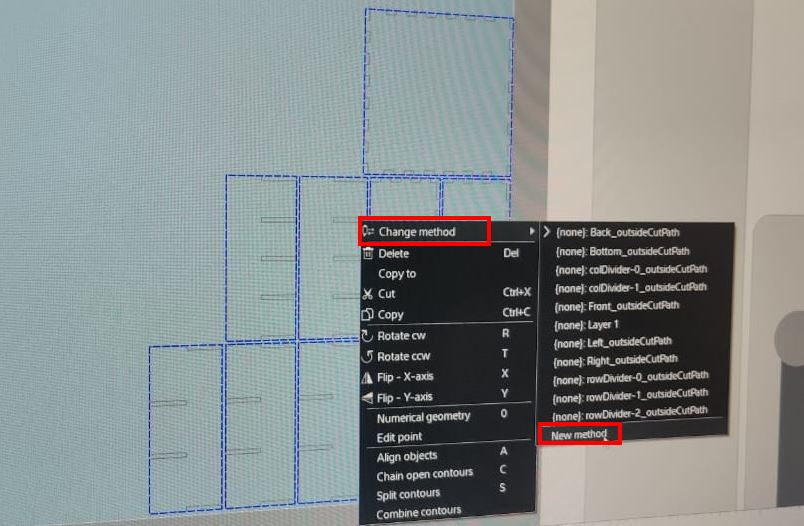

- Then Select the design and right click on it, then click on "Change Method" and select "New Method".

- Then I selected "Thru-Cut" since I'll be cutting through.

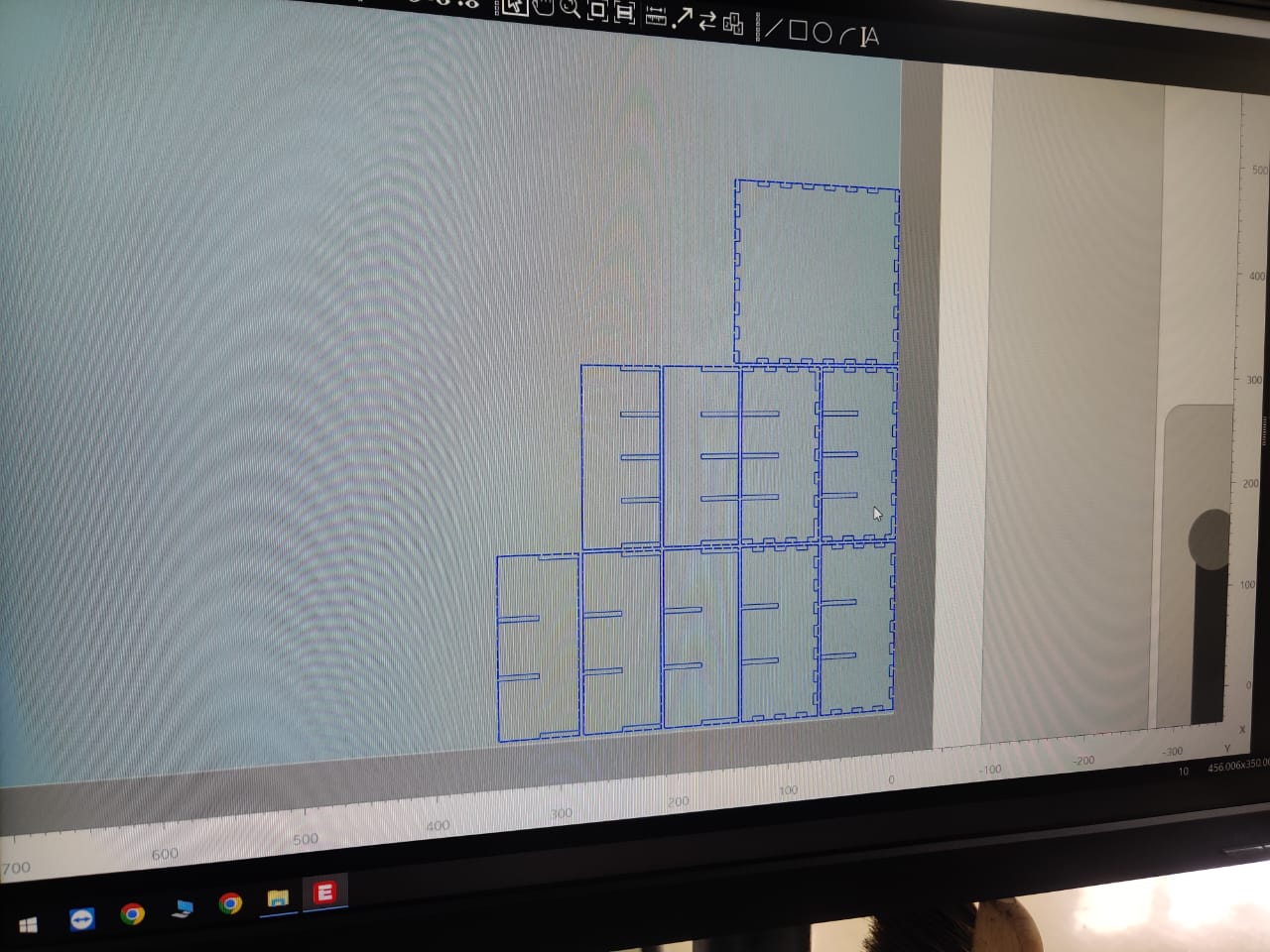

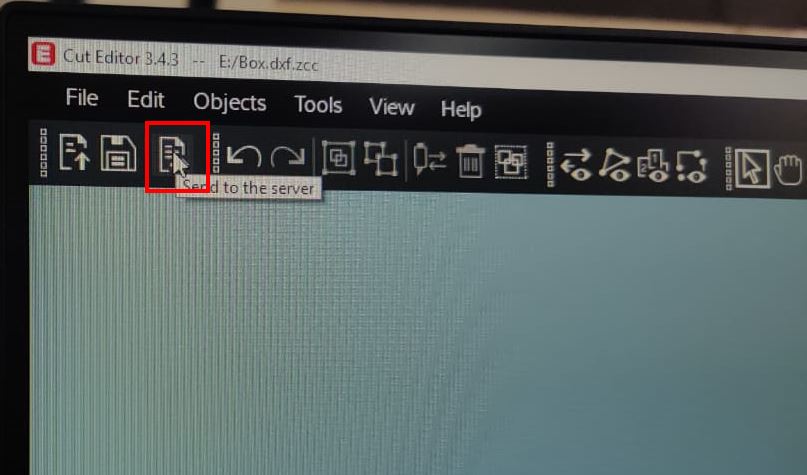

- After assigning the method, the last step in the Editor is to send the file to the Server by clicking on "Send to the Server" on the top Left side as shown below. Then the edited job will be saved and sent to the "Cut Queue"

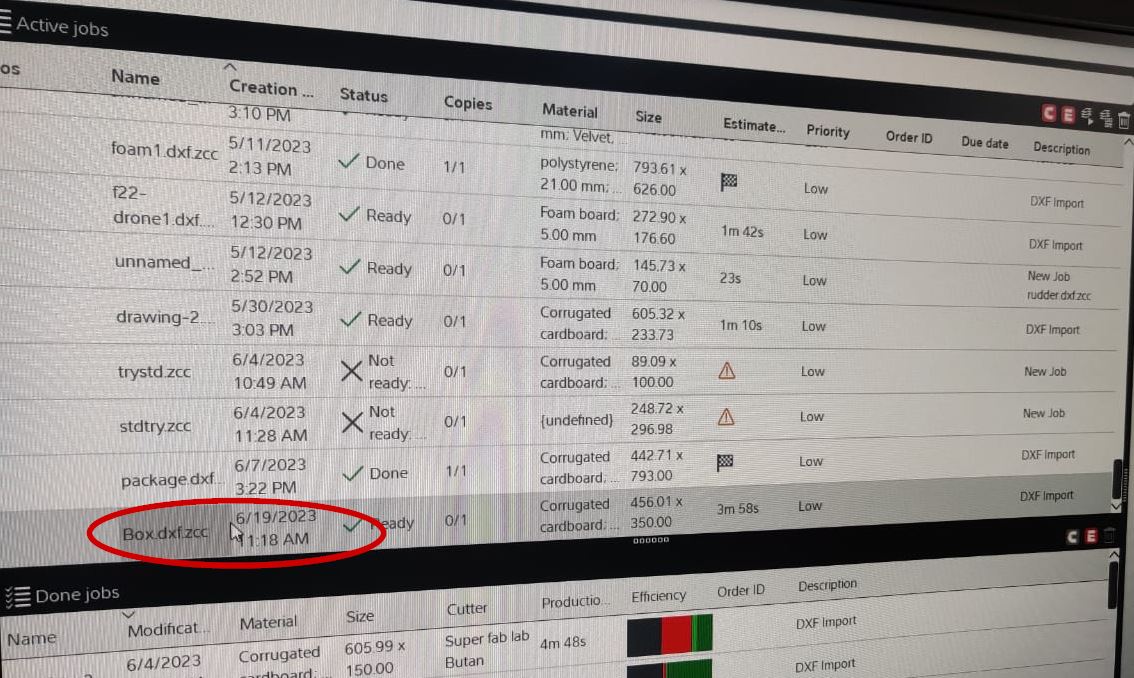

- Now, Clicked on "Cut Queue". Then Search for your saved job in the "Cut queue" and Click on it to open in the cut center.

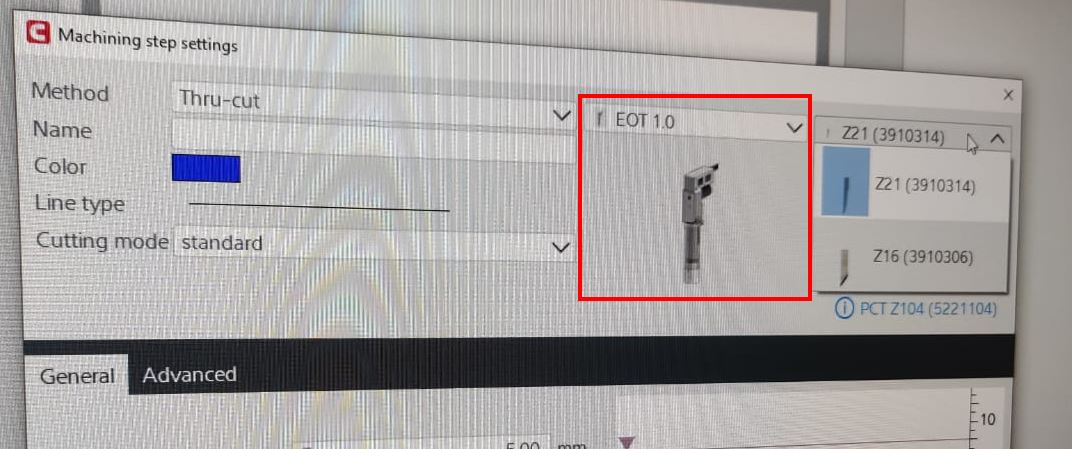

- Then in the Cut Center, have to change the tool and module according to the material that we are cutting on. For Thru-cut, I went ahead with EOT(Electrical Oscillating Tool) which is used for cutting corrugated cardboard.

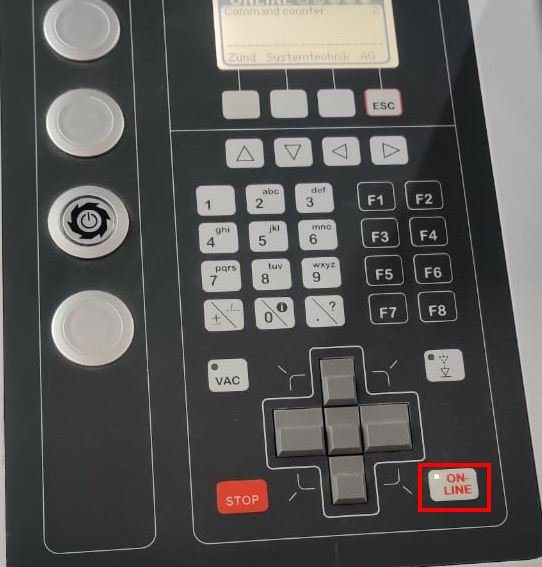

- Before Clicking on "Start Job", first we need to Press "Online" on the operating keyboard of the machine. And turn on the Vacuum of the machine to hold down the job piece securely.

- After that, we can Click on "Start Job" on the Cut Center and the register process will start. After registering the borders of the Job Piece, the Cutting starts.

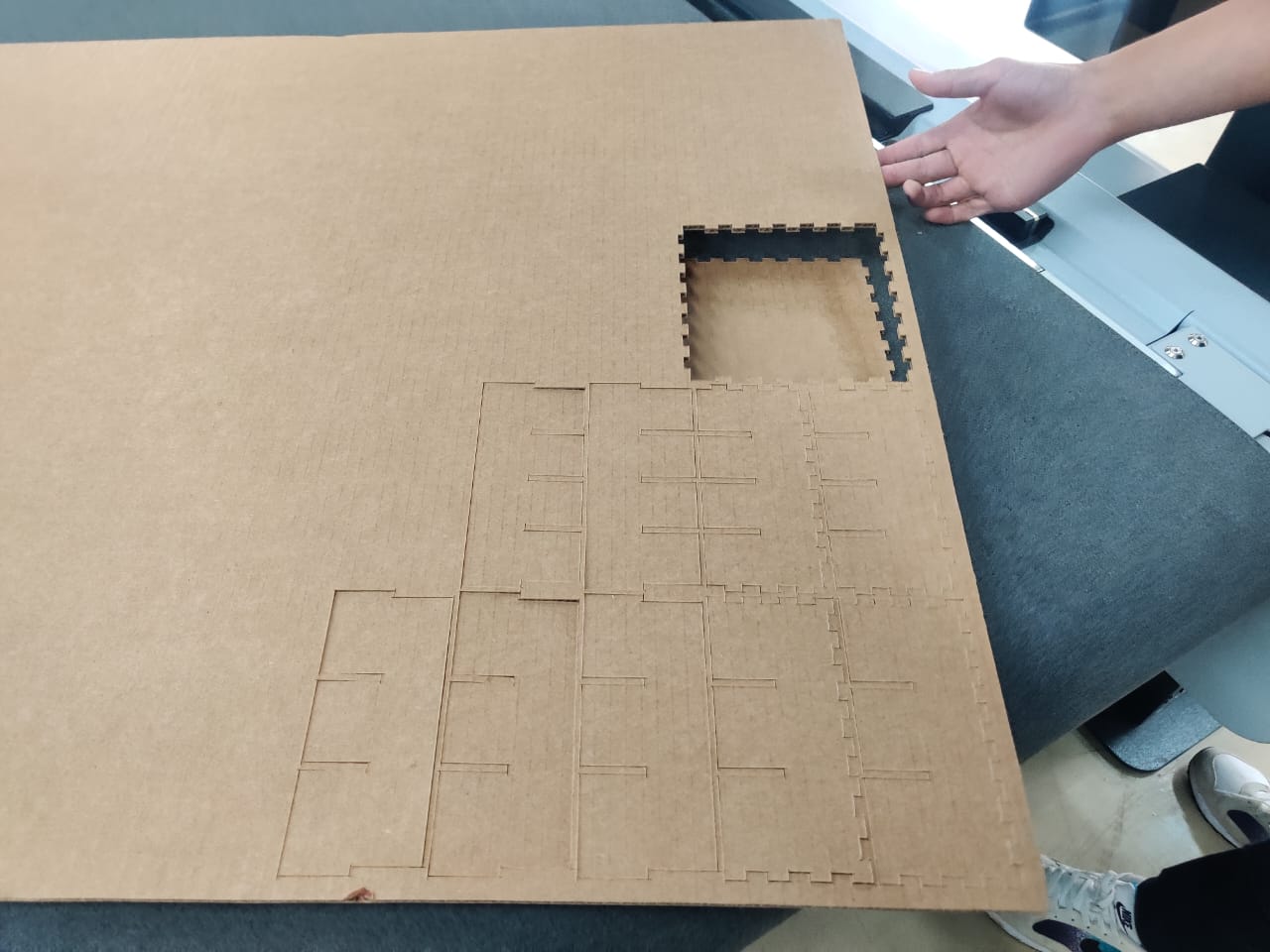

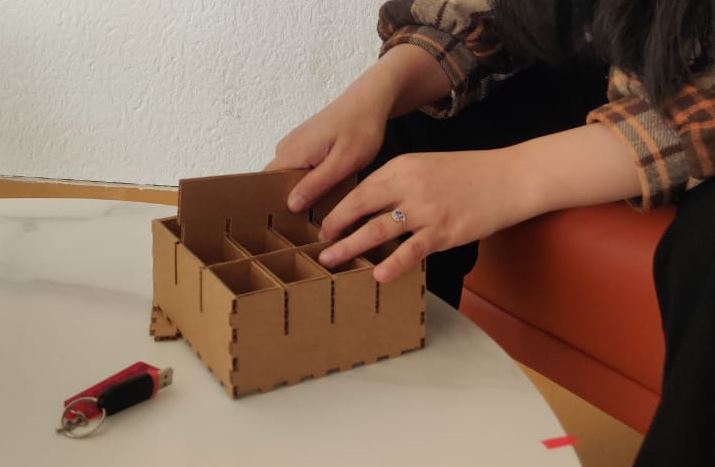

- This is a picture after the cut.

- Here is a picture of me assembling and the Final Hero shot!