Designing

Inspired by the previous week on interface and application programming I used Processing as a source of creation for my designs. I always really liked errors and glitches so I looked up code examples I could use.

I found a git repository with a lot of glitch examples, so I downloaded them and try them out until I found one that would generate glitches I liked.

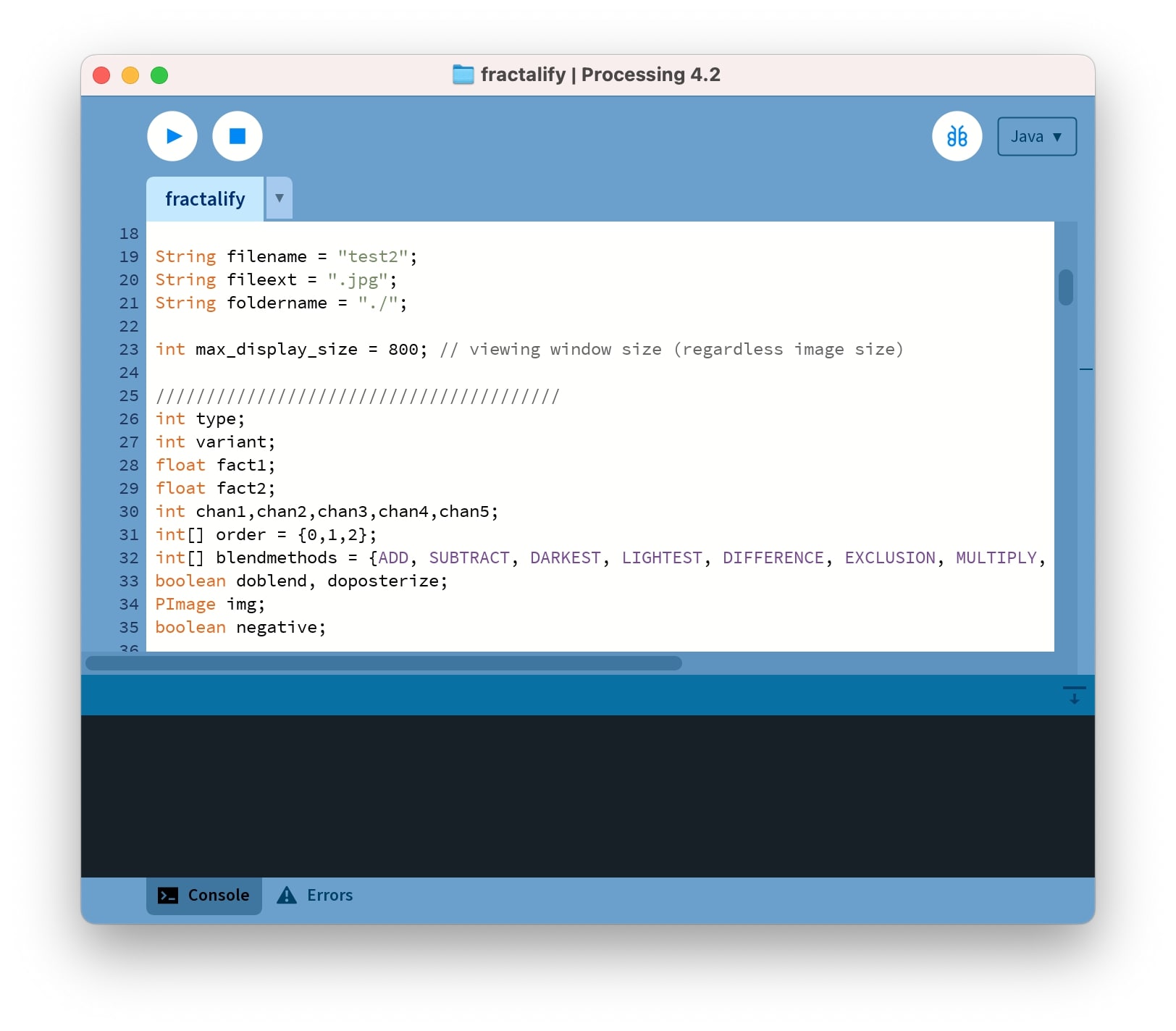

The one I liked the most its called fractalify by Tomasz Sulej. It uses a library called "processing.svg.*" and it loads an image to then apply the glitch effect on it. I used my own brand image which is a gradient I created a few years ago.

The code itself is too hard for me to understand, but the author says that the sketch draws Mandelbrot/Julia fractal using channel data to initialize/modify 'z' and 'c' variables and that there is a lot of randomnesses: channel selection (RGBHSB), coloring, blending, posterizing, fract type (Mandel/Julia), some factors. It is possible to save the drawings by pressing any key and to generate a new drawing we can simply click on the image.

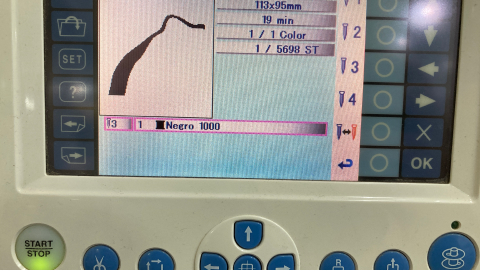

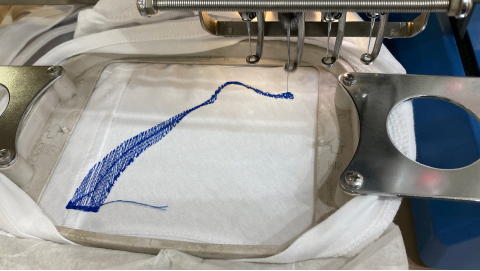

So after playing with it a bit, I generated 3 images that I liked (on the left side), the images were being generated in jpg and I needed to use vectors for the machine so I checked for plugins for tracing images in Figma, but they were all too detailed. So in the end I ended up designing the shapes by hand. From these shapes, I really liked one of them and decided to use that one in my designs.

I wanted to use the shape in several points of the t-shirt, I could achieve that by moving the t-shirt around and continuously embroidery the same shape.