WEEK 11: MECHANICAL DESIGN, MACHINE DESIGN

For this week my indispensable "fabmate" Jon Merino and I worked together and designed a machine with: mechanisms, actuation, automation and application.

IMPORTANT DISCLOSURES

Before continuing, both Jon and I want to point out that we 100% worked together during this week, so it´s very difficult for us to "separate" who did what. To be 100% fair, Jon supervised more the building part, and I supervised more the documentation part, but both worked together on every part of this super fun and stressful experience of making our own machine..

You can check our work here: Machine week.

INDIVIDUAL CONTRIBUTION

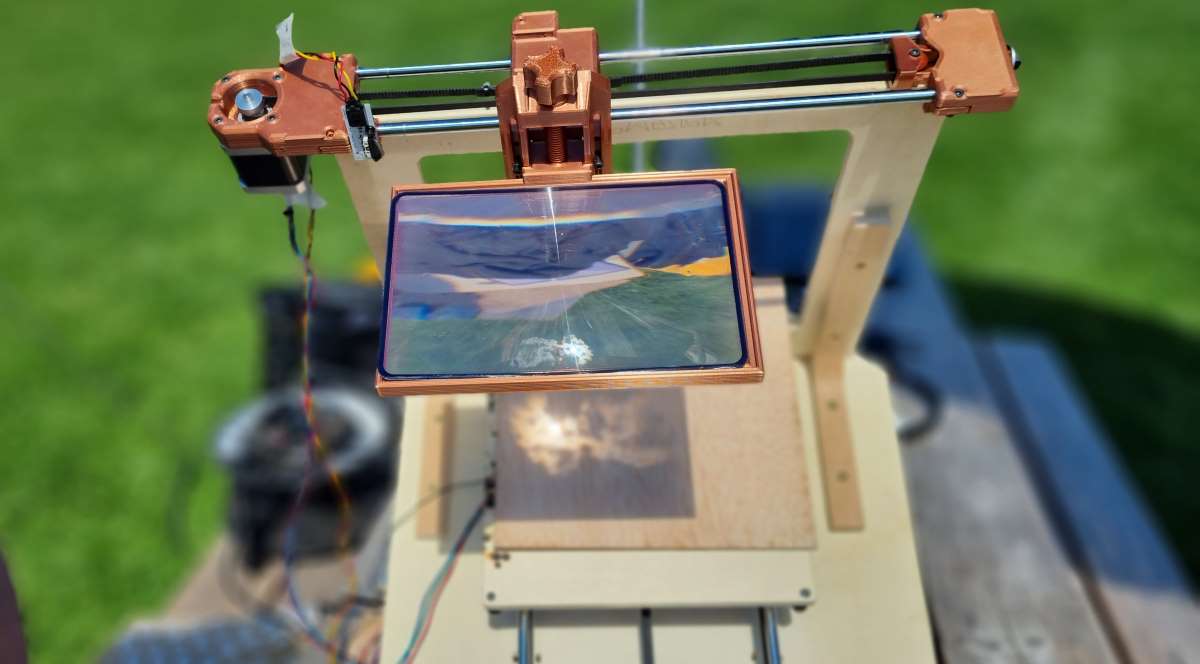

As an individual contribution and reflection of what each of us did is mandatory, I´ll try my best to reflect on this experience, and share what parts or steps I worked more can be considered relevant or key. First of all, I would like to give full credit of the idea to Jon Merino. He came up with this crazy idea, ¿Why not create a solar engraving/cutting machine with the use of a Fresnel lens..? It sounded incredibly crazy and cool from the begining so, we didn´t have any other choice than to give it a try!.

CONCEPT DESIGN CONTRIBUTION

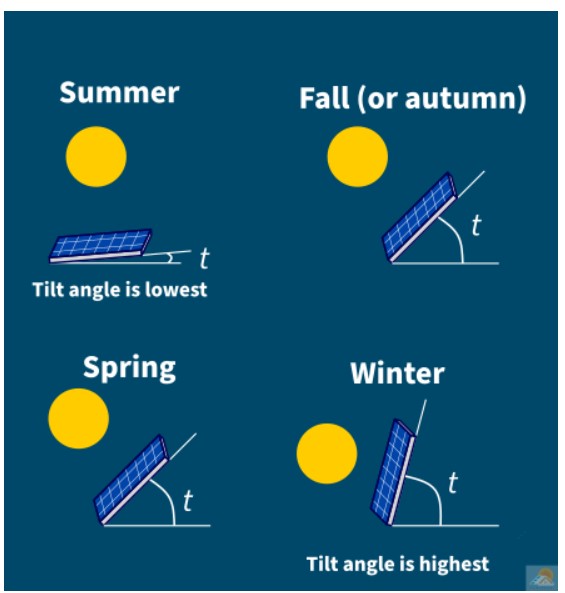

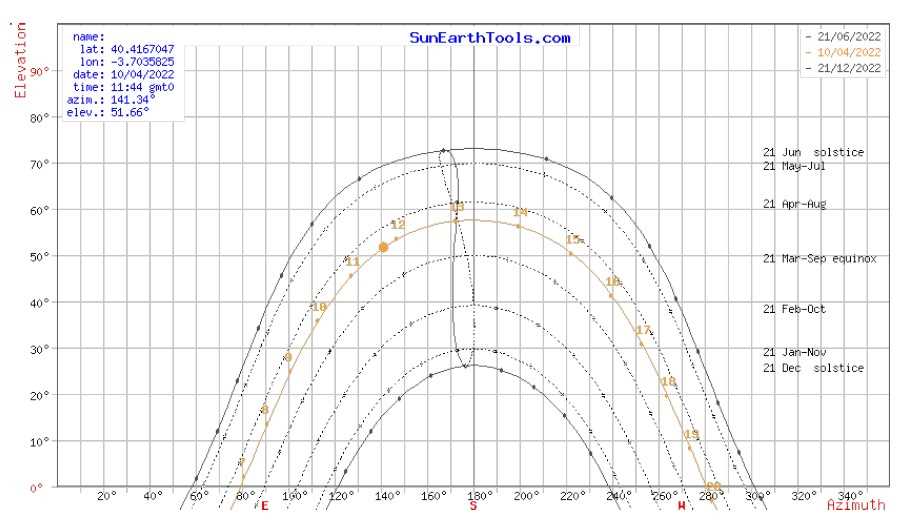

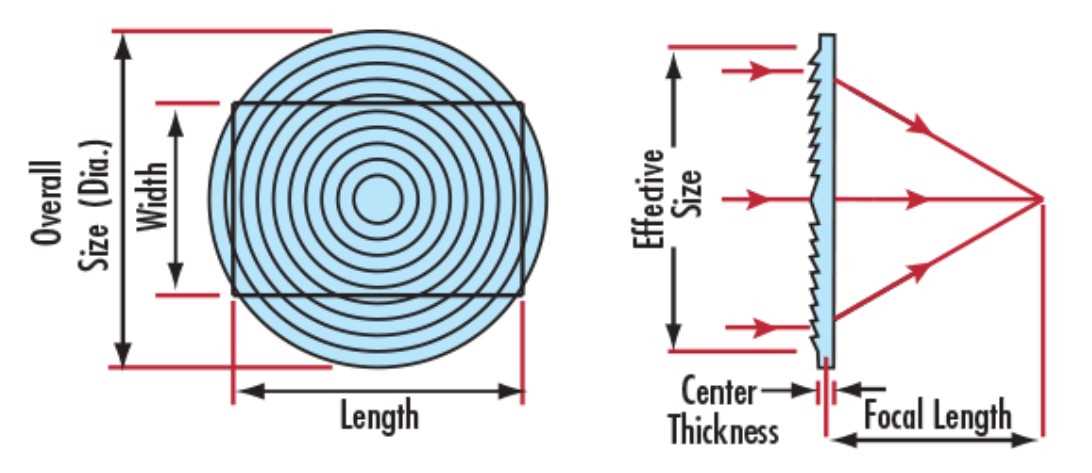

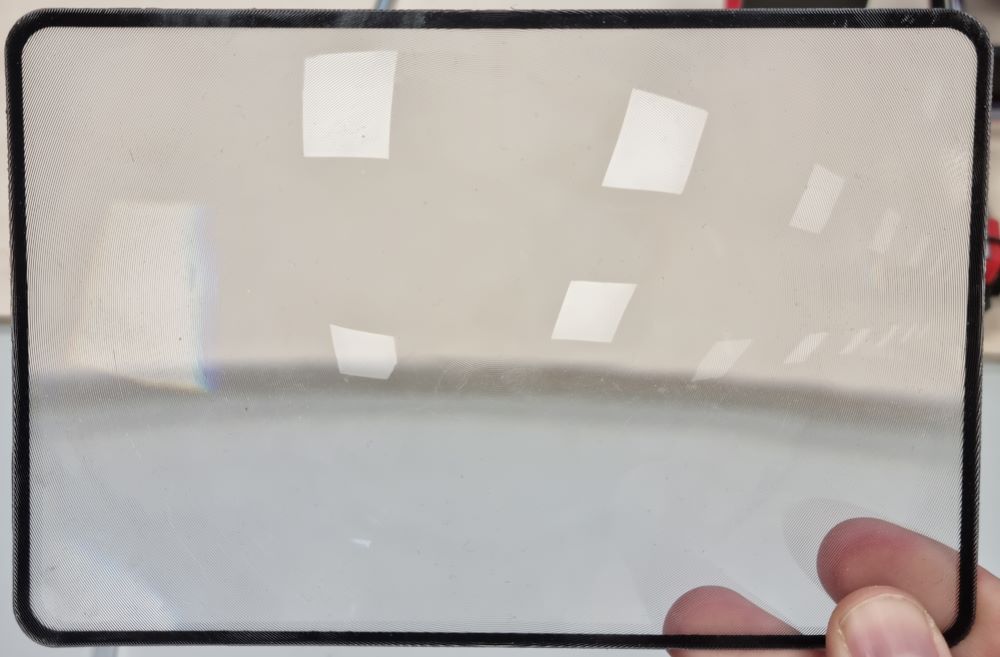

Regarding the Concept design, I researched the literature and shared with Jon, and documented in the group page, how solar panels worked, and which is the optimal tilt angle range in Spain as you can check in the machine week group link. I also deepened on explaining what is a Fresnel lens and how does it work. As you can appreciate (in the group assignment), I feel very comfortable documenting and researching all we´ve done. That´s because my learning curve is being so high, that I need to reflect on it while writing it down, so I can learn more thoroughly and of course have the info for the future! For me, doing this first research was key to burst my confidence in building my first machine ever, and of course establishing the theoretical concepts of the functioning of our machine as none of us had "worked" with solar "power" before.

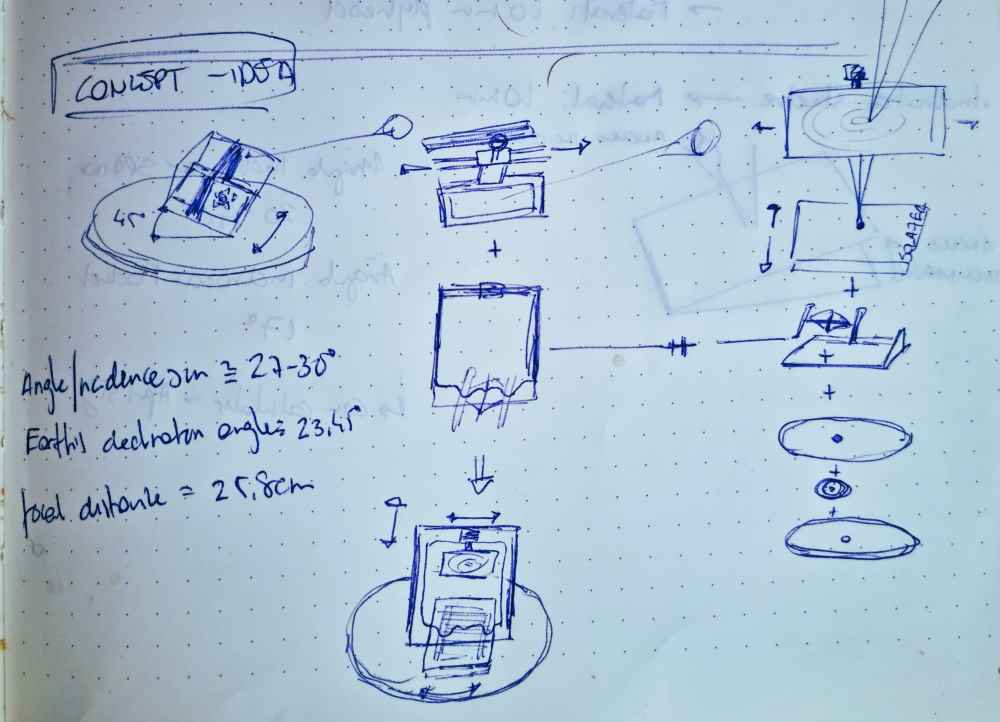

Finally, I also did the fisrt sketches of the how the machine should be, as the result of this first research.

Tilt angle examples.

Tilt angle examples. Sunpath Madrid.

Sunpath Madrid.

Fresnel lens.

Fresnel lens. First design.

First design.MECANICAL DESIGN CONTRIBUTION

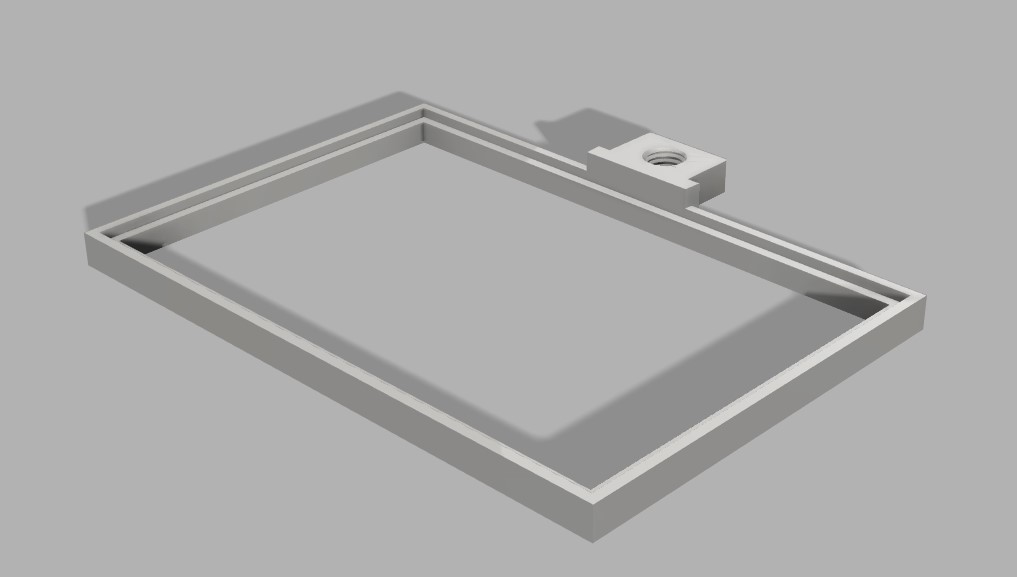

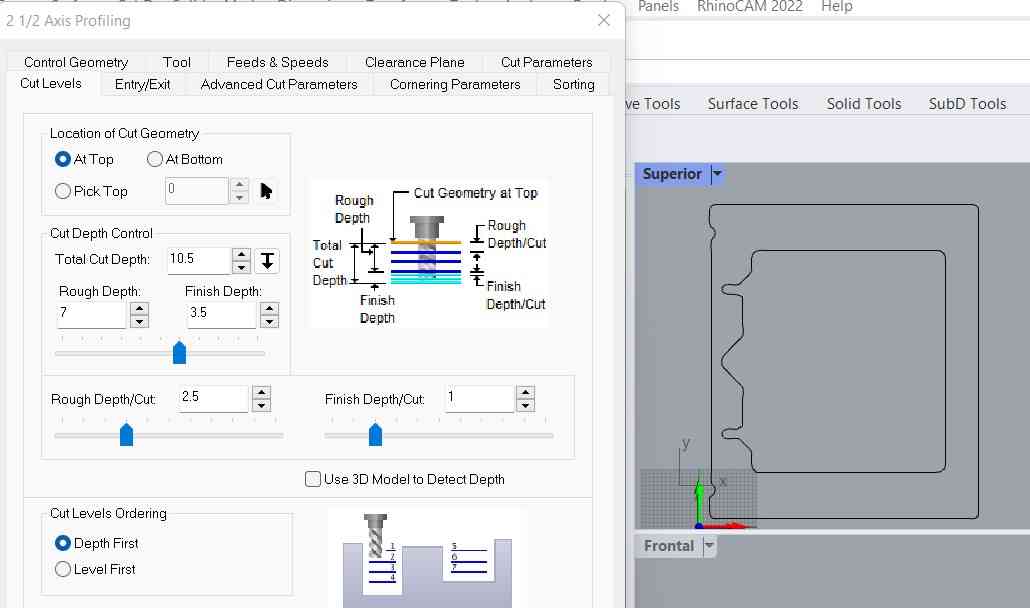

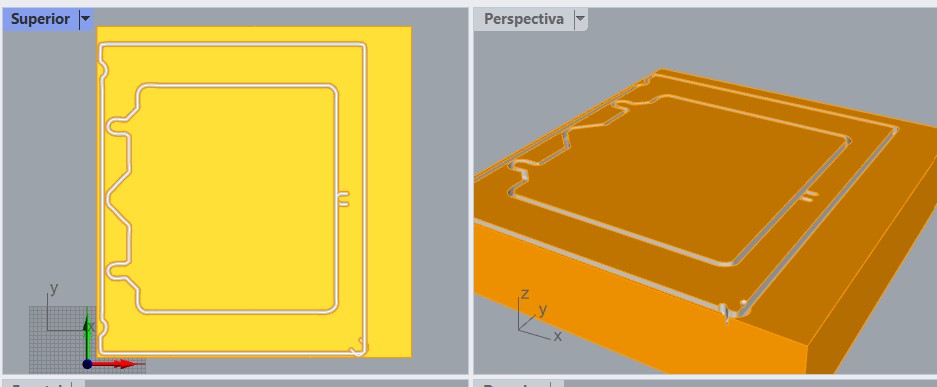

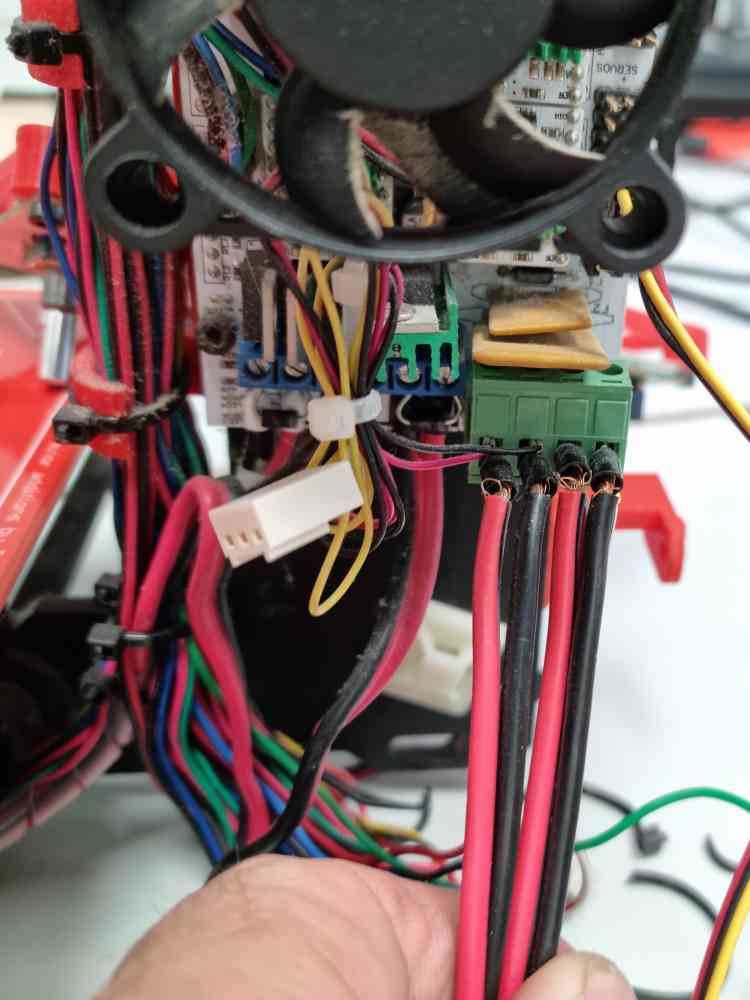

Regarding the mecanical design contribution, I worked on preparing with Rhino the CNC and 3D printing settings for all the materials we milled and printed. But all the process was done collaborative as we always work our CNC machine in pairs.

3D printed examples.

3D printed examples.

RhinoCAM

RhinoCAM Simulating

Simulating

Milling example

Milling exampleFor me, it was a perfect opportunity to apply what i´ve learned in the past weeks, using again the CNC milling machine and the 3D printers with our own design. I also had my first experience in assembling a complete funcional mecanical design, but that work was collaborative also, having Jon more responsibility, as he has more experience that I, especially when we disassembled the old broken prusa.

Dissasembling Y-axis components

Dissasembling Y-axis components

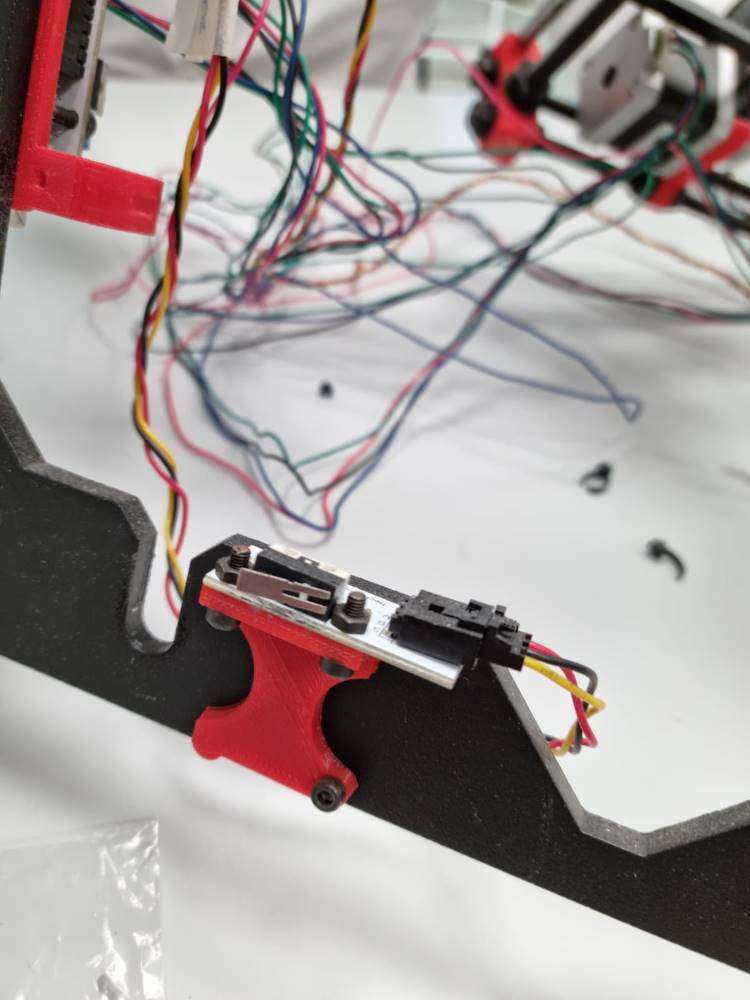

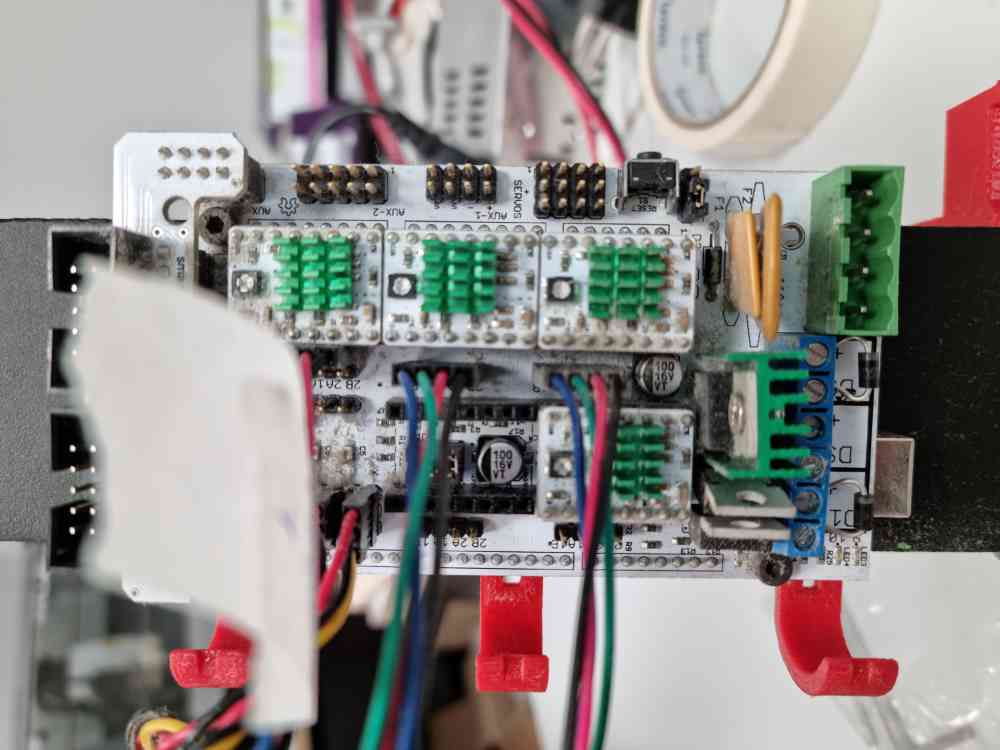

Before cable removing

Before cable removing After cable removing

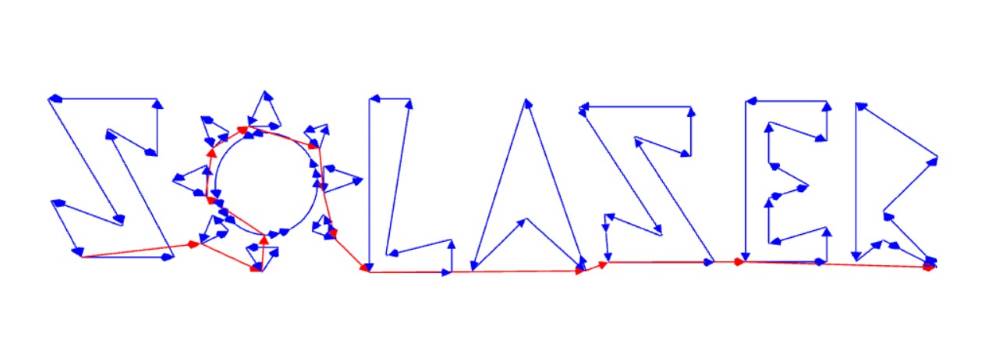

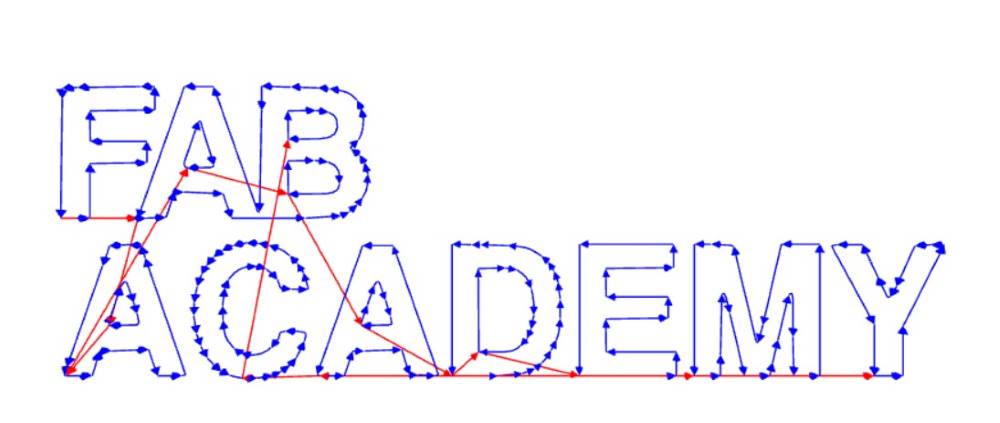

After cable removingNow that I thinl about it, It´s true that I can take full credit on all the aspects related to customizing our machine (Solazer), I designed the name logo! Jon´s says it looks like Salvador´s Dalí type.... but I know he likes it.. ;) You have to take into account that it´s very difficult to be more creative than the man that has created Neil´s muppet, with a song included!

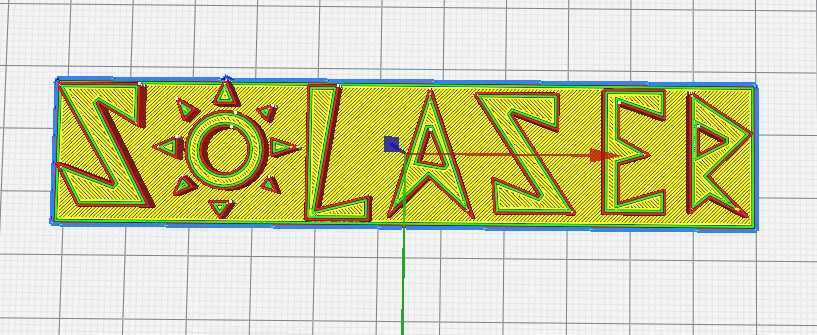

Engraving the Solaser bed.

Engraving the Solaser bed. 3D printing.

3D printing.

AUTOMATED MOVEMENT CONTRIBUTION

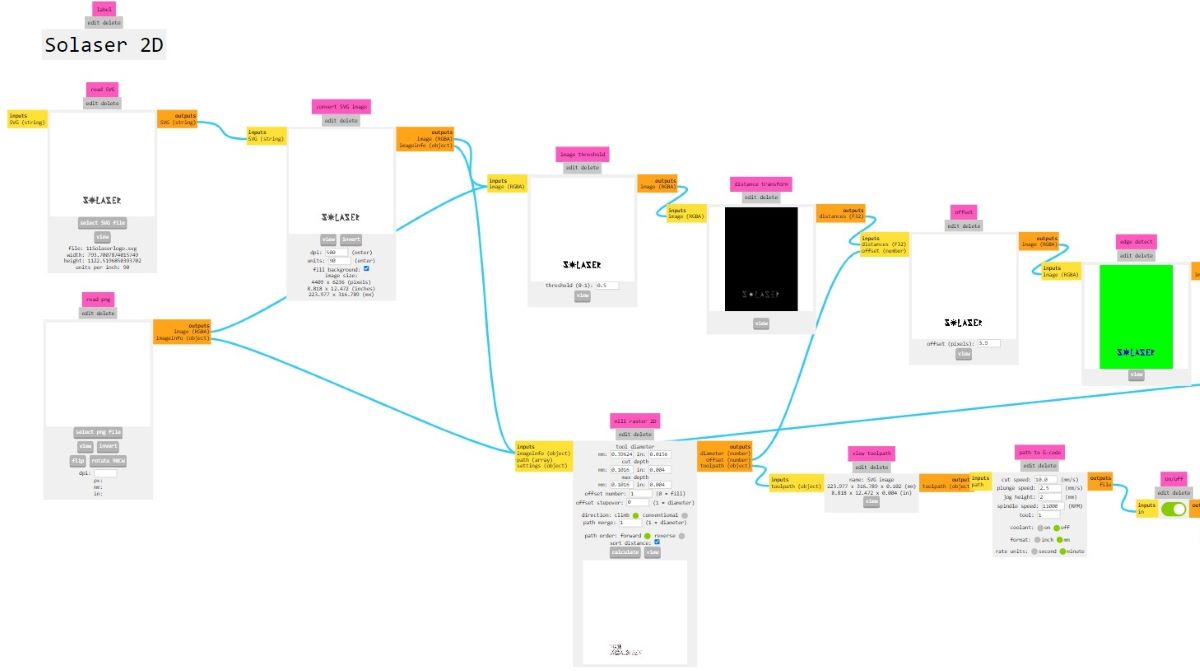

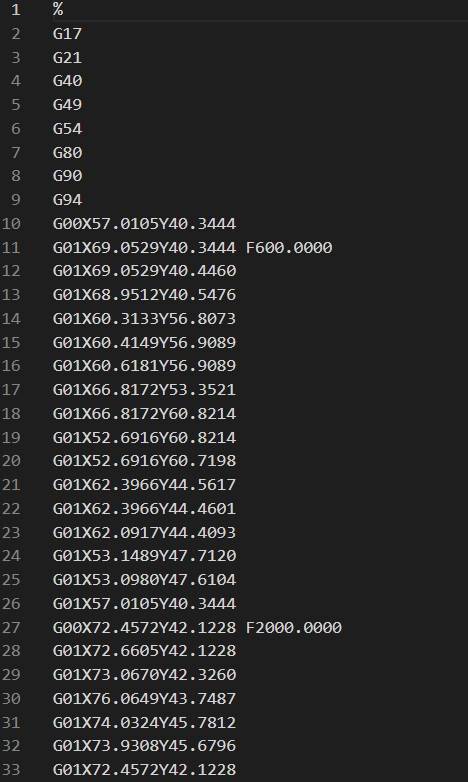

On another area I worked a lot to contribute as much as possible individually was in exploring and testing initially how we could use modsCE program to generate the G-code for our Solazer. And that´s what I documented in the group assignment. I learned that once you undestand mods its a very powerful program that you can adapt to your needs. We initially modified an existing program, but we´ve learned that we can make our own, simplifying a lot of the problems we´ve had. You can check what went wrong and how we dealed with it in the group assignment. I recently found out how we could solve an issue we´ve been having with the Marlin software used to move our machine. We struggled sometimes with an error due to the fact that the program searched for the extruder temperature, and sometimes it suddenly stopped. Now I now that adding into the initial G-CODE: M302 S0 you are telling the program no to search for the extruder temperature, solving the problem. So happy to contribute to debugging one of our problems!

Solaser2D modsCE file.

Solaser2D modsCE file. Gcode.

Gcode.

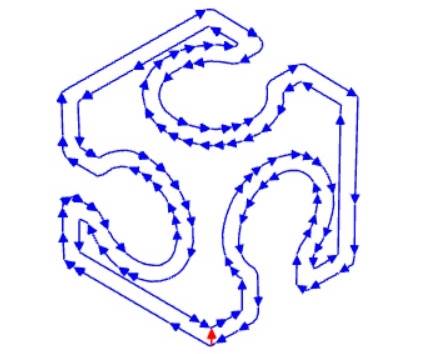

Here you can see the final toolpaths for all the test we did:

Toolpaths.

Toolpaths.

Also the designs used to "Solazer" them were created by me, but that´s not related to the machine itself.

So, definetely I can see that I contributed a lot in this incredible machine week. But, as I stated at the beggining, the best, the most rewarding experience, was to work hand in hand with my fab mate Jon. And to be capable by ourselves to make this incredible machine working was extremely satisfying. Regarding what i´ve learned.. there are so many things.. If I have to reflect on my personal experience, I´ve proven myself that I can build almost anything, that i´ve got more knowledge than I think, and it seems that good ability to do it. So this week has given me an extra motivation and confidente busrt for developing by myself my final project idea.

Back to top