Wild Card Week

In this assignment I designed a 3D Clothes, basically print a symmetrical design in a cloth.

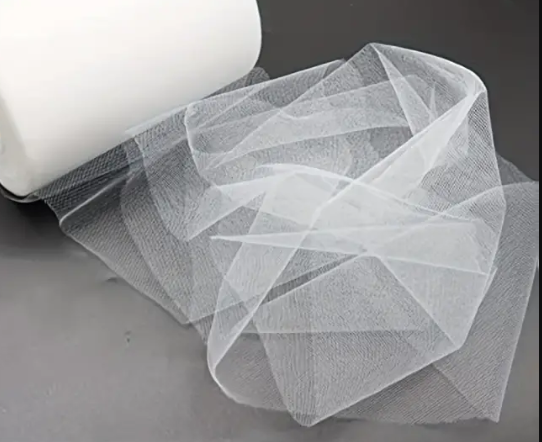

Tulle

White Tull

Vendor link: https://www.amazon.com/Expo-International-Decorative-Matte-Spool/dp/B0122G6LPC/

What is tulle fabric?

(from https://recovo.co/en/blog/article/tulle-fabric-what-it-is-characteristics-uses-and-more)

Tulle is a net-shaped fabric that is made with silk, nylon, rayon or polyester threads. It is a transparent, delicate and light material that is often used to make bridal veils, tutus and other items for special occasions. Tulle is also a popular choice for decorating weddings and events, creating backdrops and adding a touch of elegance to any setting.

Features of tulle fabric

Tulle fabric is characterized by its soft and airy feel, making it perfect for creating light and delicate styles. It is also very flexible and can be easily shaped, making it ideal for creating various items such as tutus and ballerina skirts. Tulle is also known for its sheerness, making it a popular choice for layering and adding depth to an outfit. Another characteristic of tulle fabric is its durability; It resists the passage of time well and is easily cleaned.

Applications of tulle fabric

Tulle is commonly used in the textile and fashion industries to create a wide variety of items, including bridal veils, tutus, ballerina skirts and other special occasion clothing. It is also a popular choice for decorating weddings and events, creating backdrops and adding a touch of elegance to any setting. In addition, tulle fabric is often used in the production of various fabrics, such as upholstery and curtains.

- Tulle in wedding dresses. Tulle fabric is very popular in the production of bridal gowns, such as veils and dresses. With its soft and airy feel, tulle is perfect for creating elegant and romantic styles. Wedding veils made from tulle fabric are usually long and flowy, adding a touch of timeless elegance to the bride's outfit. Tulle is also often used to create delicate layers in wedding dresses, adding depth and volume to the ensemble.

- Tulle in ballet clothes. Tulle is a popular choice for creating ballet garments, such as tutus and ballerina skirts. Its flexibility and ability to take on a variety of shapes make it ideal for creating the full, fluffy skirts often associated with ballet clothing. Additionally, the tulle fabric is lightweight and allows dancers to move freely and comfortably, making it a popular choice for ballet and dance clothing.

- Tulle in decoration. Tulle is also a popular choice for decorating weddings and events, creating backdrops and adding a touch of elegance to any setting. It is often used to create beautiful, romantic and delicate presentations that add a touch of sophistication to any event. Tulle can be used to create everything from delicate table runners to large, elaborate backdrops, making it a versatile and popular choice among wedding and event decorators.

Printing on cloth (tulle)

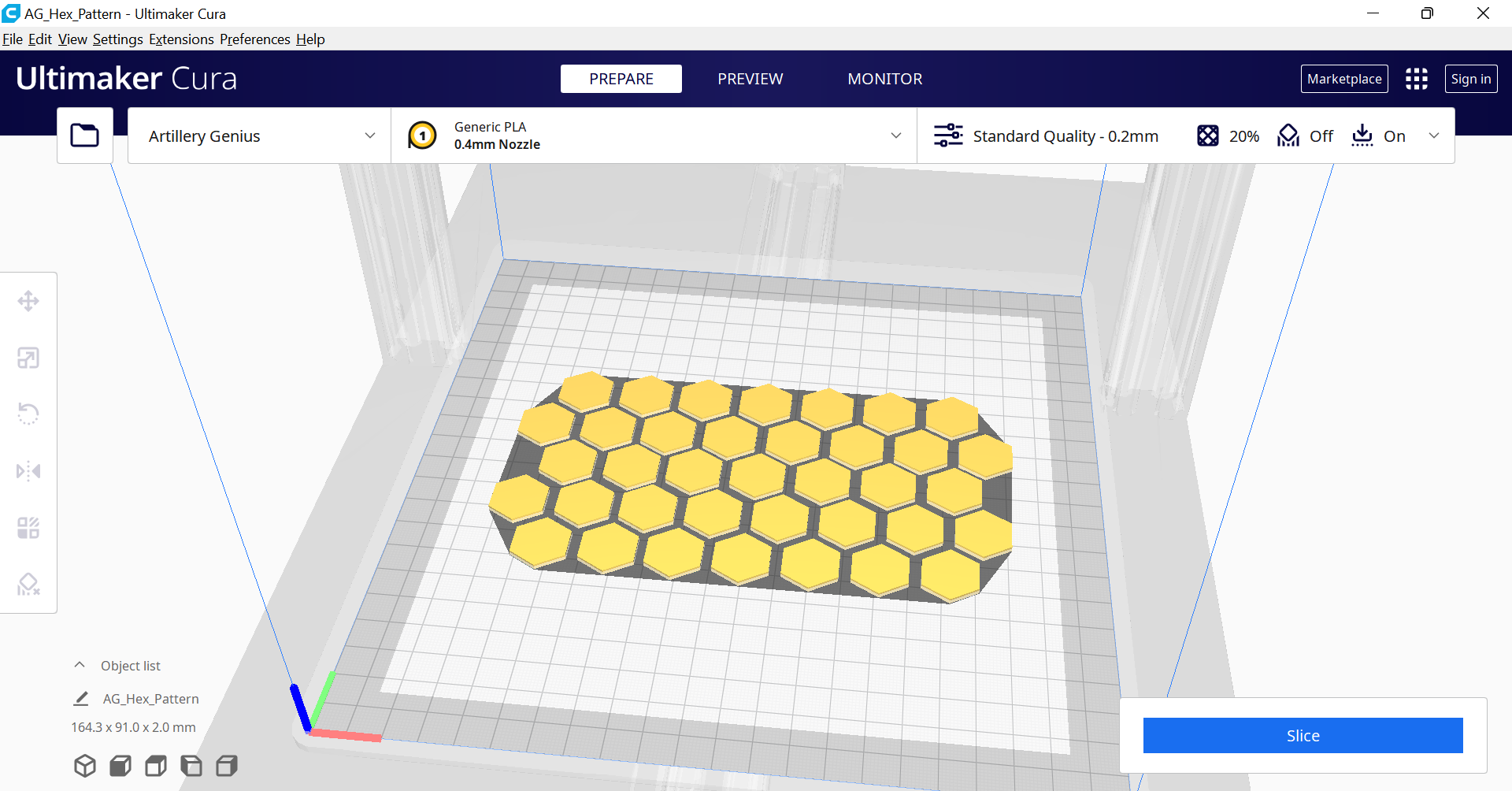

This time, I have decided to use, as a 3D printing material, white PLA (polylactic acid) filament on TULLE, which is basically a material like a thin mesh, with the purpose of making a garment with a printed pattern.

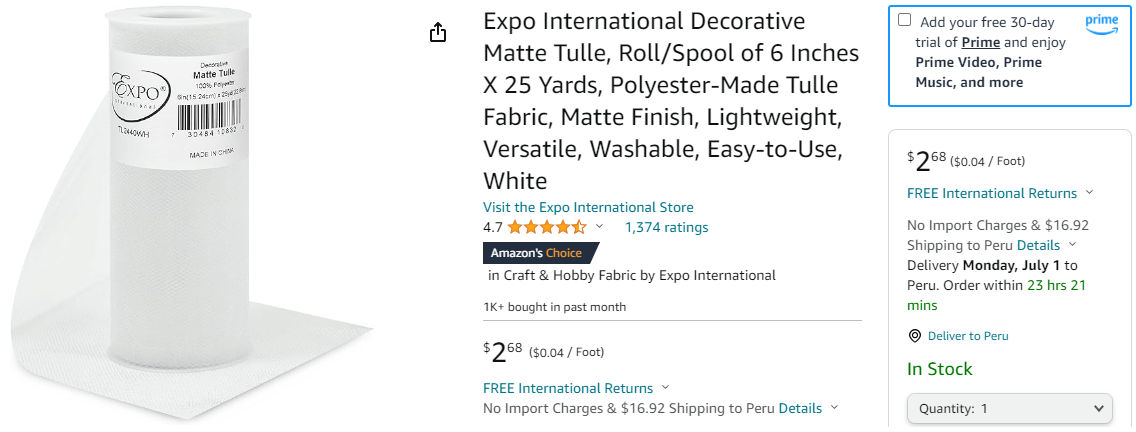

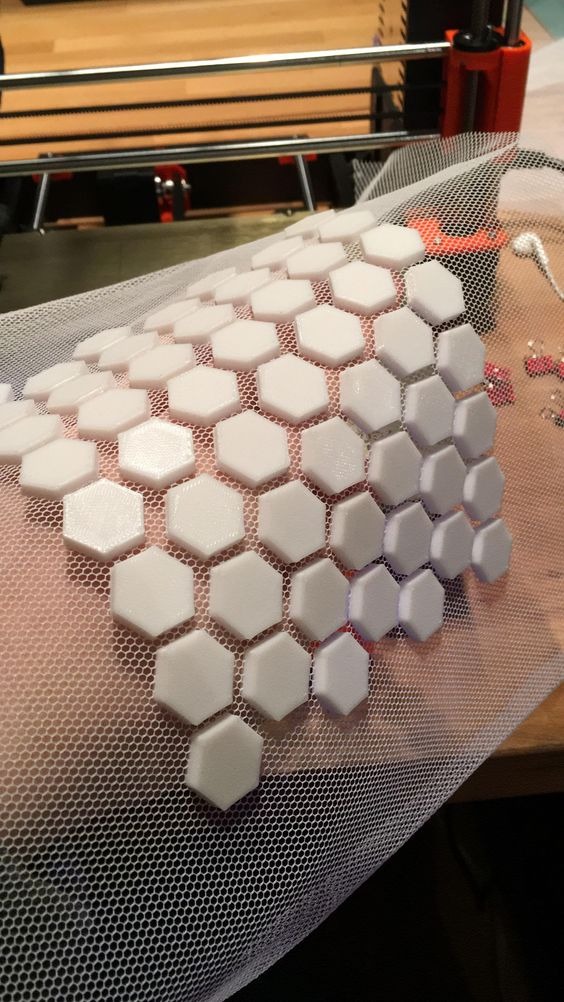

The pattern was designed in AutoCAD (hexagonal). It has a height of 2 mm.

The idea is to make a symmetrical pattern of several hexagons to place on the mesh, giving an interesting style.

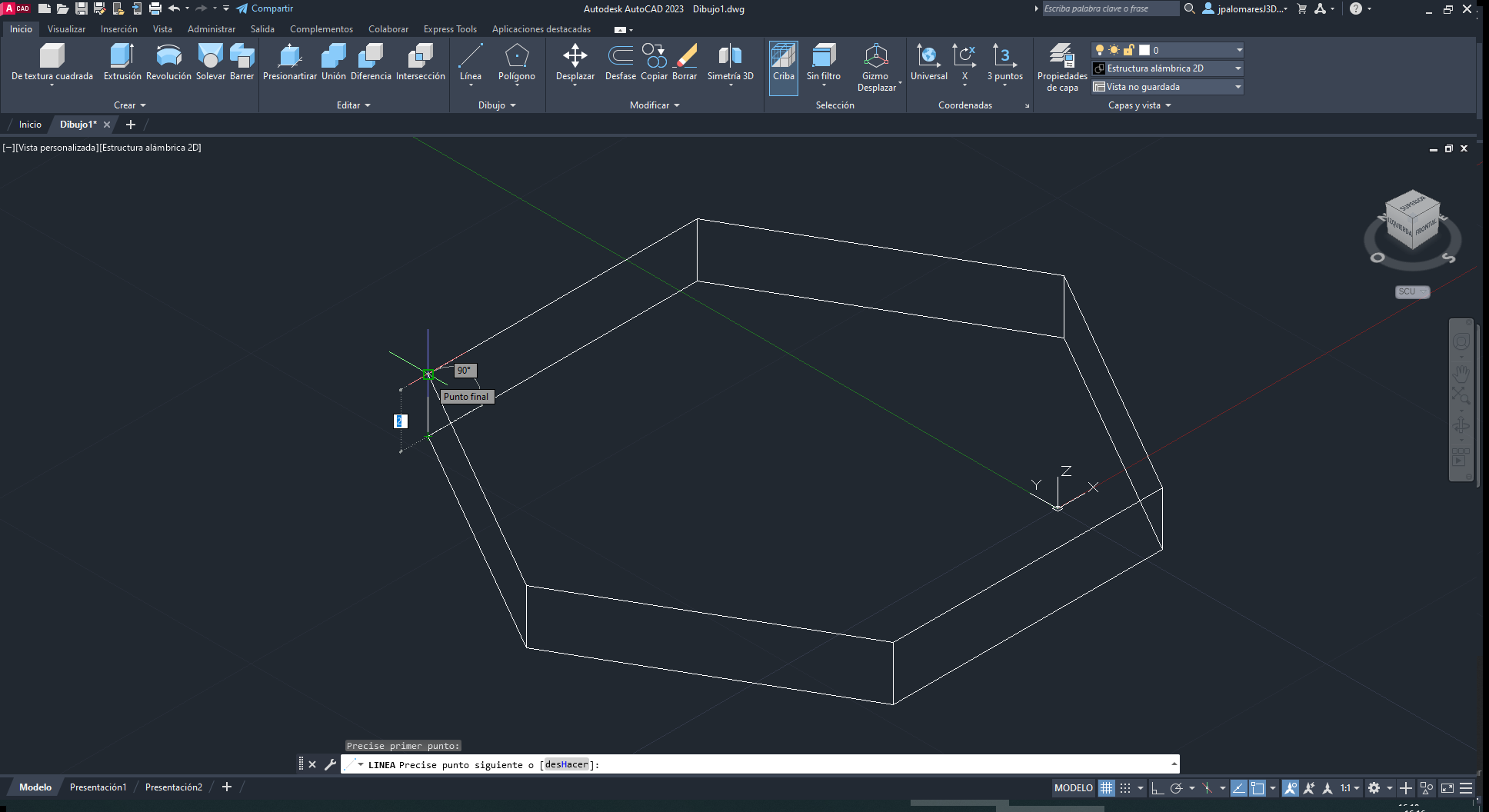

The 3D pattern was sliced in Cura software.

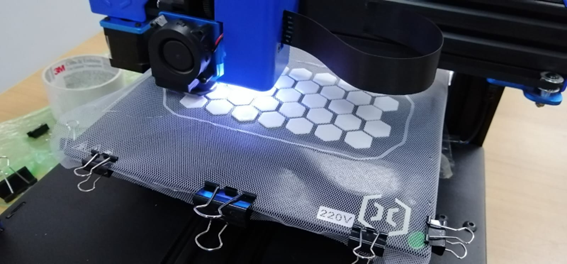

Then, printed in Artillery Genius 3D Printer over the cloth.

Some specs of 3D printer:

- Build Volume: 220 x 220 x 250 mm

- Extruder Style: Direct Drive (Titan Style)

- Hot End: Volcano Style

- Nozzle size: 0.4 mm

- Max. hot temperature: 240 °C

- Max. heated bed temperature: 130 °C

- Filament Diameter: 1.75mm

- Connectivity: USB Stick, SD-Card

- Print recovery: Yes

- Filament sensor: Yes

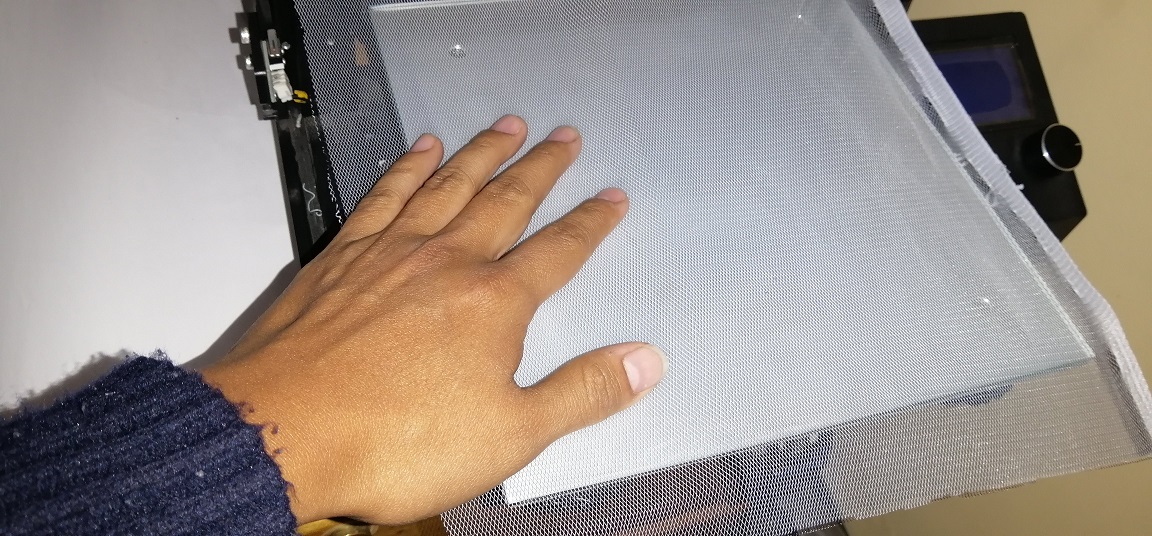

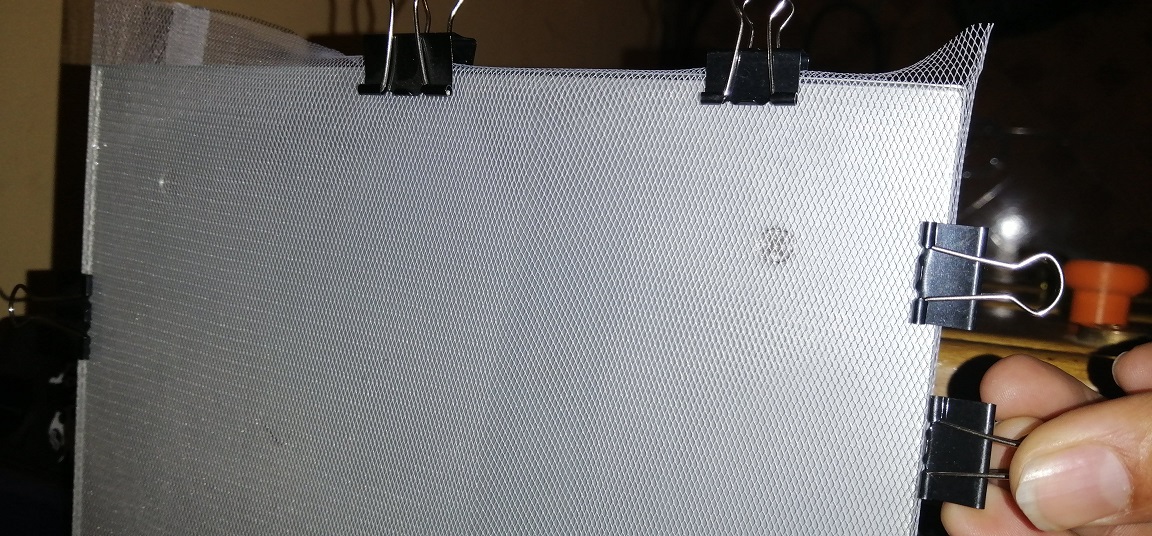

First of all, flatten the fabric so that it is as flat as possible. Next, to do is put the cloth (tulle) in the bed platform and adjust it using some clips on the edge of the platform. (both sides)

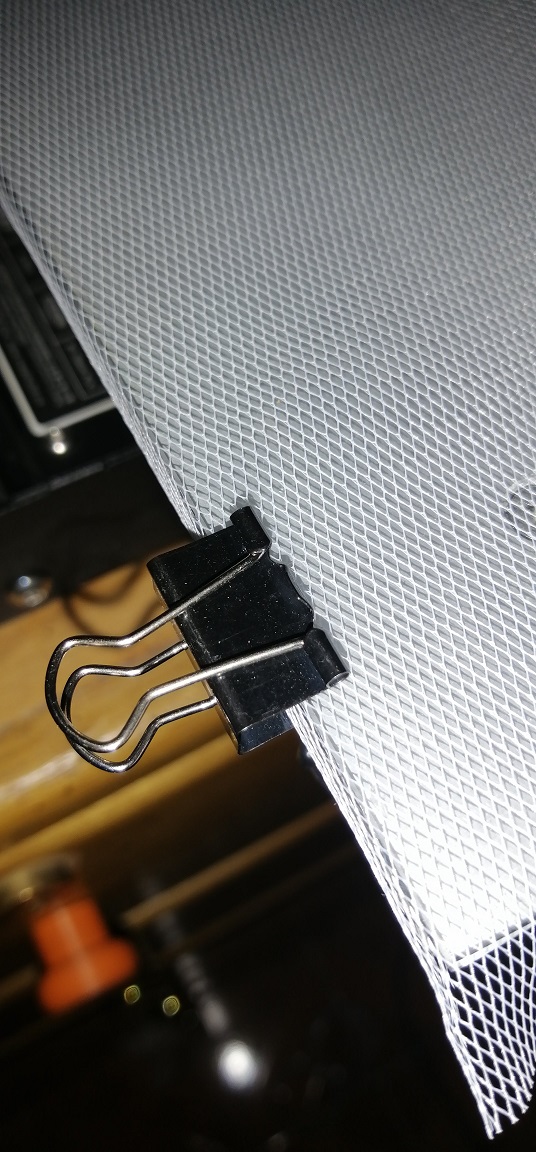

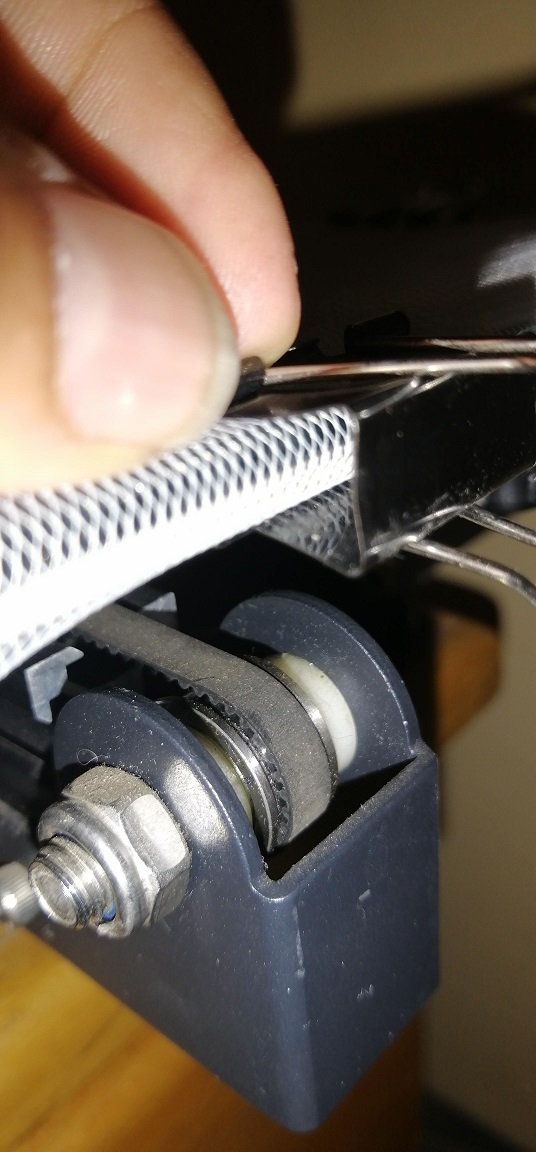

Place the fasteners as close to the edge but make sure they apply good pressure and do not come off.

Consider that it fits well, otherwise the mesh could move.

To calibrate the height, use a slightly thicker bond sheet, 0.4 mm thick. Thus setting a tolerance for the tulle fabric.

Bed temperature default value for PLA (50ºC)

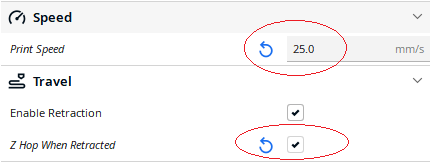

To ensure optimal printing, set the printer at a lower speed, in this case 25mm/sec. Additionally, the "Z hop when retracted" option was activated Whenever a retraction is done, the build plate is lowered to create clearance between the nozzle and the print. It prevents the nozzle from hitting the print during travel moves, reducing the chance to knock the print from the build plate.

The hex pattern was successfully printed on the cloth.

Use of 3D printing on fabric

The use of 3D technology in the fashion industry has been increasing in recent years. 3D printing is used during the creative process, for prototyping or even for production. Additive manufacturing provides a wide range of possibilities and fascinates some designers in the fashion industry. Since the early 2010s, 3D equipment has become increasingly accessible, now enabling new creative experiments, the results of which appear in numerous catwalk shows and offer consumers an innovative mass customization solution.

Problems and solutions

- In this assignment we had the challenge of making a 3D print on fabric, specifically tulle fabric.

- The first problem that was had was that the printing was not done correctly, the fabric moved or there was no precision. I fixed it by fixing on both sides with some fasteners.

- Another problem that was observed was that after some time there was a lot of material out of the nozzle. I solved it by tightening the fabric a bit and lowering the printing speed from 50mm/s to 25mm/s. Which gave me very good results. I also enabled the Z retraction parameter and with this the task could be carried out successfully.

Download

Download files generated: