5. 3D Scanning and Printing¶

5.1 Test the design rules for my 3D printers (FDM/FFF)(as group assignment)¶

5.1.1 Design rules for my 3D FDM/FFF method printer¶

FDM(Fused Deposition Modeling)/FFF(Fused Filament Fabrication) method 3D printers are very popular in maker community.

These printers are available in various sizes, grades, styles and prices.

There are four 3D printers in our Lab. All of them use FDM/FFF method.

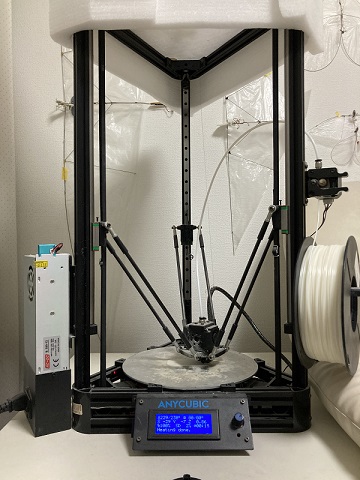

I also have my own FDM/FFF 3D printer in my home. It is ‘Anycubic Kossel Plus’ with delta-configuration(it has a circle-shaped build plate and 3 step motors for positioning of a print head).

Technical data of Kossel Plus

| Build size | 230 (diameter) x 300 (height) mm |

| Printing technoogy | FDM(Fused Deposition Modeling) |

| Extruder | Single |

| Layer solution | 0.1 - 0.4 mm |

| Travel Speed | 60 mm/s |

| Print Speed | 20 - 60 mm/s |

| Nozzle | 4 mm diameter |

| Supported print materials | PLA, ABS, HIPS, wood |

| Retail price | around 199 US$ |

I checked the design rules of the printer as follows:

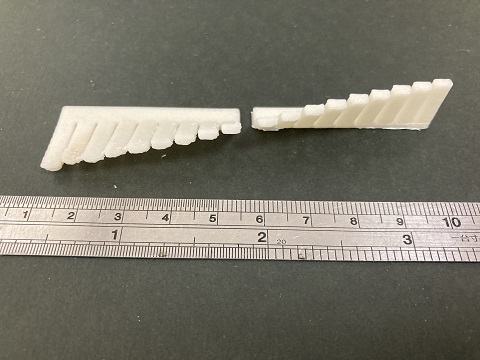

5.1.1.1 Design rule for over-hanged shapes¶

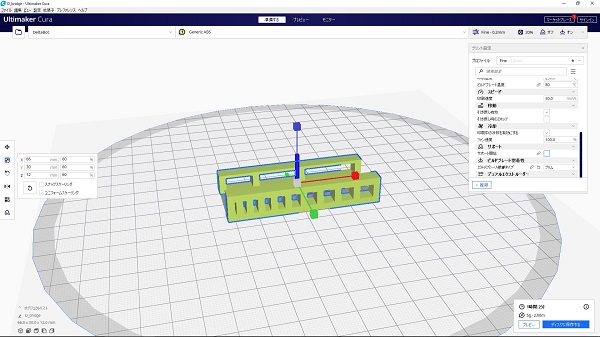

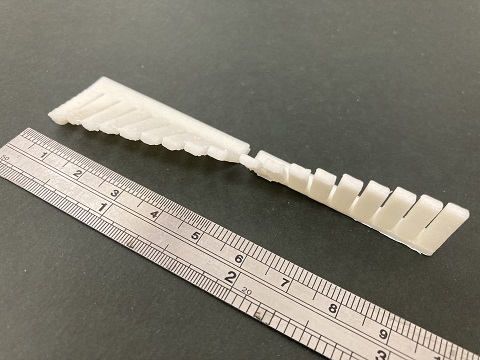

I used the test data with various angled flat plates. I printed it without supports. I used ABS filament and Cura as a slicing software.

Even without supports, most of plates could be printed, only 80 degrees one(almost horizontal) dropped down.

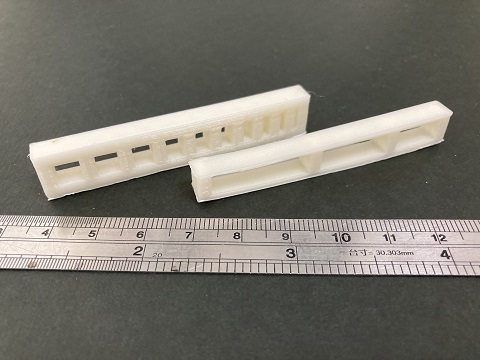

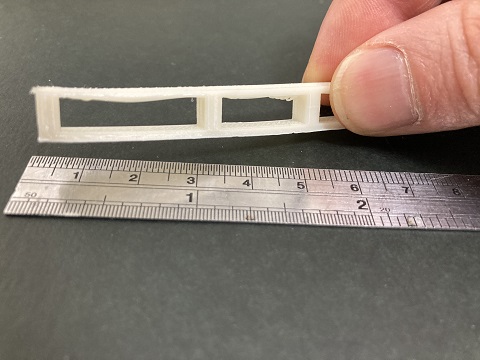

5.1.1.2 Design rule for bridged shapes¶

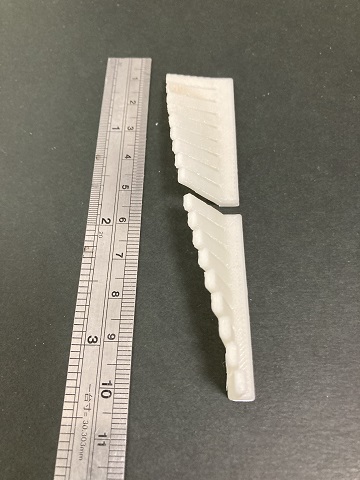

I printed the test data with several bridged shapes without supports.

Even without supports, most of bridges could be printed, only 25 mm long one slightly dropped down.

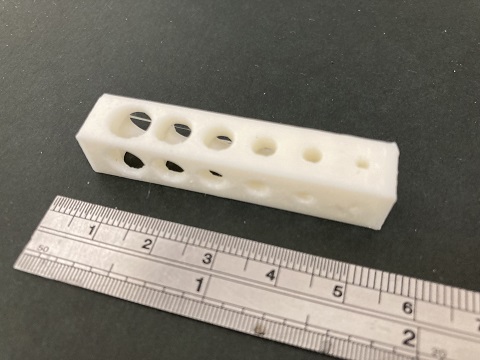

5.1.1.3 Design rule for holes¶

I printed the test data with several holes in various diameters. Some of the holes were vertical and the others were horizontal.

All holes could be printed well, but printed diameters were slightly smaller than designed(arround 0.5 mm)

Overall results were quite satisfing for me. ‘Kossel Plus’ is a good printer!

Data files:

angle.step

bridge.step

holes.step

Design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively