Molding and Casting

Design a mold around the stock and tooling that you'll be using,

mill it (rough cut + three-axis finish cut),

and use it to cast parts

Group assignment:

Group assignment

The molding and casting materials I used for this assignment summed up:

Smooth-On Ecoflex 00-30

Ecoflex 00-30 is a platinum-catalyzed silicone rubber that is soft, strong, and stretchy. It is

mixed 1A:1B by weight or volume and cures at room temperature (negligible shrinkage). It is

translucent and can be

pigmented for color effects. Ecoflex is suitable for making prosthetic appliances, orthotic

cushioning, and special effects applications. It is also certified as skin safe.

Here's a summary of the main points for using Ecoflex 00-30 silicone rubber :

- Use in a properly ventilated area and wear safety gear.

- Cure inhibition may occur with certain contaminants, so test compatibility with a small-scale application.

- Applying a clear acrylic lacquer or release agent can help prevent inhibition and make demolding easier.

- Mix Part B thoroughly before starting. Combine Parts A and B in a mixing container at a 1A:1B ratio by weight or volume. Mix for 3 minutes, scraping the sides and bottom of the container.

- Vacuum degassing is recommended to remove air bubbles. Use a vacuum pump that can pull at least 1 Bar / 100 KPa and leave space for material expansion. Continue vacuuming until the material rises, breaks, and falls. Vacuum for 1 additional minute after the material falls.

- Pour the mixture in a single spot at the lowest point of the containment field and let it seek its level over the model.

- Cure at room temperature (23°C, never less than 18°C) and post cure for attaining maximum performance properties quicker (After curing at room temperature, expose the rubber to 80°C for 2 hours and 100°C for one hour).

- If using as a mold, no release agent is necessary when casting wax or gypsum, but a release agent is recommended when casting polyurethane, polyester, and epoxy resins.

- THI-VEX can be used to thicken Ecoflex for vertical surface application, and Silicone Thinner can be used to lower the viscosity for easier pouring.

- Clean and dry the mold before storing it on a leveled surface in a cool, dry environment.

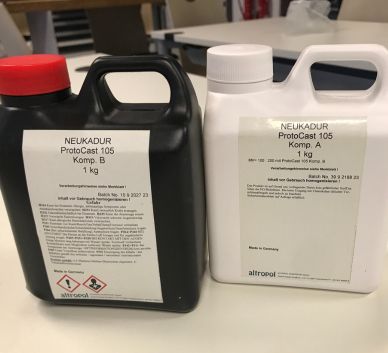

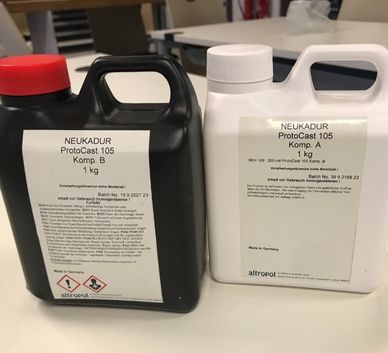

NEUKADUR ProtoCast 105

Main characteristics

- Very good flowability

- Very impact resistant

- Very good colorability

- High heat resistance

- Cures to white color

- Only suitable for vacuum casting

| Component | Color | Mixing Ratio by Weight | Density (20°C) g/cm³ | Viscosity (25°C) mPa∙s |

|---|---|---|---|---|

| NEUKADUR ProtoCast 105 Component A | Slightly yellowish | 100 | 1.05 | 650 |

| NEUKADUR ProtoCast 105 Component B | Slightly yellowish | 200 | 1.16 | 160 |

| Mixture Properties (approximate values) | PC 105 A / PC 105 B |

|---|---|

| Mixing Viscosity (25°C) mPa∙s | 325 |

| Density (20°C) g/cm³ DIN 53479 | 1.13 |

| Processing Time (25°C) Minutes | 5 |

| Demolding Time (70°C) Minutes | 60 |

| Hardness Shore D DIN 53505 after storage 2 Hours at 70°C | 82 |

| Cured Color | White |

| Recommended Layer Thickness mm | 5 |

Processing Instructions:

NEUKADUR ProtoCast 105 Component A must be thoroughly homogenized prior to processing. The

containers must be carefully sealed after each use. After 30-60 minutes, the cured material has

not

yet achieved its full impact resistance (which is achieved only after approximately 1-2 hours at

70°C), so cautious demolding, especially for thin parts, is recommended. It's recommend pouring

NEUKADUR ProtoCast 105 Component A/B into preheated molds at 70°C (e.g., made of ProtoSil RTV

245)

and tempering for at least 1 hour at 70°C before demolding. Recommended casting thickness: up to

a

maximum of 5mm.

It's recommended evacuating NEUKADUR ProtoCast 105 Component A for 15 minutes at the highest

possible vacuum, then relaxing to 20-25 mbar before adding NEUKADUR ProtoCast 105 Component B.

If the vacuum drops below 20 mbar, severe foaming may occur when both components are mixed.

Luma!

Luma!

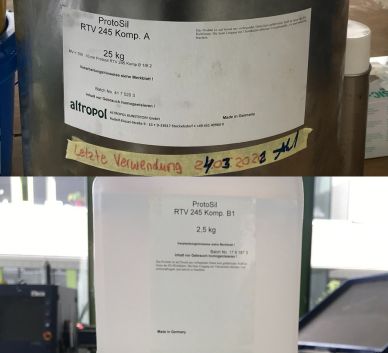

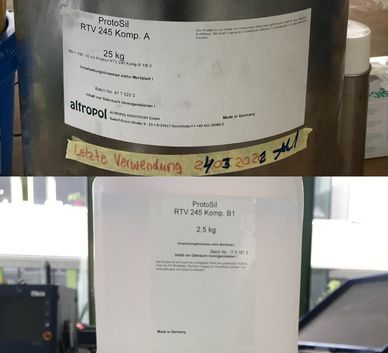

ProtoSil RTV 245

Main features

- Shore hardness A 40

- very good flow properties, translucent

- shrinkage-free vulcanization at room temperature

- can be made thixotropic

- high resistance to initial tearing and tear propagation

| Properties in the non-crosslinked state | ProtoSil RTV 245 Comp. A | ProtoSil RTV 245 Comp. B 1 (dry surface) |

ProtoSil RTV 245 Comp. B 2 (oily surface) |

NEUKASIL Thixotropic Agent SN 200 |

|---|---|---|---|---|

| Colour | colourless | colourless | colourless | colourless |

| Mixing ratio p.b.w. | 100 | 10 | 10 | 0.1 – 0.3 |

| Density 20 °C (approx.) g/cm3 | 1.1 | 0.95 | 0.96 | 0.98 |

| Viscosity 20 °C (approx.) mPa·s | 60,000 | 320 | 400 | 1,000 |

| Properties of the mixture (approx. values) | Mixture A/B |

|---|---|

| Mixed viscosity | 35,000 mPa·s |

| Pot life (1000 g) | 80 minutes |

| Demouldable after | 12 hours |

| Shore A hardness points | DIN 53505 40 |

| Service temperature | 200 °C |

Minimize air incorporation during stirring. To achieve a bubble-free vulcanized material, evacuate the crosslinker-containing formulation prior to processing. Expect the mixture to expand 3-4 times its original volume and form bubbles during vacuum creation. Processing is complete once the bubbles have collapsed and the mixture returns to its original volume. Pour the prepared material over the object to be cast with care.

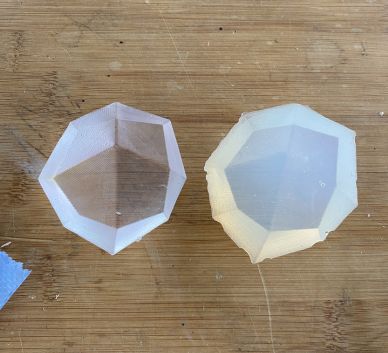

Test cast of Protosil (right) compared to the following test

cast of Epodex (left)

Test cast of Protosil (right) compared to the following test

cast of Epodex (left) - Evacuate component A for 15 minutes at maximum vacuum and then relax to 20-25 mbar before dosing component B.

- Mix NEUKADUR ProtoCast 105 components A and B together at the recommended ratio (2:1 by weight).

- Make sure that the mixing is done as thoroughly as possible.

- After casting, allow the material to cure at 70°C for at least 1 hour before demolding.

- For thin sections, use caution during demolding, as the material may not have achieved its full toughness yet.

- Recommended casting thickness is up to 10cm.

20g of component

A.

20g of component

A. Vacuum component

A (no bubbling occurs)

Vacuum component

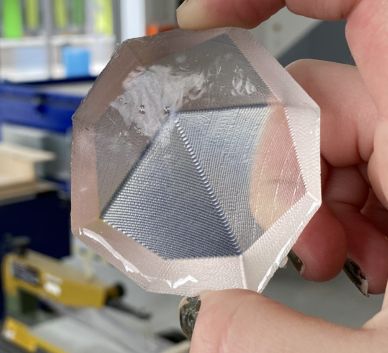

A (no bubbling occurs) The result: very clear cast, still not completely

stone-hard, but almost.

The result: very clear cast, still not completely

stone-hard, but almost.Operating the vacuum chamber

Connect

it's

power adapter to a power outlet.

Connect

it's

power adapter to a power outlet. Turn

on

the

main switch.

Turn

on

the

main switch. Turn

on

the

vacuuming by turning this switch.

Turn

on

the

vacuuming by turning this switch. Wait

until

the

air pressure (in hPa) drops to one or zero. Please note that it takes exponentially

longer

the

lower the air pressure already is.

Wait

until

the

air pressure (in hPa) drops to one or zero. Please note that it takes exponentially

longer

the

lower the air pressure already is. Use

these

two

black handles to tip over the platforms inside, if you need to. This is needed when

you

have

to

mix the epoxy/resin under vacuum.

Use

these

two

black handles to tip over the platforms inside, if you need to. This is needed when

you

have

to

mix the epoxy/resin under vacuum.  Pull

this

lever towards you to let the air back in. And you're done!

Pull

this

lever towards you to let the air back in. And you're done!Designing a mold in Fusion360

Download my Fusion project file I decided to make a

Luma keychain (from Super Mario Galaxy) for this weeks assignment.

For the Luma model I used a design

from

models-resource.com.

I decided to make a

Luma keychain (from Super Mario Galaxy) for this weeks assignment.

For the Luma model I used a design

from

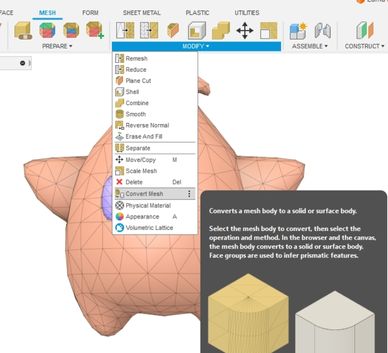

models-resource.com. This model was a

mesh though, so I first had to convert it to a

solid body in Fusion. Right

click on

the mesh in the browser and choose Convert.

This model was a

mesh though, so I first had to convert it to a

solid body in Fusion. Right

click on

the mesh in the browser and choose Convert.

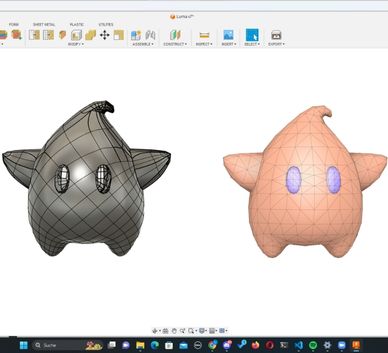

Mesh (right) vs

solid body (left).

Mesh (right) vs

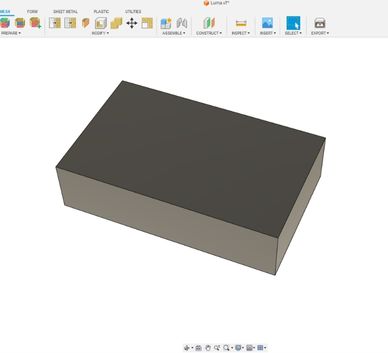

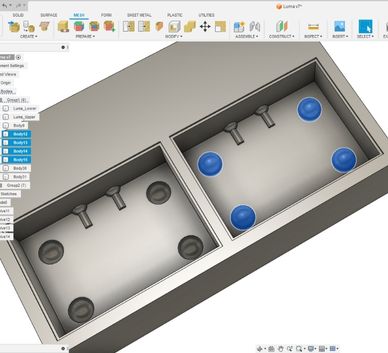

solid body (left). I created a box that

is the exact same size as my stock.

I created a box that

is the exact same size as my stock. At the places where

I wanted my negative mold to be, I cut smaller boxes into the big box. I added a

few spheres as the registration pins used to really make the

mold stay in place when casting. I also created a small step surrounding each

box, so the mold will be easier to remove later on.

(Even though this got milled away more or less, because of a collision of the

end mill with the

wax)

At the places where

I wanted my negative mold to be, I cut smaller boxes into the big box. I added a

few spheres as the registration pins used to really make the

mold stay in place when casting. I also created a small step surrounding each

box, so the mold will be easier to remove later on.

(Even though this got milled away more or less, because of a collision of the

end mill with the

wax)

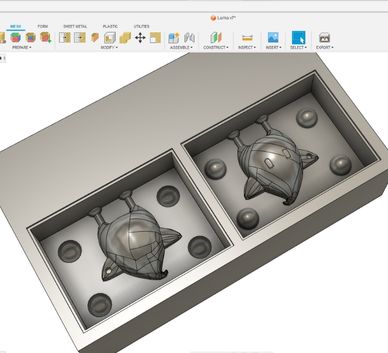

Now I used the split

body tool to cut the solid Luma model in half to have one side for each

part of the mold (two part mold).

After placing one half of Luma in each shell, I used one of Lumas feet as the

place to pour in the resin while the other one is used to let

the air out. I added small tubes to the legs to create a connection to the

outside.

Now I used the split

body tool to cut the solid Luma model in half to have one side for each

part of the mold (two part mold).

After placing one half of Luma in each shell, I used one of Lumas feet as the

place to pour in the resin while the other one is used to let

the air out. I added small tubes to the legs to create a connection to the

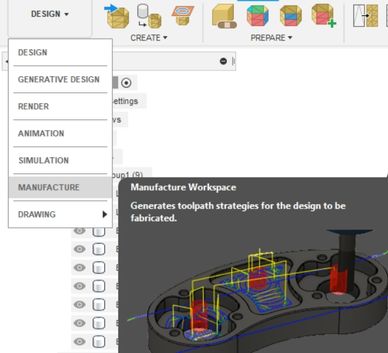

outside. Head over to the

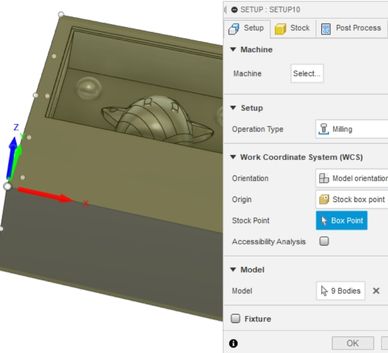

Manufacture workspace.

Head over to the

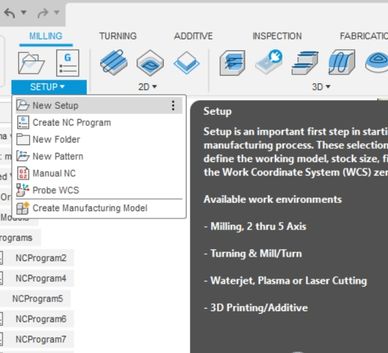

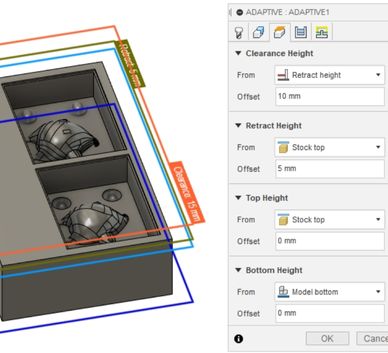

Manufacture workspace. First, create a new

setup.

First, create a new

setup. Select all the

bodies. Make sure the stock point is on one of the

upper points of the box.

You might want to check which axis is which on your CNC.

Select all the

bodies. Make sure the stock point is on one of the

upper points of the box.

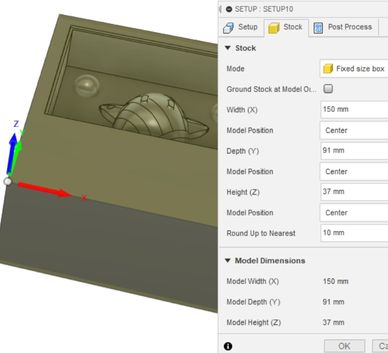

You might want to check which axis is which on your CNC. Make it a fixed

sized box. It is also very important to have the

lower edge of you model to be at the bttom of the stock box. I gave my box the

dimensions of my actual wax block, so it was automatically at the bottom.

Make it a fixed

sized box. It is also very important to have the

lower edge of you model to be at the bttom of the stock box. I gave my box the

dimensions of my actual wax block, so it was automatically at the bottom.

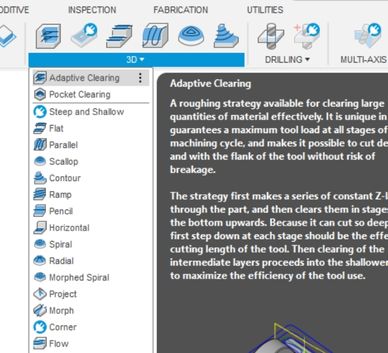

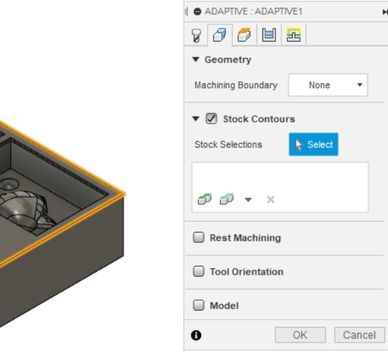

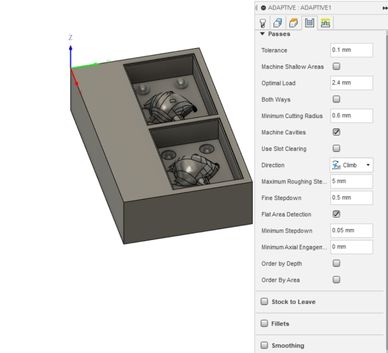

After you are done

with your setup settings, you can start with

your milling toolpaths. The first one "Adaptive Clearing" is very good for rough

milling the majority of the unneeded material.

After you are done

with your setup settings, you can start with

your milling toolpaths. The first one "Adaptive Clearing" is very good for rough

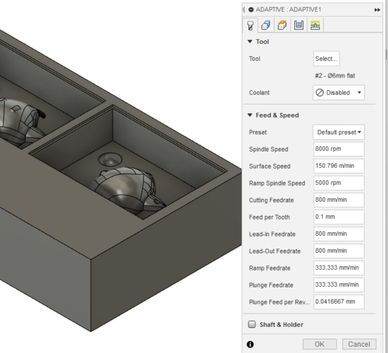

milling the majority of the unneeded material. First, you want to

select your tool.

First, you want to

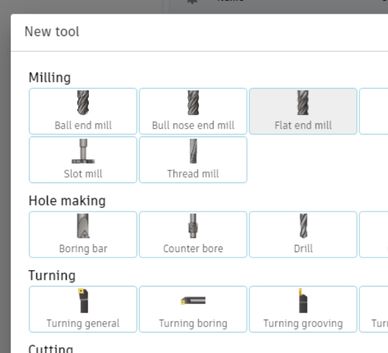

select your tool. Creat a new one,

make it a flat end mill.

Creat a new one,

make it a flat end mill.

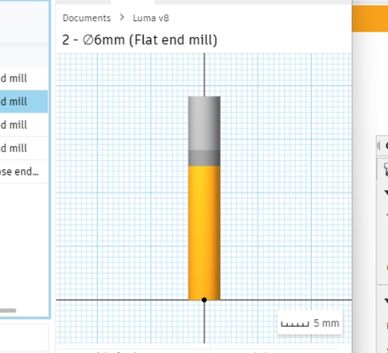

These are the

settings of this tool.

These are the

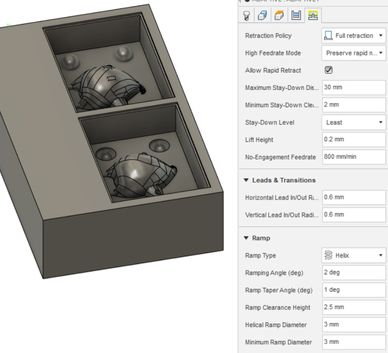

settings of this tool. Settings 1 (Make

sure Rest Machining is ticked off)

Settings 1 (Make

sure Rest Machining is ticked off)

Settings 2

Settings 2

Settings 3

Settings 3

Settings 4

Settings 4

Settings 5

Settings 5

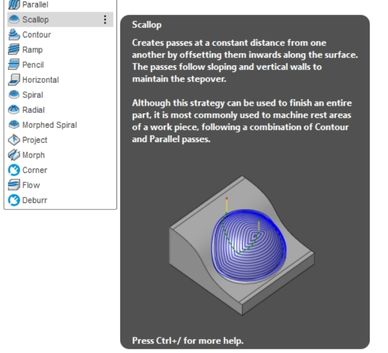

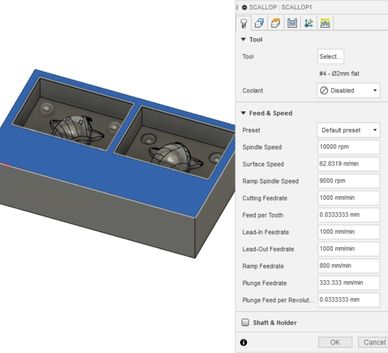

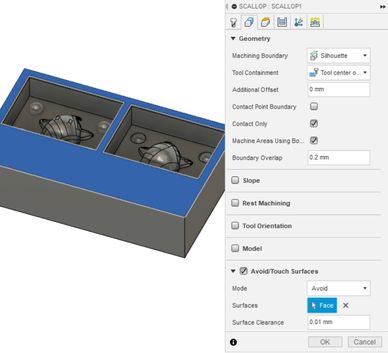

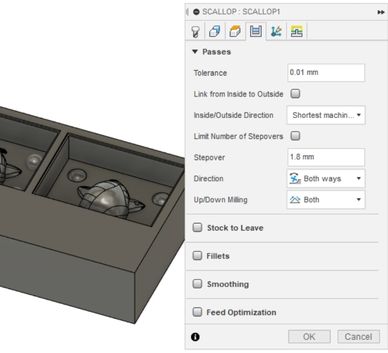

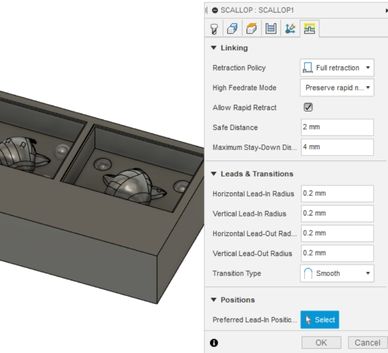

Next milling

strategy is Scallop. This is optimal for finetuning and round surfaces.

Next milling

strategy is Scallop. This is optimal for finetuning and round surfaces.

Settings 1. I am

using a 2mm flat end mill tool for this as this allows for much finer

milling.

Settings 1. I am

using a 2mm flat end mill tool for this as this allows for much finer

milling. Settings 2

Settings 2

Settings 3

Settings 3

Settings 4

Settings 4

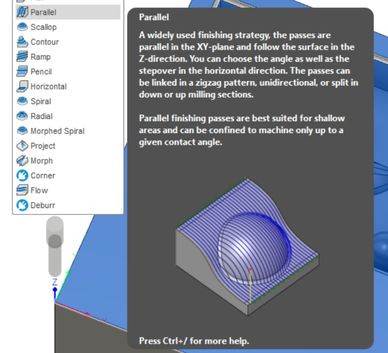

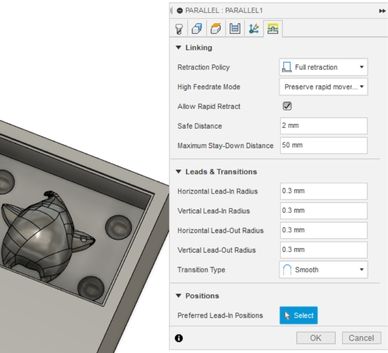

Last milling

strategy is Parallel. This is optimal for finishing passes.

Last milling

strategy is Parallel. This is optimal for finishing passes.

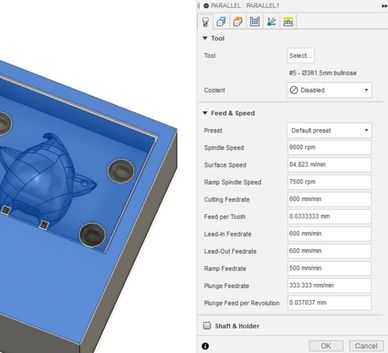

Settings 1. I am

using a 3mm bull nose end mill.

Settings 1. I am

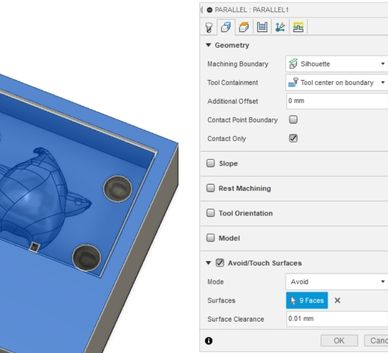

using a 3mm bull nose end mill. Settings 2

Settings 2

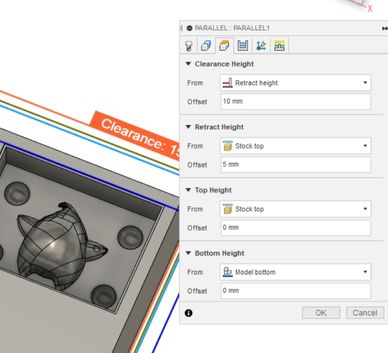

Settings 3

Settings 3

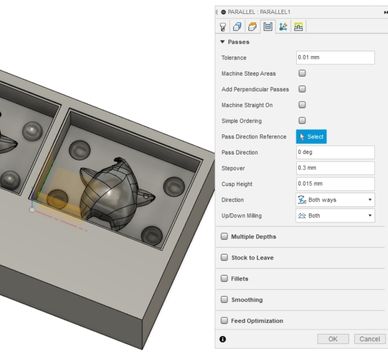

Settings 4

Settings 4

Settings 5

Settings 5

I used scallop and

parallel twice to get a really smooth finish.

I used scallop and

parallel twice to get a really smooth finish.

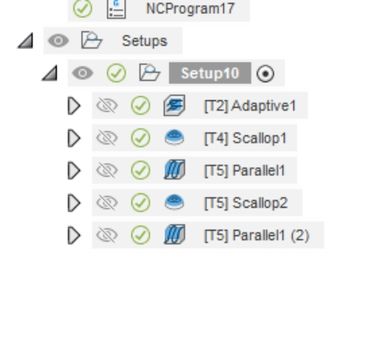

When you have set

up you milling strategies, you can create their respective NC programs. You need

one for every different tool. I chose the post processor of the Roland MDX as I

worked with this CNC for this assignment.

When you have set

up you milling strategies, you can create their respective NC programs. You need

one for every different tool. I chose the post processor of the Roland MDX as I

worked with this CNC for this assignment.

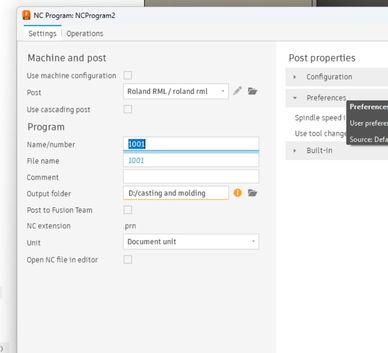

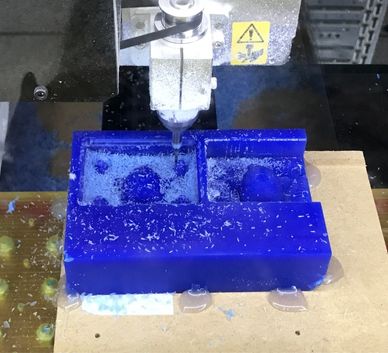

3D Milling

I used 3 different end mills during the whole process. 6mm flat end mill, 2mm flat end mill and 3mm bull nose end mill. Wax block is 15 cm x 9,1 cm x 3,7 cm (LxBxH)

Adaptive clearing

milled away most of the wax and also made quite the mess, but I easily cleaned

this with a vacuum cleaner.

Adaptive clearing

milled away most of the wax and also made quite the mess, but I easily cleaned

this with a vacuum cleaner.

Scallop as the

first finer milling process.

Scallop as the

first finer milling process.

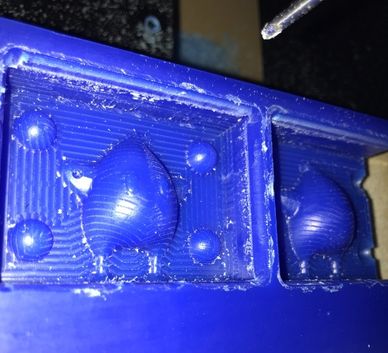

The finished wax

model looked very nice. It had a very good level of detail and was quite smooth!

Time to make the molds.

The finished wax

model looked very nice. It had a very good level of detail and was quite smooth!

Time to make the molds.

Molding and casting

Let's start with

the materials I actually used. First off is Smooth-On Ecoflex, I used this to

make a negative mold.

Let's start with

the materials I actually used. First off is Smooth-On Ecoflex, I used this to

make a negative mold.

ProtoSil was also

used to make a negative mold.

ProtoSil was also

used to make a negative mold.

I used Neukadur to

cast Luma!

I used Neukadur to

cast Luma!

And these colors

along with it to give Luma a yellow-ish color.

And these colors

along with it to give Luma a yellow-ish color.

My work station for

now, with all the materials, a scale and I am wearing gloves of course!

My work station for

now, with all the materials, a scale and I am wearing gloves of course!

I started with

ProtoSil. I mixed component A and B under a vacuum.

I started with

ProtoSil. I mixed component A and B under a vacuum.

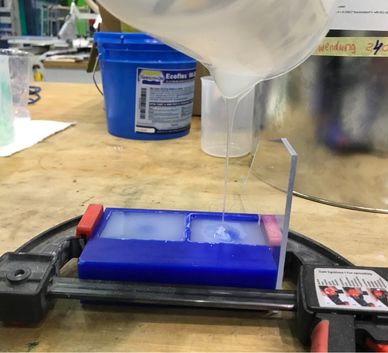

Since one side of

the wax got milled away, I used acrylic glass as the missing wall. I poured the

vacuumed mix inside.

Since one side of

the wax got milled away, I used acrylic glass as the missing wall. I poured the

vacuumed mix inside.

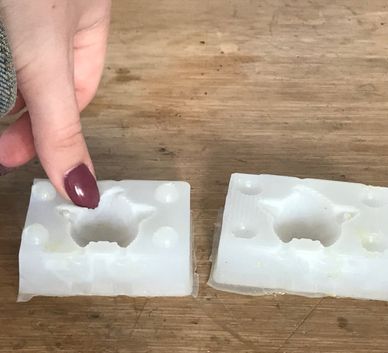

The cured mold

looks like this, it was very easy to remove and sturdy while also being a bit

bendable. Just like in the Group assignment test casts.

The cured mold

looks like this, it was very easy to remove and sturdy while also being a bit

bendable. Just like in the Group assignment test casts.

I repeated the same

process with Smooth-On Ecoflex and this is the result, a super stretchy negative

mold.

I repeated the same

process with Smooth-On Ecoflex and this is the result, a super stretchy negative

mold.

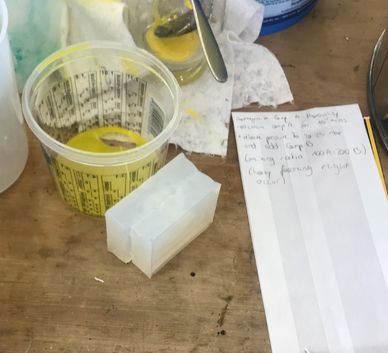

Now mixing

Neukadur, as I already learned from the test cast, you have to mix this very

fast, as the pot-life is 5min or less. It took me a few tries to get this right.

Now mixing

Neukadur, as I already learned from the test cast, you have to mix this very

fast, as the pot-life is 5min or less. It took me a few tries to get this right.

Vacuumed it as

well. I didn't actually measure the time, but it felt as if this mixture had a

slightly prolonged pot life compared to the test cast. I have a hunch that maybe

the color I added might

have caused this.

Vacuumed it as

well. I didn't actually measure the time, but it felt as if this mixture had a

slightly prolonged pot life compared to the test cast. I have a hunch that maybe

the color I added might

have caused this.

Now pouring it in!

As you can see I use one hole for pouring and the other for letting air out.

I had to use hot glue to seperate the two holes, because in my first attempts he

mix would get into the second opening as well. I also used the hot glue to

really seal the seam of the two touching negative mold parts.

Now pouring it in!

As you can see I use one hole for pouring and the other for letting air out.

I had to use hot glue to seperate the two holes, because in my first attempts he

mix would get into the second opening as well. I also used the hot glue to

really seal the seam of the two touching negative mold parts.

The fully cured

model looked very nice. It had a very good level of detail and was quite smooth!

Now only a bit of painting is left and it's done!

The fully cured

model looked very nice. It had a very good level of detail and was quite smooth!

Now only a bit of painting is left and it's done!