Computer Controlled Machining

Make (design+mill+assemble) something big.

Group assignment:

Group Assignment

Choosing and measuring the material

I choose MDF 12mm for the assignment.

We measured the different materials the Lab has in stock. Most were

12mm.

We measured the different materials the Lab has in stock. Most were

12mm.  Since I want to paint my shelf later, we choose MDF as its easiest to

paint.

Since I want to paint my shelf later, we choose MDF as its easiest to

paint.

We carried the plate to the CNC

We carried the plate to the CNCCAD and CAM in Fusion

Creating the test files in Fusion and preparing the toolpath:

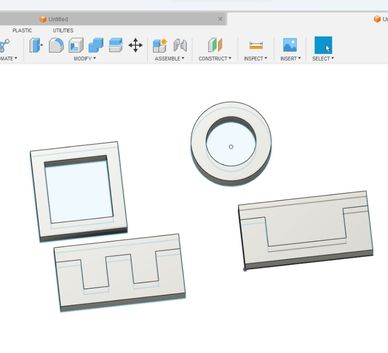

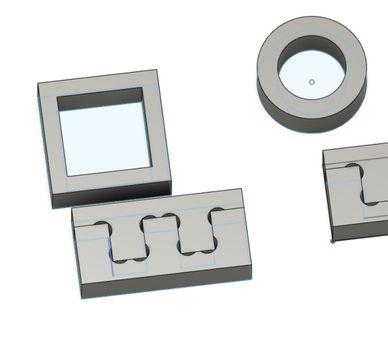

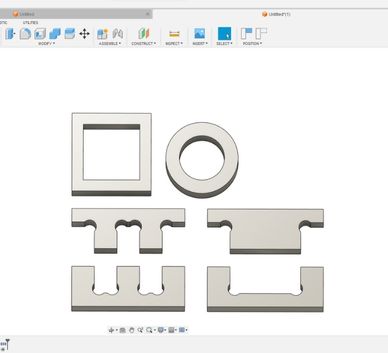

Create some simple test models. One to test joints, a circle for

runout, a

rectangle for alignment.

Create some simple test models. One to test joints, a circle for

runout, a

rectangle for alignment.  Add dogbones with the dogbone add-in (explained below) or by

hand.

Add dogbones with the dogbone add-in (explained below) or by

hand.

Align them (make sure they are at least the diameter of the tool away

from

each other)

Align them (make sure they are at least the diameter of the tool away

from

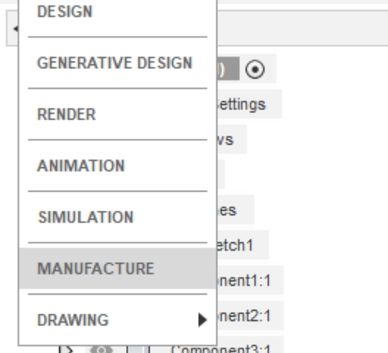

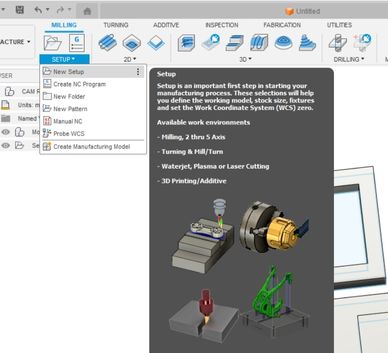

each other) Go to the manufacture workspace

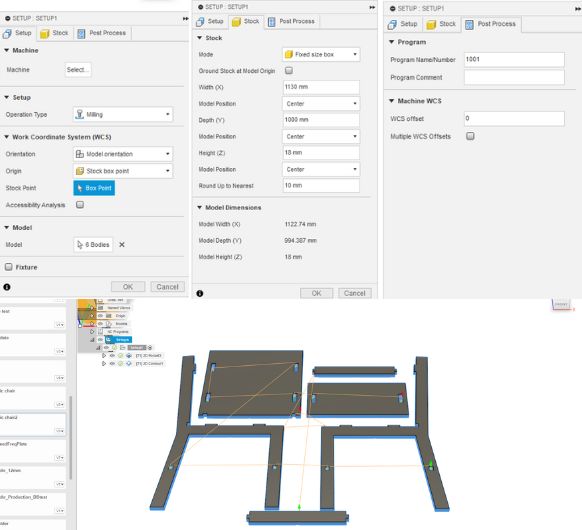

Go to the manufacture workspace Create a new setup

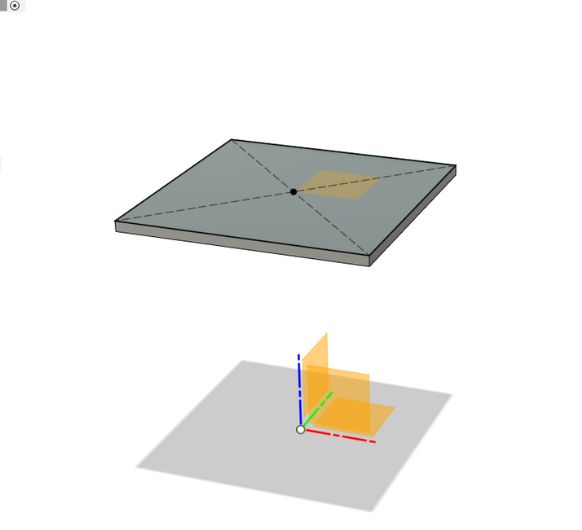

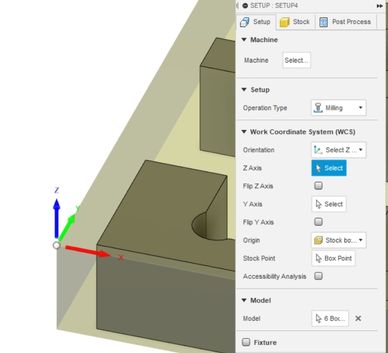

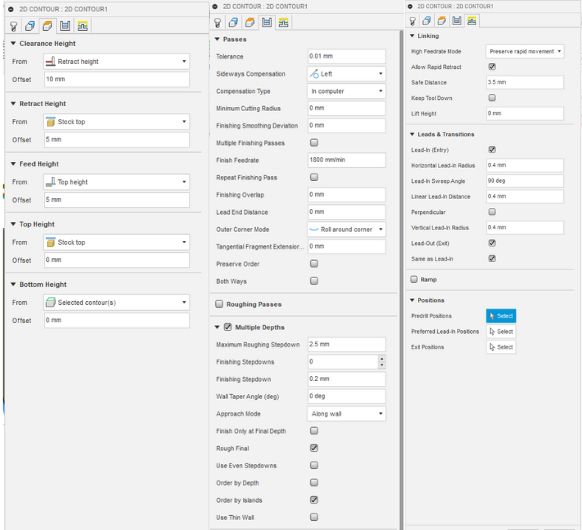

Create a new setup First to set is the orientaton (select Z and Y option) and the origin

(selected by hand, see pic)

First to set is the orientaton (select Z and Y option) and the origin

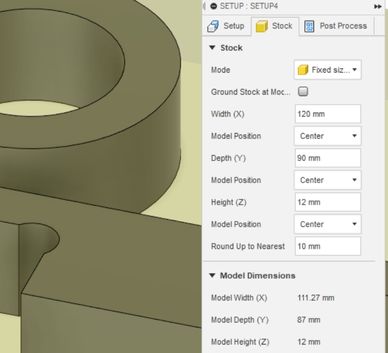

(selected by hand, see pic) Now adjust the stocksize. The material I'm using is 12mm thick. Hit ok

for

the setup

Now adjust the stocksize. The material I'm using is 12mm thick. Hit ok

for

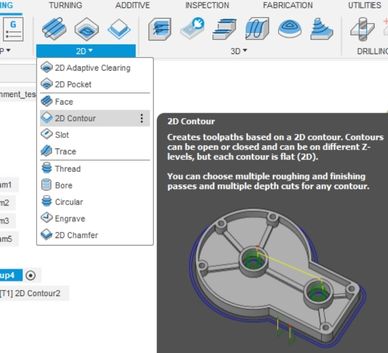

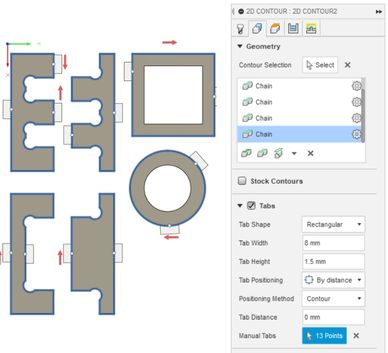

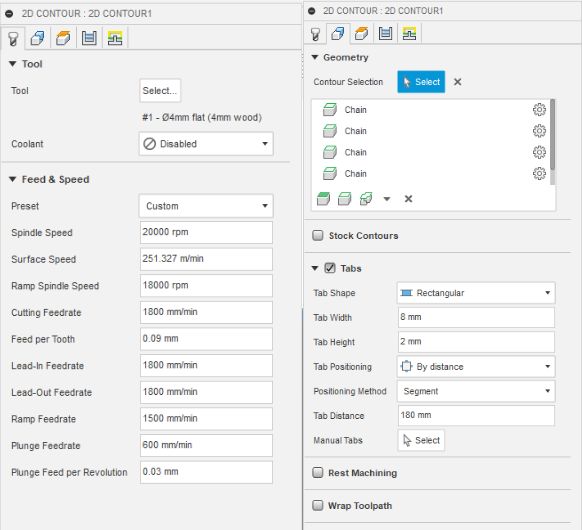

the setup Select 2d contour as the toolpath

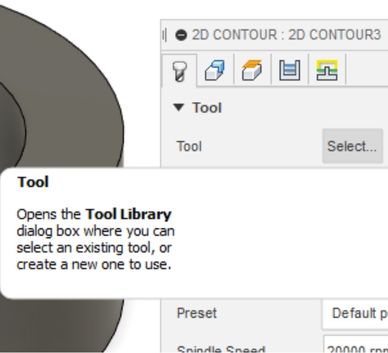

Select 2d contour as the toolpath Select tool

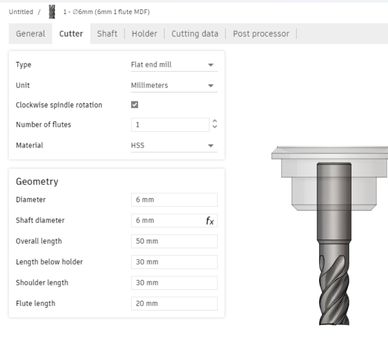

Select tool If you need to make a new

one, click the plus and this window will appear.

Add the dimensions of your flute

If you need to make a new

one, click the plus and this window will appear.

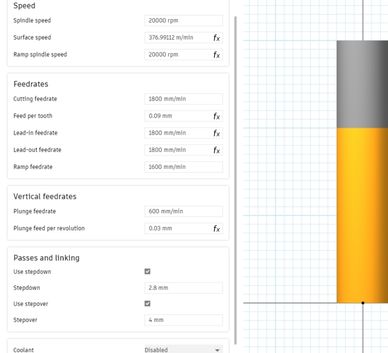

Add the dimensions of your flute Adjust the cutting data to your needs

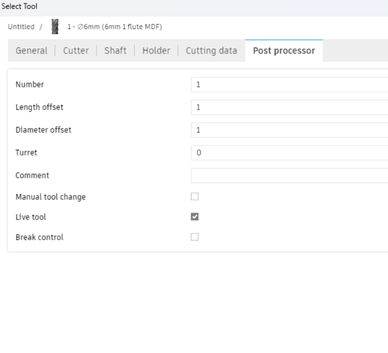

Adjust the cutting data to your needs Set this to 1

Set this to 1

After you added the

tool,

select the edges to mill (make sure to select the bottom ones)

After you added the

tool,

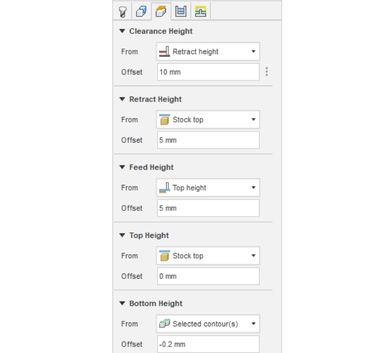

select the edges to mill (make sure to select the bottom ones) Set the bottom height

offset to -0.2mm to fully cut through the material

(make sure that there is a sacrifical layer of wood on your cnc that yo can cut into

underneath)

Set the bottom height

offset to -0.2mm to fully cut through the material

(make sure that there is a sacrifical layer of wood on your cnc that yo can cut into

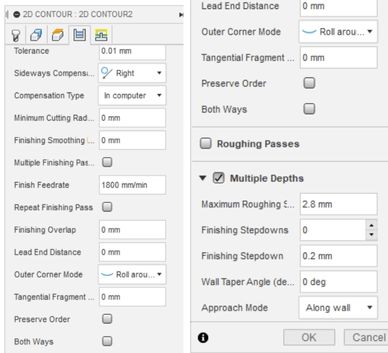

underneath) Set the sideways

compensation to right and the maximum roughing stepdown to about a fourth of the

material thickness

Set the sideways

compensation to right and the maximum roughing stepdown to about a fourth of the

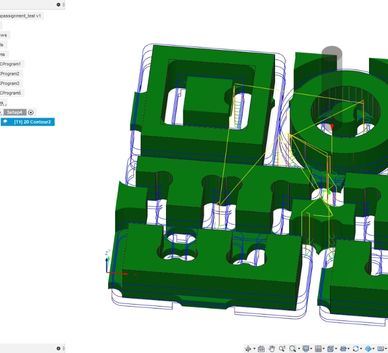

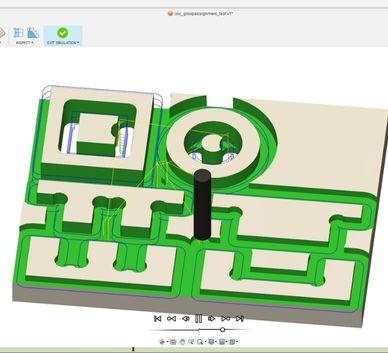

material thickness If you hit ok now, it should look somewhat like this

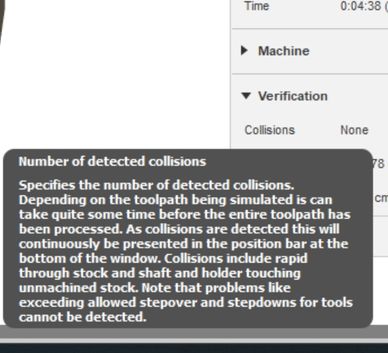

If you hit ok now, it should look somewhat like this You can simulate the toolpath now (Actions>Simulate)

You can simulate the toolpath now (Actions>Simulate) No collision should

occur. You might need to change your tool settings otherwise.

No collision should

occur. You might need to change your tool settings otherwise. If you are happy with

the path, you can hit post process

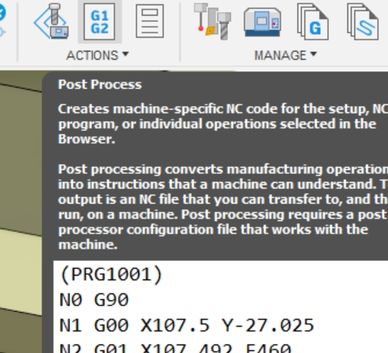

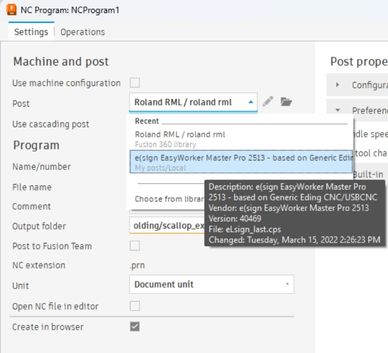

If you are happy with

the path, you can hit post process Select the

post-processor of your cnc (usually needs to be downloaded first) and choose a

location to save. Click Post.

Select the

post-processor of your cnc (usually needs to be downloaded first) and choose a

location to save. Click Post.Test results

Now that the models

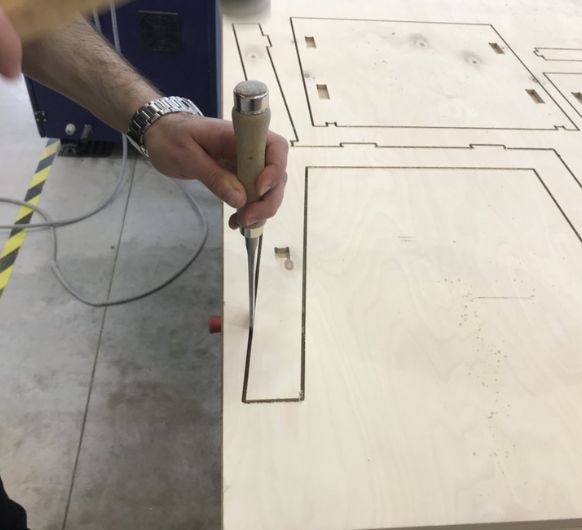

Break the tabs to release the model

Break the tabs to release the model The result is rather bad, very jagged edges. This is because the tool

is already quite old. For my actual shelf, I will use a sharper tool.

The result is rather bad, very jagged edges. This is because the tool

is already quite old. For my actual shelf, I will use a sharper tool.

All cutouts

All cutouts Sanding the edges to smooth them out

Sanding the edges to smooth them out The cleaned models. Some edges weren't accessible with the sanding

paper and some other parts broke off. The parts are very small and these problems

wouldn't occur on a much larger scale

The cleaned models. Some edges weren't accessible with the sanding

paper and some other parts broke off. The parts are very small and these problems

wouldn't occur on a much larger scale The joints fits together verywell. I did not create any offset

for these. But the MDF is rather "soft" so I could easily hammer them in place.

For future designs I'll add a small offset (about 0.075mm per side) just to be on

the safe side.I will test this again before cutting my actual design.

The joints fits together verywell. I did not create any offset

for these. But the MDF is rather "soft" so I could easily hammer them in place.

For future designs I'll add a small offset (about 0.075mm per side) just to be on

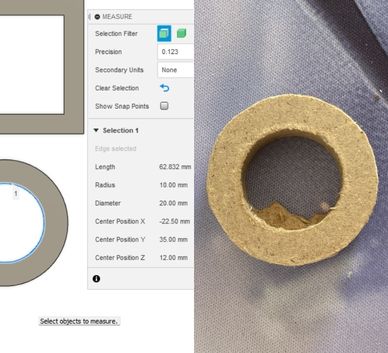

the safe side.I will test this again before cutting my actual design. The circles inner

diameter is 20mm in Fusion and it's also 20mm in the cut part. So there is no runout

in the tool. It's center and the spinning axis are aligned.

The circles inner

diameter is 20mm in Fusion and it's also 20mm in the cut part. So there is no runout

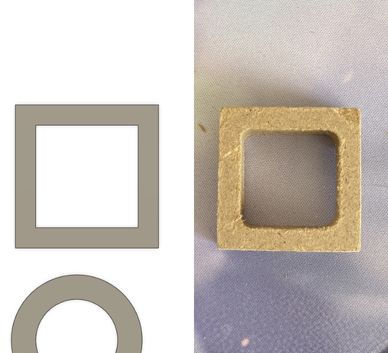

in the tool. It's center and the spinning axis are aligned. For the square the inner corners are rounded off. This was to be

expected, as the tool diameter is 6mm. The angle is 90°, so no alignment issues with

the machine

For the square the inner corners are rounded off. This was to be

expected, as the tool diameter is 6mm. The angle is 90°, so no alignment issues with

the machineDesign in Fusion360

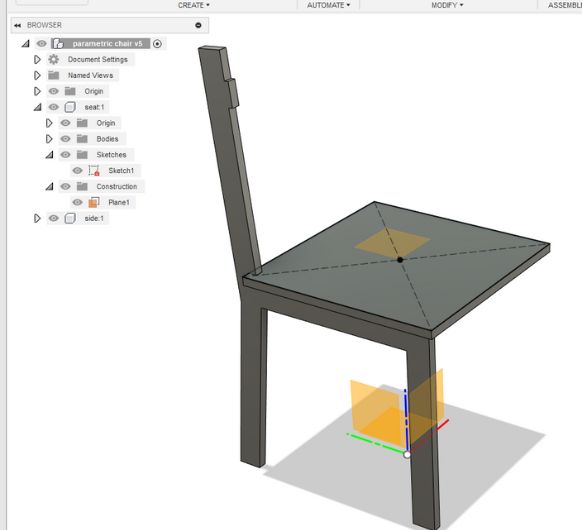

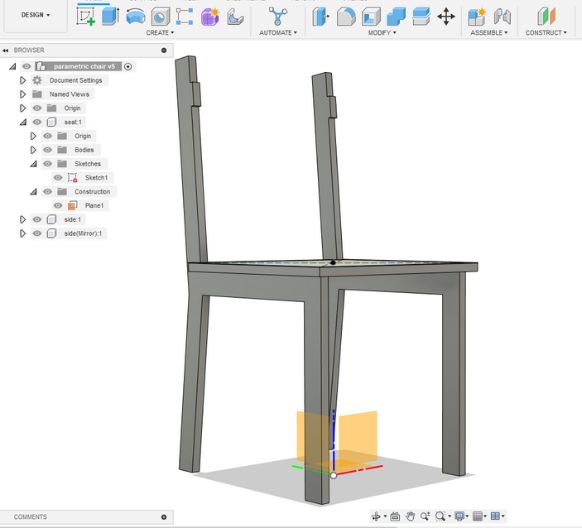

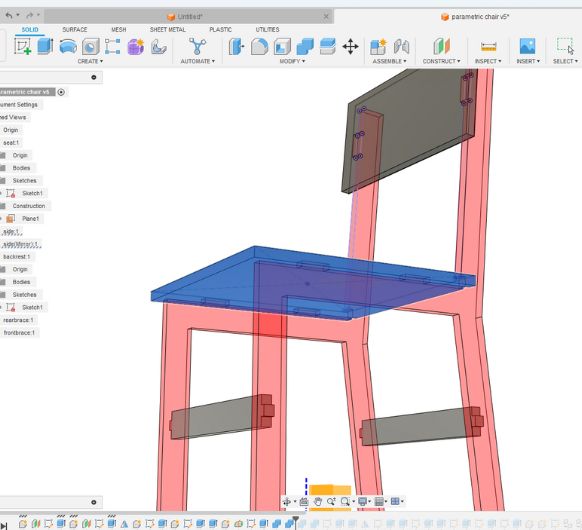

I designed a chair, following this tutorial.

Next up are the legs. I

designed the left side first, already integrating the parts where I will stick it

together.

Next up are the legs. I

designed the left side first, already integrating the parts where I will stick it

together. Using construction

planes and the mirror tool Icopy the right leg.

Using construction

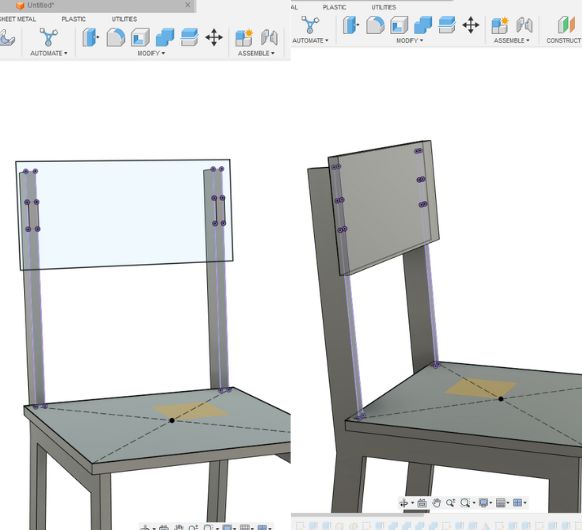

planes and the mirror tool Icopy the right leg. Adding the back plate

:)

Adding the back plate

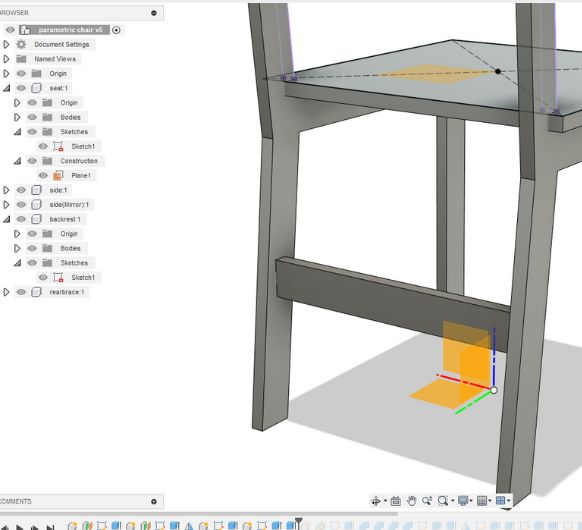

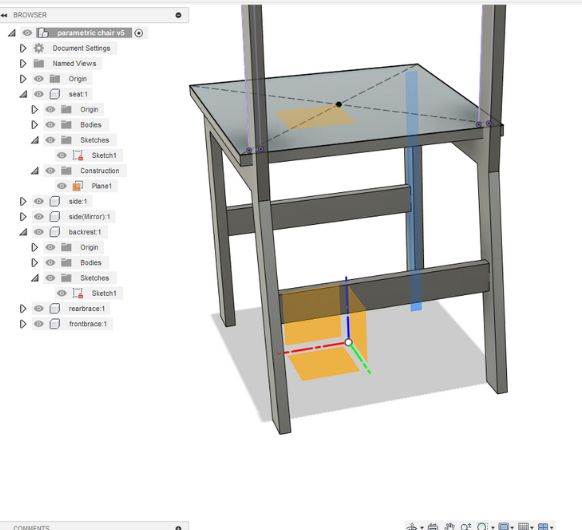

:) Forstability, I am

adding these braces.

Forstability, I am

adding these braces.  Front and back.

Front and back.

I still need to cut

some pockets into the backplate and the sitting plate.

I still need to cut

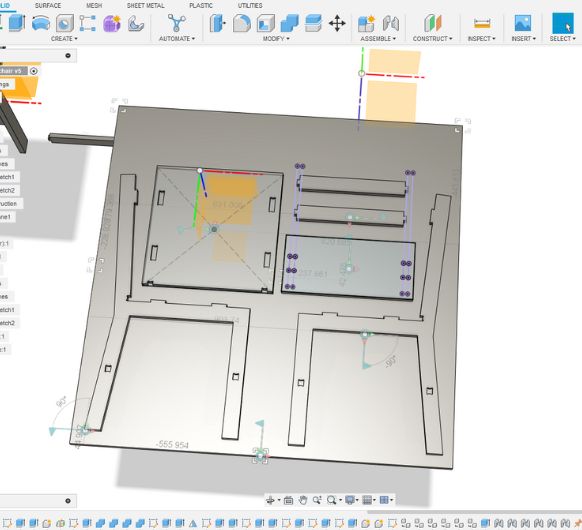

some pockets into the backplate and the sitting plate. Lastly I am arranging

the components on a plate that has the size of the wood I'll be using.

Lastly I am arranging

the components on a plate that has the size of the wood I'll be using.Adding dogbones

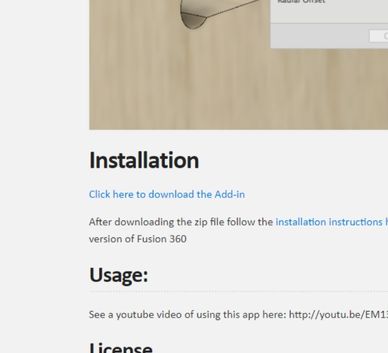

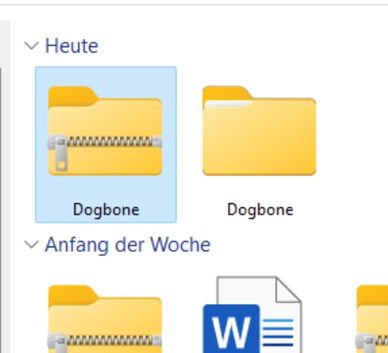

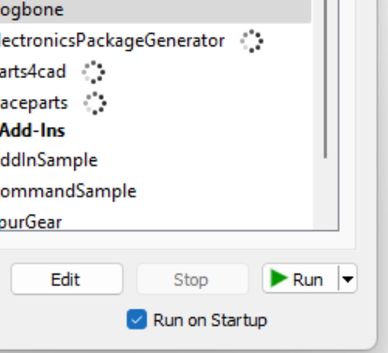

Now we I need to add dogbones to all my inner corners. This needs to be done, because the milling tool has a cylindrical shape and a certain diameter, therefore there cannot be any sharp inner corners in the design. I followed this tutorial to install a add-in for fusion which adds dogbones automatically. Follow this link: http://tapnair.github.io/Dogbone/ and install the add-in:

Extract all the files and rename the folder to just "Dogbone". Ctrl+C

the

folder.

Extract all the files and rename the folder to just "Dogbone". Ctrl+C

the

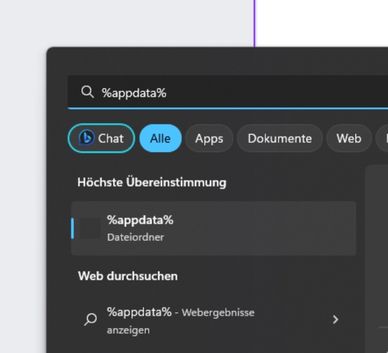

folder. Head over to your AppData folder.

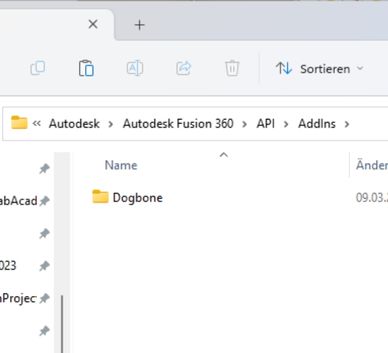

Head over to your AppData folder. Open: Autodesk > Autodesk Fusion 360 > API > AddIns and then paste

the Dogbone folder there

Open: Autodesk > Autodesk Fusion 360 > API > AddIns and then paste

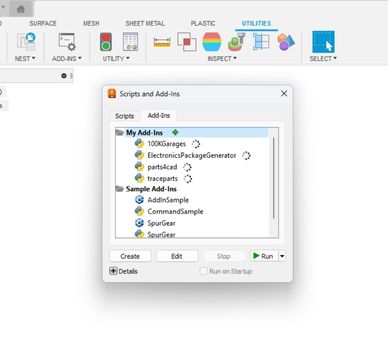

the Dogbone folder there (Re-)Start Fusion. Head to Utilities and open Add-Ins. Click on the

green plus to add a new one.

(Re-)Start Fusion. Head to Utilities and open Add-Ins. Click on the

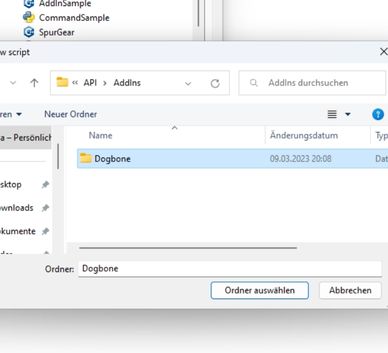

green plus to add a new one. Select the Dogbone folder inside the master folder and add it

Select the Dogbone folder inside the master folder and add it

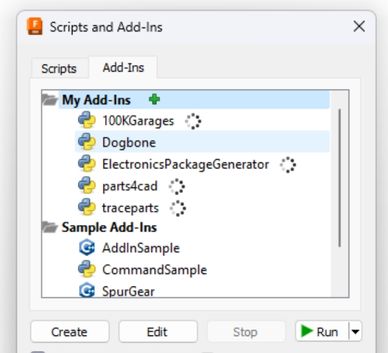

It will now appear in the list

It will now appear in the list Activate the checkmark and hit Run

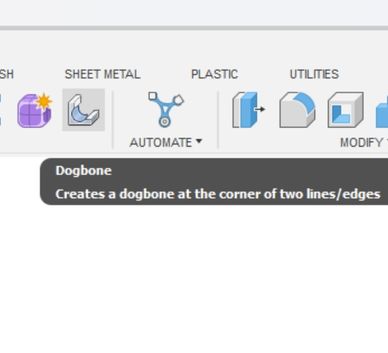

Activate the checkmark and hit Run Now, in the solid workspace, you will find this Dogbone tool

Now, in the solid workspace, you will find this Dogbone tool

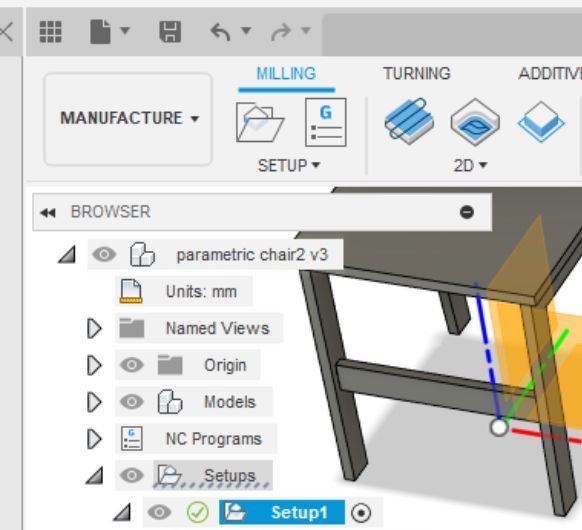

CAM Toolpath

Apply all of the

needed settings for the setup.

Apply all of the

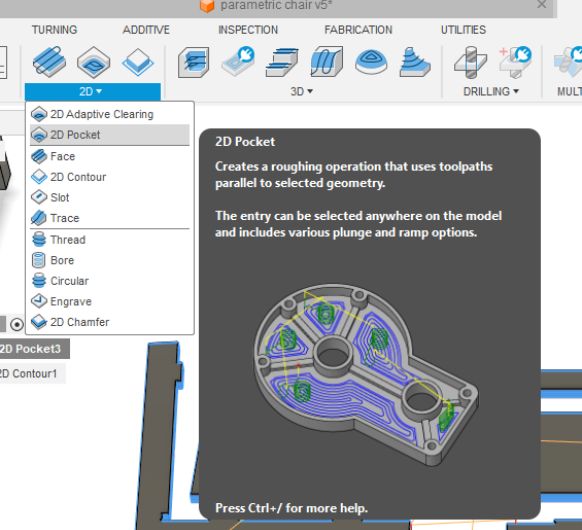

needed settings for the setup. The first thing that

will be cut are the pockets. So I am starting with 2D pocket.

The first thing that

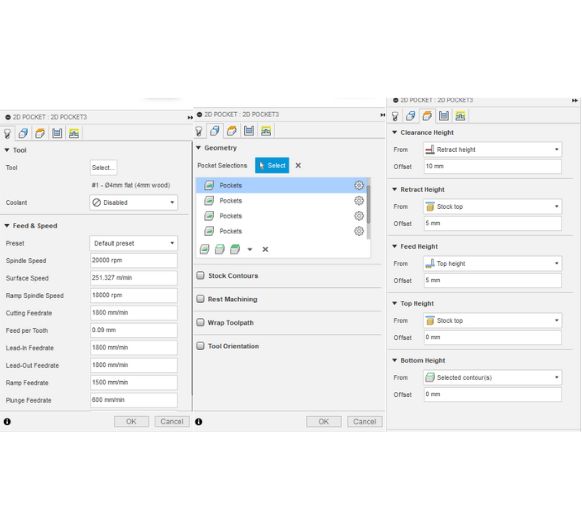

will be cut are the pockets. So I am starting with 2D pocket. These are the

settings. Make sure you select all the pockets in you model.

These are the

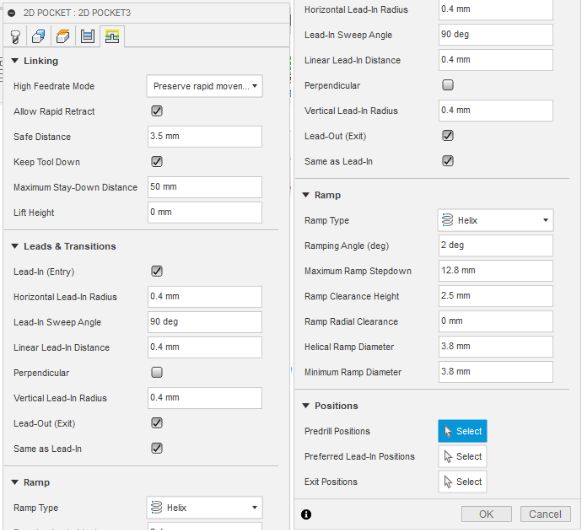

settings. Make sure you select all the pockets in you model. Last two setting pages

of 2D pockets.

Last two setting pages

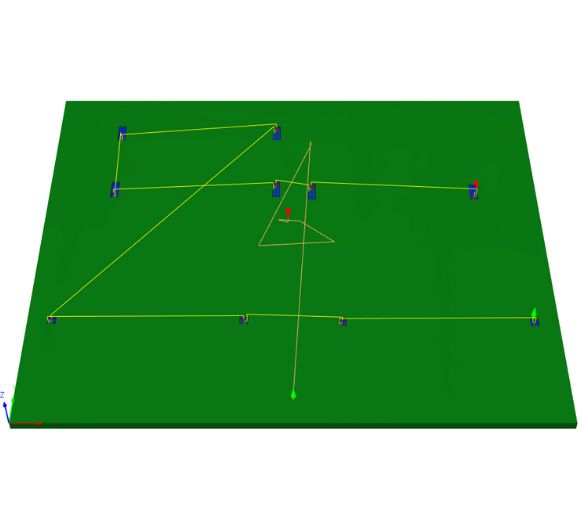

of 2D pockets. Here you can see the

toolpath which the machine will take. You see all of the pockets being

milled.

Here you can see the

toolpath which the machine will take. You see all of the pockets being

milled.

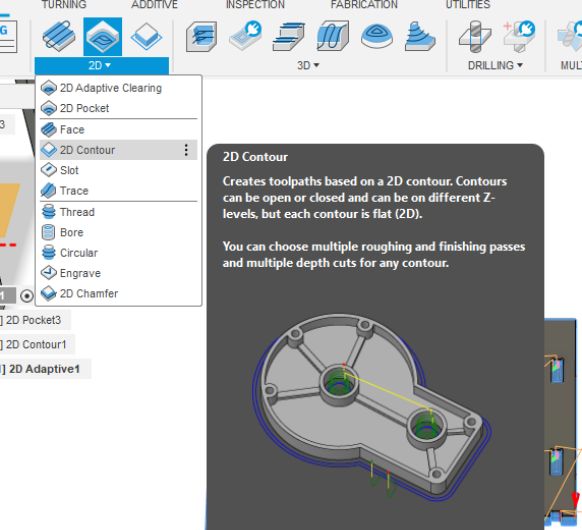

I still need to do the

edge cuts though. 2D contour is the optimal tool for this.

I still need to do the

edge cuts though. 2D contour is the optimal tool for this. I am setting a 4mm

flat end mill as the tooland select all the edges.

I am setting a 4mm

flat end mill as the tooland select all the edges. Here I am setting the

Passes settings and so on.

Here I am setting the

Passes settings and so on. Also here, you can see

what the toolpath looks like.

Also here, you can see

what the toolpath looks like.Export this and go to your CNC.

Download my Fusion project file

Operating the big CNC

The tool holder

The tool holder

valve for the high

pressured air

valve for the high

pressured air The extraction station

with the On/Off switch

The extraction station

with the On/Off switch The control station for

the extraction pipes (This is there because

there are multiple machines connected to the extraction, and to get the best pull to

the extraction station, the ways to the other tools can be closed electricly)

The control station for

the extraction pipes (This is there because

there are multiple machines connected to the extraction, and to get the best pull to

the extraction station, the ways to the other tools can be closed electricly)

And the vacuum bed

control. A compressor creates the vacuum for the

bed.

And the vacuum bed

control. A compressor creates the vacuum for the

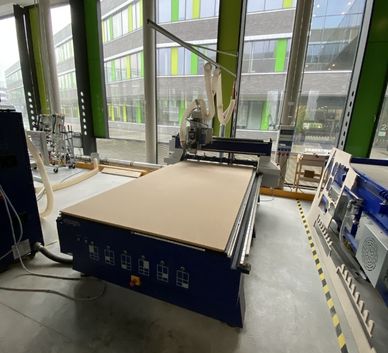

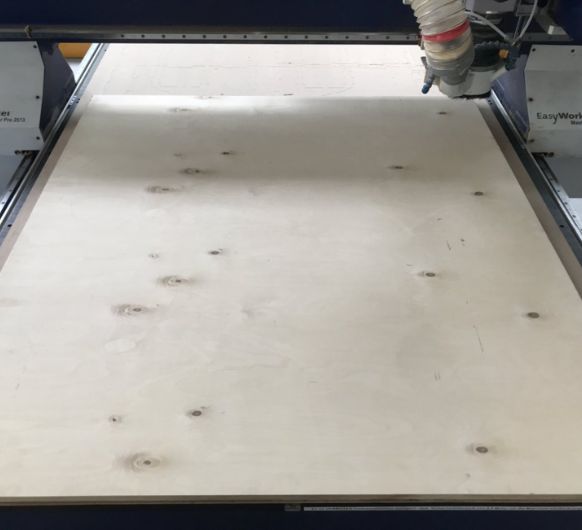

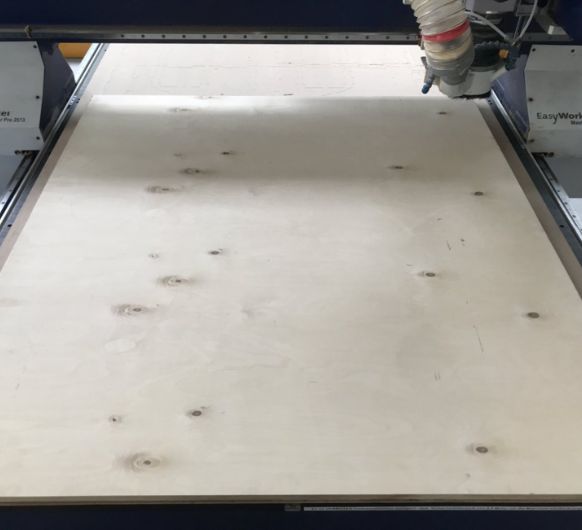

bed. In order to operate the

milling machine, we first loaded the bed with

the material we wanted to mill. In my case this was a circa square sheet of wood

with 12mm thickness. Under this sheed of wood was a sacrificial layer of MDF.

In order to operate the

milling machine, we first loaded the bed with

the material we wanted to mill. In my case this was a circa square sheet of wood

with 12mm thickness. Under this sheed of wood was a sacrificial layer of MDF.

After

loading the stock, it's time to prepare the CNC:

- Start the PC.

- Press the green start button after the program has started.

- Start the machine after the program and stop the machine before closing the program to avoid information discrepancies.

- Incorrect order of operation can lead to the mill crashing into the tool swapping station. The CNC lacks collision detection and could be damaged in such a scenario.

When zeroing the z-axis,

the machine offers multiple automatic processes. Firstly, the

machine can determine the length of the current tool automatically using a sensor

located at the back. Secondly, the Gantry is equipped with a zeroing sensor similar

to

our Roland MDX-40. This step requires the assistance of

two individuals. One person holds the zeroing sensor while the other initiates the

process, keeping a finger on the escape button or the emergency stop in case any

issues

arise. The escape button serves as an immediate stop for the machine's

operation.

When zeroing the z-axis,

the machine offers multiple automatic processes. Firstly, the

machine can determine the length of the current tool automatically using a sensor

located at the back. Secondly, the Gantry is equipped with a zeroing sensor similar

to

our Roland MDX-40. This step requires the assistance of

two individuals. One person holds the zeroing sensor while the other initiates the

process, keeping a finger on the escape button or the emergency stop in case any

issues

arise. The escape button serves as an immediate stop for the machine's

operation.- Let's begin the milling process. Firstly, we ensured our safety by wearing earbuds and protective eye gear.

- Next, we proceeded to open the high-pressure air valve.

- Then, we started the vacuum bed with all neccessary vacuum zones active.

- Following that, we activated all the necessary vacuum zones to start the vacuum bed.

- Lastly, we initiated the exhaust system while confirming if the exhaust to the mill was either closed or open, considering that other connected machines might have been used.

- Once these preparations were completed, we loaded the toolpath that was created in Fusion360. After carefully reviewing the projected job in the software, we commenced the milling process either by clicking the "start" button in the program

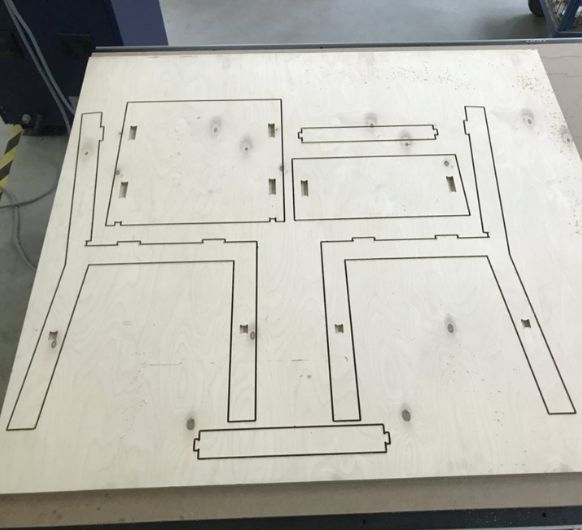

-This is what it looked like after milling. There were no big

complications while cutting.

-This is what it looked like after milling. There were no big

complications while cutting. Ahmed helped me break the tabs. I also sanded the edges a bit.

Ahmed helped me break the tabs. I also sanded the edges a bit.

And lastlyI assembled the chair. I had to use a hammer to get

everything together. But now that it fits it's so tight it's making the chair very

stable. I have already stood on it and itdidn't wiggle.

And lastlyI assembled the chair. I had to use a hammer to get

everything together. But now that it fits it's so tight it's making the chair very

stable. I have already stood on it and itdidn't wiggle.