Week 9: Molding and Casting - Group Assignment

Molding and Casting is the process where we can produce many copies of the original item. Mold is the liquid materials that we pour on the item in the box to be casted. Mold materials harden on getting set to flexy material taking the shape of the item that is used.

Casting is the process where we pour semi liquid materials (usually the materials like cement paste which harden on getting set) into the mold and letting it dry.

One mold can cast as many as possible to create a copy of original item.

Instruction:

Group Assignment:

Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Extra Credit:

☞ Try other molding and casting processes

Molding and Casting Materials

Mold making Materials:

For molding we are using Mold Star - Platinum Silicon Rubber. It contains in two part as Part A and Part B, which are require in equal amount for mold making.

Safty Precuation

Respiratory Protection

Respiratory protection is not normally required when using this product in open environments with adequate ventilation.

Hand Protection

Wear any liquid-tight gloves such as butyl rubber, neoprene or PVC.

Eye Protection

Safety glasses with side shields per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

Other Protective Clothing/Equipment

Additional protective clothing or equipment is not normally required. Provide eye bath and safety shower.

Comments

Never eat, drink, or smoke in work areas. Practice good personal hygiene after using this material, especially before eating, drinking, smoking, using the toilet, or applying cosmetics. Wash thoroughly after handling.

Casting Materials:

Hydro-Stone:

We used Hydro-stone for casting for our assignment. It becomes hard and rigid after setting or cooldown.

Precuations to be taken in Handling and Storage:

During handling wear the appropriate respiratory, eye and skin protection if warranted per environmental conditions. Keep dry. Dew point conditions or other conditions causing presence of liquid will harden this material during storage.

The ratio to mix the hydro-stone to water is 100g:32g respectively. Cooling time for hydro-stone can be around four hours.

Lead Metal:

Lead metal is also presented in the lab, so we used lead metal to test cast for our group assignment.

Safety Precuation:

Ventilation:

Use adequate local or general ventilation to maintain the concentration of lead fumes in the working environment well below recommended occupational exposure limits. Supply sufficient replacement air to make up for air removed by the exhaust system. Local exhaust is recommended for melting, casting, welding, grinding, flame cutting or burning, and use of lead powders.

Protective Clothing:

Gloves and coveralls or other work clothing are recommended to prevent prolonged or repeated direct skin contact when lead is processed. Appropriate eye protection should be worn where fume or dust is generated. Where hot or molten metal is handled, heat resistant gloves, goggles or face shield, and clothing to protect from radiant heat and hot metal splash should be worn. Safety type boots are recommended.

Respirators:

Where lead dust or fumes are generated and cannot be controlled to within acceptable levels by engineering means, use appropriate NIOSH-approved respiratory protection equipment (a 42CFR84 Class N, R or P-100 particulate filter cartridge). When exposure levels are obviously high but the actual concentration is unknown, a self-contained breathing apparatus which supplies a positive air pressure within a full face-piece mask should be worn.

General Hygiene Considerations:

Do not eat, drink or smoke in work areas. Thoroughly wash hands before eating, drinking, or smoking in appropriate, designated areas as well as at the end of the workday. A double locker-shower system with separate clean and dirty sides is usually required for lead handling operations to avoid cross-contamination of street clothes. Contaminated clothing should be changed frequently and laundered before each reuse. Inform laundry personnel of contaminants’ hazards. Workers should not take dirty work clothes home and launder them with other personal clothing.

- Melting point of the lead metal is 328°C

- Boiling Point/Range: 1,740°C

Test Casting

We tried casting with different materials in the negative mold that we have made.

Hydro-Stone:

First we used hydro-stone to test cast the mold. The ratio of Hydro-Stone powder to water to make a mixture is 100:32 in gram respectively. We measured the require amount of hydro-stone powder and water.

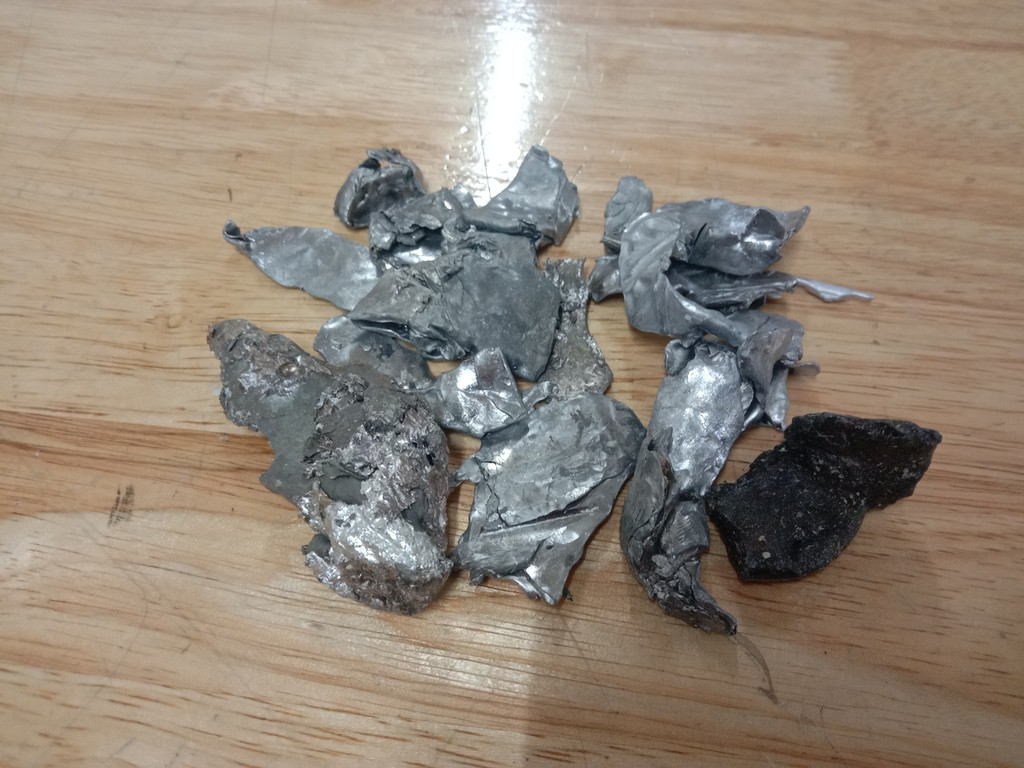

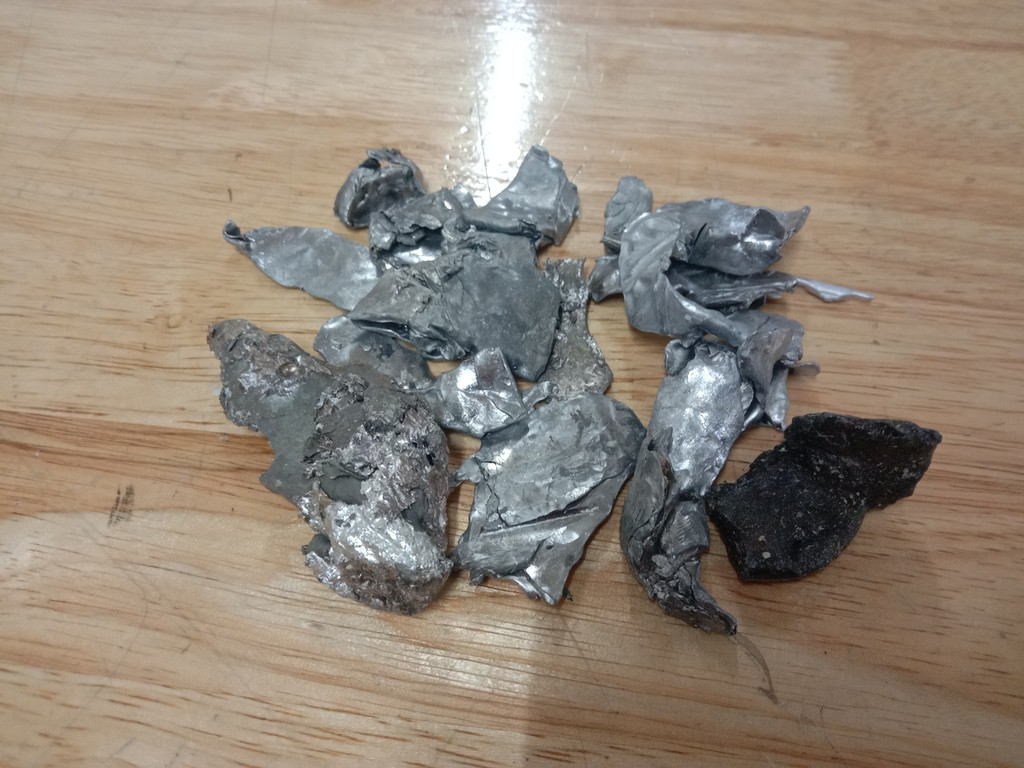

Lead Metal:

We also tried using lead metal to cast. It required a huge lot of time to get melt in order to pour the casting.

Test cast using lead metal failed. The product came out as above where the casting broke while removing. As it requires time for melting and due to oven problem, We couldn't try again.

Wax Powder:

We also tried using wax powder from milling of the positive mold. We melt it in the oven well and than pour in the negative mold.

This is the result comparison of hydro-stone cast and wax cast. Usually wax cast is having bubble but much reliable as it doesnot break easily.

Reference

- Silicone Safty Datasheet: https://www.smooth-on.com/msds/files/BD_DS_Eco_Equ_EZB_EZS_Psy_MS_OOMOO_Reb_ST_SS_Soma_Sol_Sorta.pdf

- Hydro-Stone safty Datasheet: http://shop.clay-planet.com/MSDS/plaster/Hydrostone%20Plaster.pdf

- Lead metal Datasheet: https://www.teck.com/media/2015-Products-Lead_Metal_SDS-T2.5.pdf