Electronics Production-Group Work

Group Assignment for Week 4

Group Assignment:

characterize the design rules for your in-house PCB production process

extra credit: send a PCB out to a board house

The group two of Fablab Mandala are:

Sonam Paldon Dorji

Zina Yonten

Anith Ghalley

Kencho Wangdi

Sangay Penjor

In house Design Rules

Due to covid-19 restrictions and protocols, we were not able to sent a PCB out to any board houses.However, we did test the PCB Milling Machine that and its precisions.

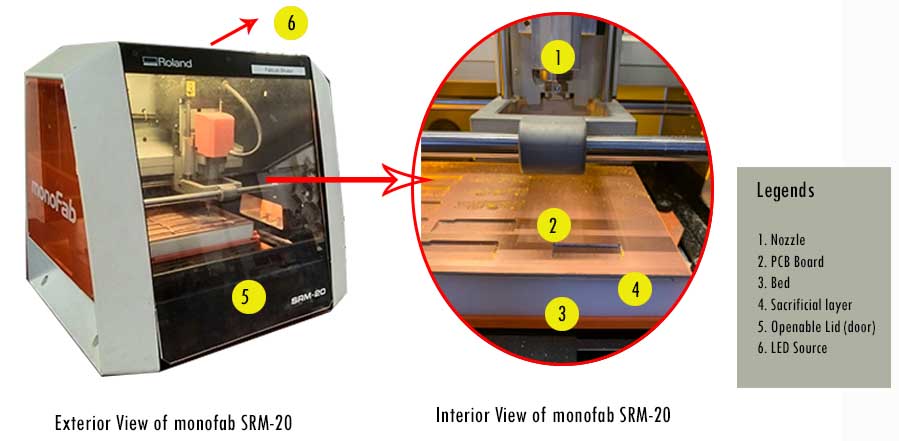

The Monofab SRM-20 Milling Machine

The description about the machine is given here.

The Monofab SRM-20 Tests

We learned about the machine specifications. A detailed specification is given here This detailed specifications made our works much faster and reliable to test the machine. The following table shows the machine specifications:

| Parameters | Specifications |

|---|---|

| Cuttable Material | Modelling Wax, Chemical Wood, Foam, Acrylic, Poly acetate, ABS, PC board |

| X, Y, and Z Operation Strokes | 203.2 (X) x 152.4 (Y) x 60.5 (Z) mm |

| Distance From Collet Tip to Table | Max, 130.75mm (5.15 in) |

| Loadable Workpiece Weight | 2 kg (4.4 lb) |

| X-, Y-, and Z-Axis Drive System | Stepping motor |

| Operating Speed | 6 - 1800mm/min 0.24 - 70.87inch/min |

| Software Resolution | 0.01 mm/step (RML-1), 0.001mm/step (NC code) 0.000039 inches/step (RML-1), 0.000039 inches/step (NC code) |

| Mechanical Resolution | 0.000998594 mm/step 0.0000393 inches/step |

| Spindle Motor | DC motor Type 380 |

| Spindle Rotation Speed | Adjustable 3000 - 7000 rpm |

| Cutting Tool Chuck | Collet method |

| Interface | USB |

| Control Command Sets | RML-1, NC code |

| Power Requirements | Machine: DC24V, 2.5A, Dedicated AC adapter: AC 100-240 V ±10%, 50/60 Hz |

| Power Consumption | Approx. 50 W |

| Operating Noise | During operation: 65 dB (A) or less (when not cutting), During standby: 45 dB (A) or less |

| External Dimensions | D451.0 (W) x 426.6 (D) x 426.2 (H) mm |

| Weight | 19.6 kg (43.2 lb) |

| Installation Environment | Temperature of 5 to 40°C (41 to 104 °F) 35 to 80% relative humidity (no condensation) |

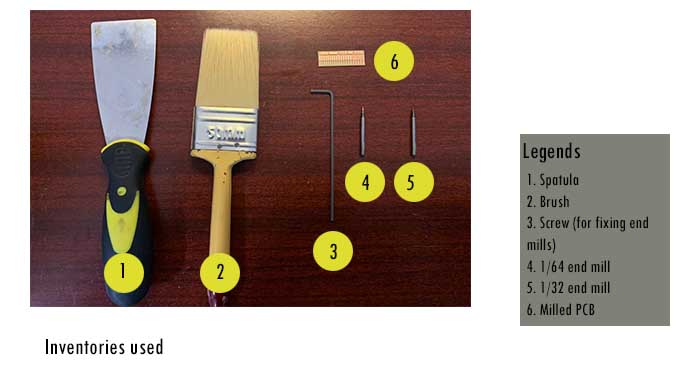

The inventory in our lab has 1/64" end mills and other 0.010" is unavailable.Therefore, we tested with 1/64". The inventories we sued to mill our

test prints are:

We used the the example file available from schedule here

We used the the example file available from schedule here

The Milling Process

1. Downloaded the files

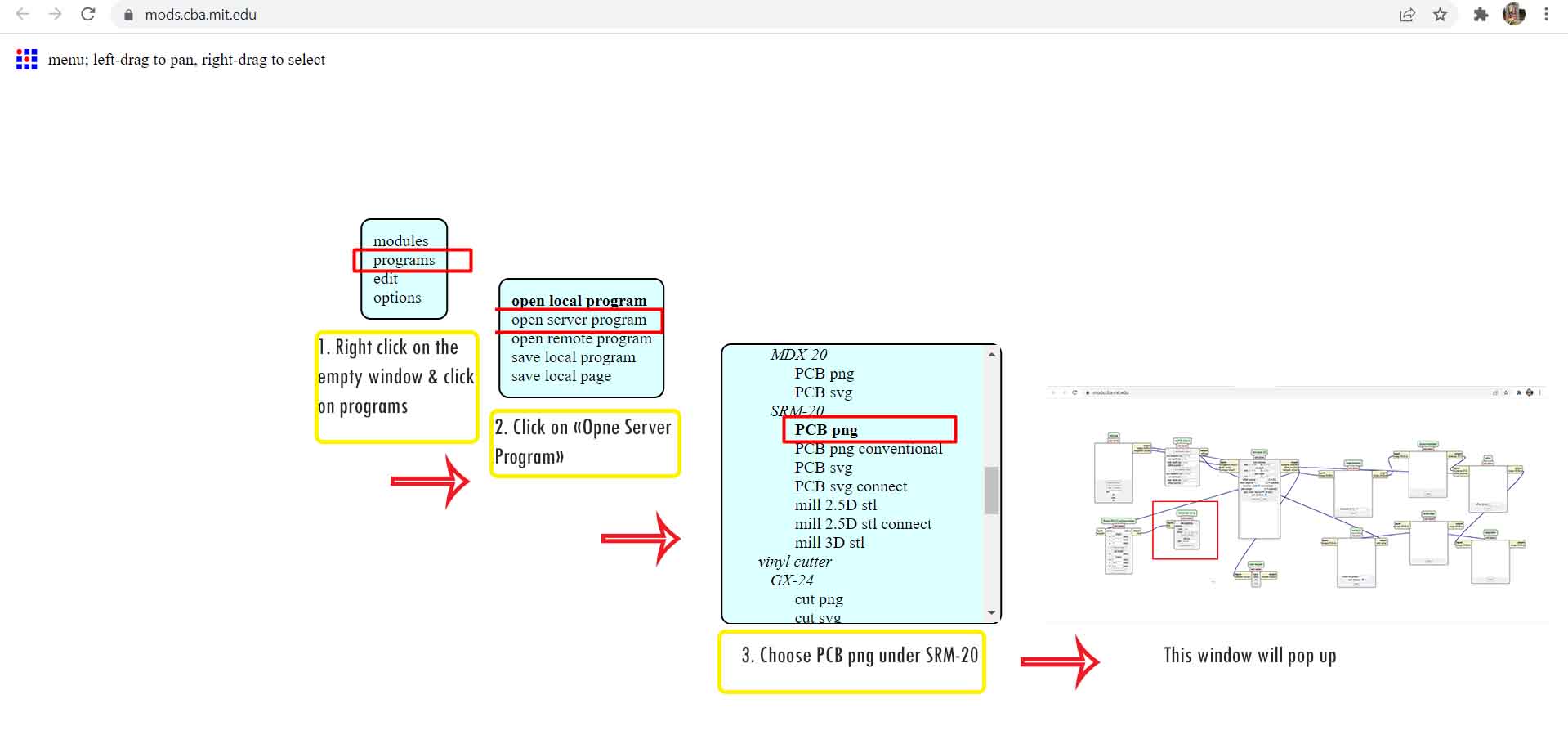

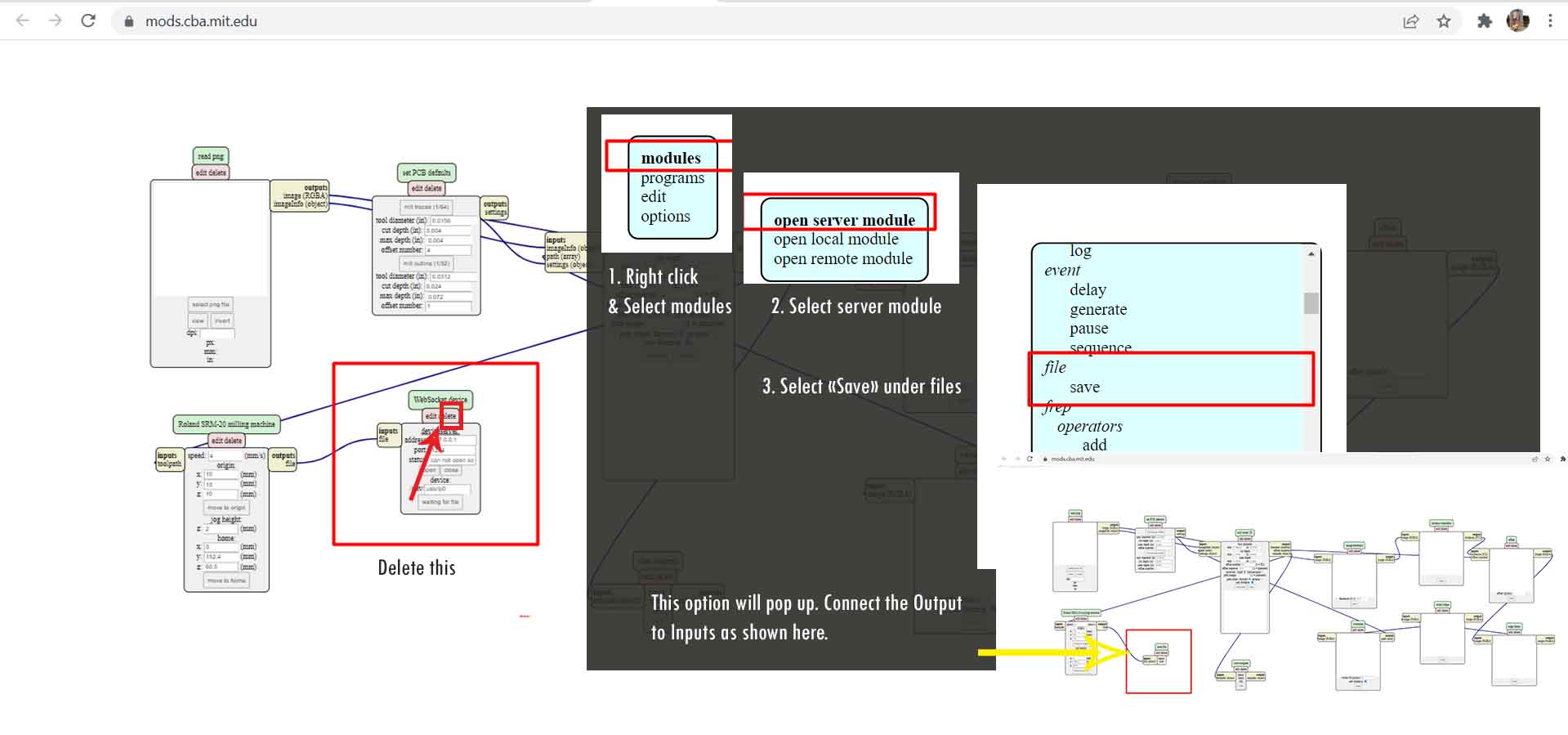

2. Prepared the rml files using mods community version here or the MIT mods version here. We used MIT mods version

3. Follow the following steps in the image:

4. The windows above, delete the "WebSocket Device" as highlighted below and follow the steps to save the rml file.

4. The windows above, delete the "WebSocket Device" as highlighted below and follow the steps to save the rml file.

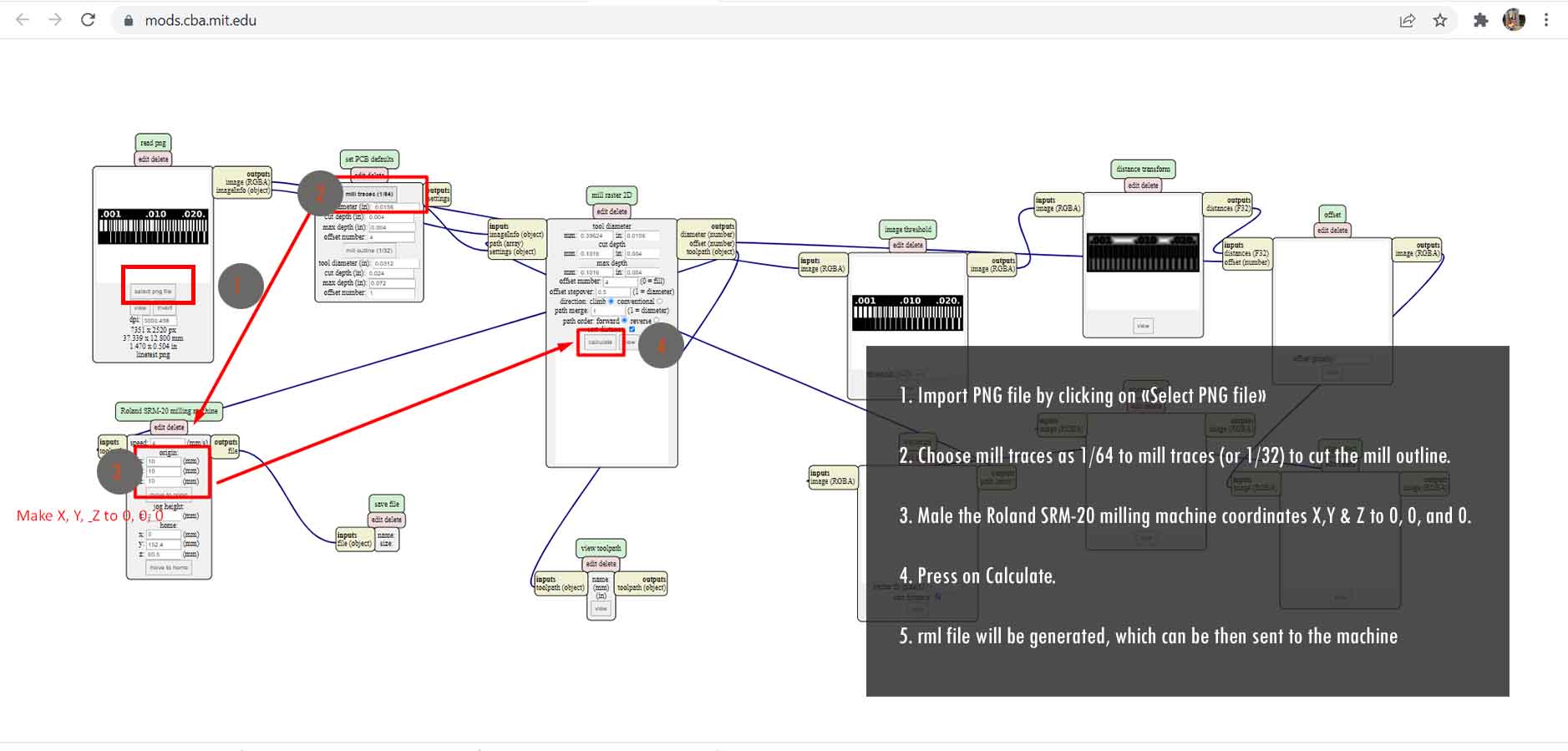

5. After that follow the following steps:

5. After that follow the following steps:

6. The rml file generated is then sent to "Vpanel for SRM-20", a software which is used to set zeros and print the PCB board.

6. The rml file generated is then sent to "Vpanel for SRM-20", a software which is used to set zeros and print the PCB board.

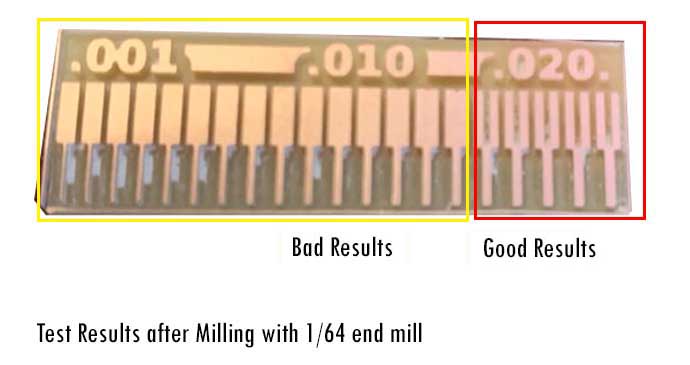

The results are as shown below: