CHECK LIST

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include (but are not limited to).

3D printing on fabric

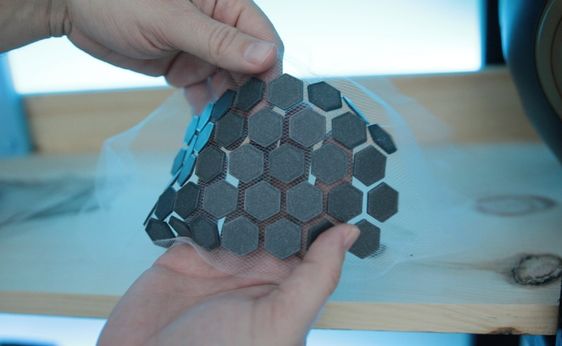

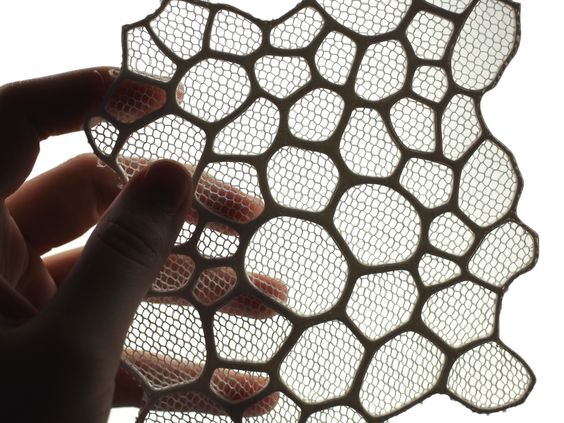

I have been reviewing some references about 3D printing on fabric and it has been very interesting to discover all the possibilities.

The following pictures show some inspiration, and were taken from thingiverse and

Raumprobe

The following site has been very useful to carry out this exercise Geeetech

1. Select the fabric

The first step is to select the fabric, among the most common are cotton, polyester or blends.I have selected polyester since it is a very common synthetic fabric in the market and it has several characteristics such as:

- non-absorbent

- is resistant

- high elasticity

- resists stretching

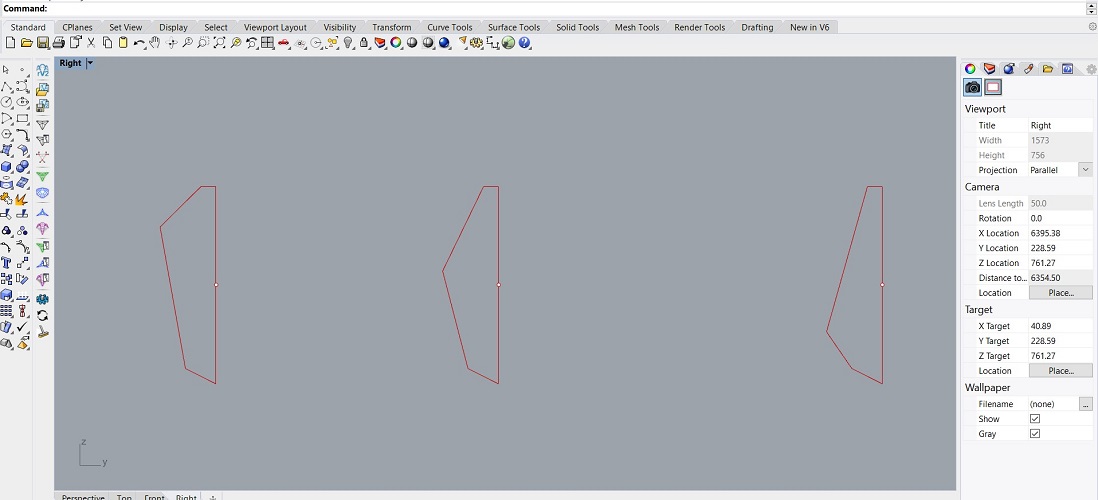

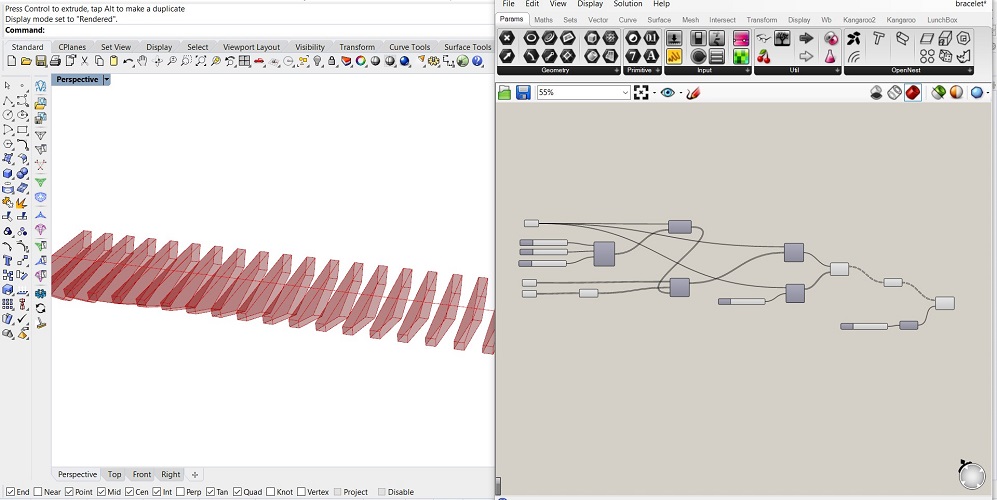

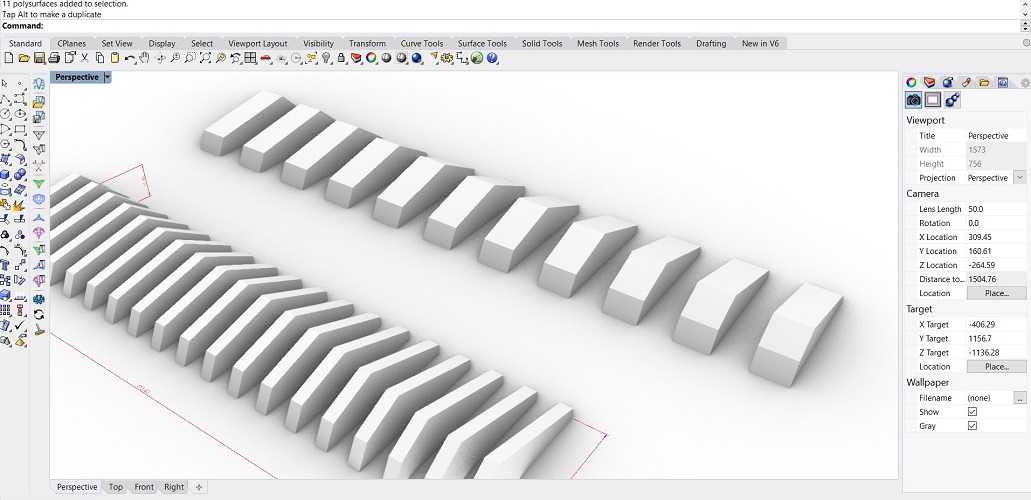

2. 3D design

The design I have in mind is to generate a bracelet. I have used Rhino and grasshopper to test the possibilities and that it can be parametric.

Once the 3D file is ready, export it as .stl.

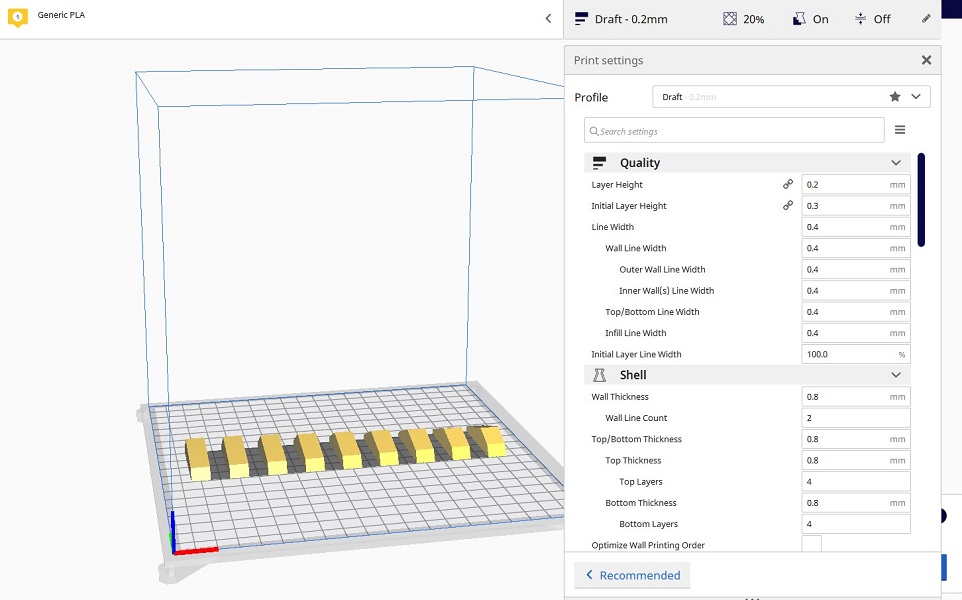

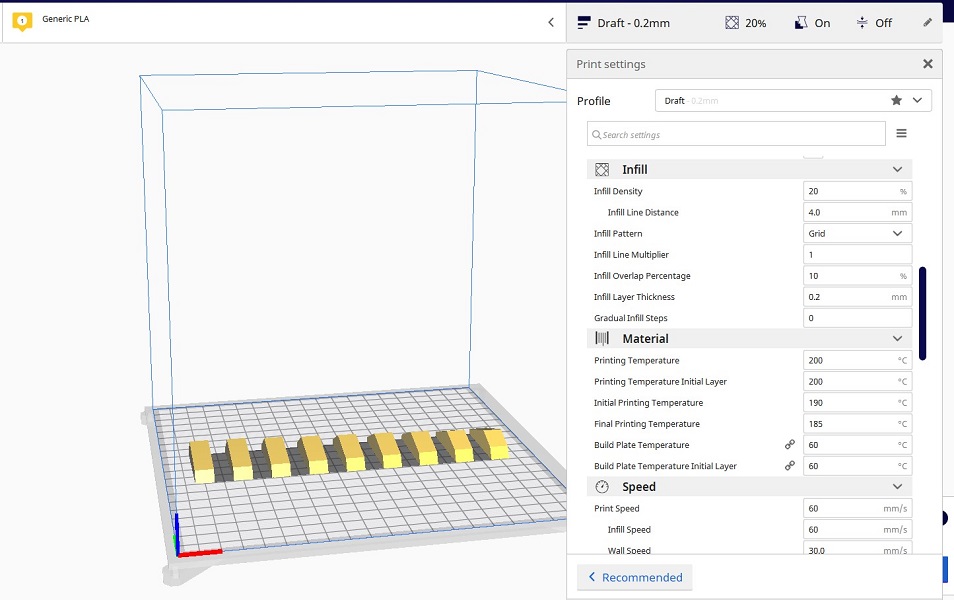

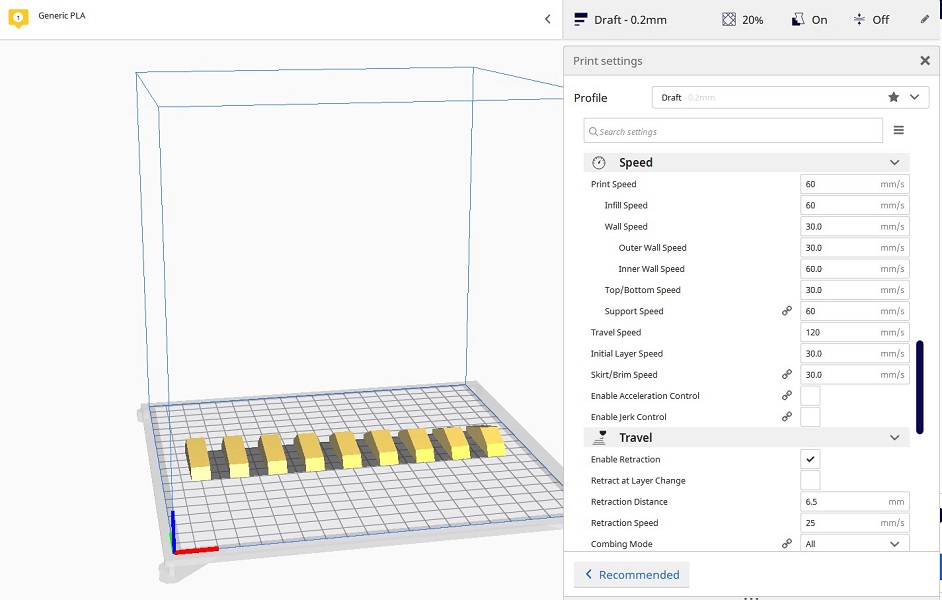

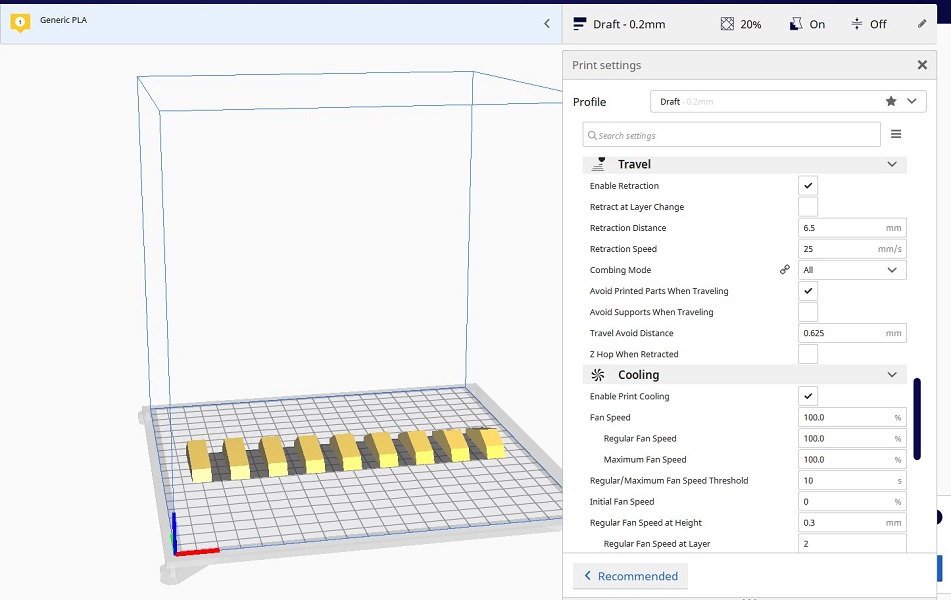

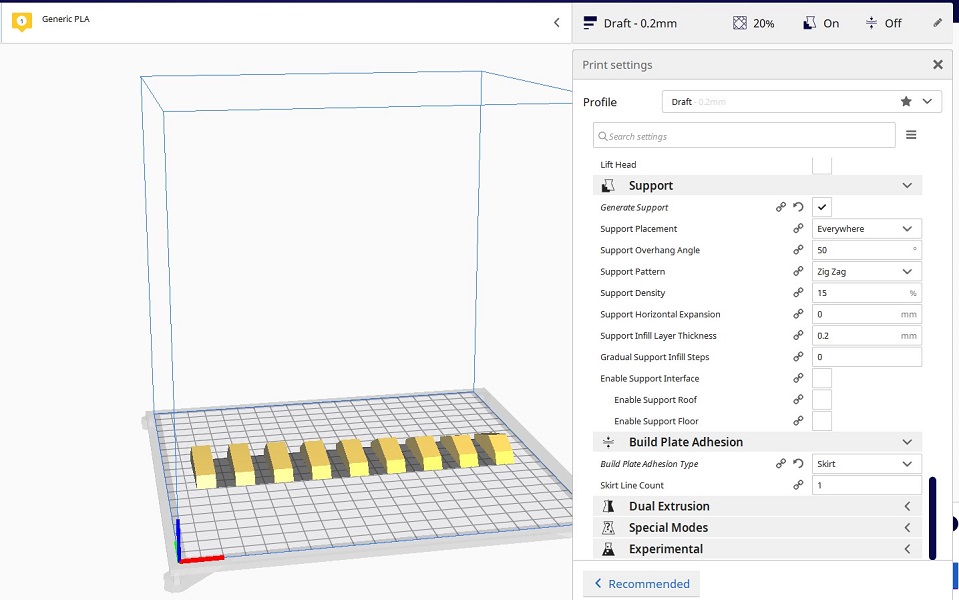

To print the object I'm going to use the Prusa i3. Open the file and set the parameters, these are the ones I used:

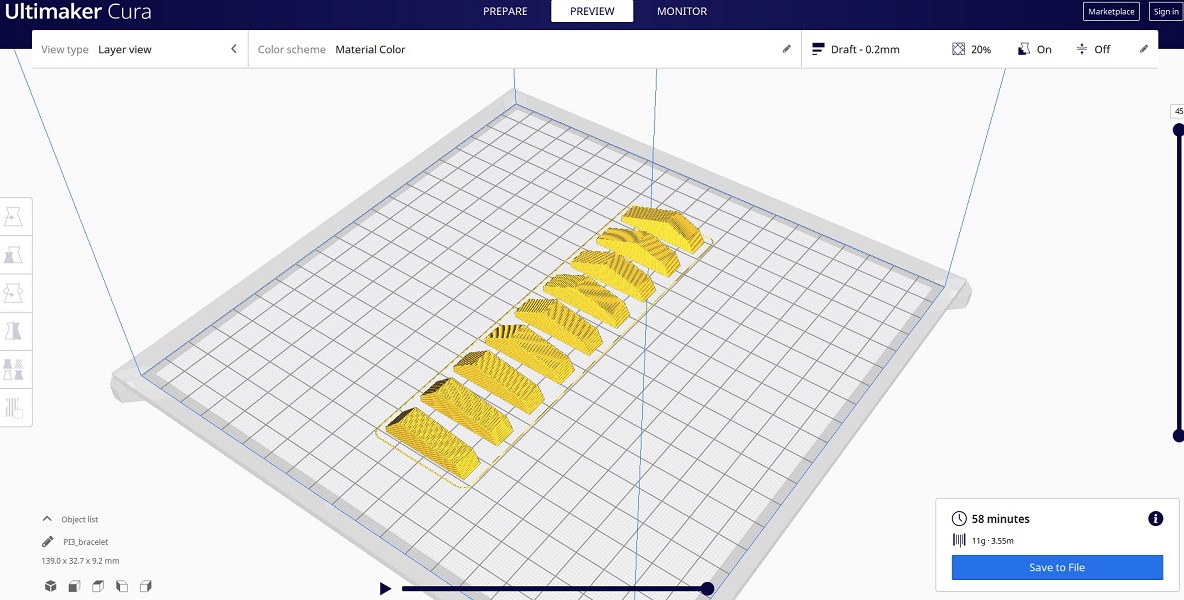

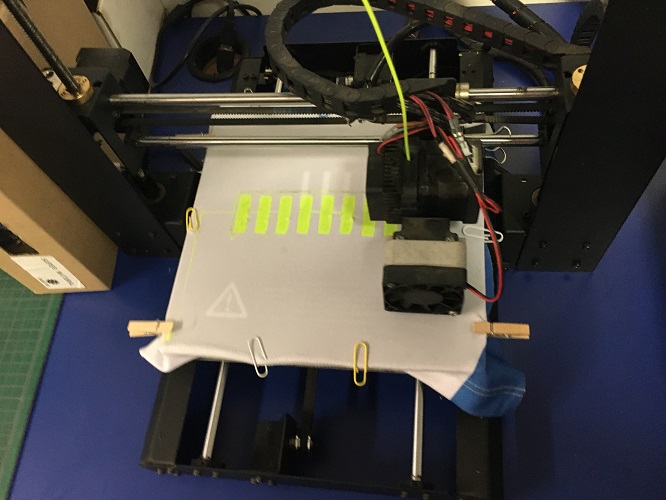

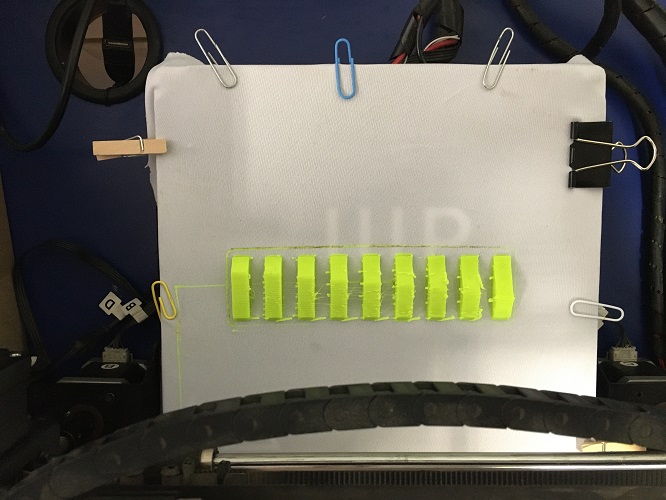

3. Place the fabric

Place the fabric stretched out on the printing bed, it is important that it does not have wrinkles, if it is not smooth it will generate errors.

To hold the fabric I used small clothes pegs and paper clips.

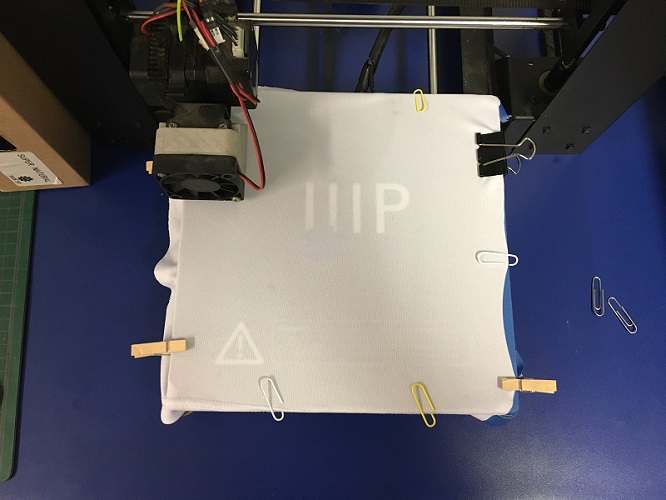

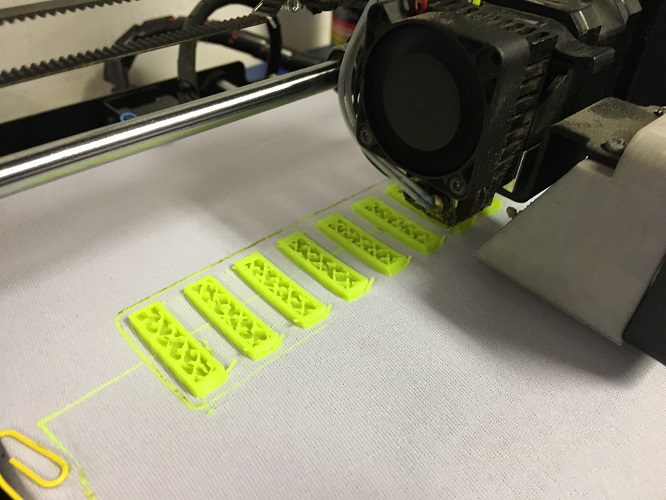

4. 3D print

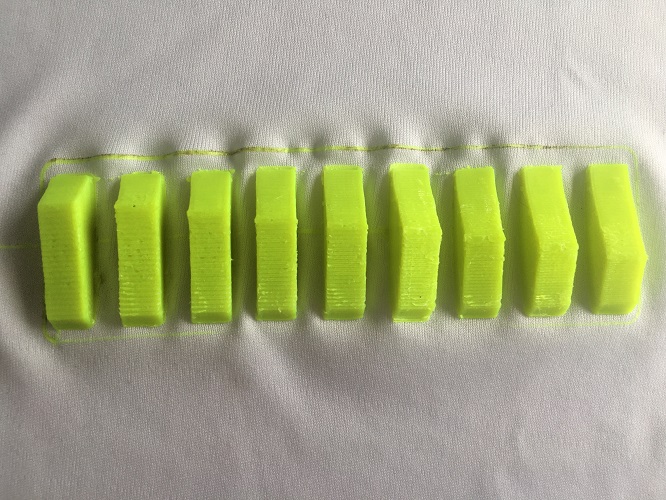

The following pictures show the process and final result.

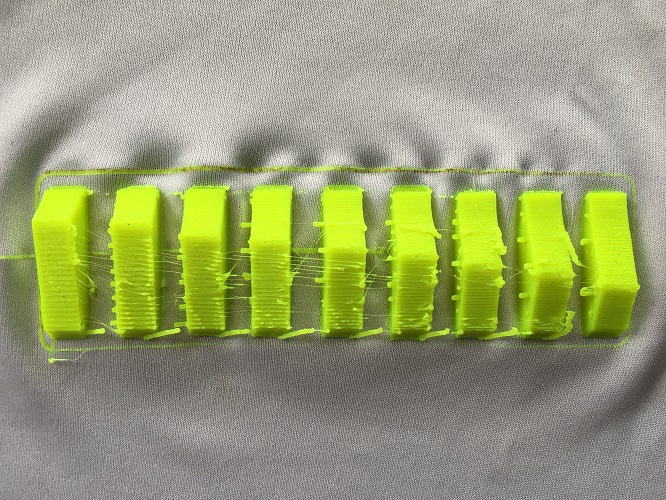

5. Final touches

When printing the last layers of the pieces began to move from one side to the other since the fabric also moves. Despite being tense,

it does not have the necessary support, which is why it generated those residues.The layers are not properly supported by the preceding layer,

making the following layers to print partially. For a new test I could try lowering the temperature, lower the layer height and slow down the speed.

To clean the residues use a blade, they were easy to remove and did not need to be sanded

After cleaning the residues this is the result. :

I sewed the piece to a velcro tape so that it can be secured to the wrist, this is the result

Some thoughts about this process

It is also important to observe how the fabric returns to its original state, which causes these folds between the pieces.

Being stretched allows the PLA to pass through the fibers and hold, once it cools it adheres to the fabric.

It may seem like a flaw in the result, however it gives the bracelet flexibility.

It will be interesting to try other textiles and 3D designs in the future, I find this technique very interesting to

develop many wearable options.I'll leave this video here for future inspiration, it's now in my project's list to try

the dragos scales.

3D print on fabric for cosplay

FILES

COMPOSITES (or what I thought could work as composites)

I want to incorporate the idea I have for this week as part of my final project. I have designed the door with a base structure of interlocking serial

planes that will function as a support for wooden sheets that will be glued one on top of the other, they will be held with tweezers until the glue takes effect.

The following images describe the process in detail:

- Laser cut the pieces and put the together

- Add one by one the "balsa" sheets. For this I used carpentry glue dissolved in water 1:2, evenly spaced with a brush

- To hold the pieces together I used plastic clamps and let it dry for a night

- Next day remove the clamps and this is the final result

- Placed with the outer case, it looks like this

Files

Rhino file - front door (wood sheets support)

SOME TOUGHTS ABOUT THIS WEEK

This week has been very difficult for me to complete. In the beginning I want to do something that works for my final project for which I had in mind to use wood composites made in layers and that can be molded on a curved support. It was difficult to find the materials, I rambled a lot in the ideas of how to do it and what to do it with, until I finally decided to do a test using 1mm balsa wood sheets. I'm still not sure if this process meets what is necessary within the week and I am willing to try something new that I will do in the next few days (days later I tryed the 3d printing on fabrics I talked about above in this site).