Principle and practice

about Final Project

Origin of Idea:

The idea I choose to work with originated from larger kitchens like mess. Incubators are helpful device in such areas. It provide a control enviroment which control the growth of organism helping us in maintaining the quality of a product example curd making, mushroom farming etc

Sprouting is a part in our regular cooking. So far so long people doing it tranditionally without any big challenges except sometime with some seeds like chawli(black eyed bean), Rajma(kidney beans), kabuli chana(Garbanzo beans) etc that occur only when large Produce is involved and excess water stays trap in it. This been observe in a work done by a student "Miss. Kajal jadhav".

Objective:

Making of small-medium size incubator for large kitchens or mess to produce constant good quality sprout of all viable seeds throughout the years.

Principle and Concepts:

Sprouting is the natural process in which seeds start germinating, where microgreens are baby plants almost in the stage when it produce initial leaves. Both things are plants natural growth process. In most Traditional practice sprouting is done in several steps maybe little differ in each culture but phases are same, It needed care from soaking seed overnight, then tie it tight in cloth and hanging it out on tree in rain. Due to continuous rain on it, it get wash with fresh water each time which result into wonderful growth. where microgreens are not so common in normal kitchens and It is difficult to some extend because it take longer period and needed more care compare to sprout which is quick and easy. Another thing sprout need no light so it can be produce in dark area or contained where microgreens are young plants and as name suggest it is green means it now require light.

How it will work:

The Grocubator will work on same tranditional steps hence its produce will be completely organic. Intention of this is just to reduce repitative task and effort require for producing buck quantity.

Since design is not finalize but on a imagination level there will be two option to move on. One we can load seed batch without pre-soaking it this will make machine little more easy but will take little more human effort everytime and another is loading dry seed so machine will takecare of soaking also.

How to give water to seed and to growing sprout is another question two option are, raining water on seed continuously or deeping whole seed batch into water which will add more mechanism and will make project heavy and costly.

Another thought to work on is to reuse Water require in whole process. So water need to be treated everytime. In nature as we see running water are clean compare to still water because of it Dissolve Oxygen. Anaerobic growth of bacteria are primary reason in spoiling water and this also make it smelly. Good dissolve oxygen prohibit anaerobic activity which help in maintaining water health. So my system will need something which let oxygen get dissolve in water. Idea is to air bubble in water like we do in aquarium

To cut water loss and drying of seed everything is in close system. With electronic sensors for temperature and humidity inner climate will be maintained to constant.

One issue in a large scale production is seeds trap extra water which promote fungi growth and rottening. So to remove excess collected water some mechanism need to be in work like vibration can eliminate excess water from it.

Sprout will get ready withing 4-5 days.

If kept for Growing microgreens it will continue even longer.

After sometime it will need light for further grow. approx. it will take month to mature as microgreens and then will ready for harvesting.

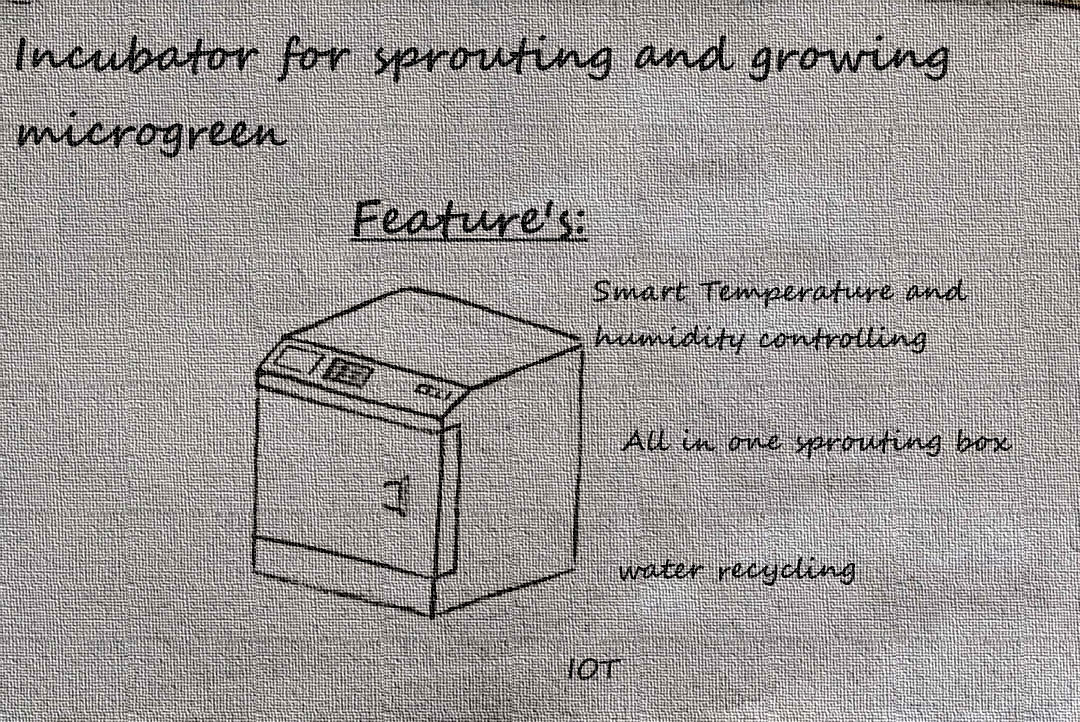

Rough idea and design: