Molding and Casting

Making of positive and negative molds for Casting

Intro.

So I don't remember any experience with molding and casting before maybe I had done some experiment with foods you may or may not believe that making ice in home is also kind of similar thing. Here water is a casting material use to make ice cube using plastic molds.

.jpg)

Week Task:

Group Assignment:

review the safety data sheets for each of your molding and casting materials,

then make and compare test casts with each of them

Individual Assignment:

design a mold around the stock and tooling that you'll be using,

mill it (rough cut + (at least) three-axis finish cut),

and use it to cast parts

Group assigment: summary

In group we performed test experiments with different materials. Here by doing this we got idea of what material we going to use how it look like and feel like.to known more visit our group work

Individual Assignment:

Materials

Here in my whole experiment I used material like silicon that use for making molds, Epoxy resin, Hard wax, Softwood, paraffin wax.

To know more about materials and different process can be use for this week assigment visit fab moldingandcasting page

Designing

So I thought to design something artistic so I use blender for my 3D modeling. I plan and made heart shaped part that can be used as pendal or making of earrings.

so using grease pencil and sculpture tool I made smooth heart shape and then converted it into path.

.jpg)

Made multiple copy of path and using diferent sizes bevel on each path with different ends point I made this design.

Next I added oval shape in center of heart and added donut shape on up so it can be hook with anything.

.jpg)

After combining all shape using boolean modifier to give it diamond texture, I used remesh modifier.

Next I took two cube shape, stretched it little bit placed it in my design to make inlet and outlet. Here I began with making positive mold from my design. This two rod kind of shape will form tube like structure in negative mold which will allowed us to pour in our casting materials into mold where another will support it by letting air to come out when material take it place. This structure is for displacement of material in molds.

.jpg)

adding more cube structure I finish mold design here.

.jpg)

next you see in image I have added rod like shape or plugs to connect two side of molds. This also help to keep design align

.jpg)

I decided to explore mods for generating path. But it only able to provide rough pass. I found no option or setting to give finishing pass so I increase resolution and that consumed to much time

.jpg)

Here is path and next I begin with SRM20

.jpg)

To make positive mold I have used hard wax block. It can be melted and recreated again and again which make it ideal material to work with

.jpg)

SRM20 is same machine I have used in PCB milling and now for making wax mold. To do so I just have to use new bits which is use for this job

.jpg)

We have 3/32, 1/8, & 1/16 flat end and rounded bits each respectively to do our jobs

I have here used 1/16 bit for this job and that how it came out.

.jpg)

Next I prepare for making negative mold first by considering volume of material require to do so. I calculate volume using water that I filled in mold and then measured it

.jpg)

.jpg)

.jpg)

Here I have done small cheat that maybe wrong to work with but I don't wanted to stuck into calculating thing so I not consider exact number of volume but I used plastic glass and marked water level.

Than I have weigh material in it given ratio and made sure I prepare material upto marked glass level. Hence I performed whole experiments only with little or no maths

.jpg)

Ratio was right for silicon rubber and negative mold came out well since this was first experiment I did I am happy with result

.jpg)

Since issue with whole things was bubble formation. This was because pouring error and another material was old and It already got thick that made it challenging to pour and spread evenly

.jpg)

.jpg)

Some improvement I oberserve in my design needed to be done after observing material properties is to remove narrow filling space form my design hence I changed plugs form cylindrical shape to half sphere

.jpg)

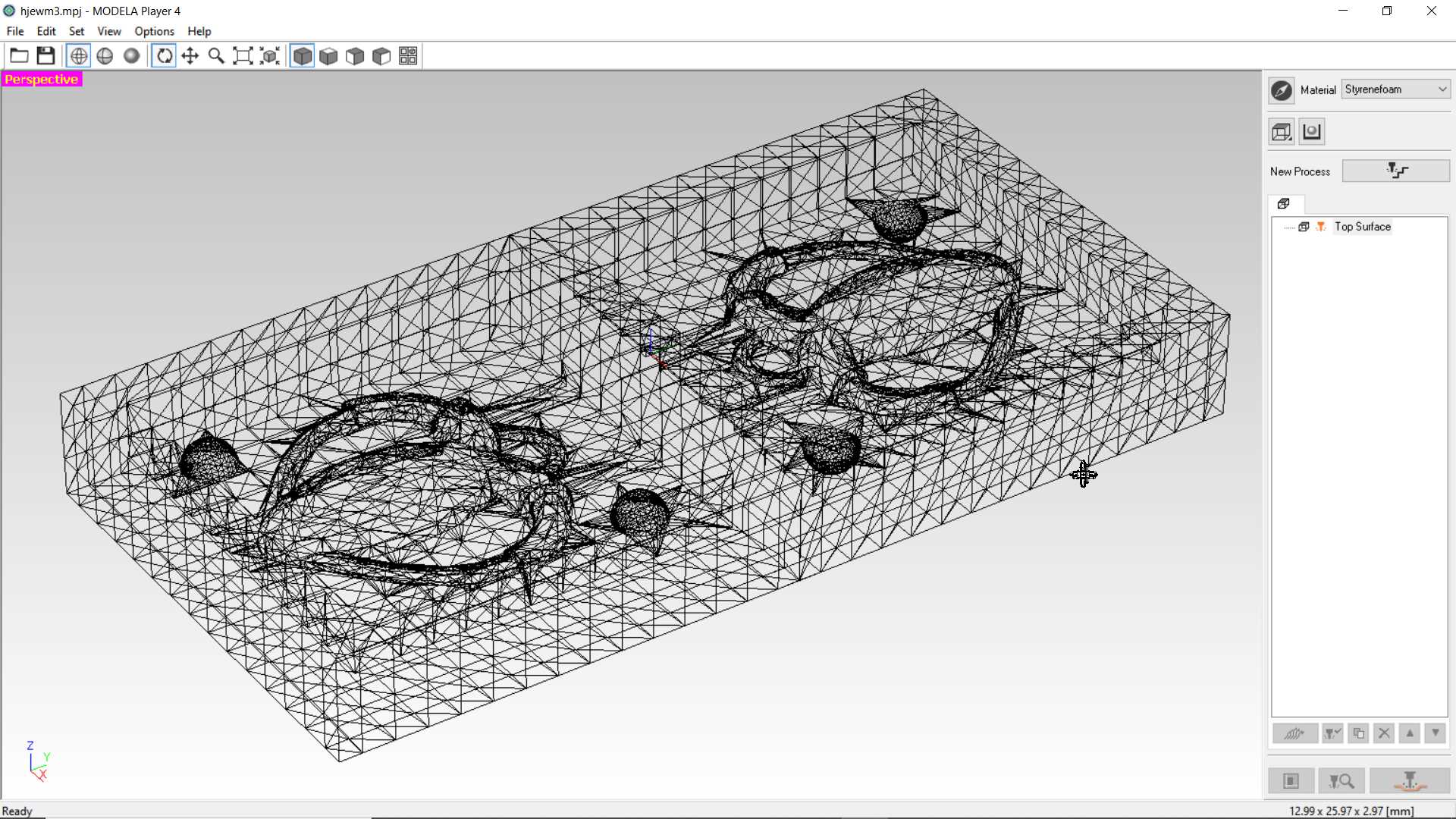

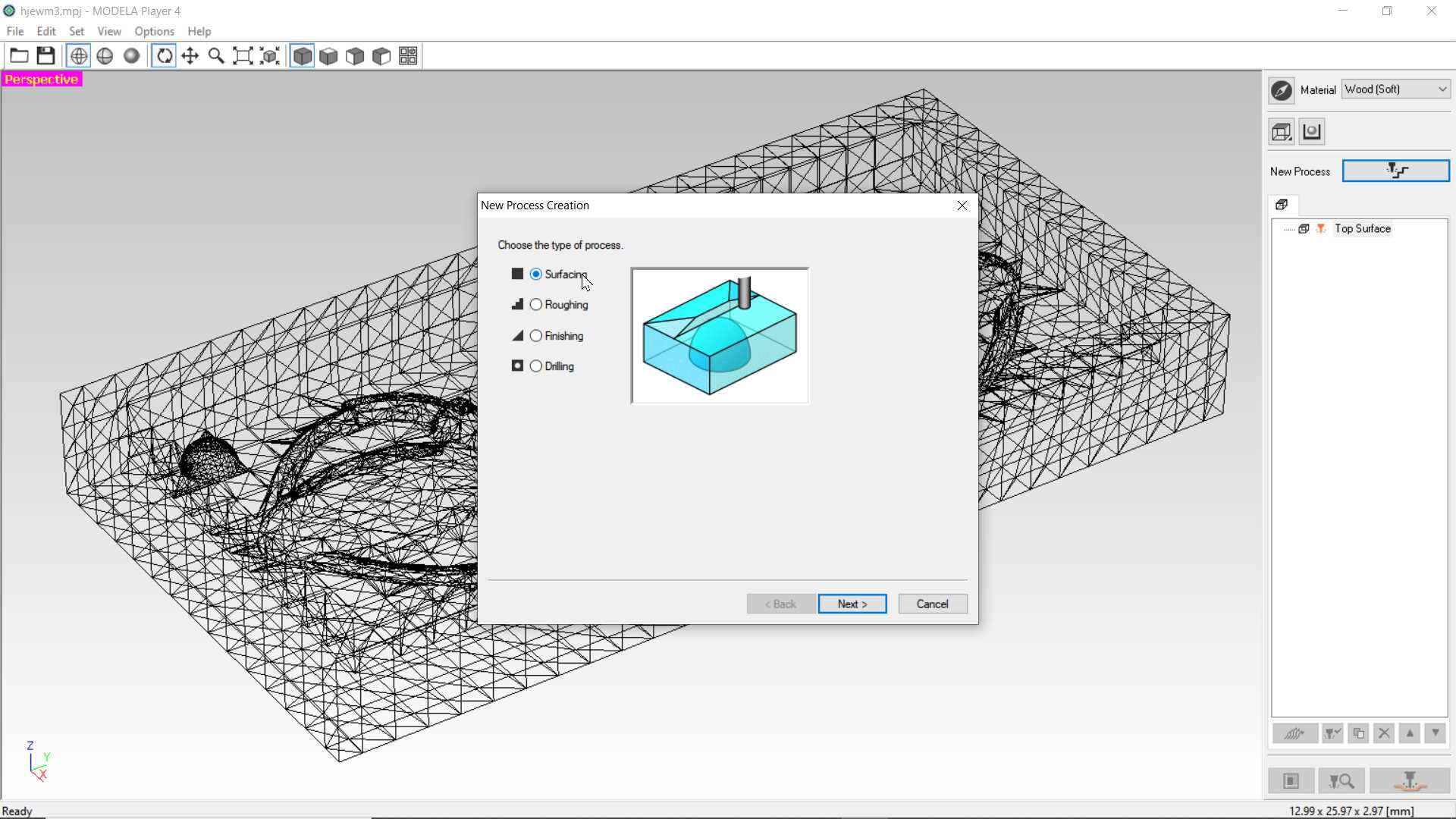

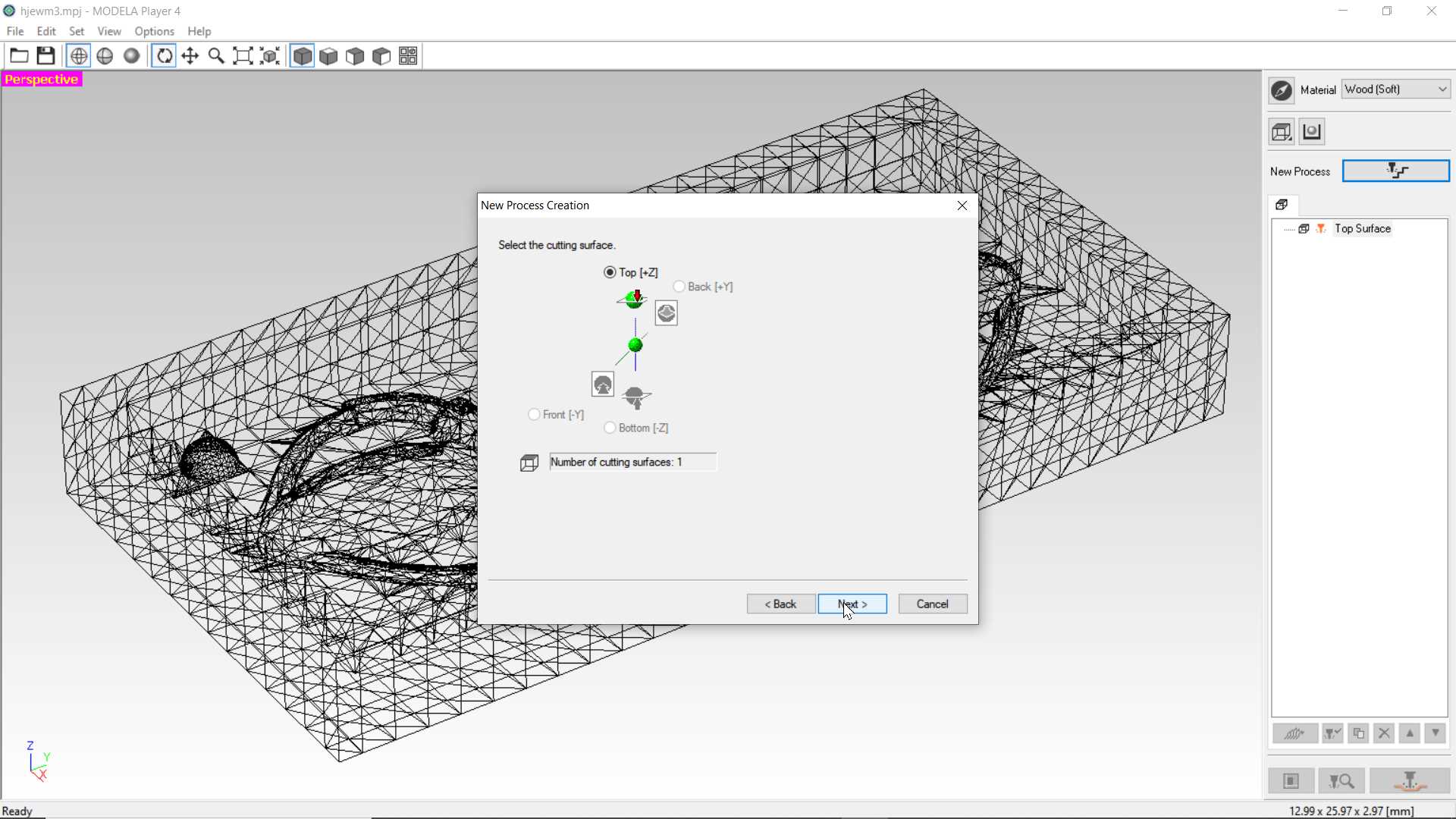

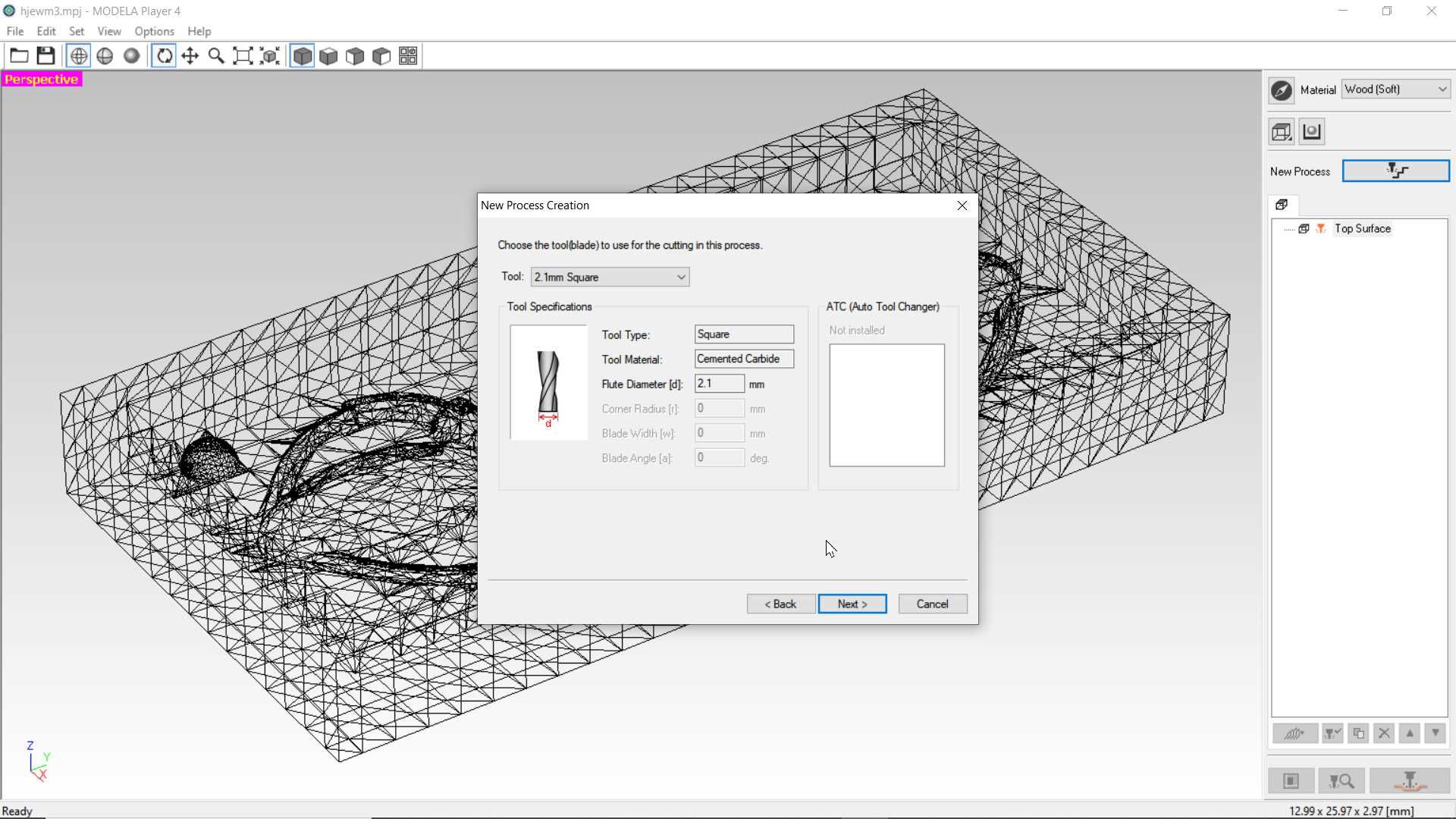

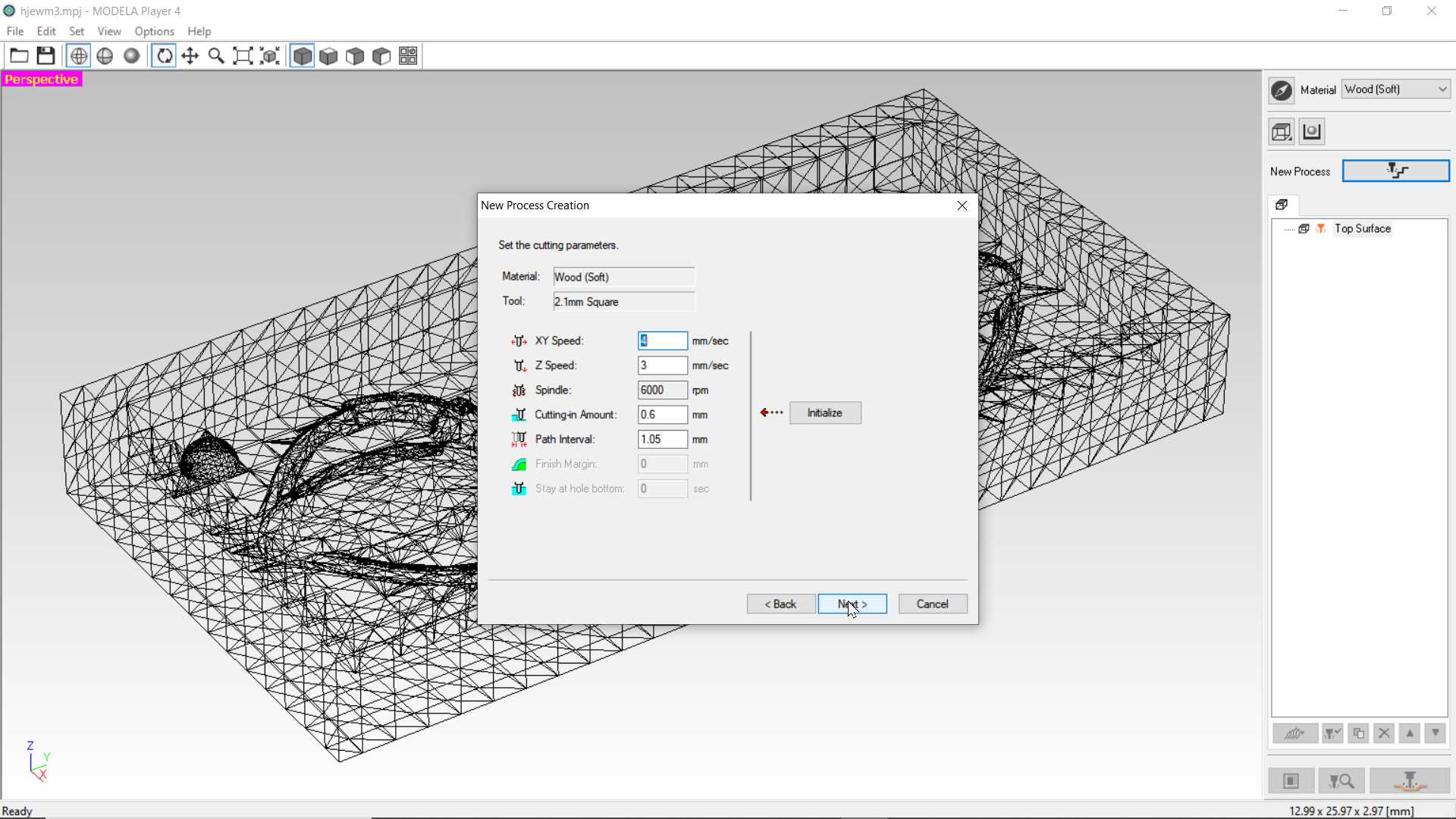

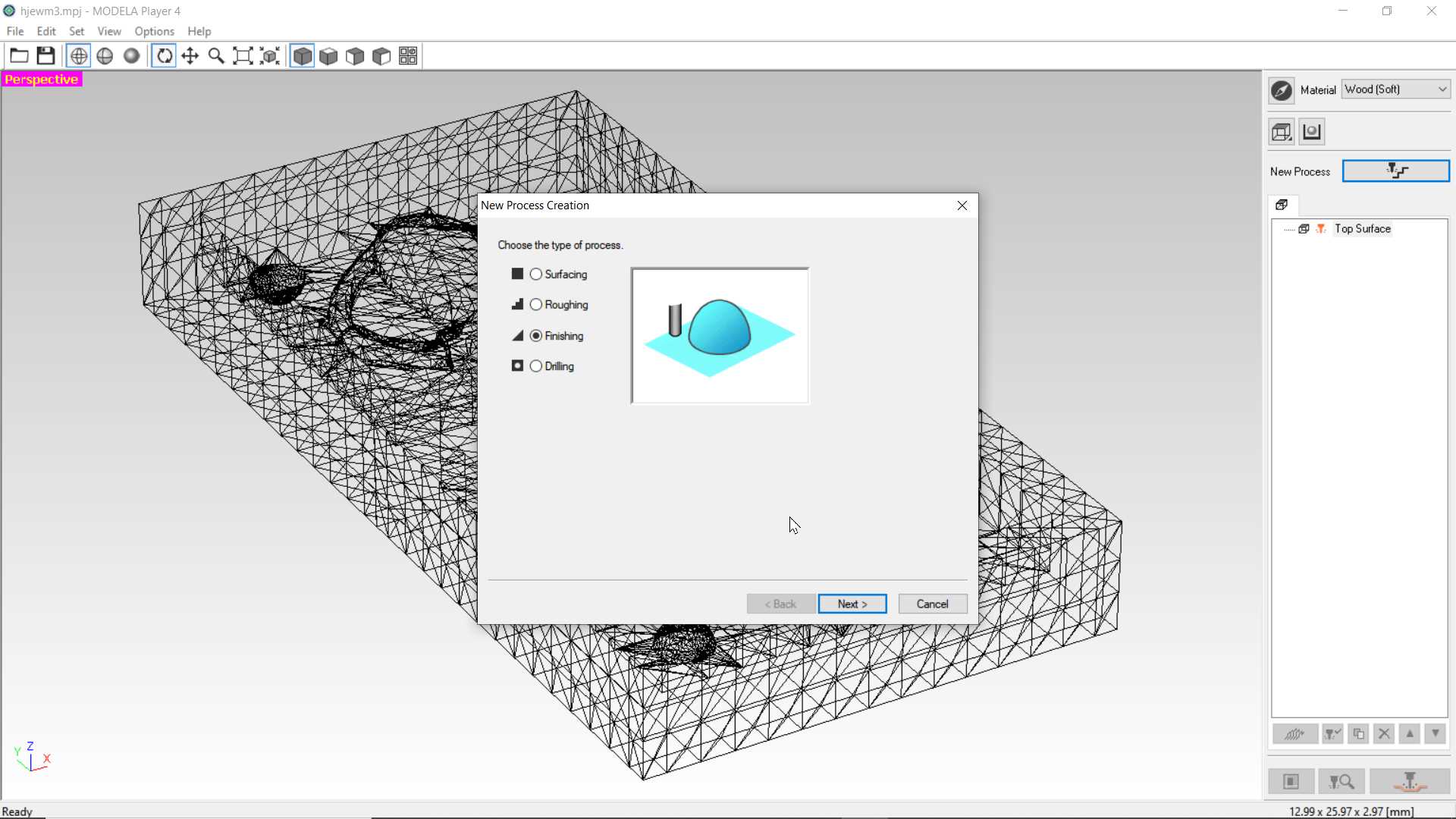

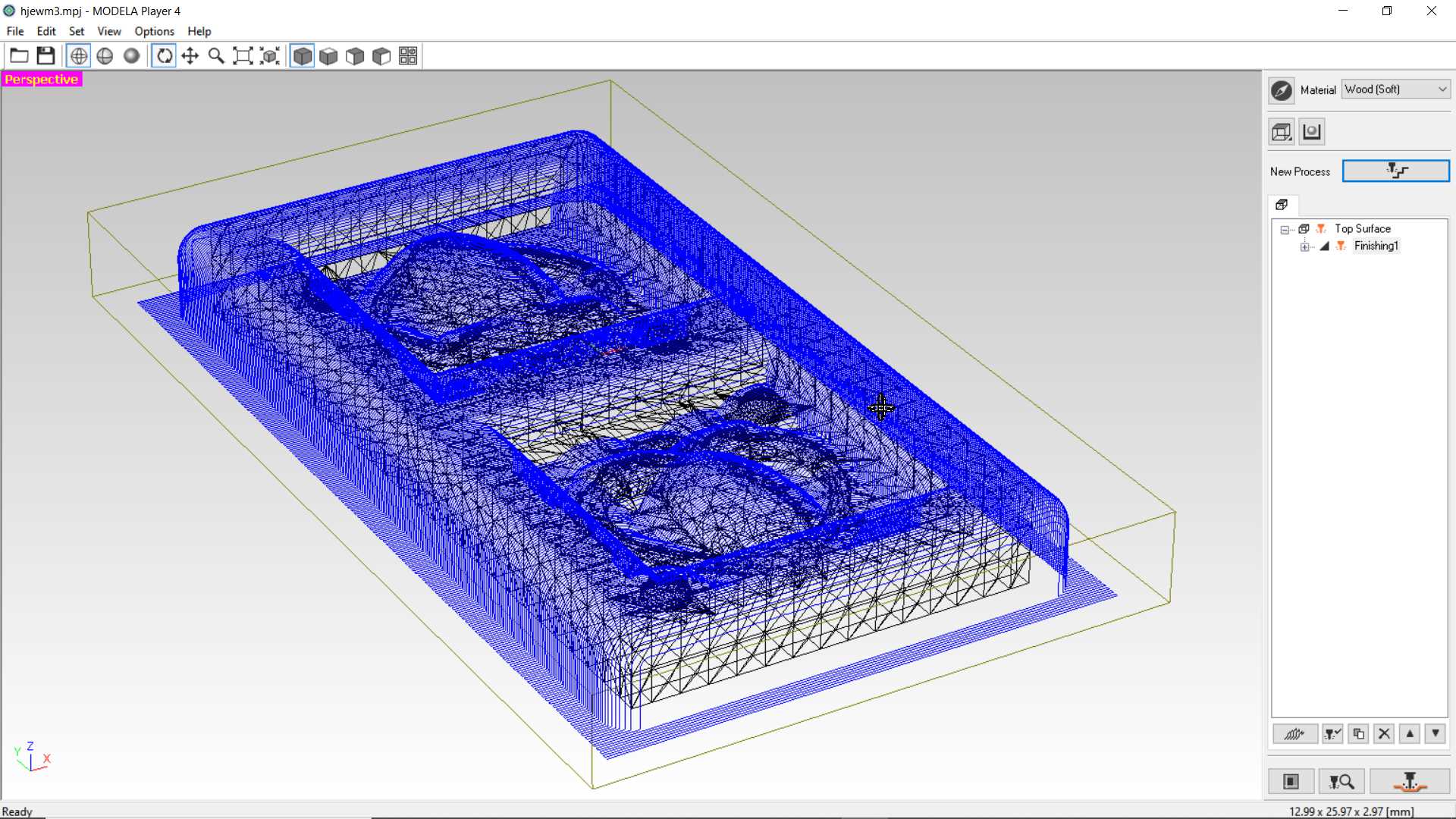

so before I have used modsproject to make path but this time I used modela player 4. Here I found all option to making finish design. Like as you see in down images I have applied different process like surfacing which help to flat surface evenly.

Next I select process for rough cut and last finishing cut

surfacing and roughing used 1/8" flat end mill and for finishing to be smooth I used and it is required to used rounded bit that is also 1/8" bi with round end

Next all step are same as above done in first experiment. After completing finish cut of positive mold using silicon I made negative mold and in negative mold I used wax to cast design and as you see in given images

.jpg)

.jpg)

.jpg)

.jpg)

I have planned to do metal casting for this design so I have done wax part but I lost energy and time ended so for now I kept it as it. so I am happy in completing this much for now

Next using sculpture tools in blender I made new design to work with

.jpg)

.jpg)

.jpg)

Next using same design process I made positive mold design

.jpg)

Here next I wanted to try different machine and material. So we have one machine called NUMAC HITECH which is a powerful cnc router machine and material I selected to work with is softwood. It have 300x300mm bed size and 20mm depth movement and spindle have water cooling to keep temperature stable while operating on high speed high power.

.jpg)

.jpg)

Here you see little accident that happen by me while working with this machine. Thankfully nothing bigger happen but let me warn you that this machine is powerful and have no safety guard

.jpg)

So this machine is instruct by software known as NCstudio you need to generate gcode in other software I have used artcam and for tutorial I refer youtube tutorial

Here on image you can see surfacing path in NCstudio. Since here I am using different pc I took less screeshot but all step are same as shown in tutorial

.jpg)

Here it do surfacing since wood I have was not flat so to do flat it is important

.jpg)

Next I applied rough pass

.jpg)

.jpg)

then finishing pass

.jpg)

Here it came out like this

.jpg)

using hand saw I had cut off piece from wood

.jpg)

So here for casting negative mold which is made from silicon first I applied epoxy coating on wood because wood have rough surface that make it difficult for casting silicon. This idea had work and I made silicon mold then using epoxy and little glitter added in it I have cast out model.

.jpg)

Learning Outcomes:

This week was interesting but something not working for me. I came into phase where material I was using like silicon, epoxy I not liking to use that dont know why felt like dirty experiments. But yes with all thing and my own mood swing I managed this much to complete. I will not say this was best but I done this much and Happy after finishing that. First issue and struggle I got while working with mods because It not gave finishing I expected for. Second I was using instinct to prepare recipe not calculation still worked well maybe because I am from chemistry background and I have done all those before like mixing something. I am not able complete metal casting so in future I definately will try it.