Electronics Production

Week Five

- • Describe the design rules for your PCB production process.

- • I must make an in-circuit programmer by milling the PCB, program it, then trying other processes.

- • Document everything!

- 1. Fabricate (PCB)

- 2. Soldering components

- 3. Programming

This week we will focus on electronics Production.

The goals for this week were the following:

Group Assignment:

Individual Assignment:

In-system programming (ISP) : it is also called in-circuit serial programming (ICSP) is the ability of some programmable logic devices (electronic component), microcontrollers, and other embedded devices to be programmed while installed in a complete system, instead of requiring the chip to be programmed before installing it into the system.

This week we will Fabricate PCB and program it the reference to the tutorial provided.

Week Requirements:

- 1. Design Circuit.

- 2. Schematic.

- 3. Layout.

- 4. PCB fabmodule.

- 5. Milling.

Steps of Fabrications PCB:

The techniques can be used to Fabricate PCBs:

1. Fabricate PCB using a CNC machine.

I try this week Milling which is a machine designed to cut or shape metal using a rotating tool .The picture will be saved as .PNG file extension in other hand the milling machines only reads files with .rml [Red line markup language file] extension. So the files needed to converted by using an online tool called FAB modules.

The steps to file conversion is the following:

I download ready PCB images (traces and outline) click for reference

PCB Milling machine Steps:

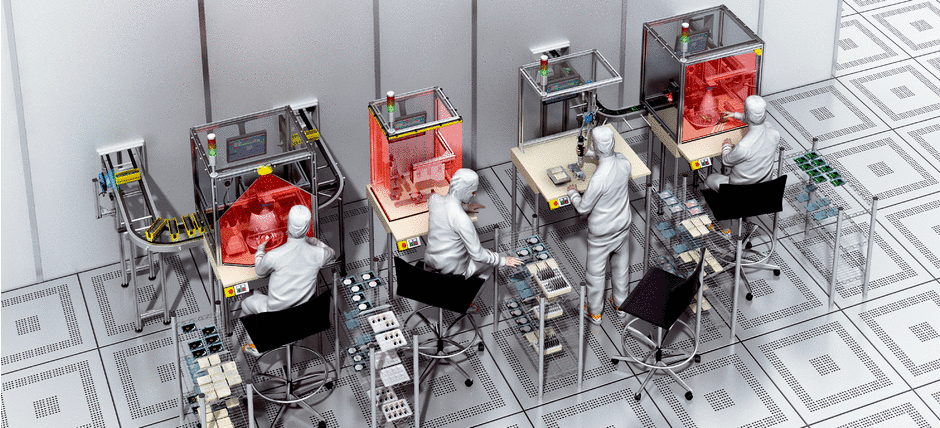

In the lab we will use CNC Machine which stand for Computer Numerical Control it is a milling machine. Which used to engrave the traces and the outlines on an FR1 [copper clad Flame Retardant 1] printed circuit board.

the picture below shows the machine that I will use:

We have used two different milling bits:

The picture below shows milling the traces :

The final PCB as shown, it is ready to start soldering :

Soldering PCB components:

Organizing the components:

Tools I need :

Soldering steps:

After I finished soldering I must remove the extra solder and check the connections .

Important Note:

LEDs have a slight green line on one side representing the side connecting to ground. Zener diodes have a fade sliver line on one end which must indicate to the ground.

The PCB after soldering:

Connector wiring:

The equipment I used to program my PCB .

Equipment tools:

Programming :

We can use the tutorial as a guide to install the programmes :

Install the following:

I have downloaded the software and the files

unzipped/placed them in the program files

I added the paths of GNU make software ,GNU toolchain and AVRdude software

control panel - system and security-system -advanced system settings -environment variable-then add the new paths by copying them.

By launching Zadig I can checked the device and re-installed the driver.

To check the correct installation of the programs

Access git bash tool

Type make -v to check for the GNU make software

Type avr-gcc --version to check for the GNU toolchain.

Type avrdude -c usbtiny -p t45 to check for AVRdude software.

open firmware in gitbash to create a .hex file by typeing run make.

plug my and Hashim isp programmer with a ribbon to my computer than the red light will flash on both boards.

Important Note:

The two ISPs via the ribbon must be connected in way that the VCC and the GND points are the same along the two ends of the ribbon as shown below:

Then ran the commands make flash in gitbash.

Important Note :

Make sure there are no short circuit before plugging PCB in to the laptop to avoid burn, by using multimeter.

Ran the command make fuses

To check the USB , I had to plug my own board directly to my computer and check if it detects the device.

That can be by accessing the >> device manager >> libusbK USB devices.

The last step in programming is running command make rstdisbl.

The command will disable the ability to re-program the board.

Electronic Production

This week’s group assignment goal was the following:

• Describe the design rules for your PCB production process.

Group Assignment Climb Milling vs Conventional Milling

The group assignment that I have to make is by using Conventional while engraving with different type of milling bit to compare between them. Also my friend Sara use climb milling.

Type of milling bit I chose:

The steps for Conventional direction :

The picture below shows the traces of 1/64” (0.4 mm) milling bit.

Deferent Between Climb Milling vs Conventional Milling

I am milling 4 pieces to see the difference between them

As you can see the difference between Conventional Milling and Climb Milling As I read in the websitethe different are:

The Conventional Milling: is starts cutting from zero and increases which cause more heat on the chip to cut it. Used for hard materials such as stainless steel and steel.

The Climb Milling: Creates cleaner surfaces that will increases tool life. After cutting the material the machine make clear adjustments for a better surface finish.