Individual Assignment.

*Read the safety data sheet (SDS) and technical data sheet (TDS) for the resins that you're using.

*Design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it, with resin infusion and compaction.

In this week we have many options to work on that, for example: Composites, Textiles, Biotechnology, Robotics, and Cooking.

I choose the first one that is Composites. In composites, the individual task is to Read the safety data sheet and technical data sheet

for the resin which we are intending to use. And, also this task includes designing and fabriicating a 3D mold and produce a fiber composite

part in, with resin infusion and compaction.

The theme of this assignment is to be aware about the basics of composites.Composites, as its name suggests that its the combination of

two or more things/materials which makes something new by combining/joining them. In this case, the output material is strong material.

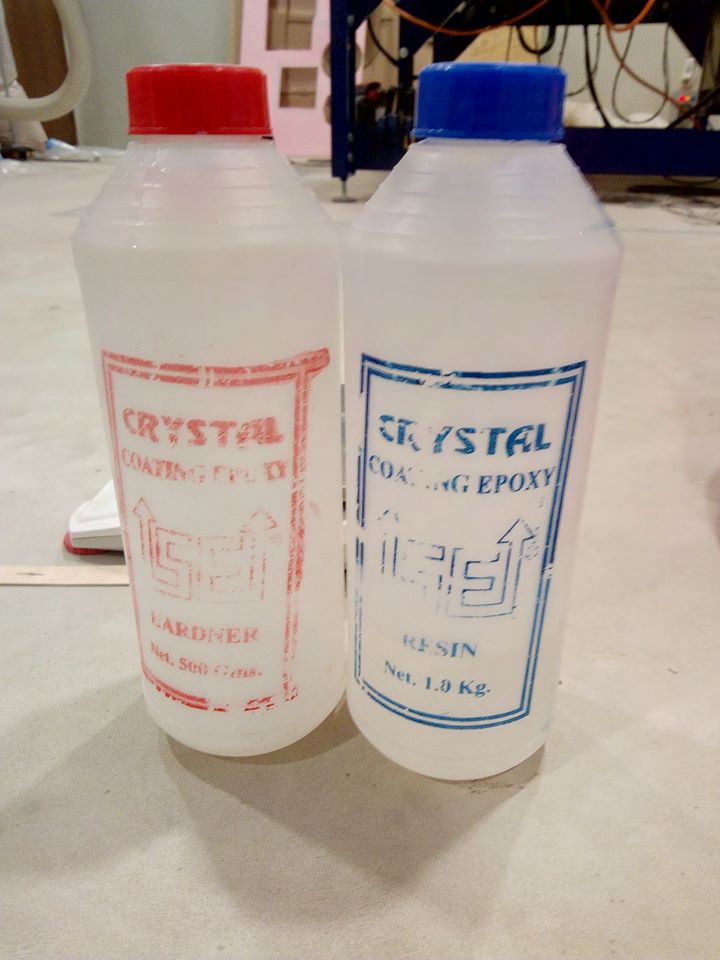

The epoxy resin which I used in my this assignment, was bought locally from the market. The epoxy which we are using in our lab is:

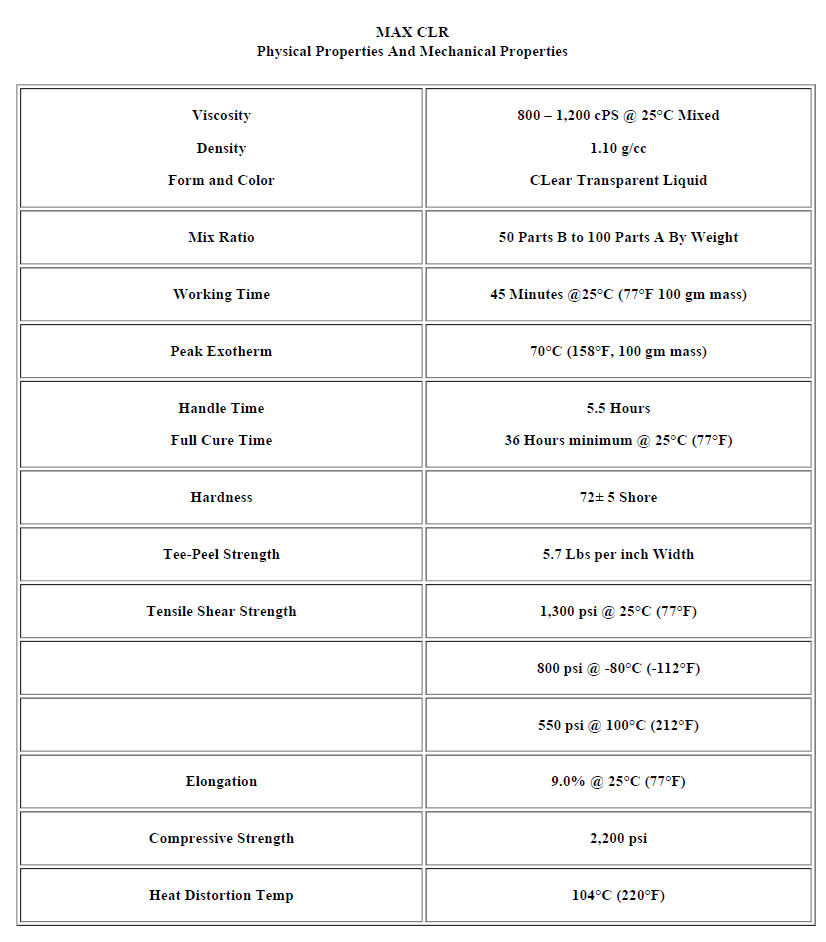

Reading Datasheet:

Before working with chemicals, we must be aware about there properties and safety precautions related to the use of that material

.The material we are using is combined in the ratio 2:1 which means that 2 parts of material A(resin) and 1 part of material B(curing agent).

A picture of the datasheet of material is attached below:

material datasheet

material datasheet

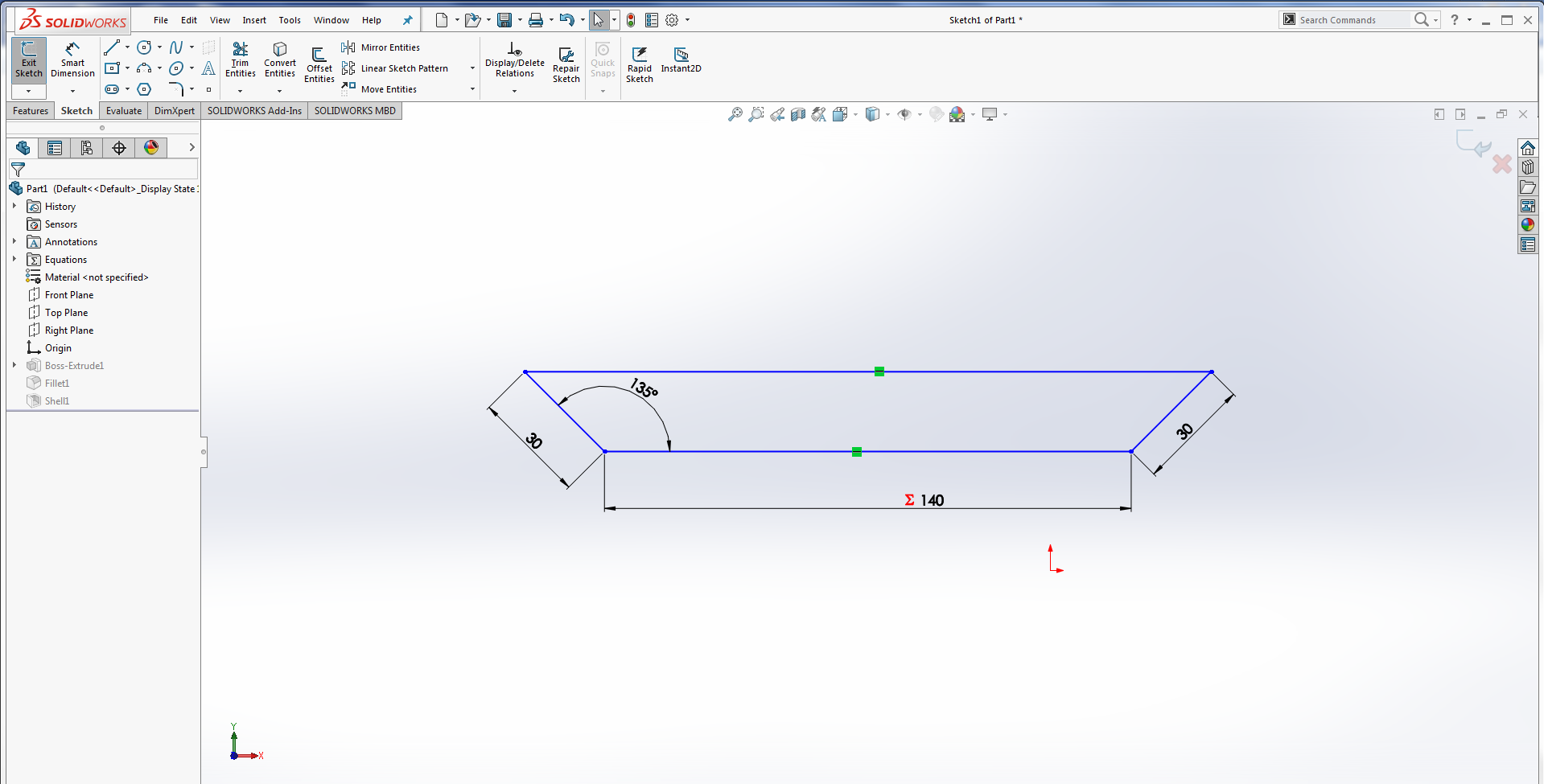

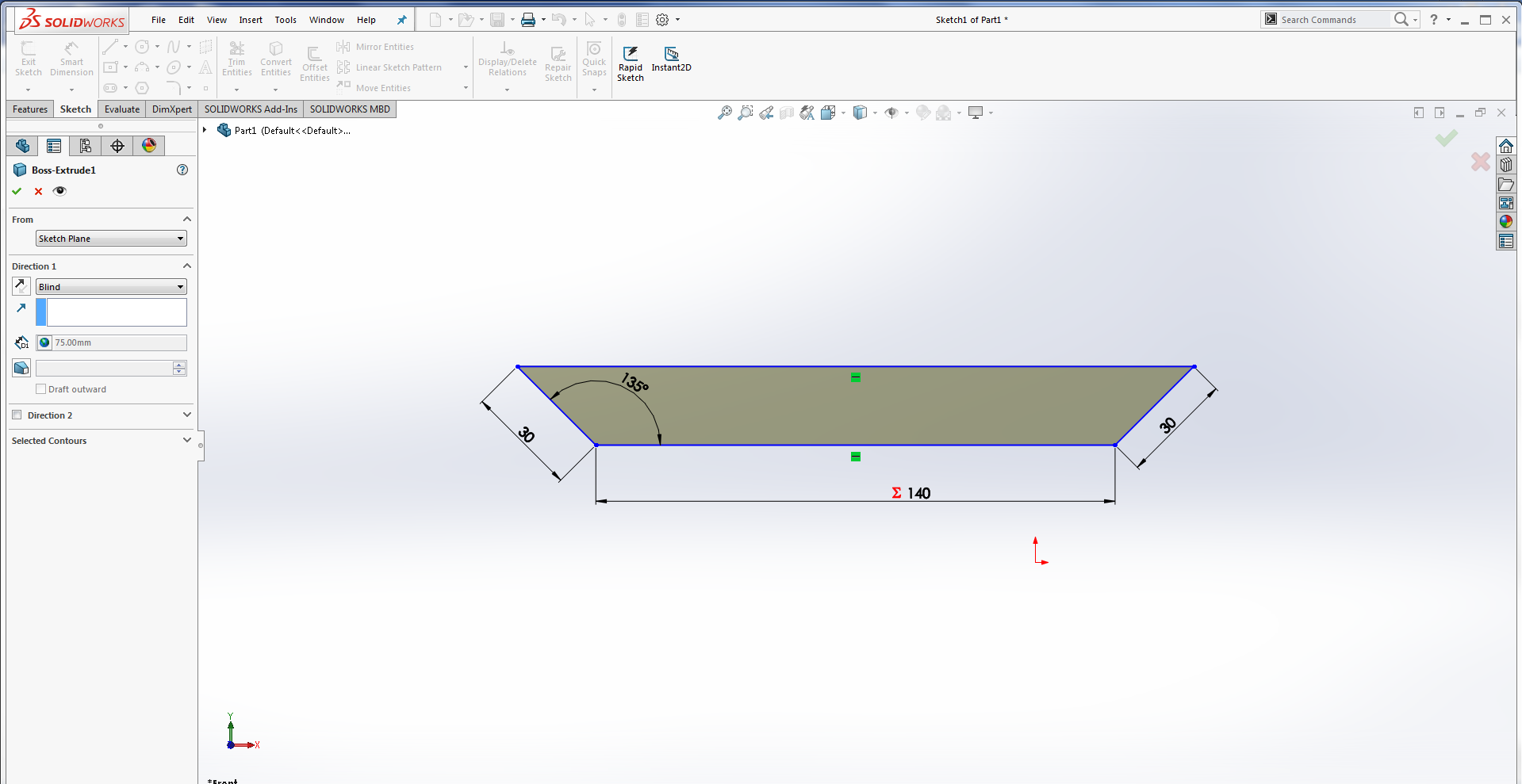

Designing the mold

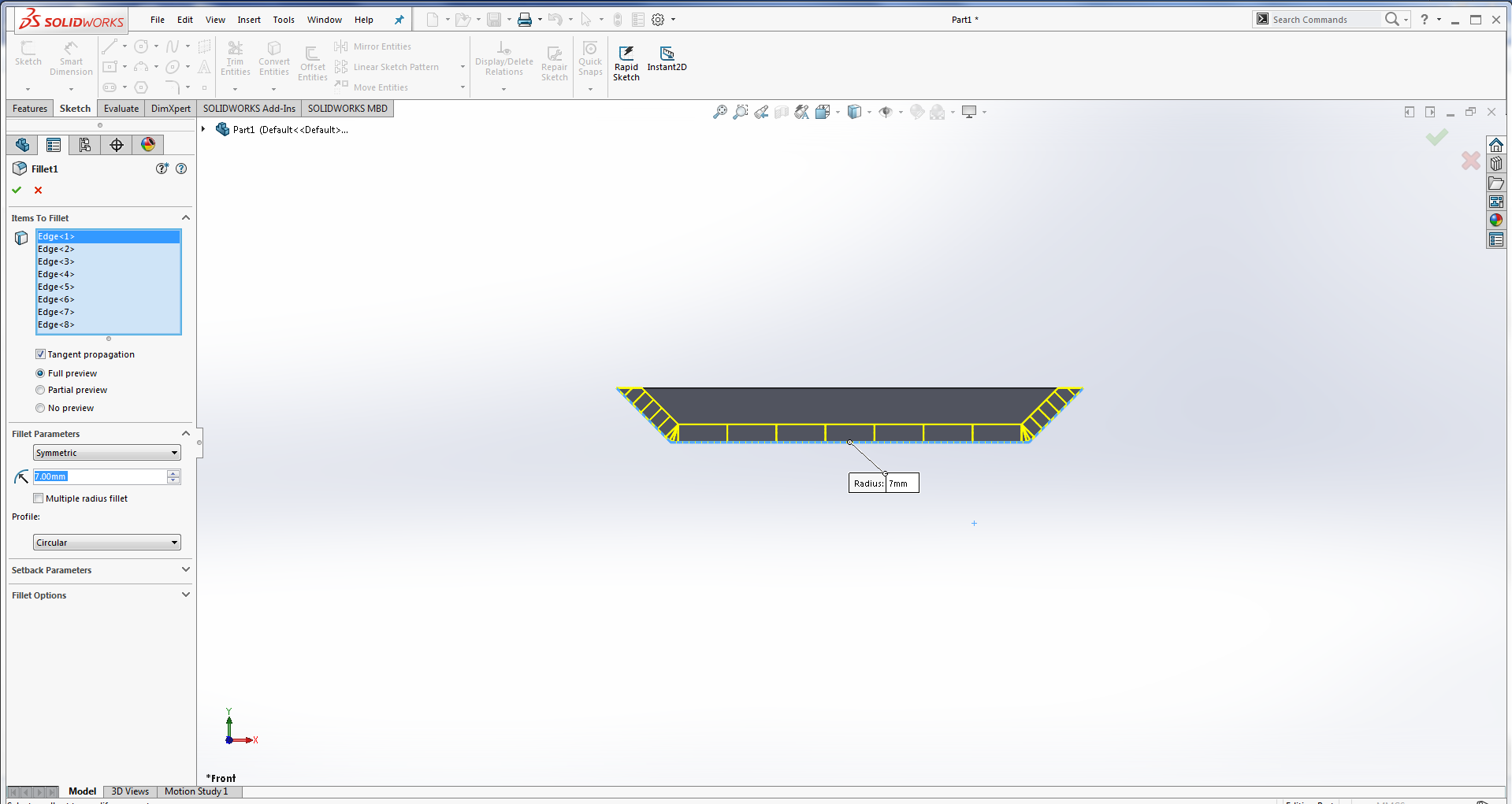

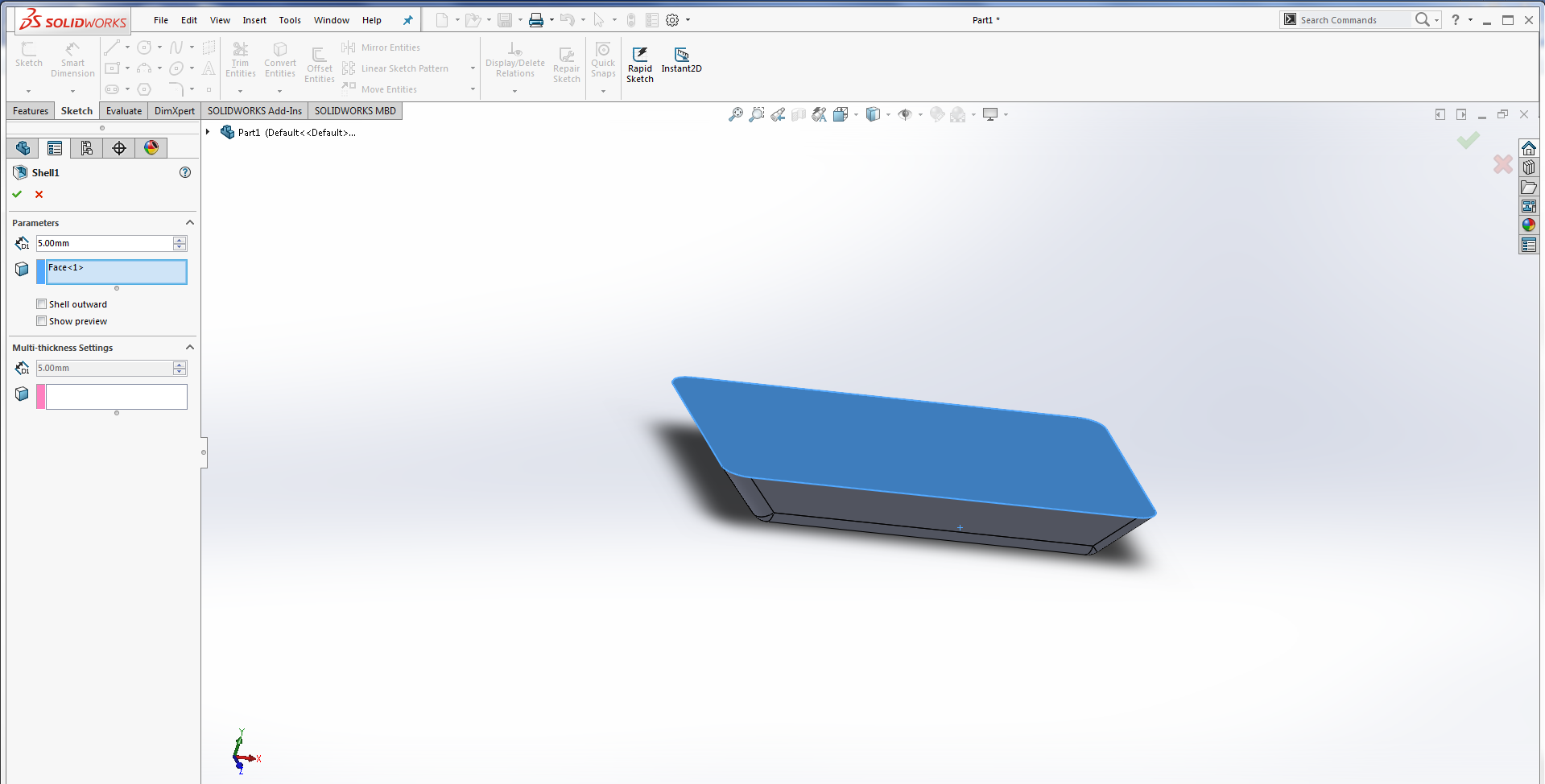

For this week I Want to make a trar for that designing I use the Solidworks first I open the solidworks and sketch tha line and then another line with giving angle. And then after that I gave the extrude base and fillet with shell as :

Designing tray in solid works.

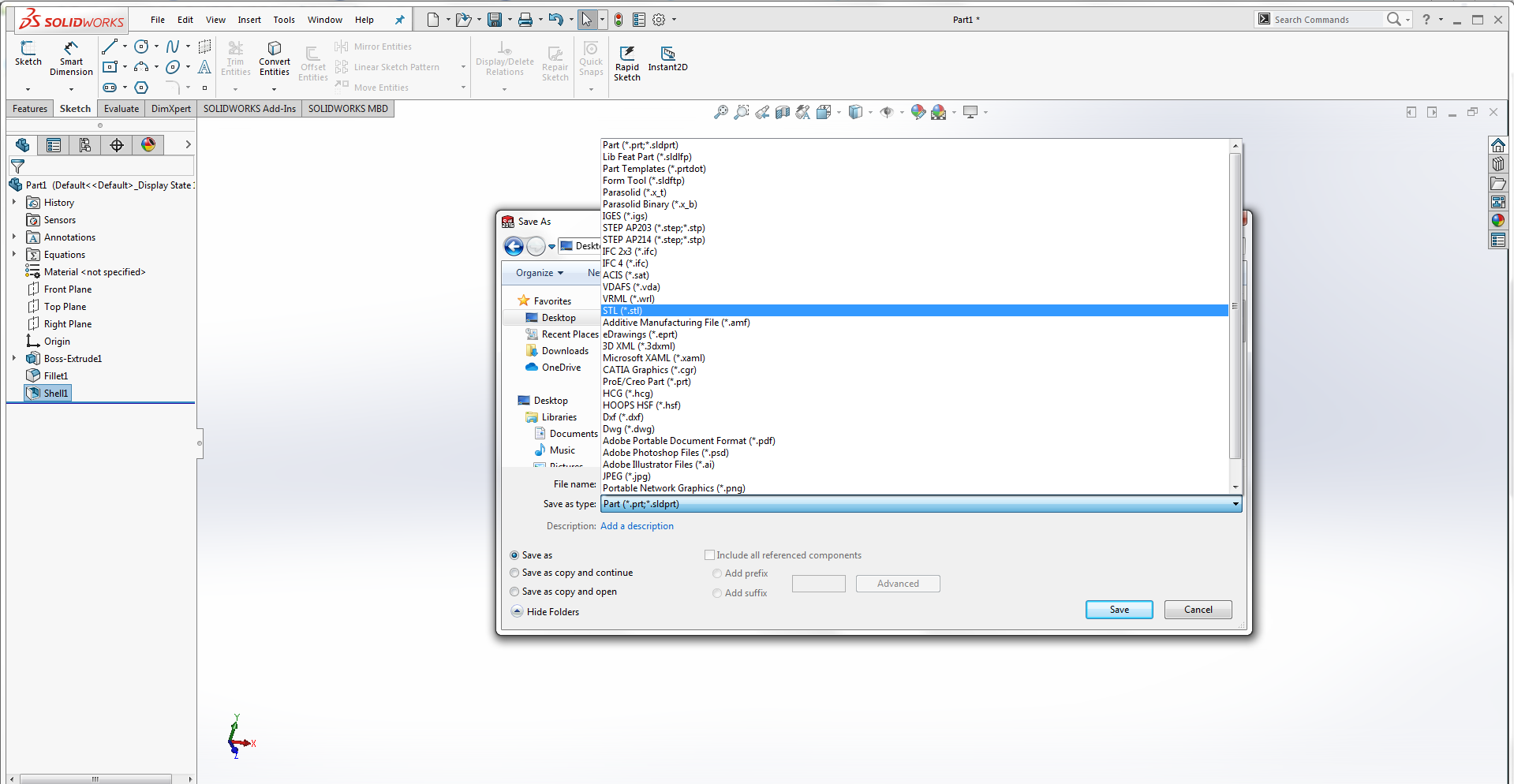

After making the design I save it as .stl file

saving stl file.

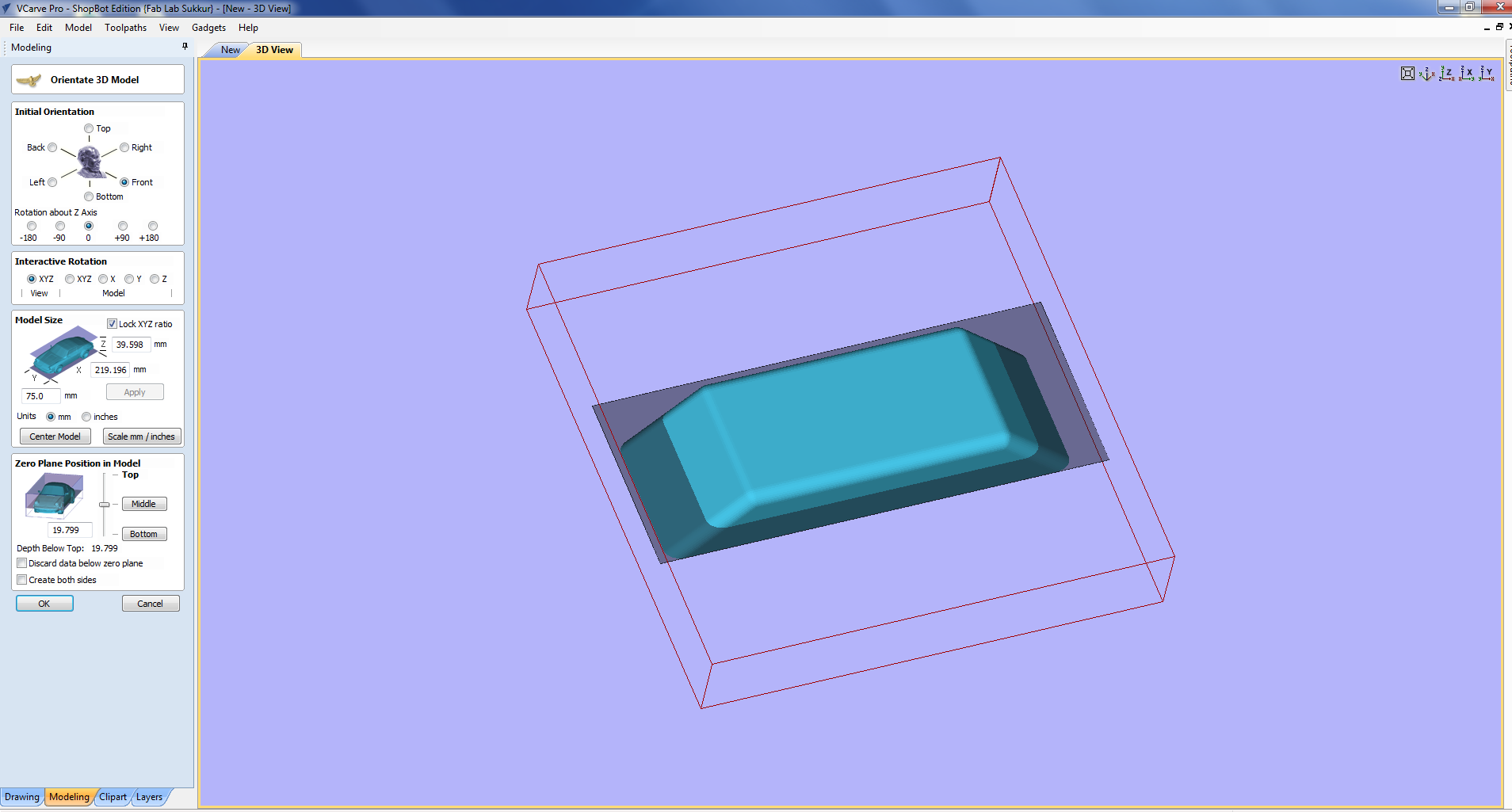

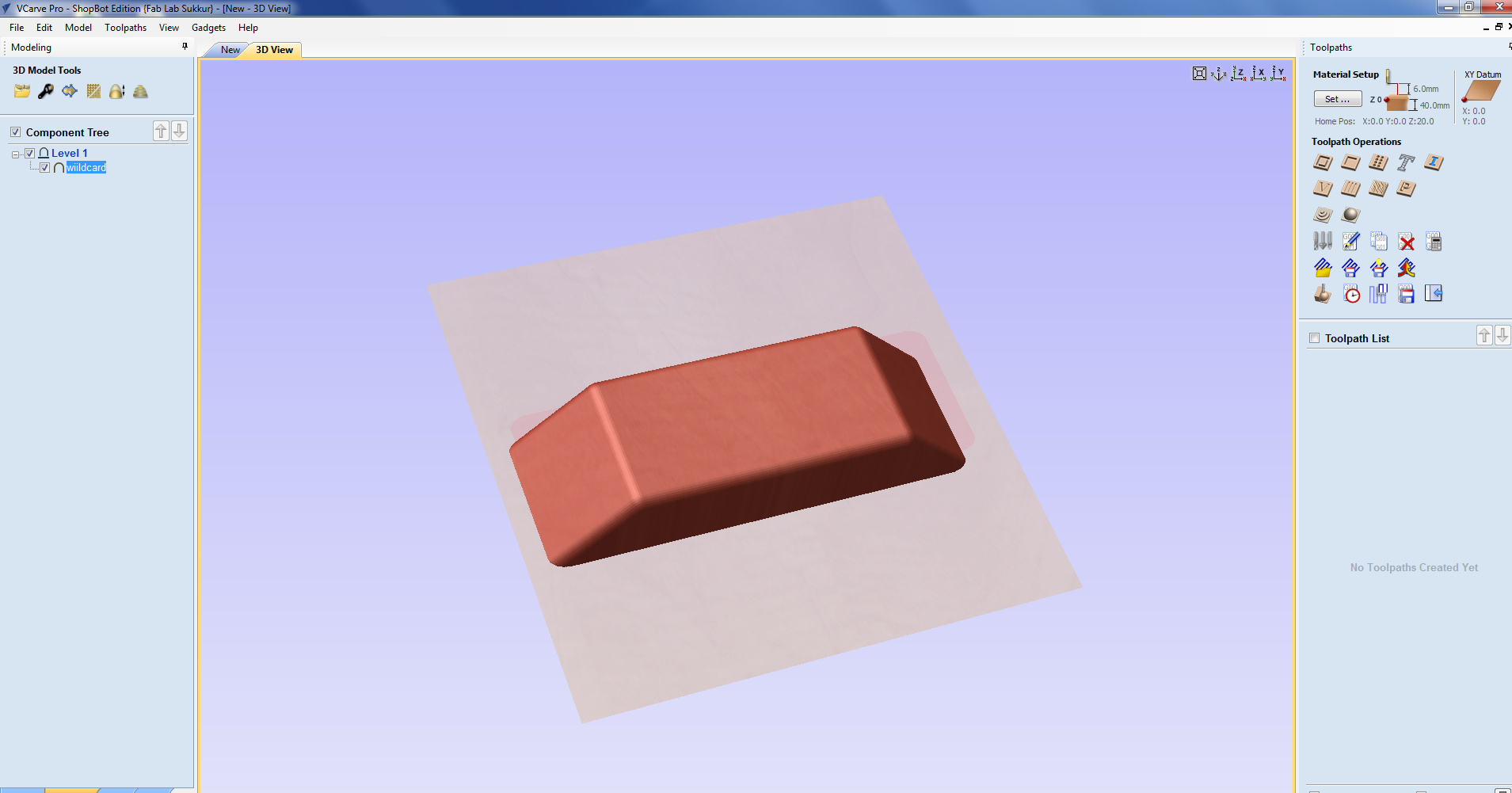

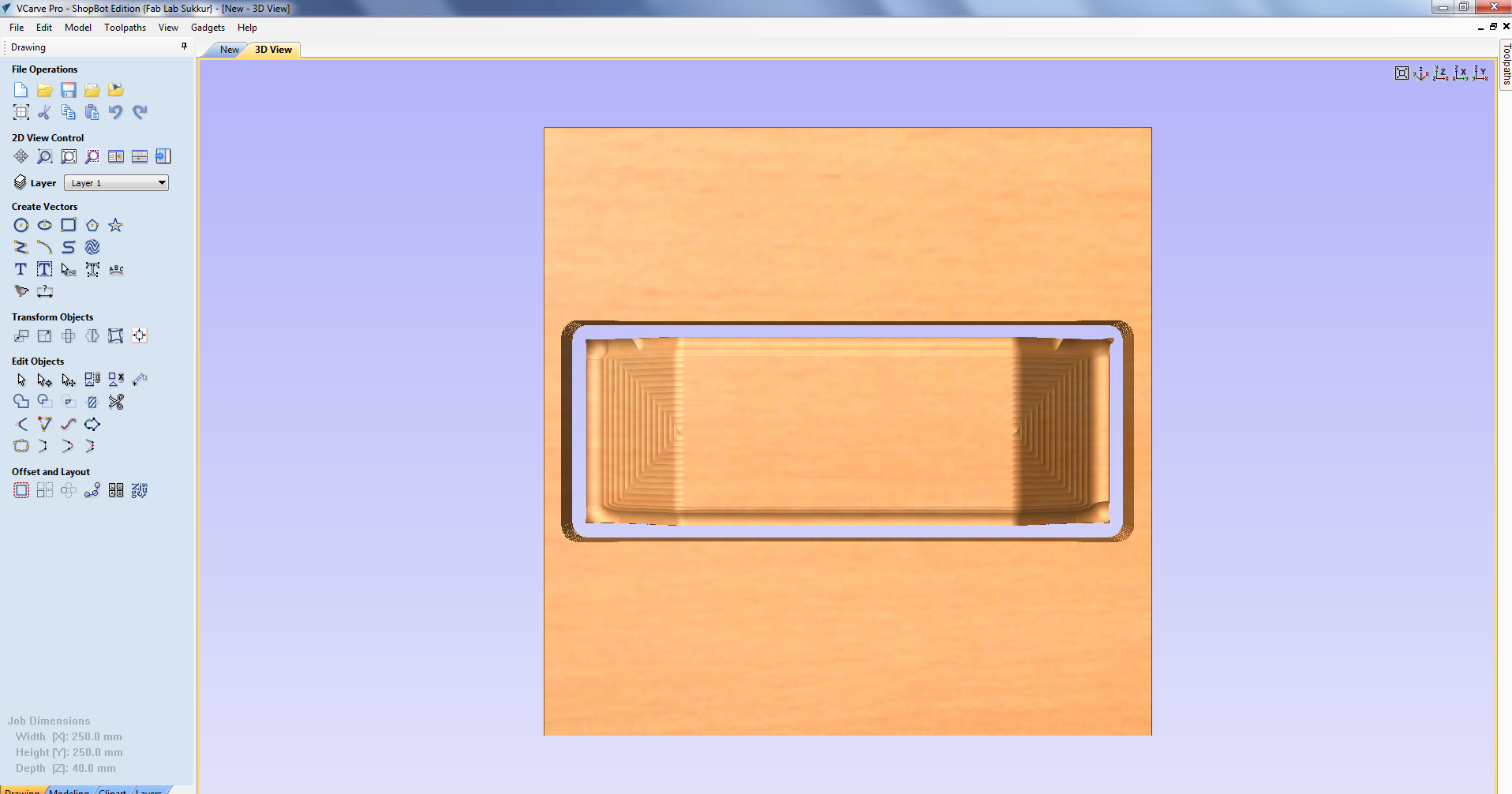

Now, It is the time to generate toolpaths in Vcarve for files for shopbot machine. I Generated two files, one for 'roughing' and one for 'finishing'.

.

The steps for making the tool path are as follow:

After calculating and preview of all toolpath

Then I went on to shopbot to cut my job,

After Milling

Fabric and Composites

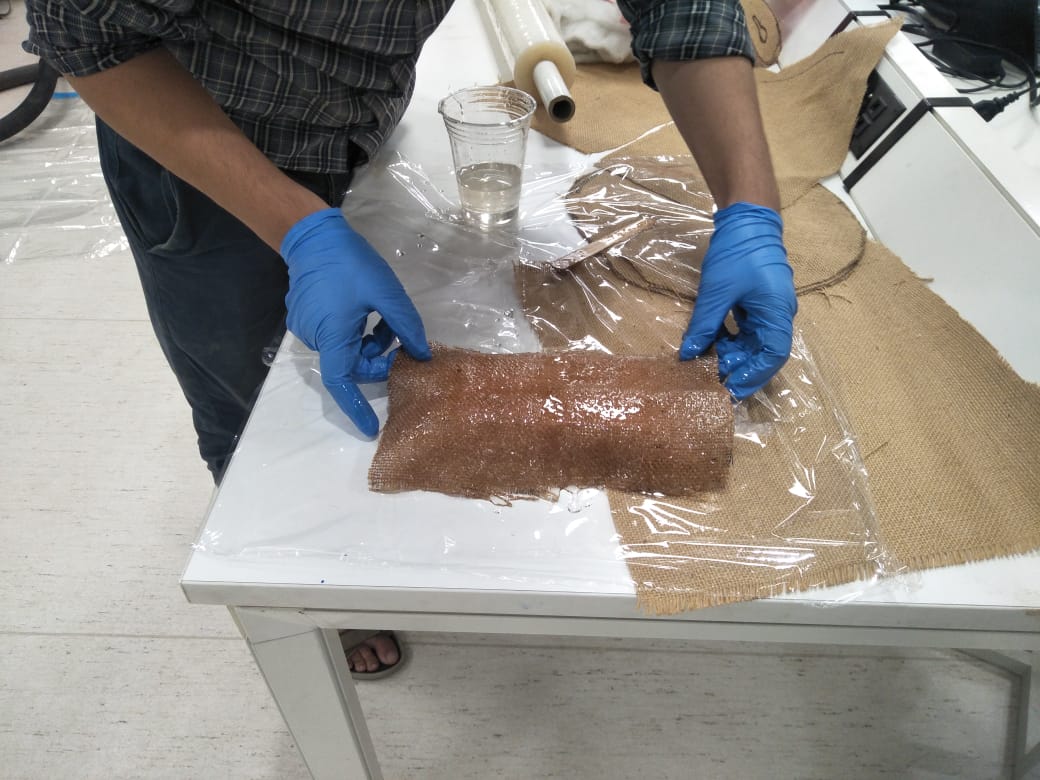

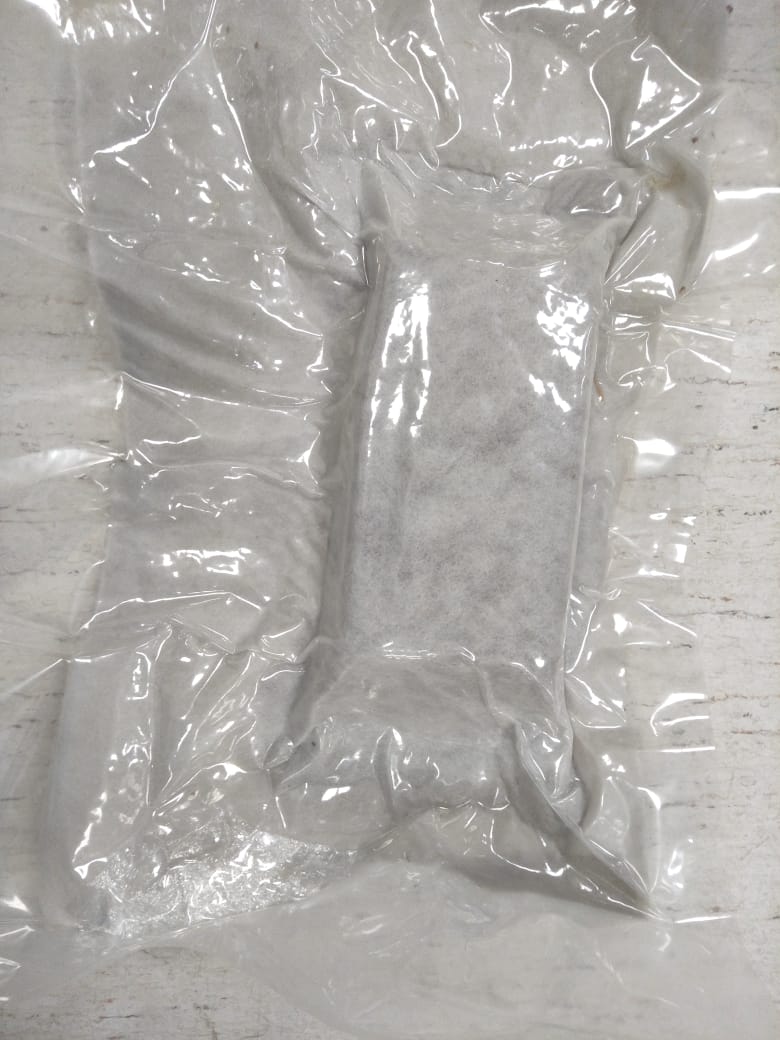

I am using double layer of fabric in my assignment, it makes the surface more hard. The fabric are in arrangement that one layer is set to another with 45 degree of angle. Annd then after that I raped the foam with food raping plastic .

rapping with plastic

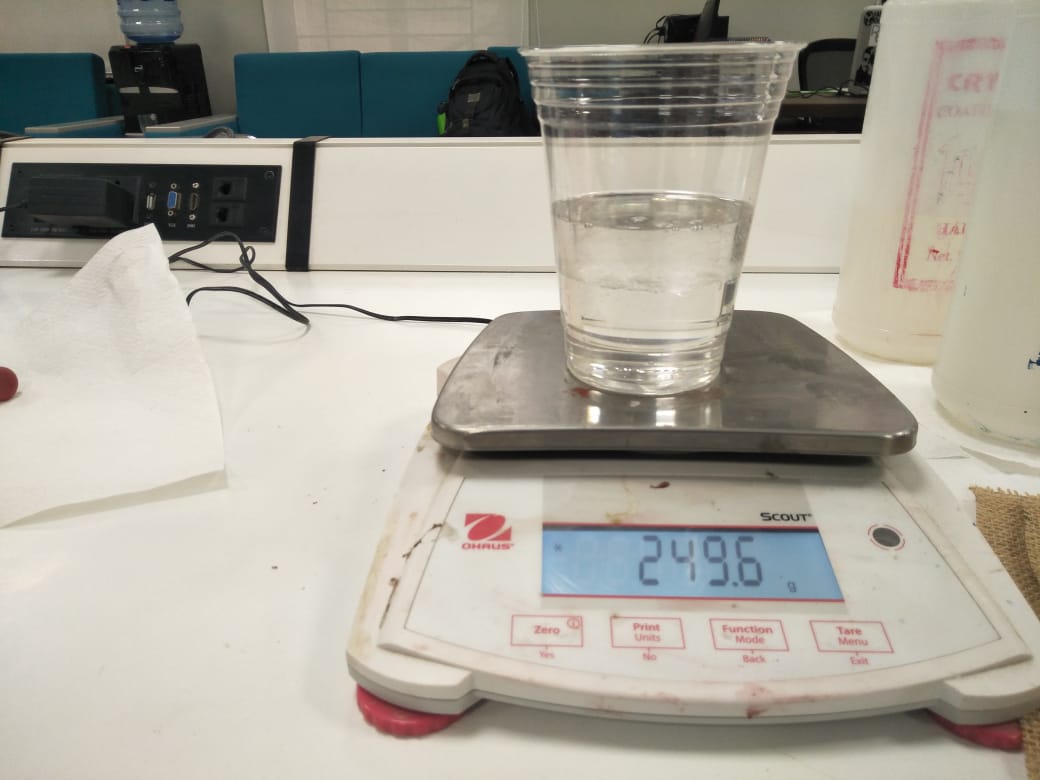

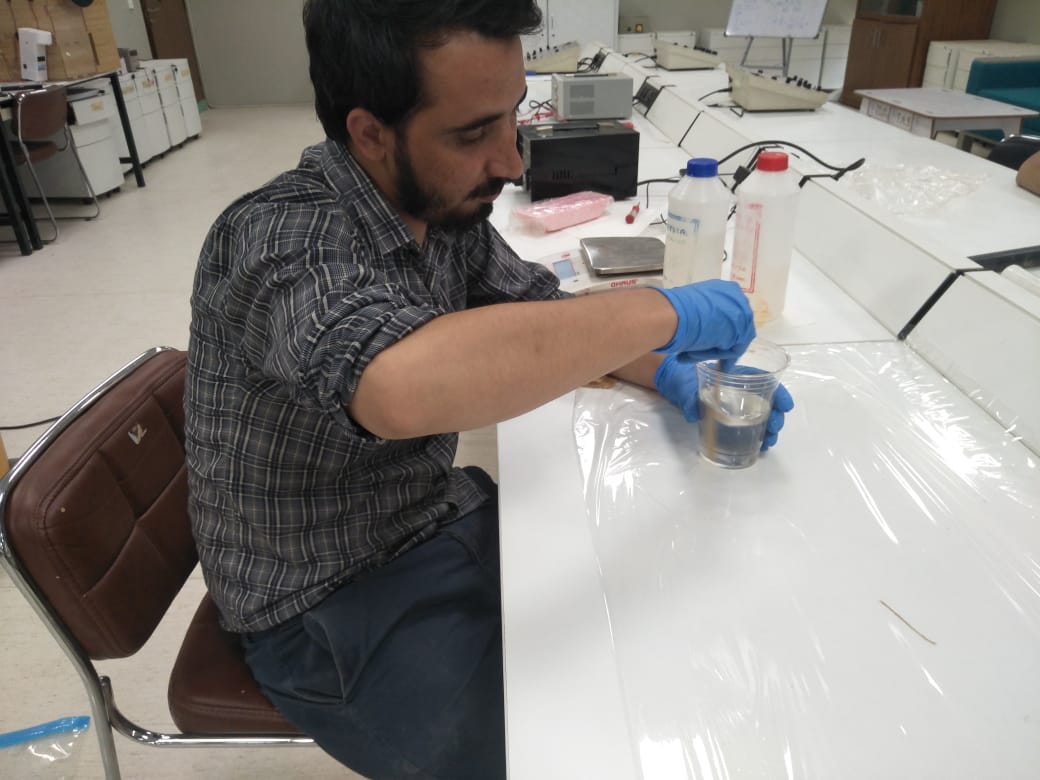

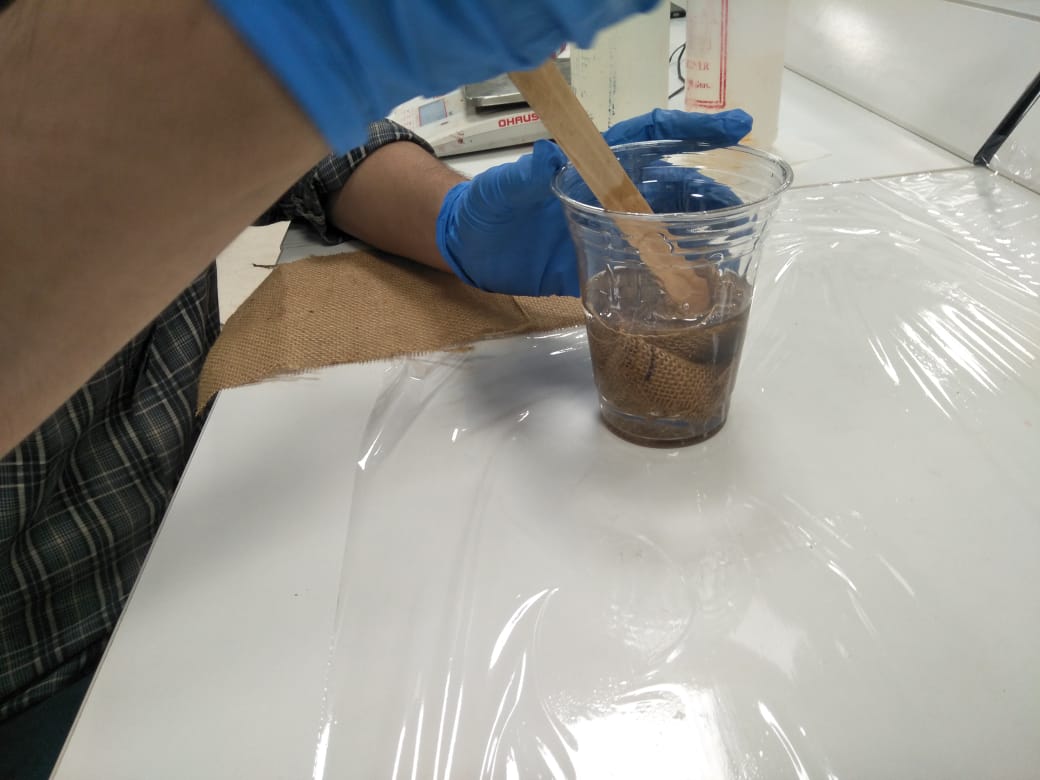

Then I Mixed the PartA and PArtB Resin as 3:2 according to the weight of fabric which is equal to 250gram and mixed them:

After mixing

Now Dip the Fabric on the solution and Paste the resin dipped fabric on Mold then again make a layer of plastic on it and squeeze it over surface so it can attain a shape

After pasting

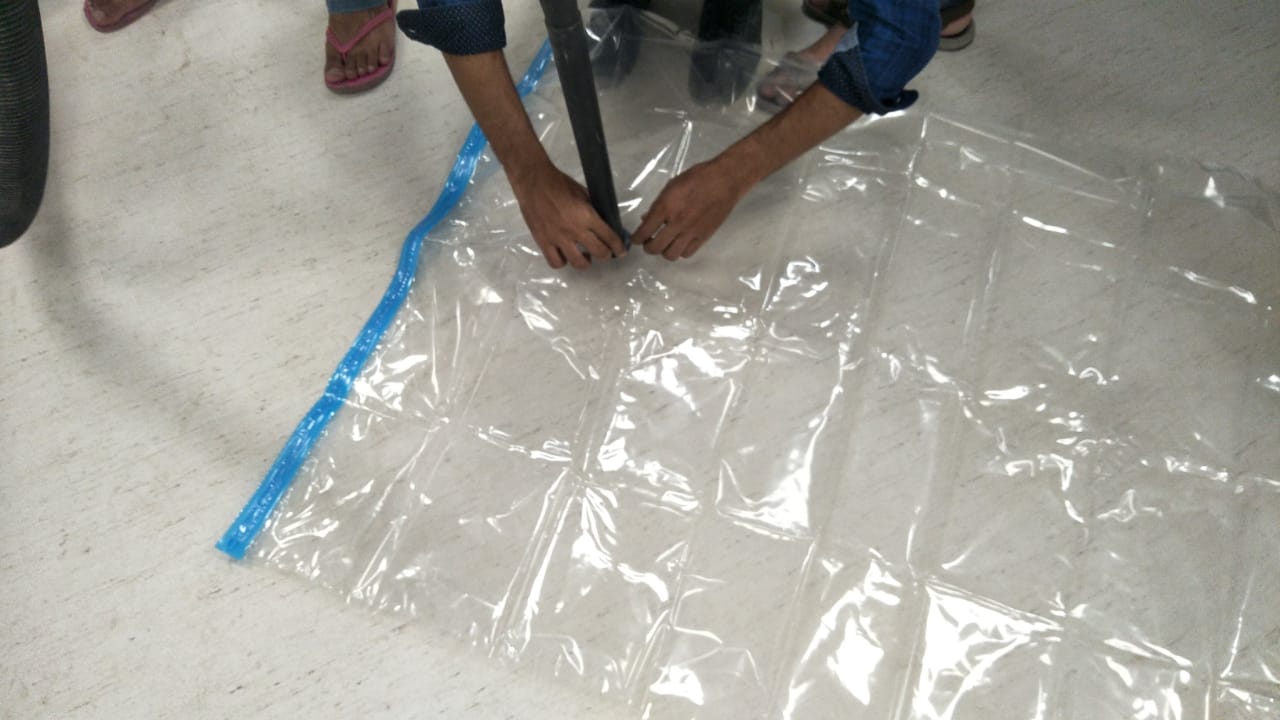

Place a breather and put the whole experiment into air bag which is used to suck the air and build pressure on composite to attain the shape.

after vaccumming

Wait a day to dry the material and the result was hard like rock

Final result

Download all files from here