Final Project

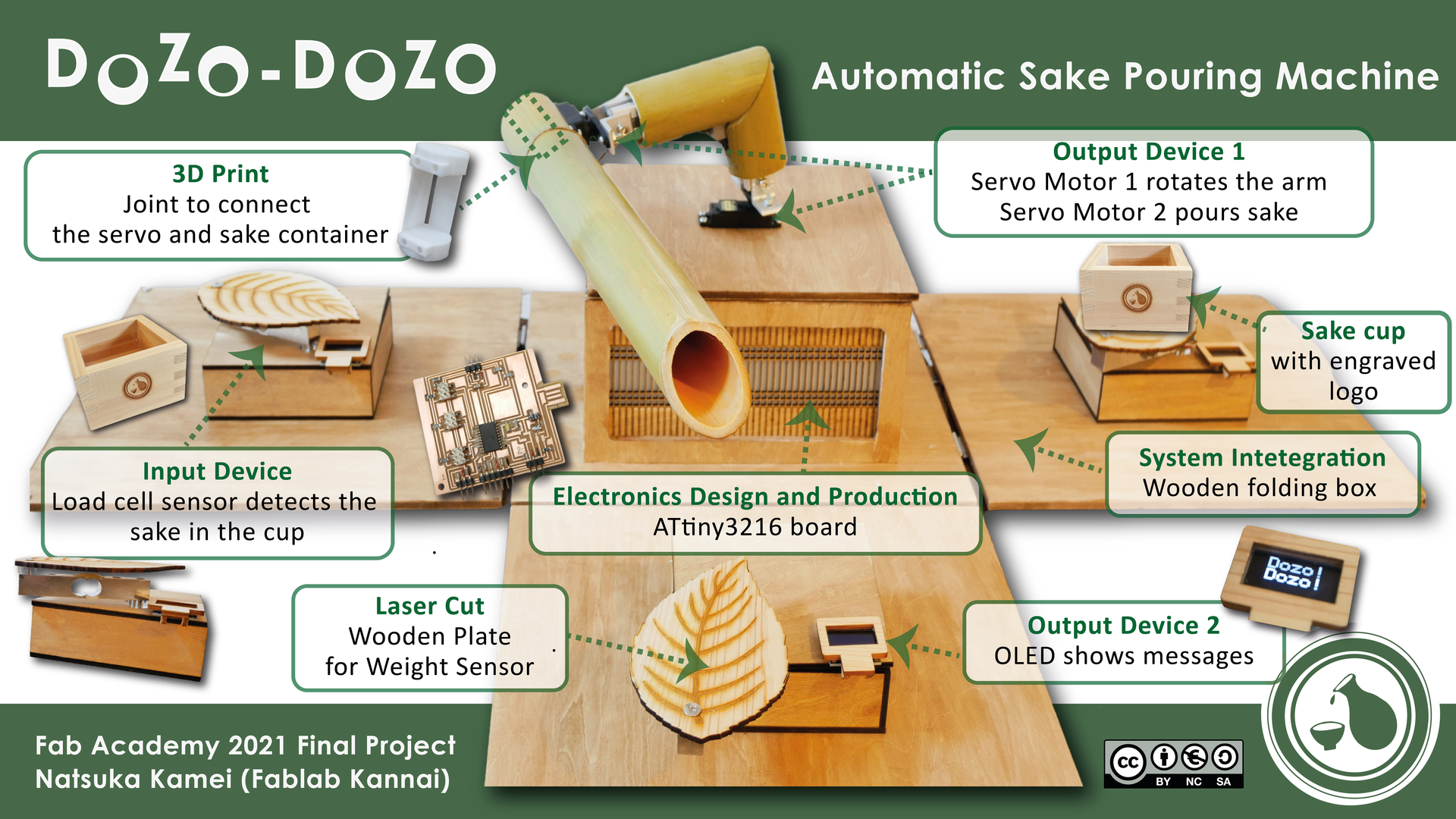

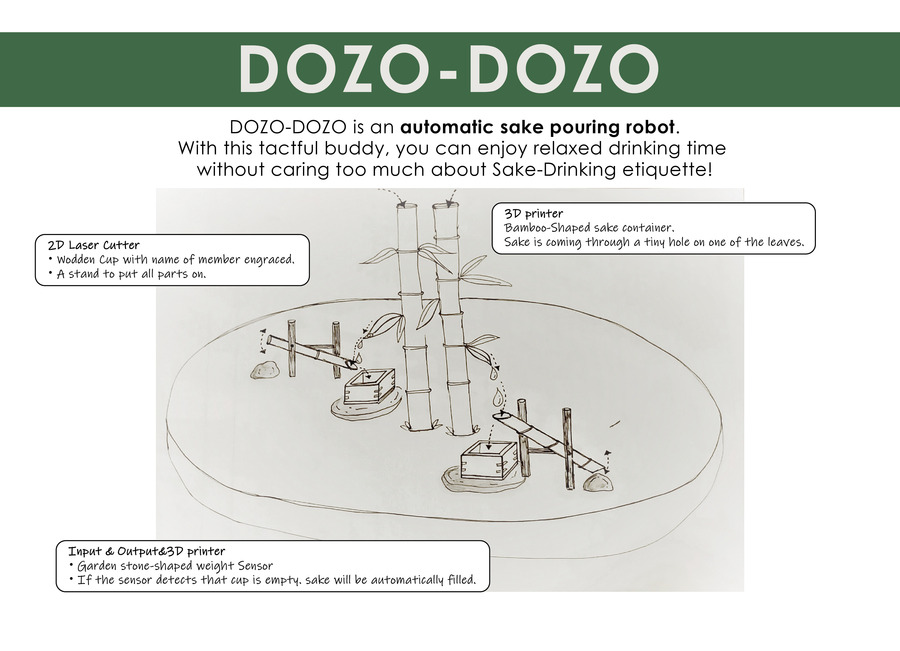

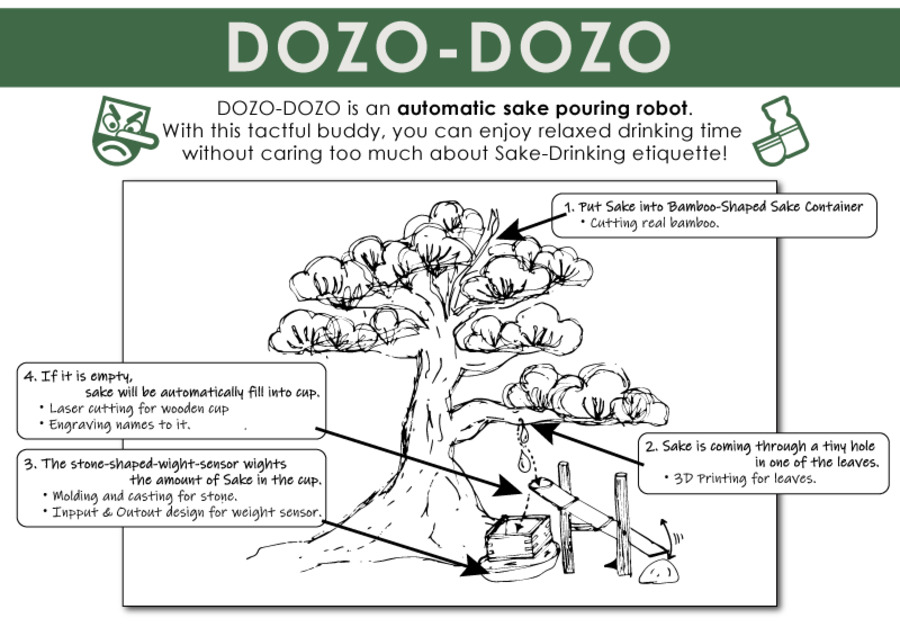

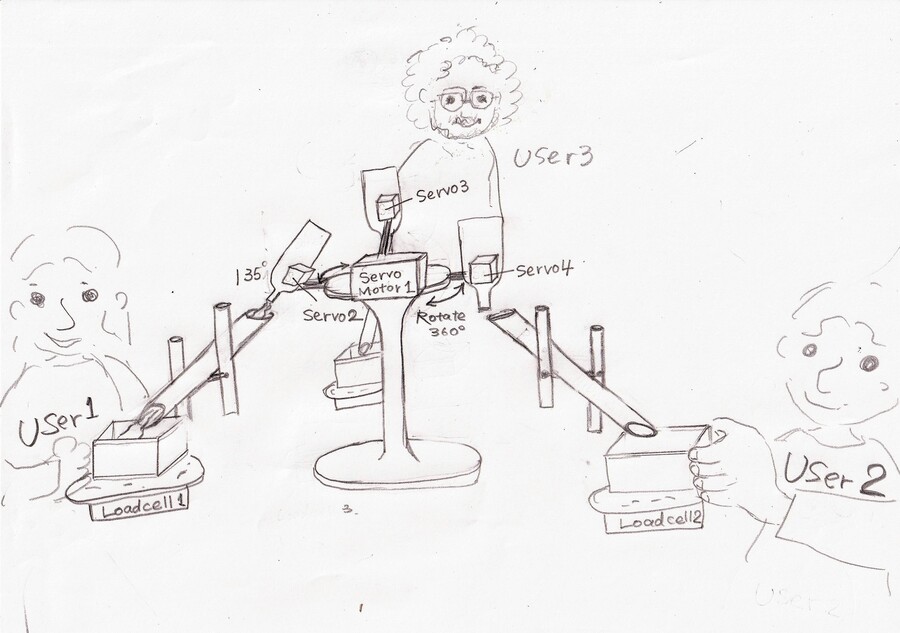

My final project is the automatic sake-pouring machine.

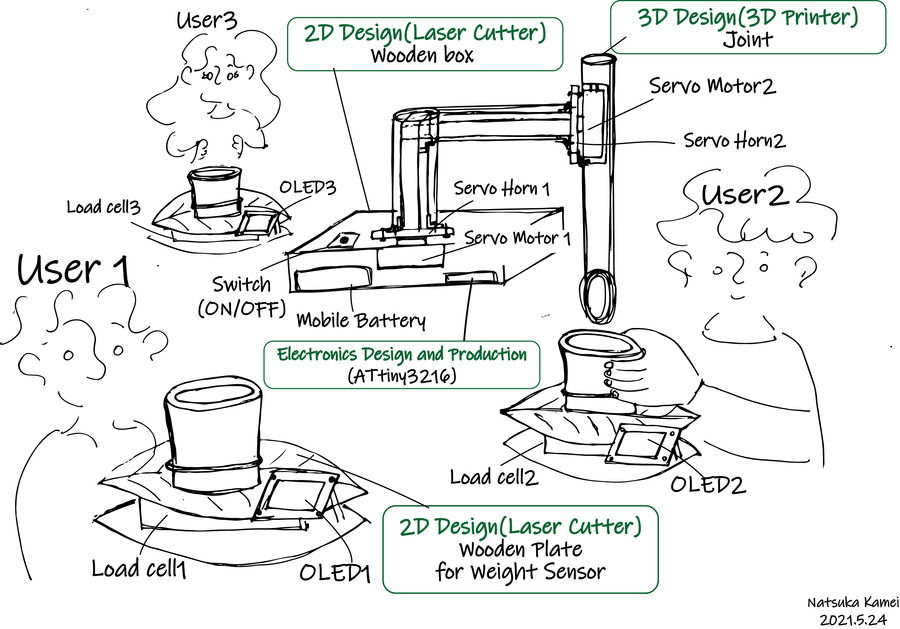

It contains three load cell sensors to detect the weight of remaining sake in the user’s cups, and two servo motors to rotate and lean the arm with the sake bottle.

It's named Dozo-Dozo (Japanese phrase to encourage others to do something or have some food or drink).

Dozo Dozo will be a perfect buddy who pours the drinks in the right timing, so you can enjoy drinking without caring about drinkig manners too much.

1.In the preparation, add sake into a bamboo shaped bottle beforehand.

2. A user turns on the mobile battery to power on the machine.

3. Users can start drinking.

Only thing they should care about is that placing their drinking cups on the leaf-shaped weight sensor(load cell sensor).

4.The weight sensor detects the weight of remaining liquid.

If the weight is light, the arm holding a bamboo bottlerotate will rotate 180 degree of x and y axis by the servo motor1 to move the bamboo bottle to the front of the appropriate user.

5. Then a bamboo bottle will be rotated by a servo motor2 and sake will be poured into a user’s cup.

6.Each OLED display will show the machine Logo, welcome message.

My country, Japan has various unique traditional cultures and customs.

As is often the case with many cultures, most of them are beautiful and respectful,but some are strange.

“Oshaku” Japanese traditional etiquette for drinking, is one of them. It generally means pouring sake to the people who are on the same table.

This custom comes from a sense of hospitality for others,and it’s very nice if you do so out of kindness. The problem is,it becomes like"obligation" at some situation. For example, elderlie forces to do so to young ones at office drinking parties or some people think it's woman's task as old-fashioned gender role.

So,I decided to solve the problem by FAB.

I consider my project Dozo-Dozo as a kind of an ironic joke about “bounding by social customs”.

Dozo-Dozo forcuses on only “Japanese” custom but I believe every country has similar problems when it comes to tradition and customes.

Please remake your country-specific version of Dozo-Dozo, and laugh off those problems together!

The arm part is the main structure of Dozod-Dozo which contains the main structures of the machine, “pouring drinks to the appropriate user”

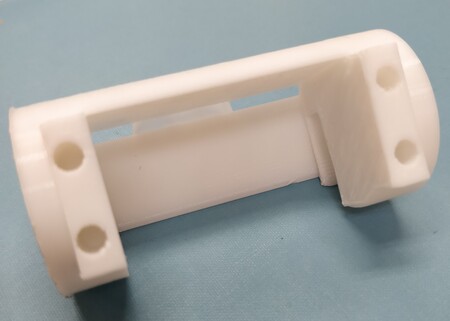

I assembled the aluminum flame,joints,and the cover made with bamboo together.

Design with Fusion 360

Final figure

Design with Fusion 360

servo 3D data were downloaded from here

Put the hot melt insert nut with the soldering iron

Final figure

Cut the bamboo with the saw by hand.

For the oil extractor of the bamboo, there are two ways.

one is to dry them over a fire, the other one is to boil them in hot water with baking soda.

I did the former when I went camping.

Final figure

The weight sensors are to detect the weights of remaining sake in the user’s cups.

I used the load cells and HX 711 board with them(commercial boards).After soldering the wires,I glued them with a glue gun to keep it strong.

In my final project, I set three weight sensors but if you would like to enjoy a bigger drinking party, you can add more!

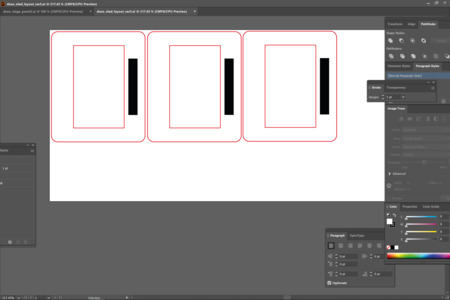

Design the top plate of the weight sensor with Adobe illustrator.

Lasercut and engrave 2mm wood for the top plate.Final figure

Cut a 5mm acrylic board into the small square parts to put between the load cell and top/bottom plate.

Wire and electronics are inside

OLEDs are set up near the user’s hand and show the messages.

Design the flame for the OLED with Adobe illustrator.

Laser cut 2mm wood.

To enjoy the relaxed drinking time anywhere/anytime, the machine and all necesally accessories are packaged in a wodden folding box and easily portable. The design of the center stage which holds the arm is inspirated by the Japanese light called Andon. It contains all electronic boards, the mobile batteries, and LED.

Design the folding box with Fusion 360.

Final figure.Laser cut 5mm wood and made groove to hide the wire.

Design the center stage with Fusion 360.The hole in the top plate is to set the servo motor.

Design the inside panel with Adobe illustrator

Final figure.Laser cut 3 mm wood and paint it with urethane varnish.

LED is on!

For the sake cup I bought Japanese traditional wooden cup and engraved the logo on it with lasercutter.

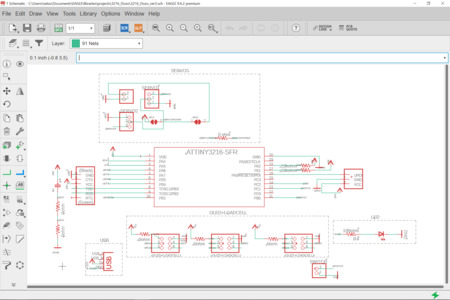

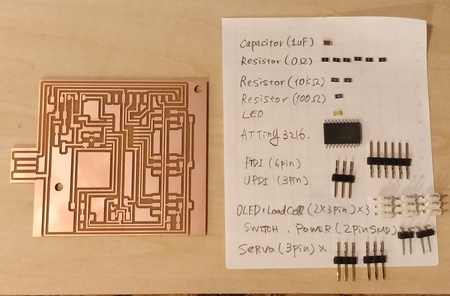

I made four PCB boards for Dozo-Dozo, one main board with ATTiny3216 and three small boards to connect OLEDs and the load cells.

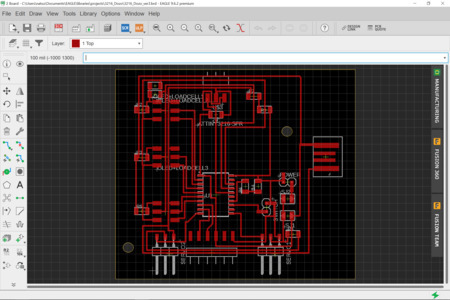

Design with EAGLE(sch)

Design with EAGLE(brd)

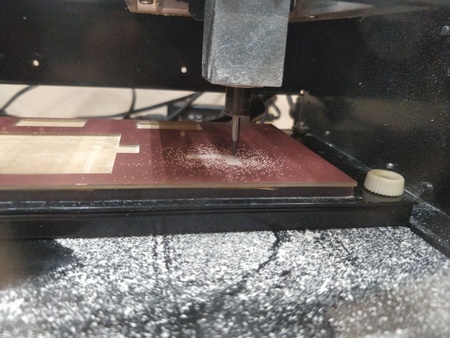

Milling

How tiny they are!

Final figure.

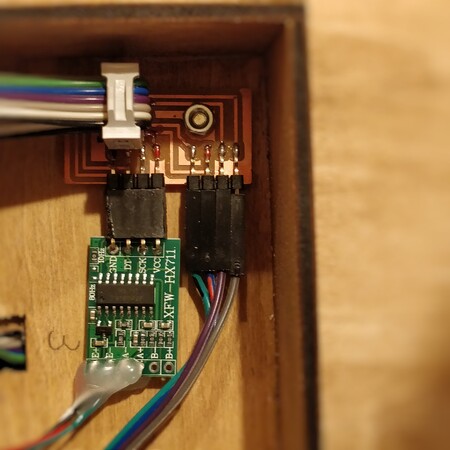

Fixed to the inside of the stage box with the bolts

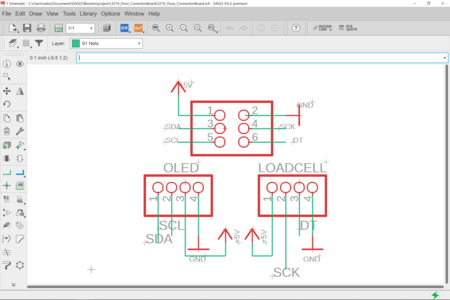

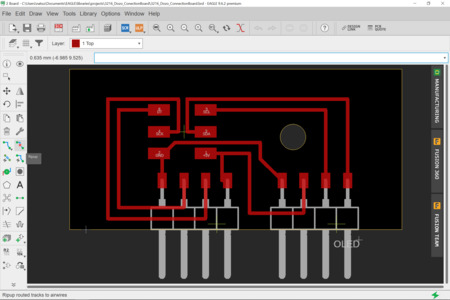

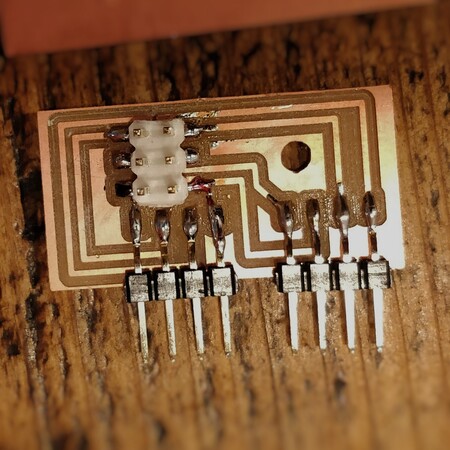

The design for small board is as follows

Schematic

Board

After milling and soldering

It contains two sets of four pin headers and each connects to OLED and HX711(the commercial board for the load cell).

The program contains description about two servo motors,three loadcells,three OLEDs, and LED.

The hardest part was to adjust the moves of the servo motors not to spill out the sake when it's pouring.

Dozo-Dozo is protected with CC BY-NC-SA Licencse.

This license allows reusers to distribute, remix, adapt, and build upon the material in any medium or format for noncommercial purposes only, and only so long as attribution is given to the creator. If you remix, adapt, or build upon the material, you must license the modified material under identical terms.

Ref: Creative Commons > What We Do > About CC Licenses

CC BY-NC-SA includes the following elements:

BY – Credit must be given to the creator

NC – Only noncommercial uses of the work are permitted

SA – Adaptations must be shared under the same terms

Week1 Principles and Practices and Project Management My website and final project page

Week2 Computer-Aided Design Logo and 3D model of bamboo waterfountain and wooden cup

Week7 Computer-Controlled Machining Wooden trunk to contain the machine,but finally decided not use this one

Week8 Embedded Programming ATTiny 3216 board with OLED and loadcell pins, not final board through

Week11 Input Devices Test of the load cells and program

Week12 Moulding and Casting The top plate of the weight sensor but didn't use this type in the end

Week13 Output Devices Test of servo motors and program

Week14 Embedded Networking and Communication Test of OLED and Program

Week16 Wildcard Week Embroideried patch with logo

Week17 Applications and Implications To deepen the idea of my project

Week18 Invention, Intellectual Property and Income To choose the license and the future plan

Week19 Project Development More work,work,and work to finish!

-Arm and 3Dprinted joint data

-OLED flame, weight sensor plate, and engraved logo on the wooden cup data

-Folding box data

-PCB data

-Program