Wild card

Assignment:

For this weeks assignment, I wanted to discover composits. I wanted to make something cool for my car, so I designed a rear bumper diffuser and tried to apply composites on it.

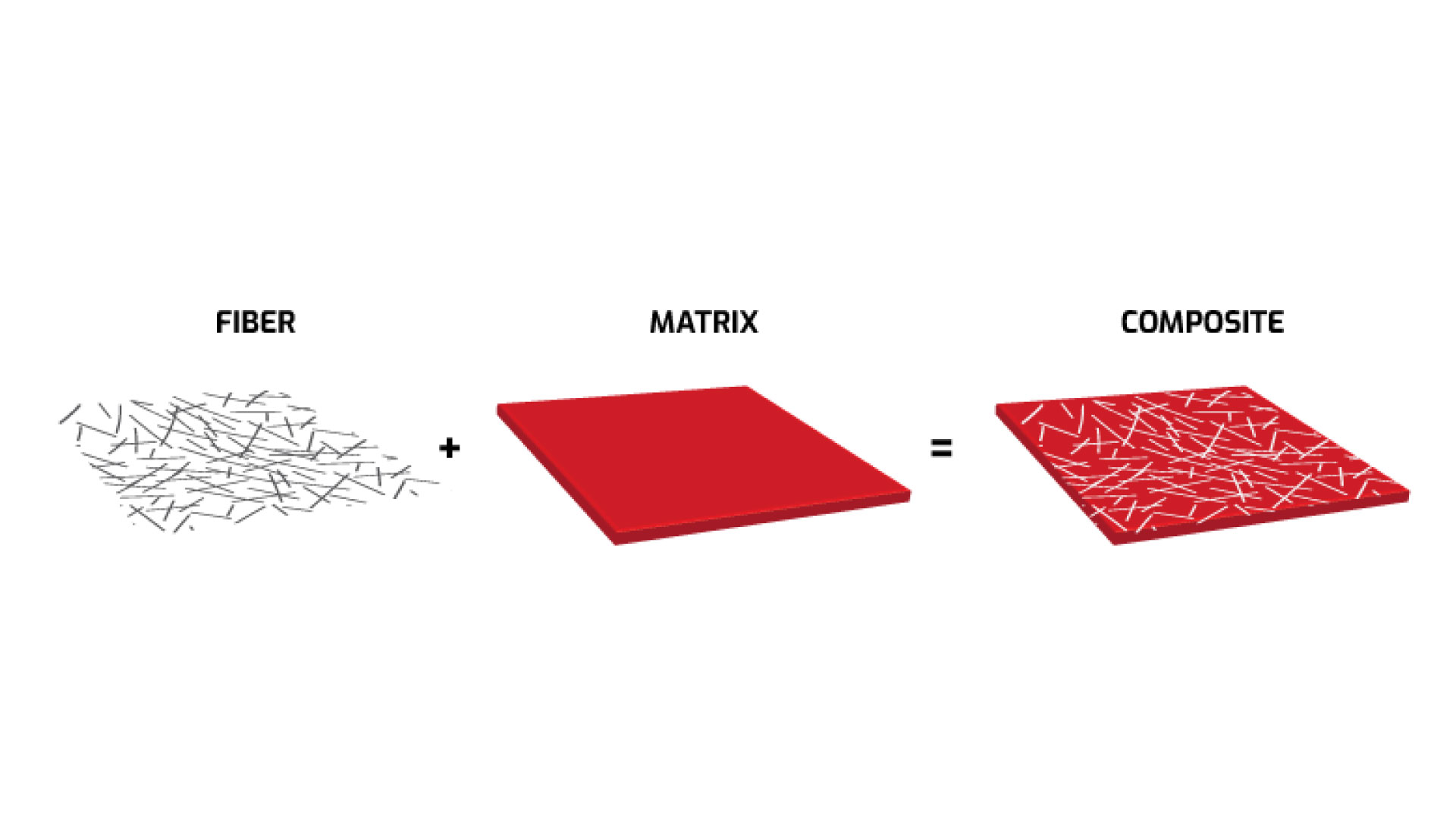

The meaning of composites:

Basically, composites are made by combining two different elements with different properties to make a stronger final product from the combination. Composites are made from a polymer matrix (resin) that is reinforced with fiber or other reinforcing material. The resin protects the fibers from external damage and fills the gaps between the fibers. The fibers, in turn, provide strength and stiffness to reinforce the resin and help it resist cracks and fractures.

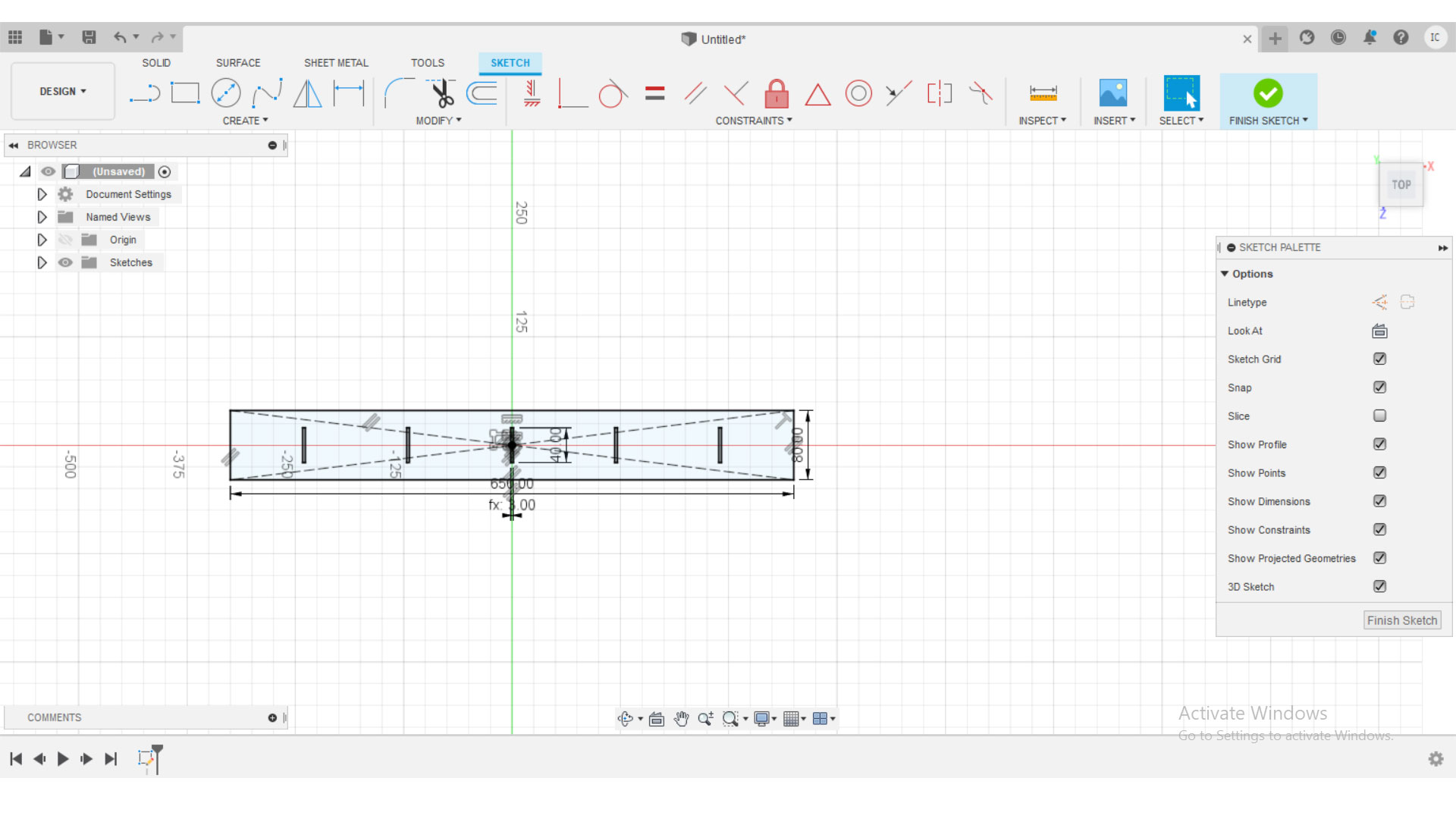

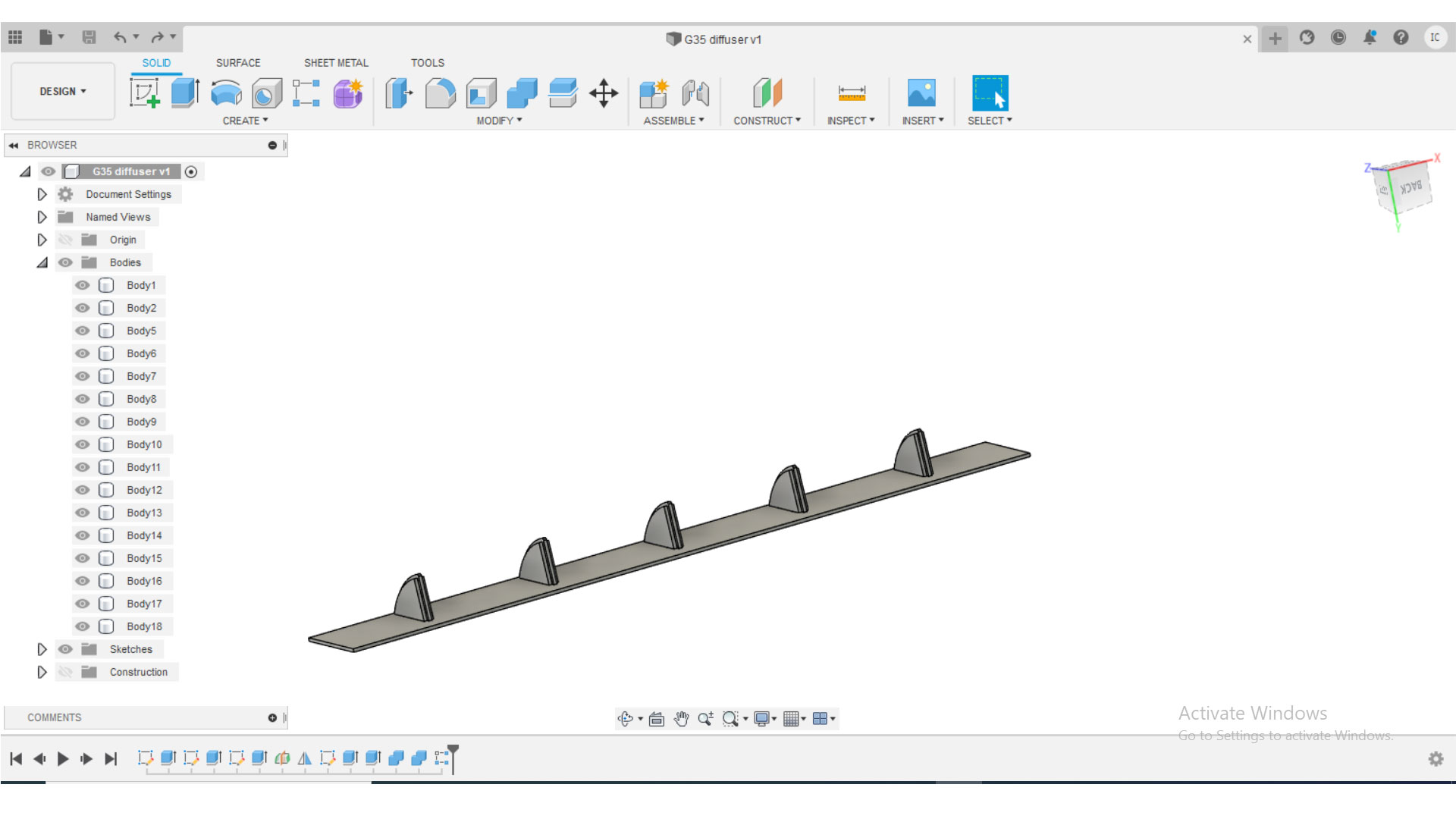

I started by measuring the dimentions of the rear bumper, then I designed the rear diffuser on fusion 360 to be laser-cut.

Then, I laser cut it using 3mm MDF.

Then, I laser cut the pieces, and assembled them.

Then I made a prova on the car:

Now that our part is ready, It is time to creatte the composite. I chose jeans as the fiber because I was curious about the reesults with this material, and for the matrix, I used VIMEPOX BETON-IMP resign. below is the technical data sheet of it:

Composition: Two-component epoxy system

Component A: Transparent solvent based epoxy resin

Component B: Transparent solvent based hardener

Mixing ratio: A:B = 3.44:1 by weight

Specific gravity of mixture: (A+B): 0.92 kg/l

Mixture viscosity: 45 mPa.s at 23 degrees celsius.

Pot lifeL about 10 hours at 20 degrees celsius

Can be coated: after 10-24 hours(priming)

Final strengths: After 7 days at 20 degrees celsius

Note: wear gloves and protective goggles, avoid skin and eye contact, apply in a well ventelated area.

Below we can see the procedure:

I let it dry overnight, and here is the final result:

I was expecting better results, but the jeans were too thick, which mad it hard to lay the layers down properly on the fins, and the surface was crumbled, so I did not place it on the car.