The tool

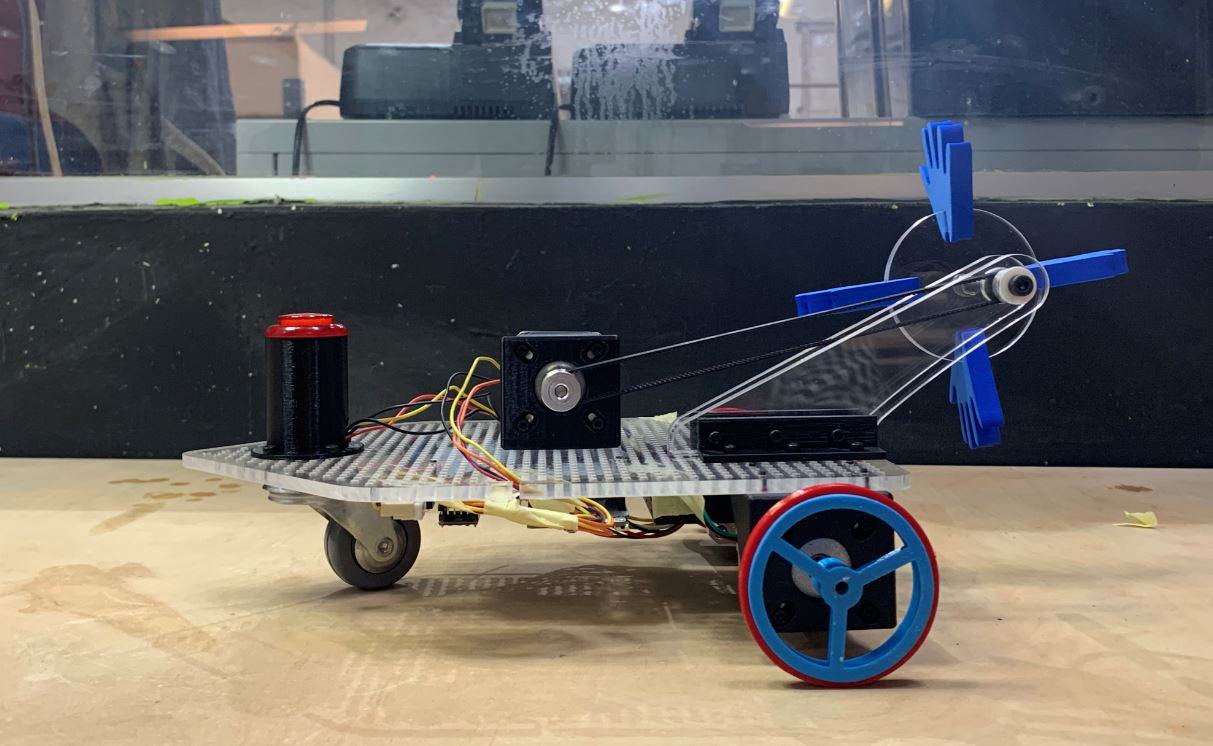

The tool itself is a mechanism to hit the other machines buttons. So we designed a tool to attach to the common base.

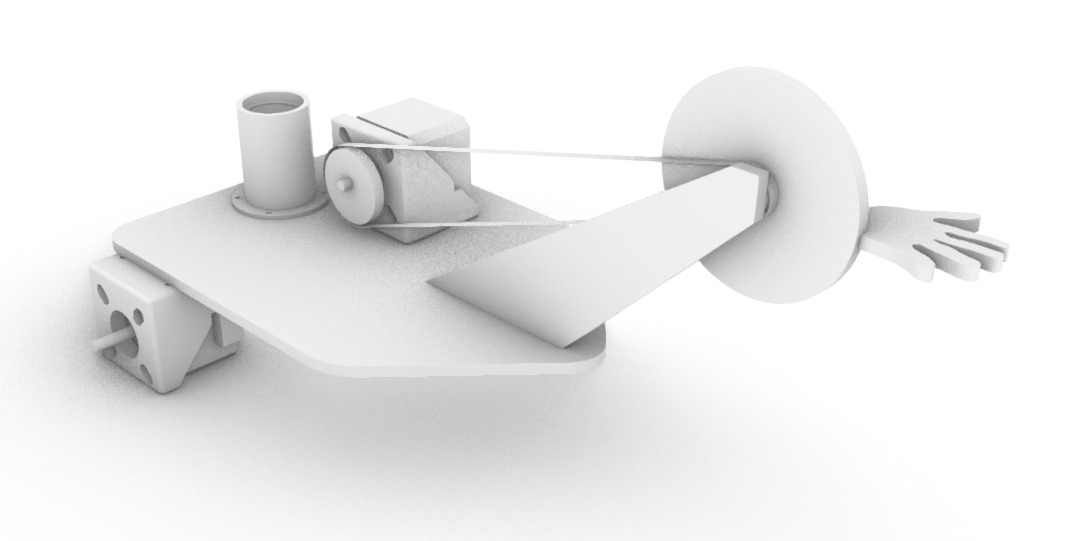

We started by designing a 3d sketch of it in Rhinoceros

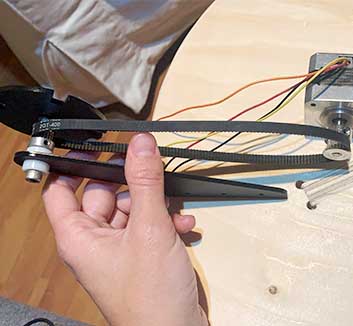

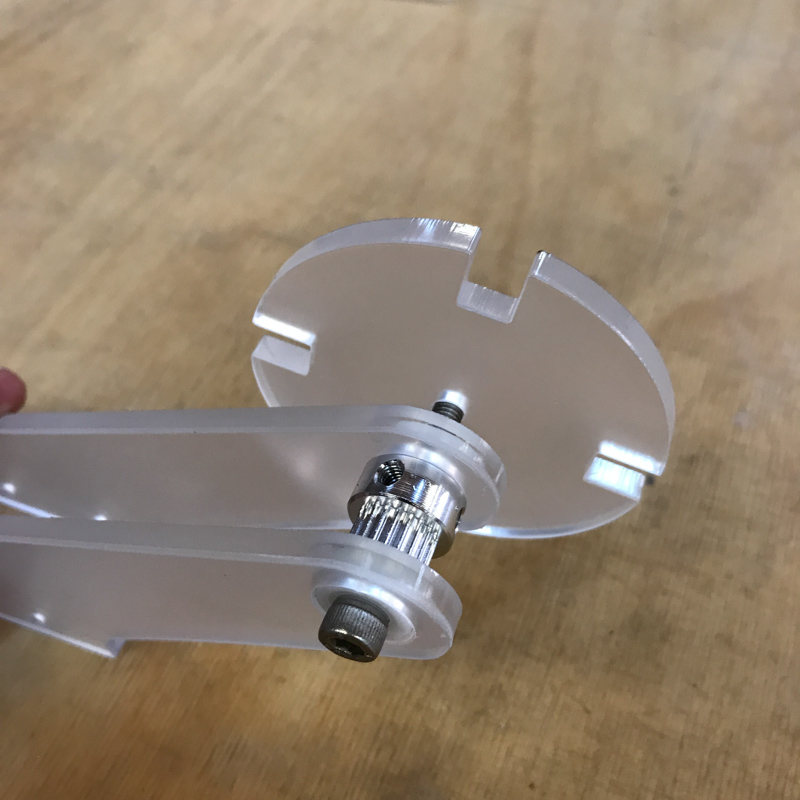

The operation, consists on a motor that rotates a wheel with hands through a closed rubber belt. The motor is fixed to the base with a support that allows to tense the belt

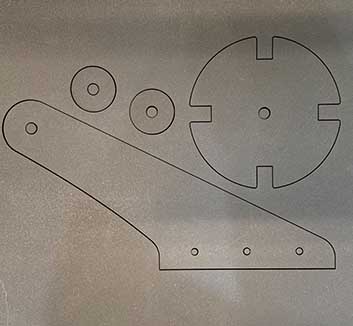

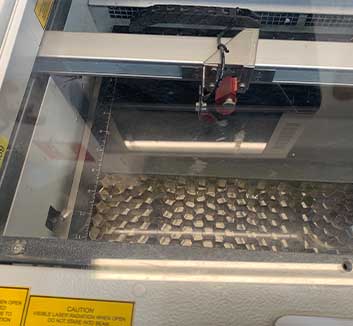

Then we started the proccess of defining all the pieces in order to send them to cut.

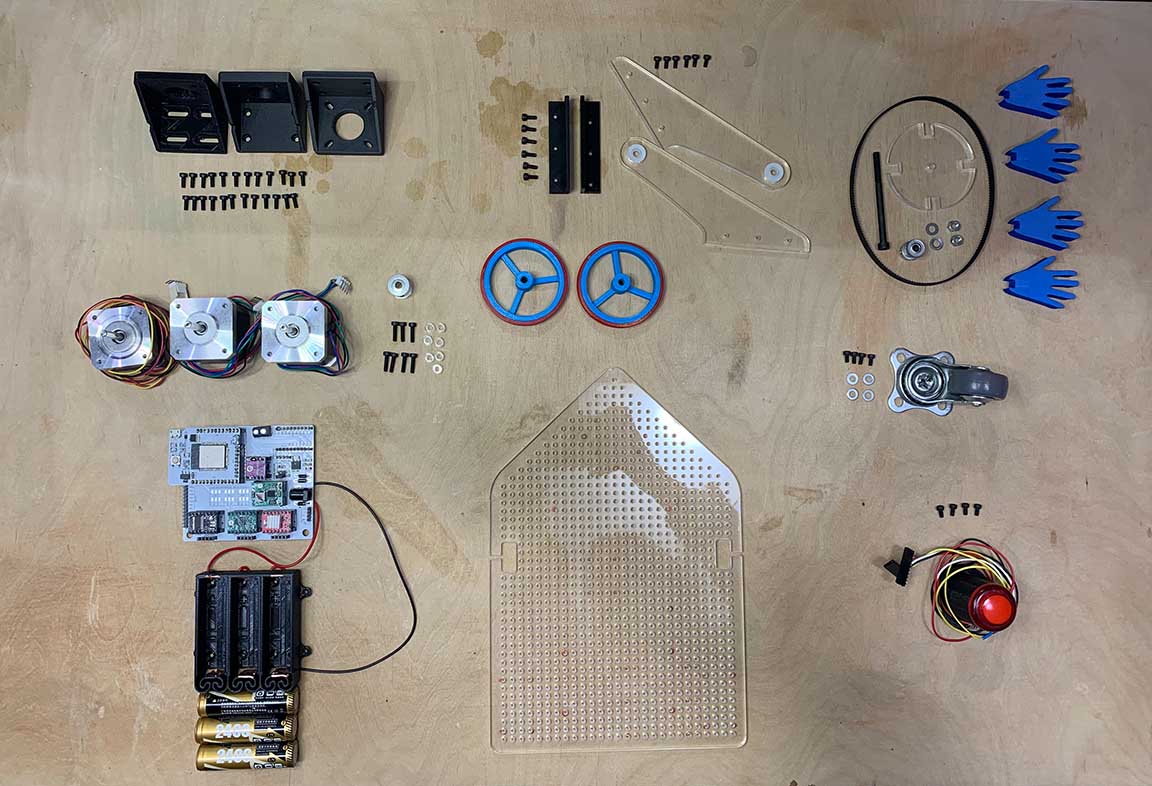

Materials:

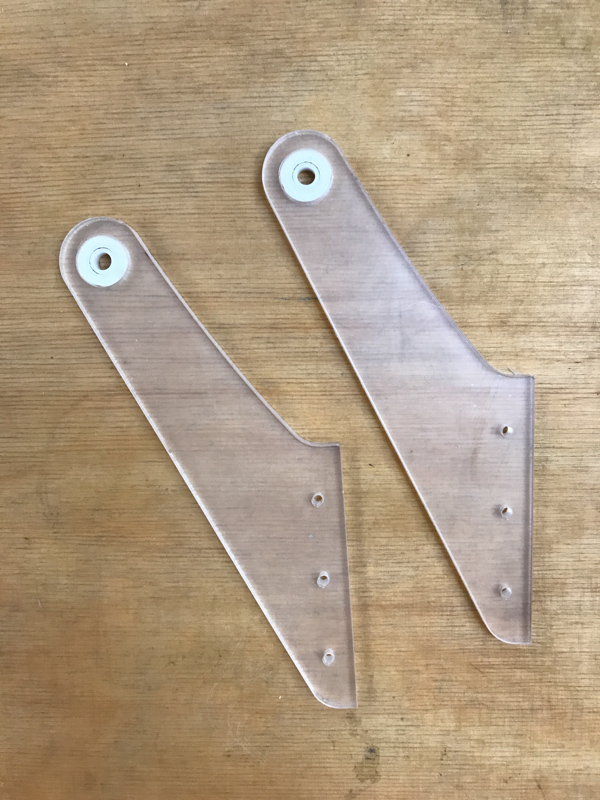

After we have everything clear and tested, we cut the pieces for the tool:

The result was good, and it did its work smoothly as it can be seen in the final video.

Components

| Name | Description | Quantity |

|---|---|---|

| Belts | GT2 Closed Loop Timing Belt 400mm rubber synchronous belt | 1 |

| Pulley | GT2 Pulley 20 Teeth 6mm Timing Belt Pulley Wheel Aluminum | 2 |

| Nylon bearing | BNL Ball Bearing, Radial, AC6000Z-ISB / 4N / D | 2 |

| Acrylic arms | Laser-cut acrylic arms 6mm | 2 |

| Printed support holder | 3D printed arm holder | 2 |

| Screws | Lorem ipsum | n |

| Stepper motor | Lorem ipsum | 1 |

| Printed motor holder | 3D printed motor holder | 1 |

FILES

STL for the battery holderSTL for the button support

STL for the motor support

STL for the tool support to the base

Rhino files for the laser cutter