Individual Assignment:

Cut something on the vinylcutter design, lasercut, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways, and for extra credit include elements that aren't flat.

A- Laser Cutting

Software:

Fusion 360

Machine:

Lasercutter

Material:

Cardboard

Steps:

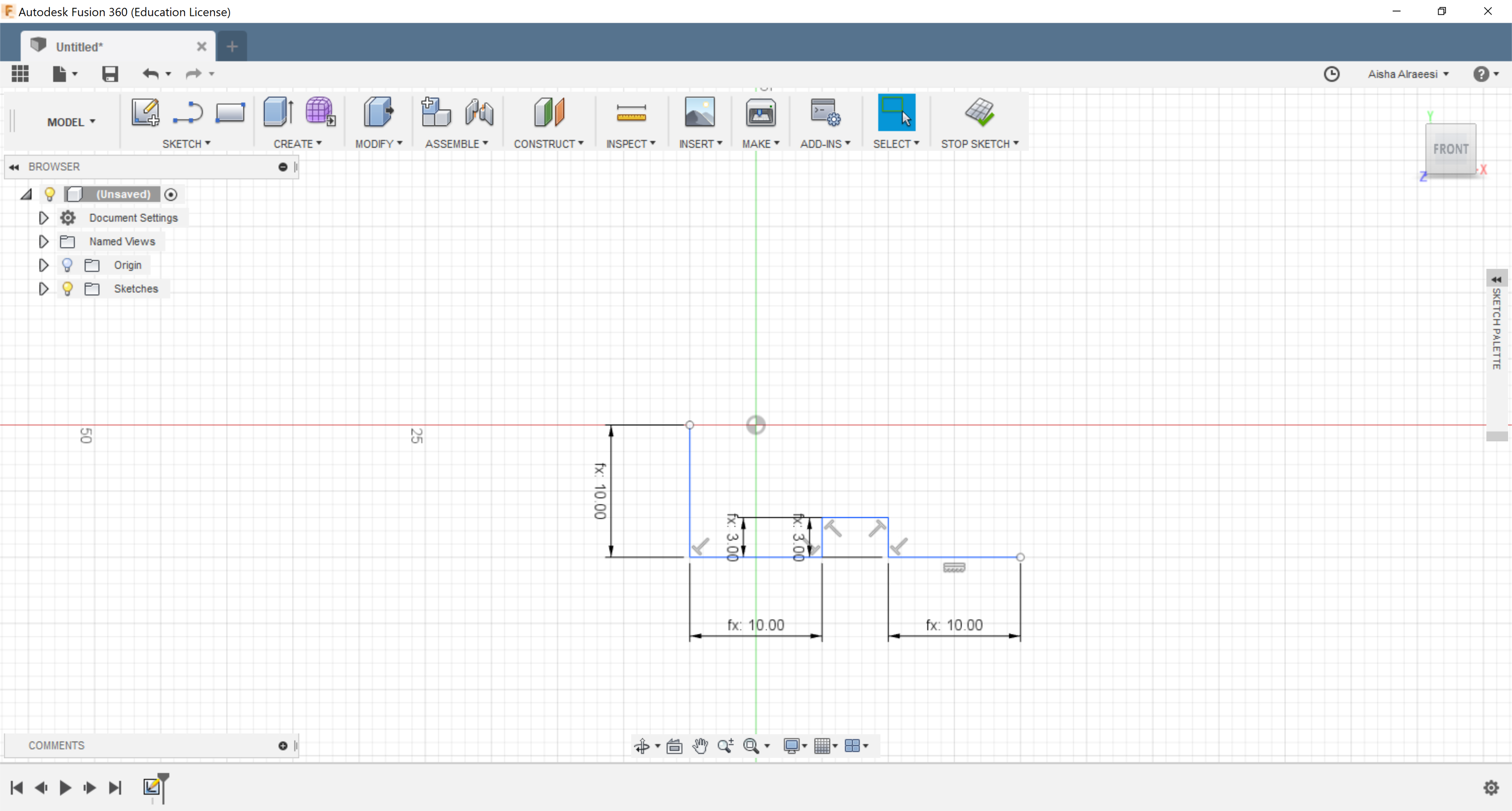

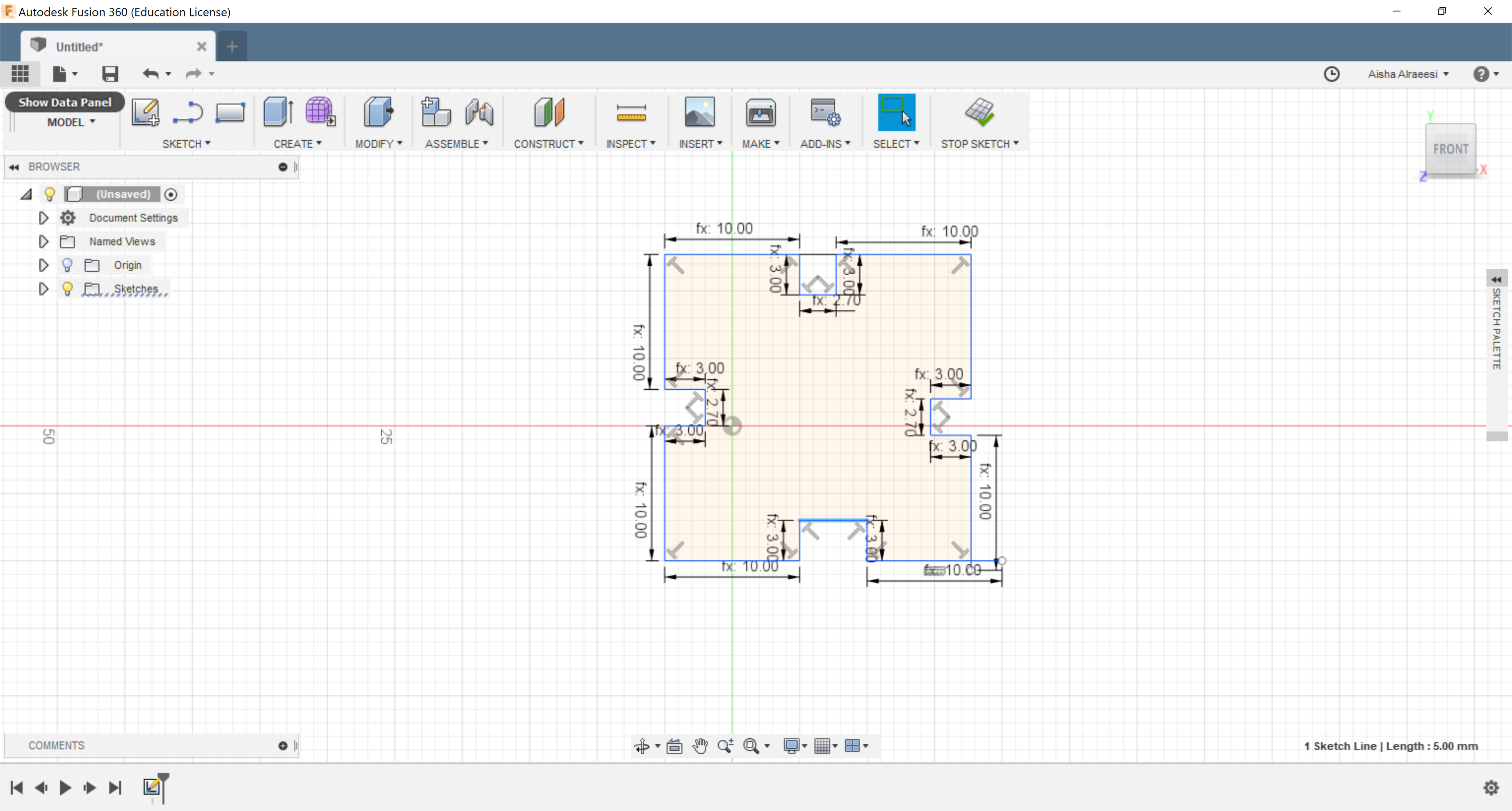

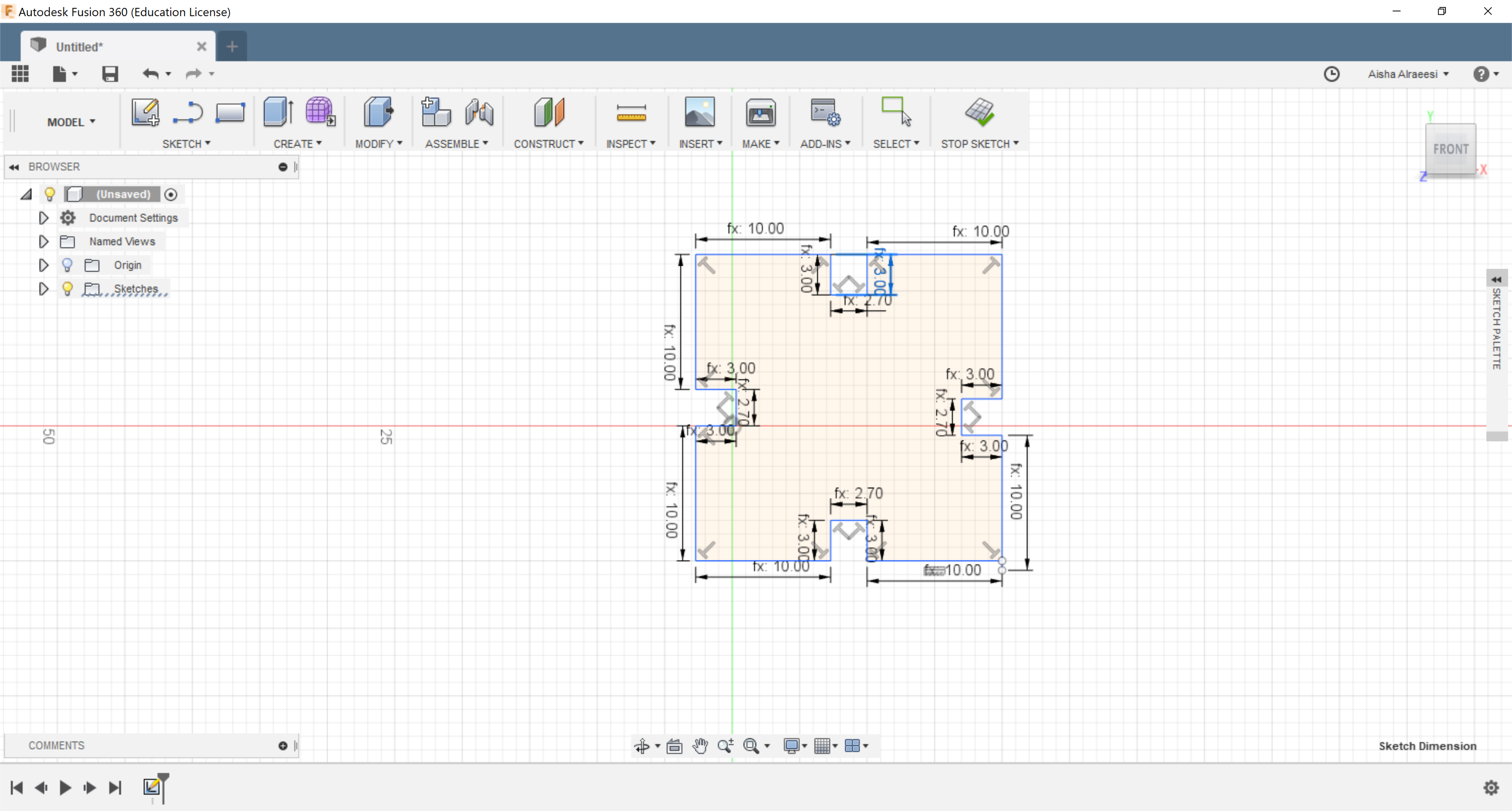

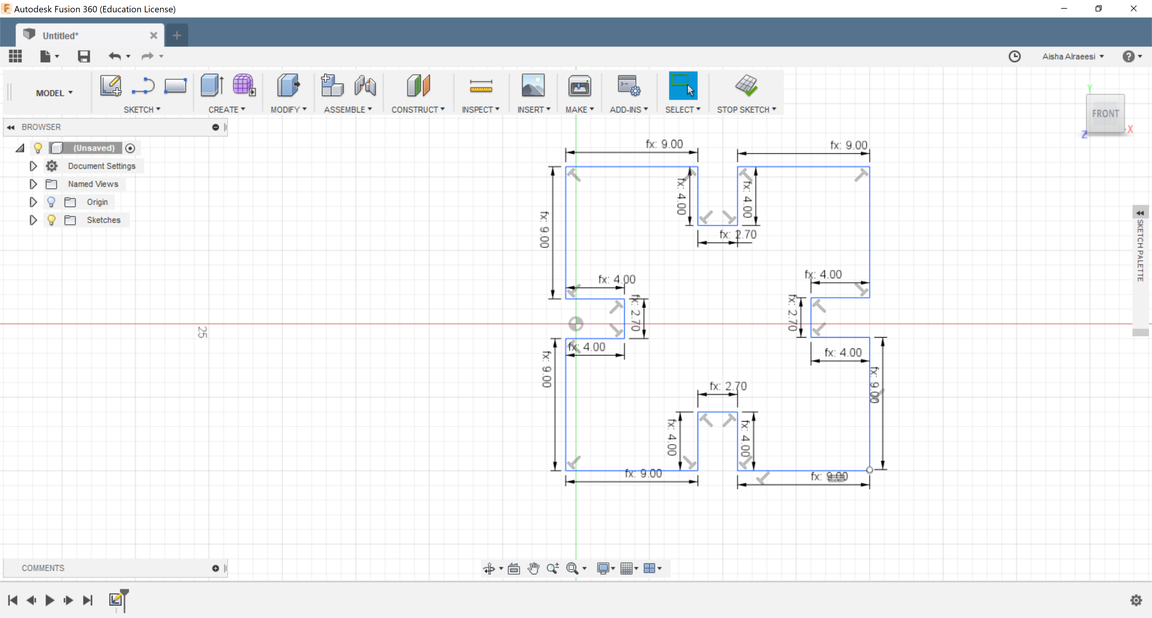

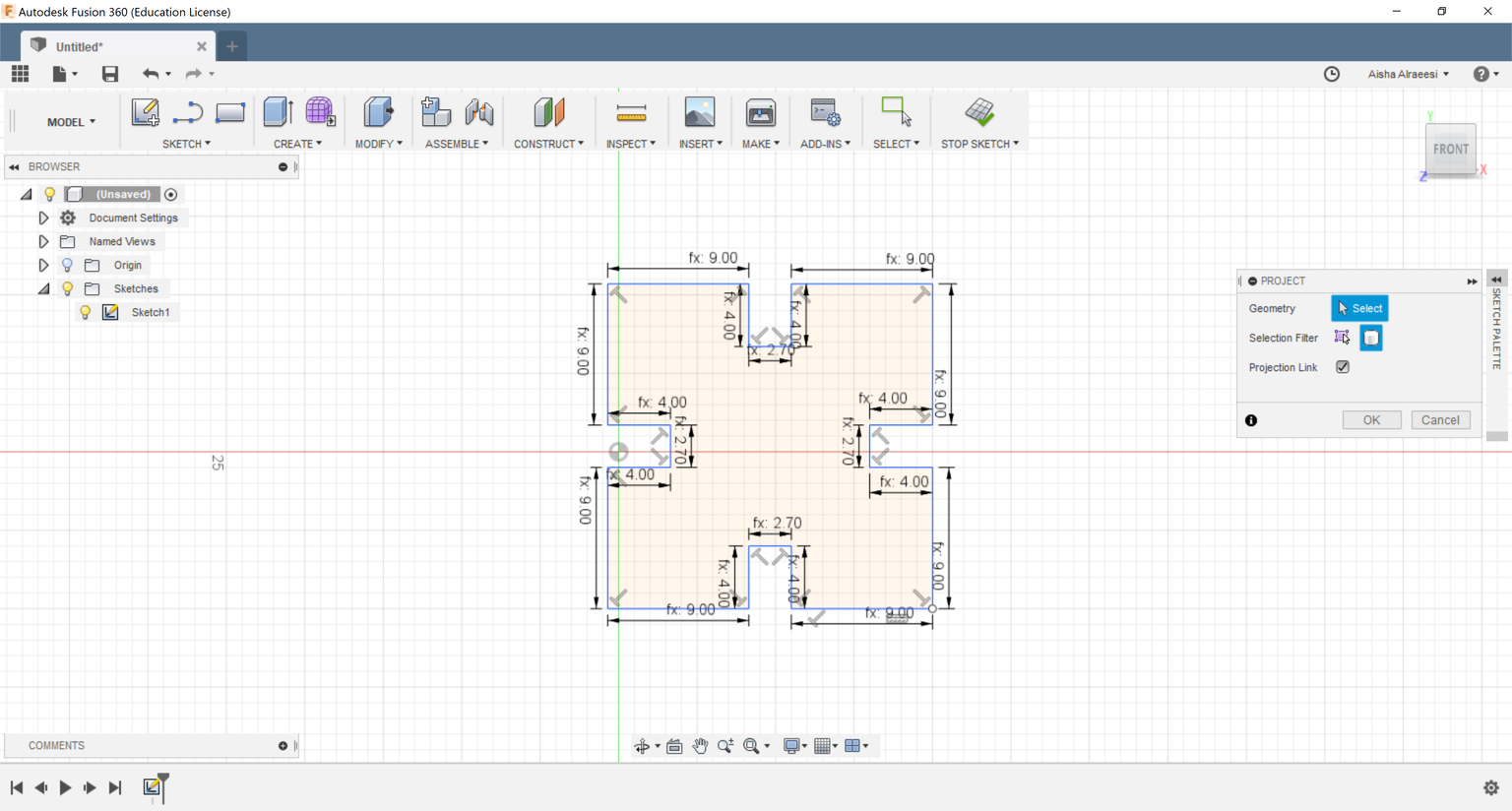

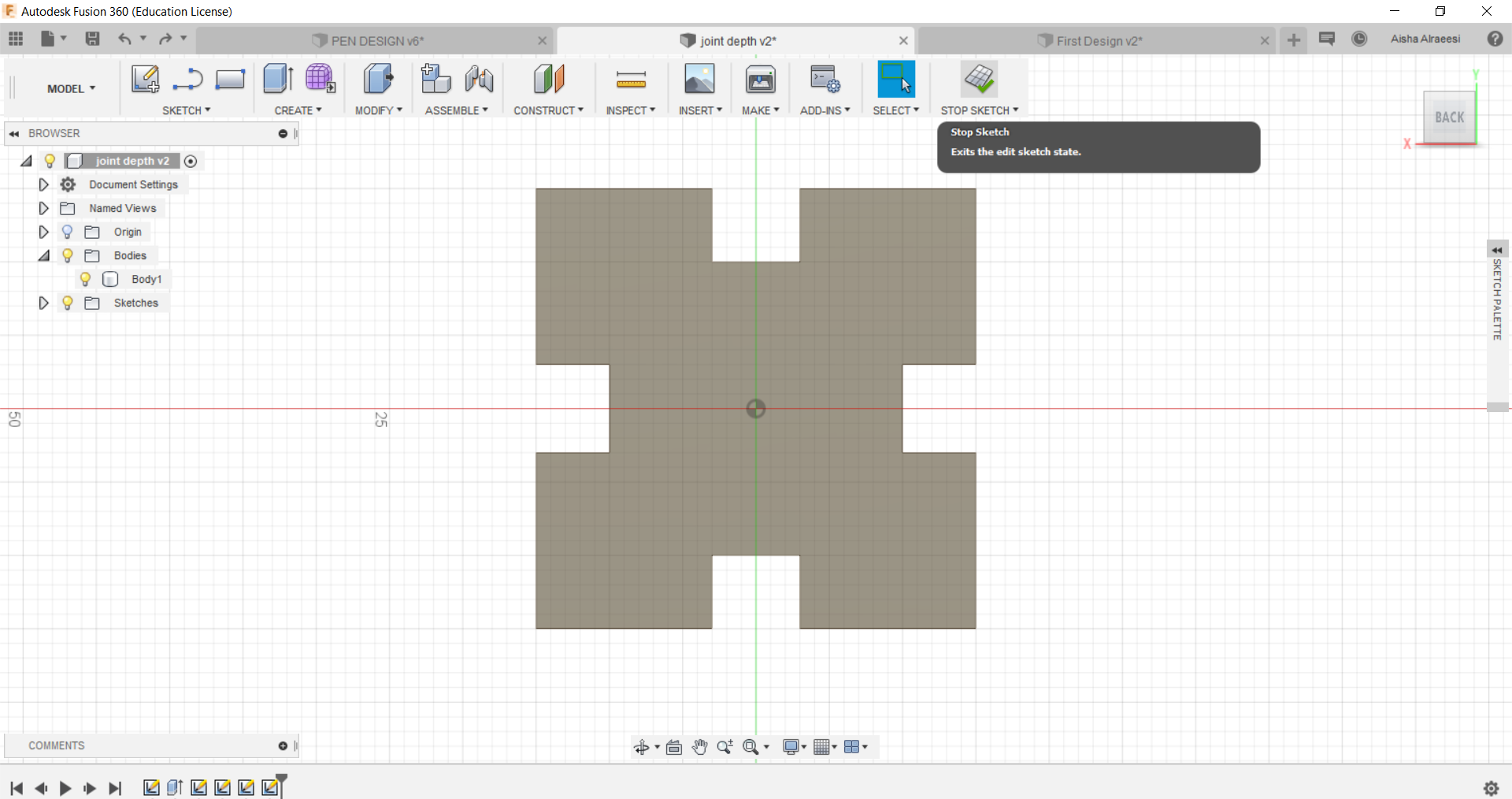

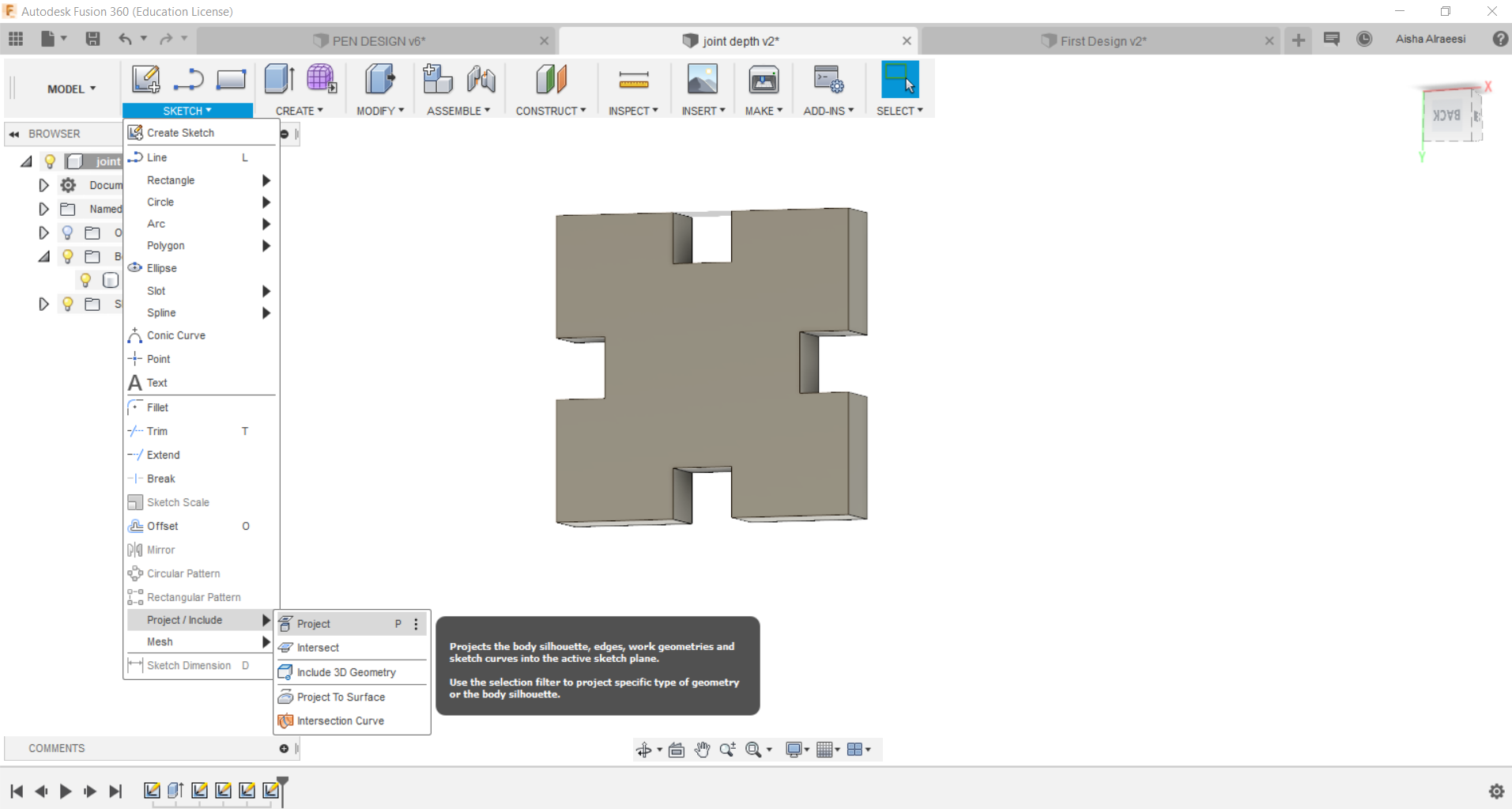

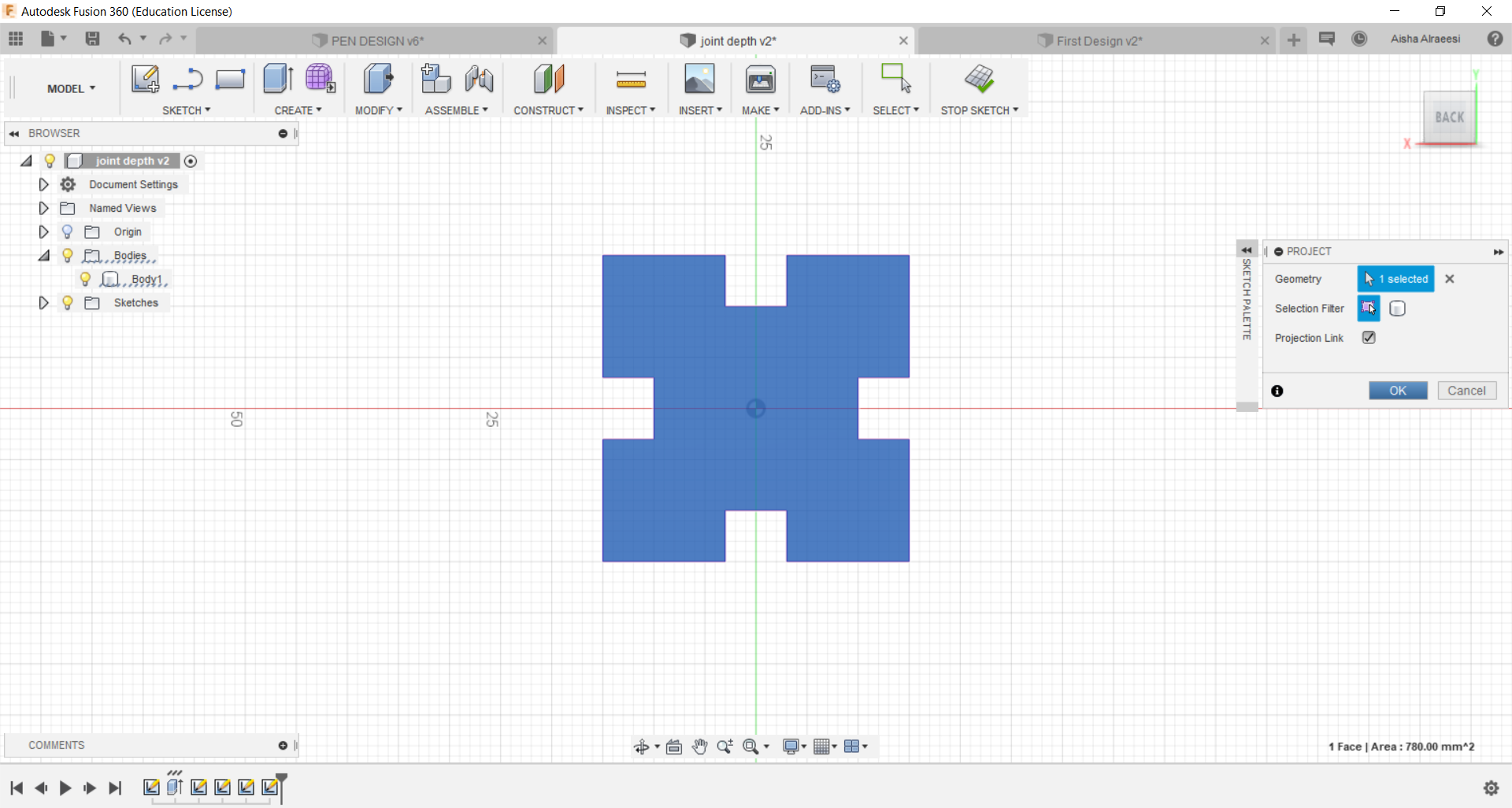

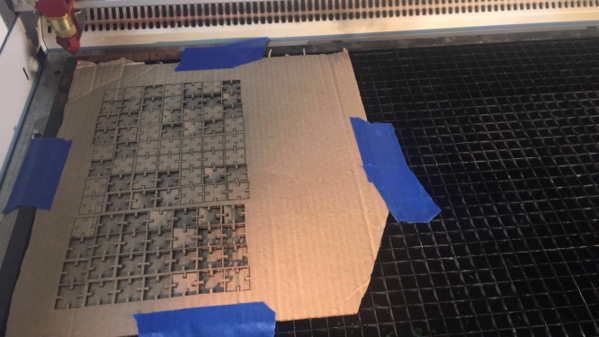

I went for a simple shape that looks like square since I don’t feel yet I am good with complex designs when it comes to using parameters.

Although it was a simple design, but I ended up with this outcome.

Used another material to practice using the machine.

Challenges:

Cardboard got burned and burned my hand a little bit since I was not aware how to extinct the fire in the machine.

Note: it’s crucial to look at the laser while it’s cutting a material specially the cardboard to avoid the above.

B- Vinyl Cutting

Software:

CoreIDRAW

Machine:

Vinylcutter

Material:

Black vinyl

Steps:

I thought about creating a sticker for my laptop.

Below pictures show machine’s settings.

Used a tape to help me get aligned text when I am going to place it on the laptop.