Week 15 (Molding and Casting)

Week 15

Week 15

To create this mold, I’ll be using my LulzBot TAZ Workhorse. To have better results on the quality of the print we need decrease the normal height of the layer but in my case CURA LulzBot edition no longer supports an “HD” profile and just changing the layer heights wont help. Changing the layer heights also involves calibrating more parameter to properly print the part. To solve this problem the setting “ Adaptive Layer Height” comes into hand (it’s considered experimental so I had to turn it ON in the advanced settings).

The slicer analyzes the angle of the outer walls of your model:

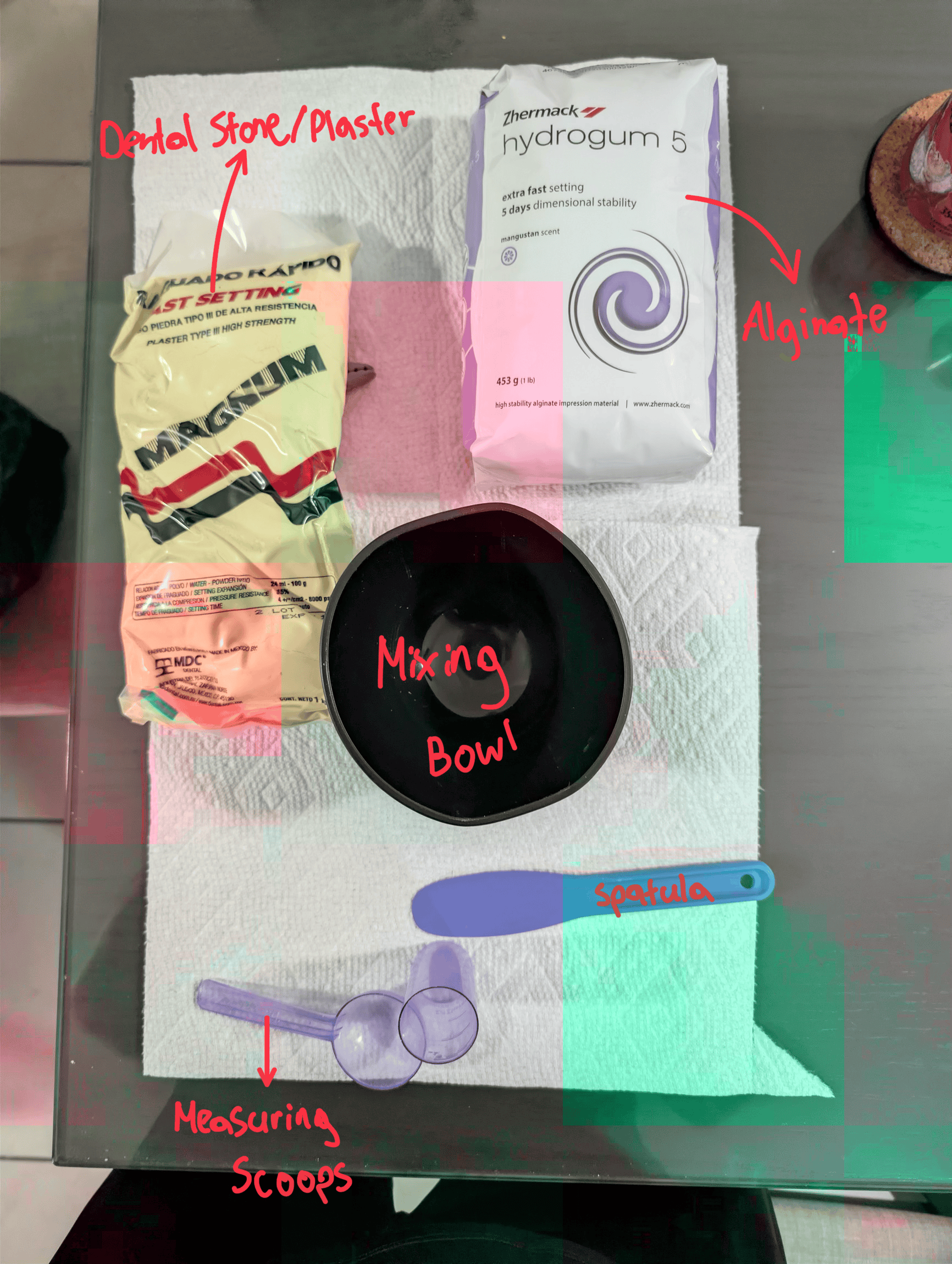

In Honduras it was easier to get dental impression and casting supplies. Long story short that’s the reason I’m using Alginate and Dental Stone/Plaster. My “brother from another mother” (Luis) and his girlfriend (Sam) are amazing dentists and helped me make this assignment possible in a short period of time. Both materials are really safe to use but always be carful with you eyes and always wash your hands when you’re done. Here is a breakdown of the specific items:

Using dental impression and casting supplies is like cooking with “Feeling”, not with a recipe. Even though you have given ratios it doesn’t guarantee the desired consistency. You also have to be really fast because you have less then 30 seconds to work with this kind of Alginate. Same with the Dental Stone/Plaster. Experience was key to make this work because I was using it outside of it’s designed environment. Please watch the following videos and see the needed consistency of both material. Alginate (4 Scoops) looks like cake cream (NO lumps) and the Dental Stone/Plaster (3 Scoops) a little more liquid then normal to make it easier to pure in the NEGATIVE. Another important thing is that you need filtered water or bottled water. Using tap water will create unwanted lumps in both materials. Air bubbles are your mortal enemies so use what to have (in my case striking the mold) to force them to the surface.

Next time I’ll try a post processing the 3D print to eliminate more of the surface marks. Another option would be to sand a little the finished sphere to have a soother surface but overall the experiment was successful.

Make (Almost) Anything