group assignment:

characterize the design rules for your in-house PCB production process

https://fabacademy.org/2022/labs/ciudadmexico/cdmx_production.html

individual assignment:

make an in-circuit programmer that includes a microcontroller:

extra credit: customize the design

mill and stuff the PCB

test it to verify that it works

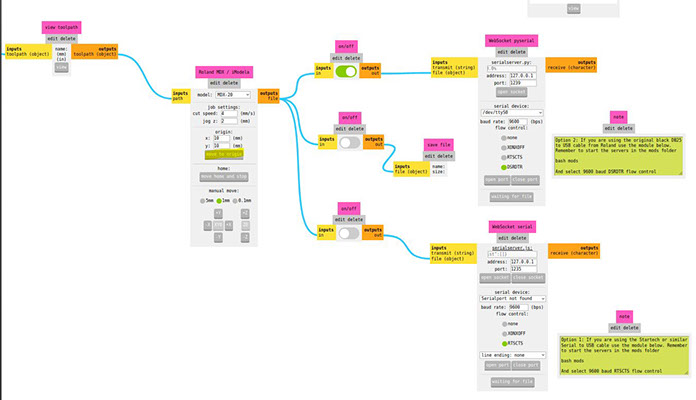

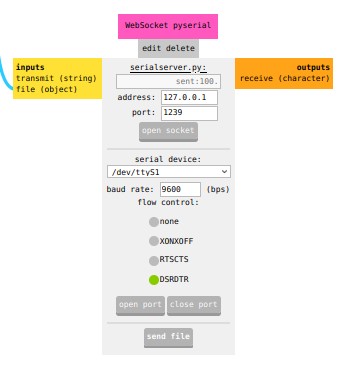

File was downloaded:

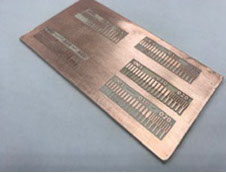

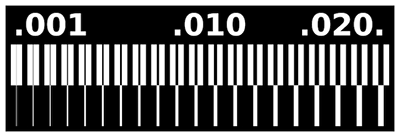

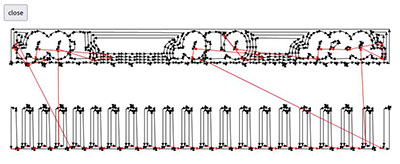

tolerance tests

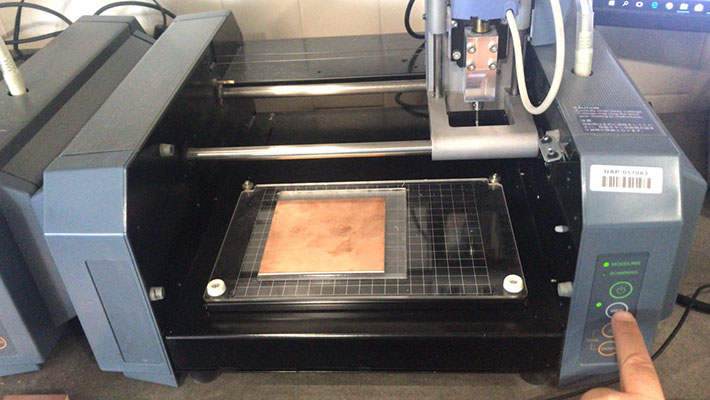

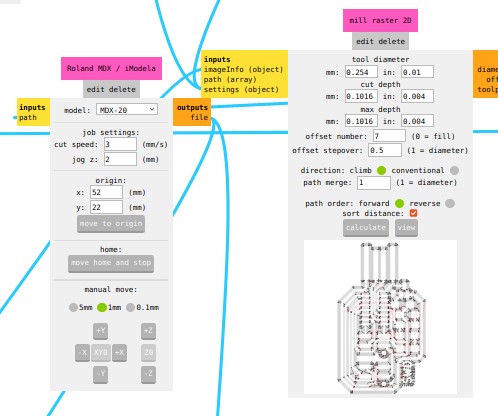

Roland Modela MDX 20

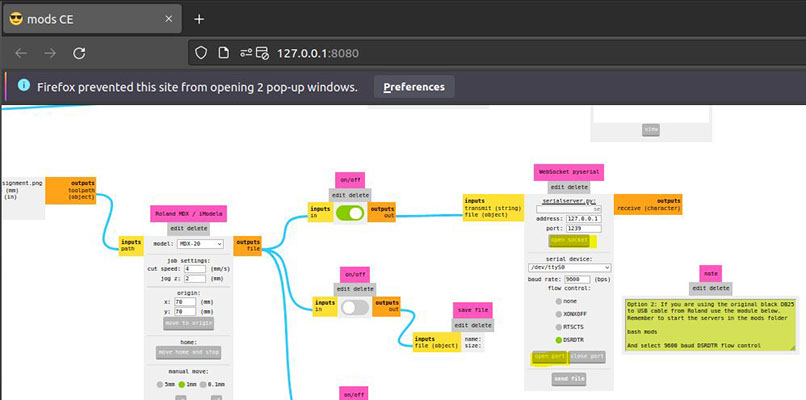

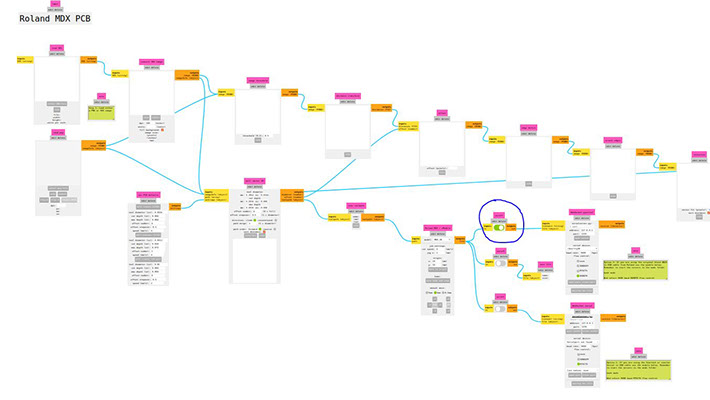

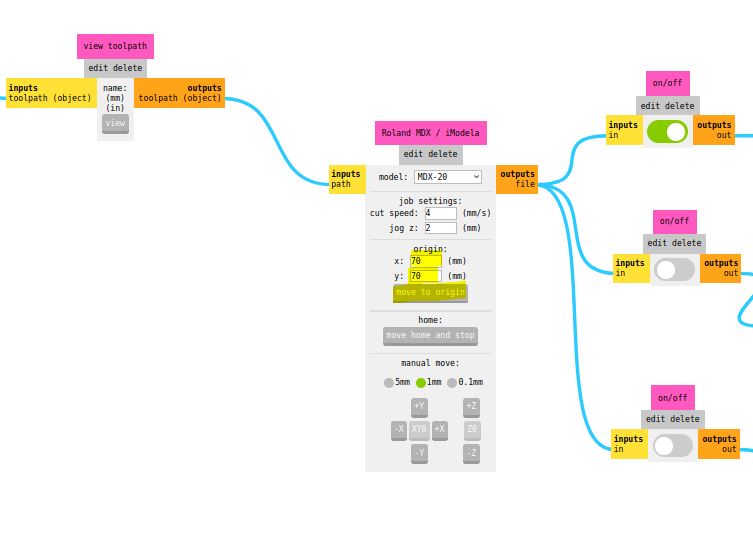

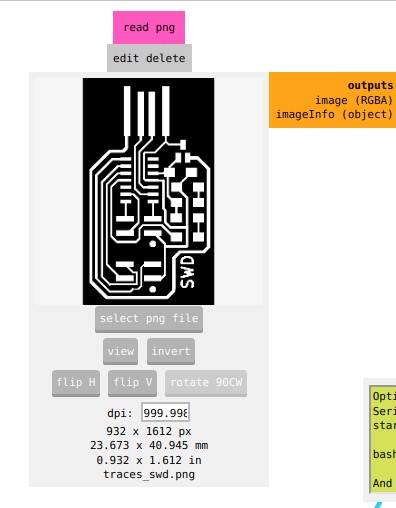

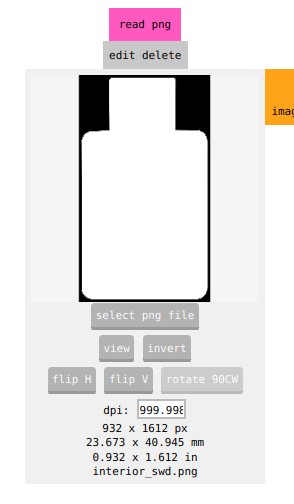

The file is opened to load it inside the mods software with the button select png file at 1200 dpi

We select the cutting tool, which in this case was 1/64" and the offset number that we will give to our machining.

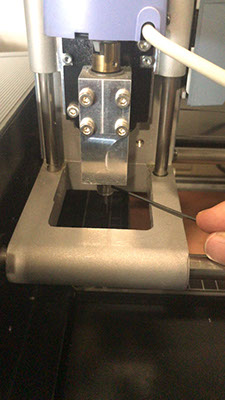

we check the diameter of the selected tool.

We calculate the cut to check the preview.

We select the socket and the port and send machining

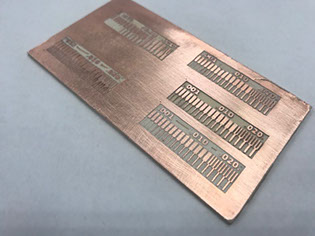

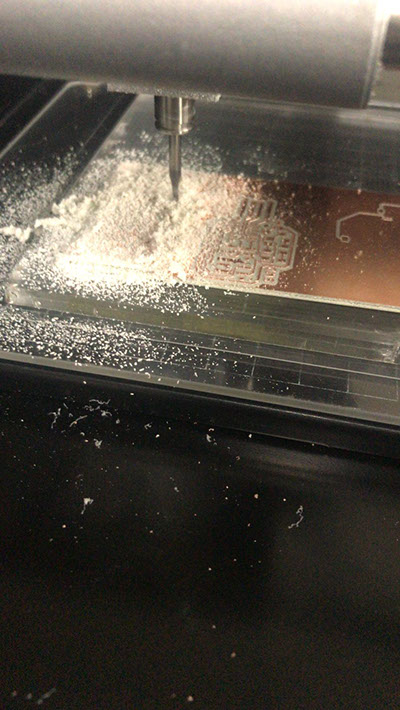

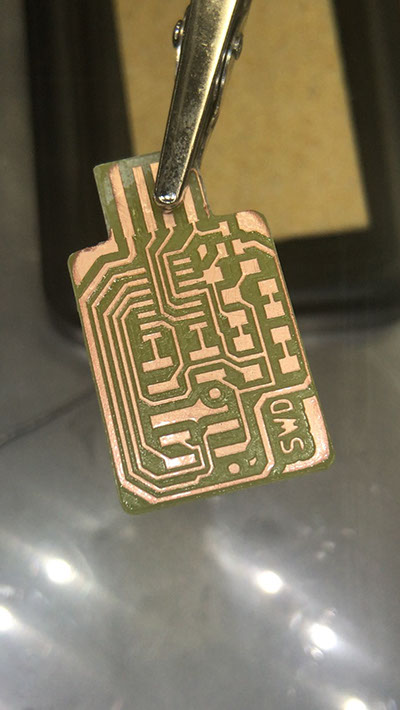

Finally the piece ready and sanded

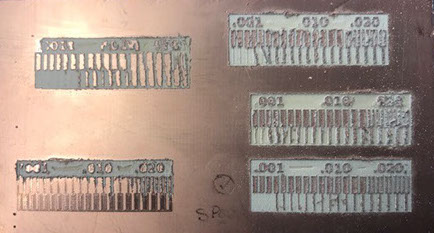

After several attempts it was possible to machine and

keep parts complete

The parameters that we must consider so that the tracks and the texts are complete

- Image at 1200 dpi

- Cutter diameter

- Work space

- Origin of x,y axes

- Z axis height

- Offset number

- Cutting speed

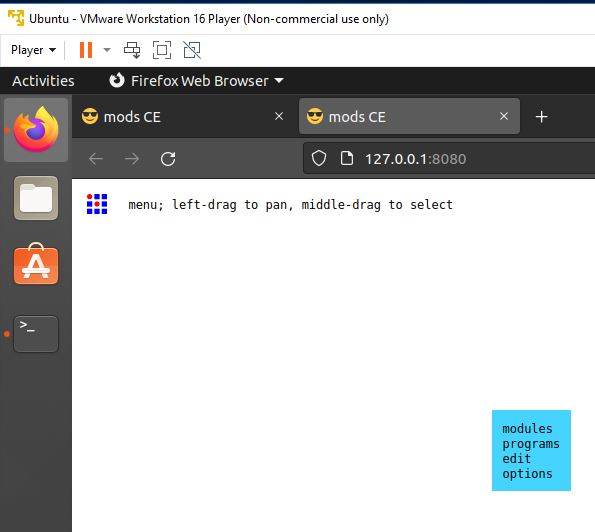

Steps to follow to machine PCB

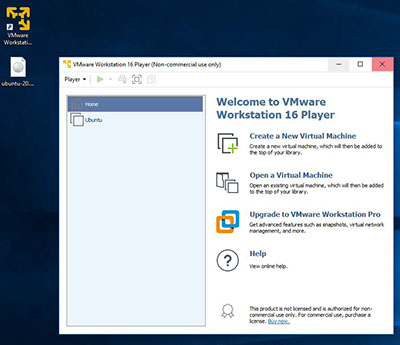

- Turn on PC

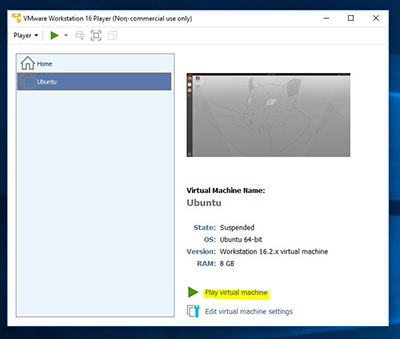

- open virtual machine

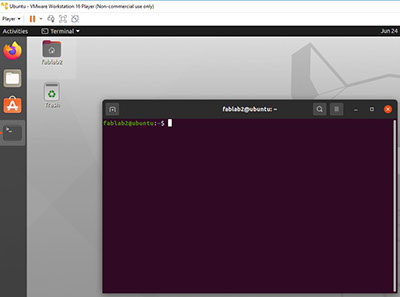

- enter ubuntu

- open terminal

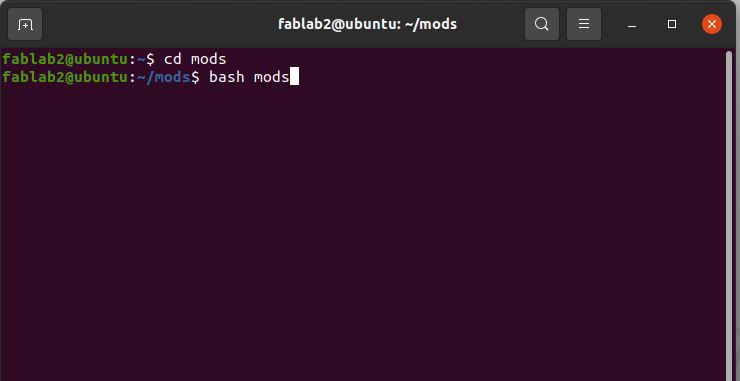

- cd keyboard mod

- typing bash mods

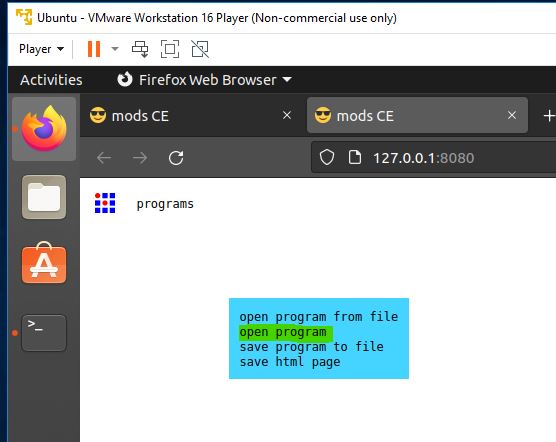

- Already in mods, right click and select open program

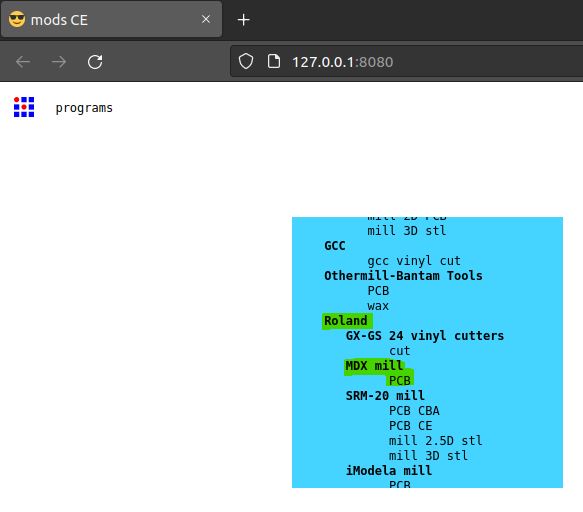

- select "model mdx mill PCB"

- Connect model "mdx 20"

9. Connect model "mdx 20"

- turn on models

- enable model virtual machine connection

- change serial port/serialport Note: for model mdx 40A save file *.rml to use the model (interface) from windows

- open socket and port

- move origin to check connection

- place copper plate

- place cutter p/traces (0.1 mil or 1.64")

- move plate center to calculate working height

- move origin to work origin (for machining)

- load file *png (file)

- Select cutter

- calculate cut (parameters, offset and speed)

- verify origin of work

- send or start cut

- Turn on PC

- Open virtual machine

3.- Enter ubuntu

4.- Click to open terminal

5.- key in cd mods and hit enter

6.- type bash mods and hit enter

7.- Already in mods, right click and select open program

8.-Select "model mdx mill PCB"

9.- Connect model "mdx 20"

-

- Turn on modela

- Enable modela virtual machine connection

c. change serial port/serialport

Note: for modela mdx 40A save file *.rml to use modela from windows (interface)

d.- open socket and port

e. move origin to check connection

f. place copper plate

g. place cutter p/traces (0.1 mil or 1.64")

h. move plate center to calculate working height

i. move origin to work origin (for machining)

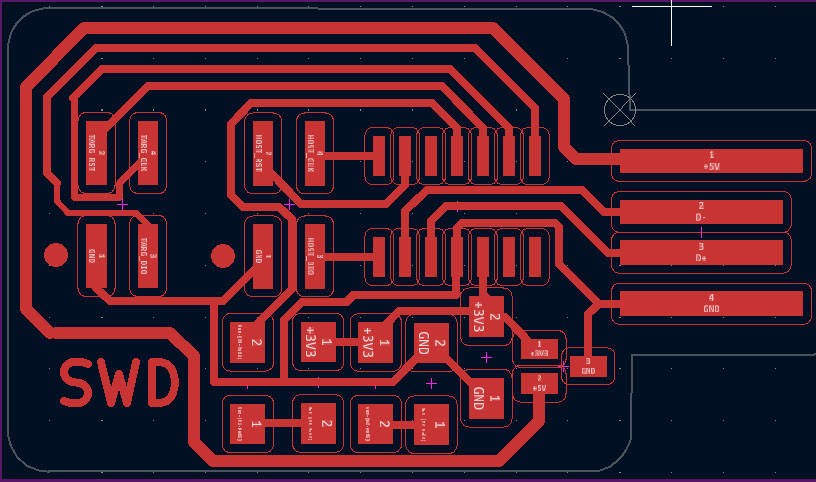

https://fabacademy.org/2020/labs/leon/students/adrian-torres/samdino.html

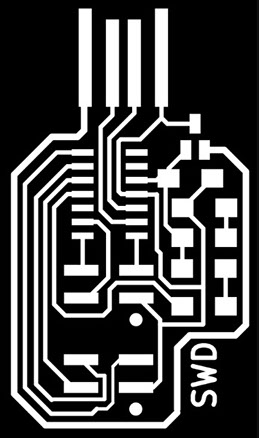

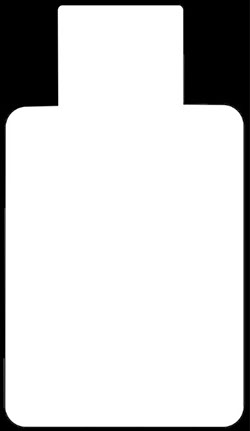

https://fabacademy.org/2020/labs/leon/students/adrian-torres/assignments/samdino/traces_swd.png

https://fabacademy.org/2020/labs/leon/students/adrian-torres/assignments/samdino/interior_swd.png

j. load file *png (file)

k. Select cutter

l. calculate cut (parameters, offset and speed)

m. verify origin of work

n. send or start cut

To send to cut the contour of our plate we follow the following steps:

https://fabacademy.org/2020/labs/leon/students/adrian-torres/assignments/samdino/interior_swd.png

- load file *png (file)

- Use the same track machining origin for X and Y

- Calculate the cut

- Send file to machine

-crop-u40018.jpg?crc=4234167400)

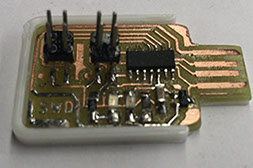

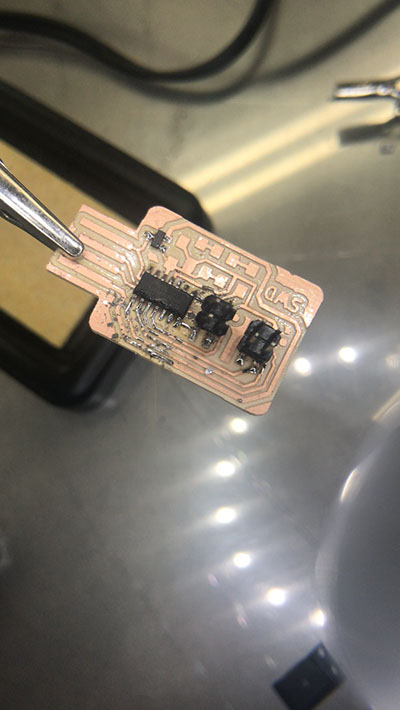

- Final result ready to assemble and solder components

LED Red

LED Green

Resistor 499.0 OHMS

Resistor 499.0 OHMS

Capacitor 10 uF

Regulator 3.3 -0.1 A

AT SMAD IIC

Header to program

other cards

Programmable Header

for our card

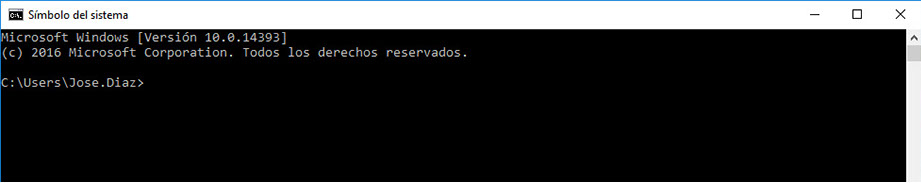

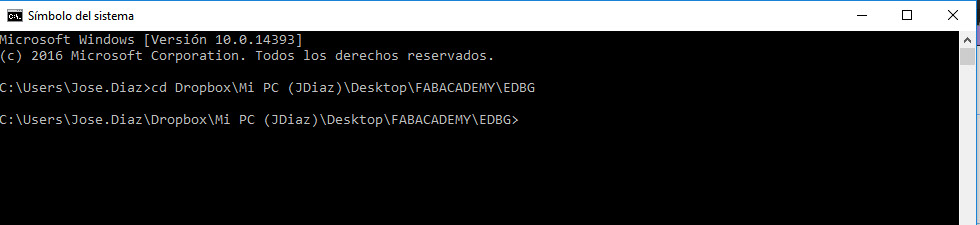

Once the pcb is ready with all the components, we program it with the help of another board and the Command Prompt program (Símbolo del sistema)

We locate in our system the EDBG folder

We change directory using cd space and then paste the address of the folder:

Dropbox\Mi PC (JDiaz)\Desktop\FABACADEMY\EDBG

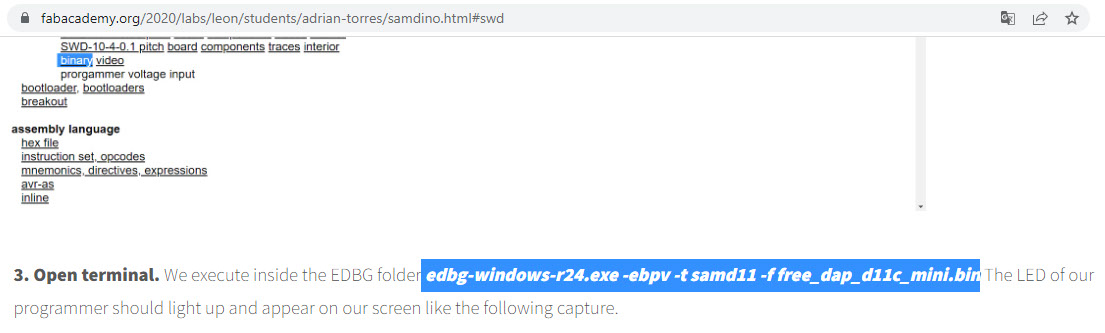

We add the code we got from Adrian Torres' page at FAbLab Leon:

https://fabacademy.org/2020/labs/leon/students/adrian-torres/samdino.html#swd

Comando: edbg -ebpv -t samd11 -f free_dap_d11c_mini.bin

NOTE: edbg It has to be the name of the program as it is in the folder (*.exe)

C:\Users\Jose.Diaz\Dropbox\Mi PC (JDiaz)\Desktop\FABACADEMY\EDBG>edbg -ebpv -t samd11 -f free_dap_d11c_mini.bin

paste the command after the symbol>

edbg -ebpv -t samd11 -f free_dap_d11c_mini.bin

The green LED on the card being programmed indicates that it is

receiving power

Once the card is programmed, the LEDs will light up