3D Scanning and Printing (Group Assignment)

Objective: Test the design rules for your 3D printer(s)

The Fab Lab CDMX have ten 3D printers, but with tree technologies differences: FDM / FFF, Polyjet and SLA

Continuing, it's a resume with the most important description for equipment.

Sindoh DP200 (tree equipments)

Work area effective: 180 x 180 x 150 mm

Technology: FDM / FFF

Nozzle diameter: 0.4 mm

Compatibilities materials: PLA, ABS

Thickness layer: 0.05 ~ 0.4 mm

Filament diameter: 1.75 mm

Figure No. 1: 3D Printing Sindoh DP200

Sindoh 2X (One equipment)

Work area effective: 220 x 190 x 280 mm

Technology: FDM / FFF (double nozzle)

Nozzle diameter: 0.4 mm

Compatibilities materials: PLA, ABS, Flex, PVA (soluble)

Thickness layer: 0.05 ~ 0.4 mm

Filament diameter: 1.75 mm

Figure No. 2: 3D Printing Sindoh 2X

Rostock Max V4 (two equipments)

Work area effective: 28 cm diameter x 35 cm hight

Technology: FDM / FFF (single nozzle, double extrusion).

Nozzle diameter: 0.4 mm (most common).

Compatibilities materials: PLA, ABS, PETG, Nylon, Flex

Thickness layer: 0.05mm

Filament diameter: 1. 75 mm

Figure No. 3: 3D Printing Rostock Max v4

MOAI (one equipment)

Work area effective: 130 × 130 × 150 mm

Technology: SLA

Resolution: 70 micron's

Compatibilities materials: general purpose, flex and lost wax.

Thickness layer: 25, 50 and 100 micra's.

Precision: 0.01 to 0.2 mm

Figure No. 4: 3D Printing MOAI

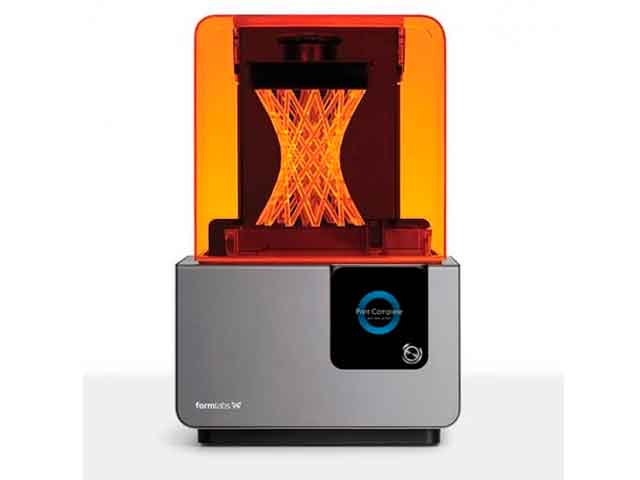

FormLabs Form 2 (One equipment)

Work area effective: 130 × 130 × 150 mm

Technology: SLA

Resolution: 56 micra's

Compatibilities materials: general purpose, flex, mechanical. etc.

Thickness layer: 25, 50 and 100 micra's.

Precision: 25 micra's.

Figure No. 5: 3D Printing Formlab Form 2

Objet30Pro (one equipment)

Work area effective: 290 x 190 × 145 mm

Technology: Polyjet

Resolution: X: 600 , Y: 600 y Z: 900 ppp.

Compatibilities materials: transparent, high temperature, emulate PLA

Thickness layer: 28 micra's (0.0011 in)

Precision: 0.1 mm (0.0039 in)

Figure No. 6: 3D Printing Objet30 Pro

Rostock Max V3 (one equipment)

Work area effective: 25 cm diameter x 35 cm hight

Technology: FDM / FFF (single nozzle, double extrusion).

Nozzle diameter: 0.4 mm (most common).

Compatibilities materials: PLA, ABS, PETG, Nylon, Flex

Thickness layer: 0.05mm

Filament diameter: 1. 75 mm

Figure No. 7: 3D Printing Rostock Max v3

Robot KUKA KR30 adapted for 3D printing

Work area effective: 900 x 600 mm

Technology: FDM / FFF

Nozzle diameter: 3 mm

Compatibilities materials: ABS and PLA

Thickness layer: 0.5 to 2 mm

Filament diameter: Use pellets

Figure No. 8: Kuka adapted for 3D printing

And have tree scans because the different use's, scan buildings, scan objects and scan persons.

Microsoft kinect hacked for use scanning 3D

Work area effective: 1 to 3 meters

Technology: mesh IR and photogrametric

Type files: STL, PLY and OBJ

Scanning 3D with color: Yes

Figure No. 9: Kkinect hacked for scanning 3D

Revscan (Fab Lab's known as Wall-E)

Work area effective: 0.20 to 2 meters

Technology: laser short range

Type files: STL

Scanning 3D with color: No

Figure No. 10: Revscan

Faro Focus 3D

Work area effective: 0.5 to 150 m (correct data) to 400 m (incorrect data)

Technology: laser large range

Type files: VRM, DXF, PTS and IGS

Scanning 3D with color: Yes

Figure No. 11: Faro Focus 3D

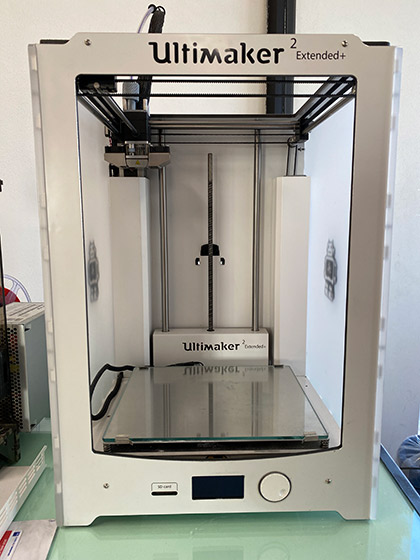

The Fab Lab Queretaro have Ultimaker 2 Extended and work this 3D printing.

To continuing, it's a resume with the most important description for equipment and the probe make this.

Ultimaker 2 Extended

Work area effective: 223 x 223 x 205 mm

Technology: FDM / FFF

Nozzle diameter: 0.4 mm

Compatibilities materials: PLA, ABS

Thickness layer: 0.05 ~ 0.4 mm

Filament diameter: 2.85 mm

Figure No. 12: 3D Printing Ultimaker

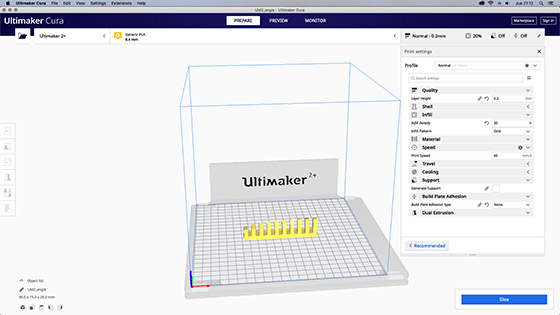

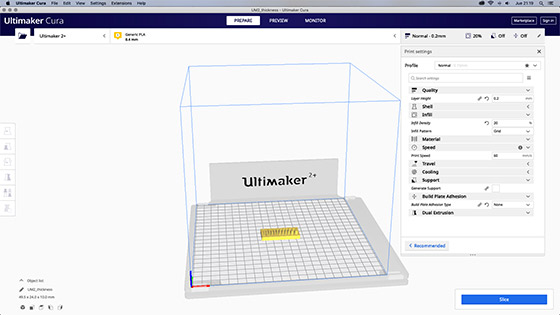

We started with the ANGLE file, sending the STL file to CURA software, and then saving the model as a new .stl (binary) file.

Ultimaker 2+ has a very nice options menu.

All the test were done at:

0.2 mm layer height

20% infill, witha grid pattern

Print speed 60mm/s

No supports

No Adhesion type

Figure No. 13: Software use Ultimaker CURA

Figure No. 14: Probe one

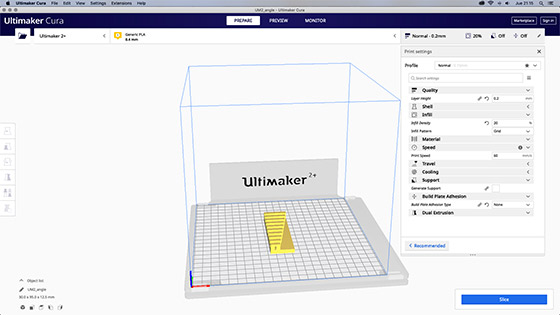

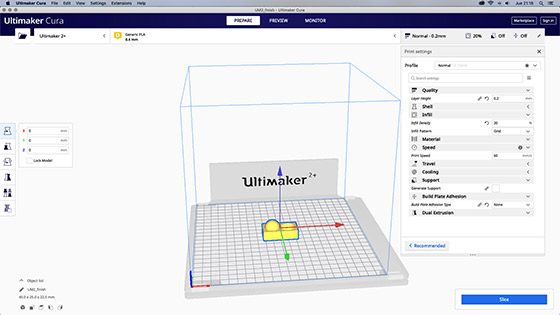

Second, We used the BRIDGING file, sending the STL file to CURA software, and then saving the model as a new .stl (binary) file.

Ultimaker 2+ has a very nice options menu.

All the test were done at:

0.2 mm layer height

20% infill, witha grid pattern

Print speed 60mm/s

No supports

No Adhesion type

Figure No. 15: Send second probe

Figure No. 16: Second probe

Third, We used the THICKNESS file, sending the STL file to CURA software, and then saving the model as a new .stl (binary) file.

Ultimaker 2+ has a very nice options menu.

All the test were done at:

0.2 mm layer height

20% infill, witha grid pattern

Print speed 60mm/s

No supports

No Adhesion type

Figure No. 17: Send third probe

Figure No. 18: Third probe

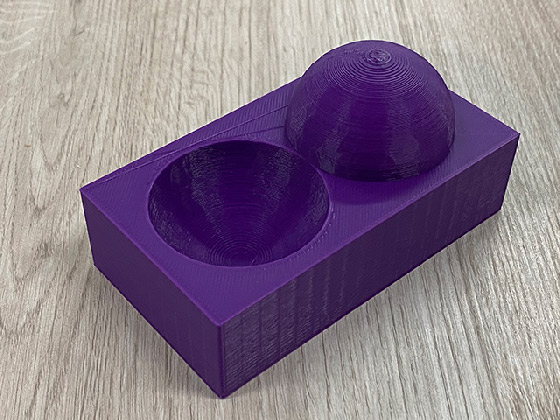

Forth and last, We used the SURFACE FINISH file, sending the STL file to CURA software, and then saving the model as a new .stl (binary) file.

Ultimaker 2+ has a very nice options menu.

All the test were done at:

0.2 mm layer height

20% infill, witha grid pattern

Print speed 60mm/s

No supports

No Adhesion type

Figure No. 19: Send forth probe

Figure No. 20: Forth probe

We have in the workshop a ULTIMAKER 2+ filament based 3d printer.

Overall, the ULTIMAKER 2+ 3D PRINTER is a magnificent desktop device for everyday prototypes, as well as small models.

It can be used for architecture, industrial design and engineering, focusing in a small scale, quite rapid and nice quality finished product.