Jose Alegria - Fab Academy

Molding

and Casting

Assignment

wHAT iS THE ASSIGNMENT ABOUT?

-

Design a 3D mold around the stock and

tooling that you will be using, mill it (rough cut + (at least) three-axis

finish cut), and use it to cast parts.

GROUP ASSIGNMENT:

Review

the safety data sheets for each of your molding and casting materials.

Make

and compare test casts with each of them.

What did I learn:

-

There are a lot of different molding

and casting processes that can be used. Each of them has a very different know

how and has its pros and cons.

1st Step. Setting

up the parameters

As

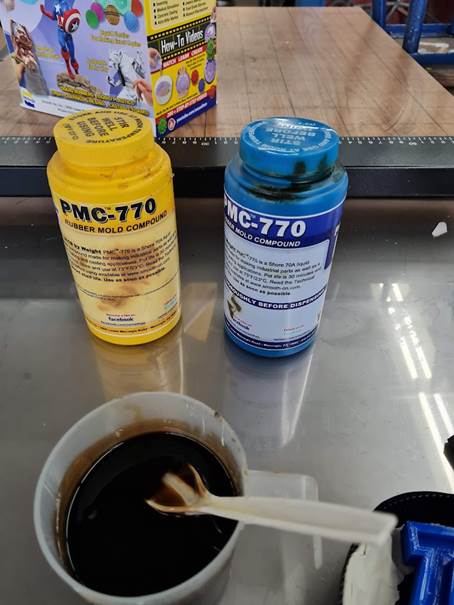

part of the group assignment, we tried to work with different materials to

expand the possibilities of molding in our lab. I took the rubber mold

compound. This requires the fabrication of a positive mold for which I decided

to use 3D Printing. I printed our university informal logo, a letter A, there

was no problem in the material needed to make the mold because this process

does not involve temperature nor mechanical forces. Then, I have to make a

negative mold using the rubber compound, for this I will be using a compound

sold by <<Smooth On>> and denominated PMC-770. Once this is done,

we can cast anything with our mold. For this assignment, I tried casting with

plaster.

So,

this is the list of materials I will be using:

-

Positive: ABS 3D Printing (Datasheet)

-

Negative: Smooth On PMC-770 Rubber

Mold Compound (Datasheet)

-

Casting: Plaster

2nd Step. Making

the positive mold

For

this I used a design that was made by my coworkers using the Anahuac University

Logo. This was made with ABS in our Sindoh 3D Wox Printer. The procedure is explained in the 06 - 3D Printing and

Scanning Assignment.

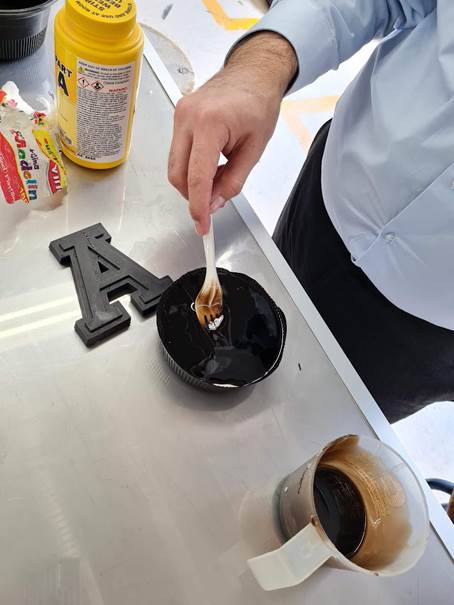

3rd step. MAking

the negative mold

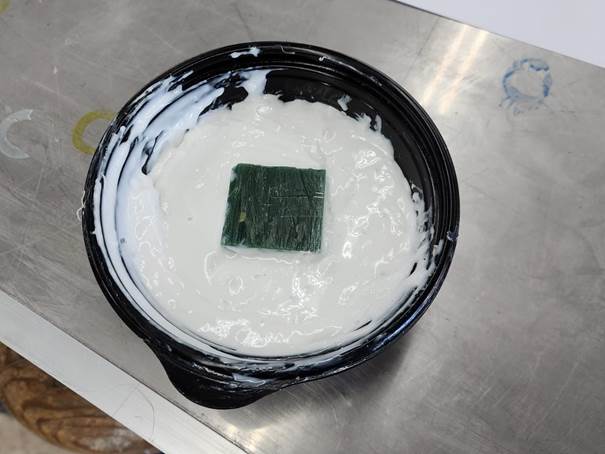

This is the main step of the assignment. Once I

3D printed the positive mold, I started the process to create the negative mold

by thermoforming. This is the procedure followed:

-

Prepare the positive mold and

container with a release agent, this could be of any supplier as long as it

does not damage the materials. The product I applied was the Universal

Mold Release from the same brand.

o

Apply a continuos

coating to model and mold surface and surrounding forms.

o

Brush the release agent to minimize

air entrapment.

o

Apply another coating and let stand

for at least 5 minutes.

-

Pour both compounds in a 1:1 weight

ratio in a different container

-

Mix it thoroughly for at least 3

minutes.

-

Pour the resulting mix in a single

spot at the lowest point of the container, let the rubber seek its level up and

over the model. The liquid rubber should level off at least 1 cm over the model

surface.

-

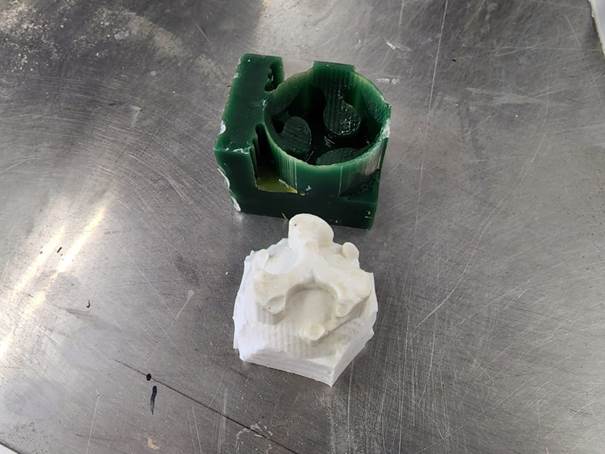

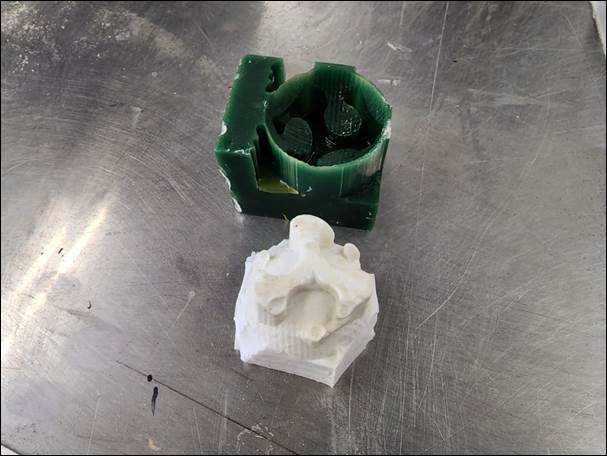

Allow the mold to cure at room

temperature for at least 16 h.

-

Release the mold and apply again the

release agent before using it to cast a model.

4th step. Casting

Having already

a negative mold, I continued to the casting step of the assignment with a

polymeric resin. The process consists in mixing the resin with an activating

compound to start a chemical reaction. This process can be seen in the

following video.

The

resin-activator ratio should be between 100:1 and 100:2.

Second

casting

I made a second iteration of this

assignment by changing the materials used and the way I made the mold. This

time I used a wax mold instead of 3D printing the negative. To do this I used a

Fablab logo to get the tilted surface I needed for

the assignment. Then, I will be using this wax mold to cast a soft rubber

piece.

1st Step. Setting

up the parameters

For

this part, I was going to make a mold milled into wax, then I will cast a soft

rubber piece out of it.

So,

this is the list of materials I will be using:

-

Negative: Wax

-

Casting: Rubber compound (Poliformas Molduflex)

2nd Step. Making

the NEgative mold

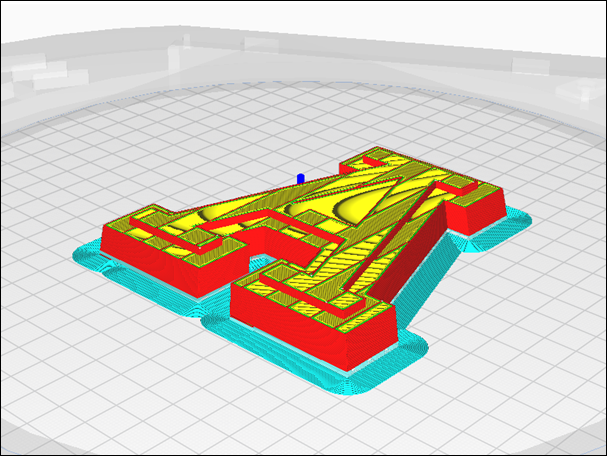

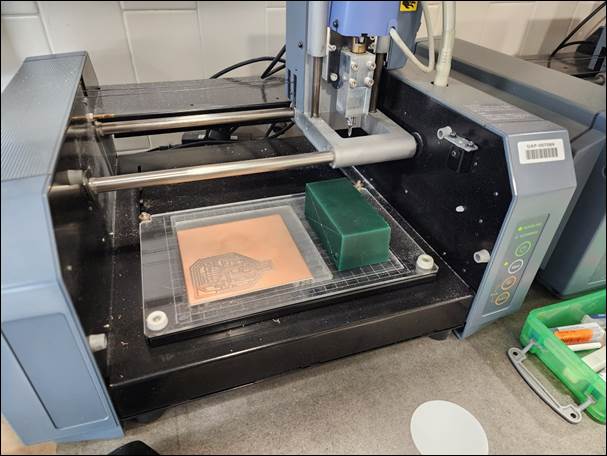

For

this, I used the design of the Fablab logo to make a wax

mold, to do this I exported the file as a .stl in order

to be able to create the gcode file that will be used

by the Modela MX-40 to mill the mold.

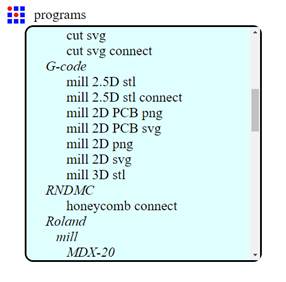

To

do the conversion from stl to the gcode

I used the mods app, then opened the

server program called mill 2.5D stl and finally followed

the steps from a tutorial

made for the Fabacademy by the Kannai Fablab.

3rd step. Casting

the piece

This is the main step of the molding and casting

assignment. This is the procedure followed:

-

Prepare the negative mold and

container with a release agent. The product I applied was the Universal

Mold Release from the first part of the assignment.

o

Apply a continuous coating to model

and mold surface and surrounding forms.

o

Brush the release agent to minimize

air entrapment.

o

Apply another coating and let stand

for at least 5 minutes.

-

Before mixing the rubber compound you

need to measure the quantities needed, for this I filled the container with

water and measured the height needed to cast the piece I needed.

-

Once I know the quantity I had to set

the catalyzer apart in a ratio of 2%-3%, which means around 100 droplets per

each 100 g of rubber compound to be used.

-

Pour both compounds in a 1:1 weight

ratio in a different container

-

Mix it thoroughly for at least 5

minutes.

-

Pour the resulting mix in a single

spot at the lowest point of the container, let the rubber seek its level up and

over the model. The liquid rubber should level off at least 1 cm over the model

surface.

-

Allow the piece to cure at room

temperature for at least 6 h.

-

Release the piece.

-

Cut away the discardable material.

Conclussions

This assignment showed us that there

are many ways to make a mold and cast anything into it. I incorporated the

digital process at 3D printing the original model at first, and by milling the

mold with the Modela at the second iteration.

Nevertheless, the mold fabrication and the piece casting is still manual.

Original

Files

Nueval

Checklist

-

Linked to the group assignment page and reflected on your

individual page what you have learned.

-

Reviewed the safety data sheets for

each of your molding and casting materials, then made and compared test casts

with each of them.

-

Documented how you designed your 3D

mold and created your rough and finish toolpaths for machining, including

machine settings.

-

Shown how you made your mold and cast

the parts.

-

Described problems and how you fixed

them.

-

Included your design files and hero

shot of the mold and the final object.

2022