Jose Alegria - Fab Academy

3D

Printing and Scanning

Assignment

wHAT iS THE ASSIGNMENT ABOUT?

This is the first approach to 3D printing and

scanning. The goal is to create something by ourselves.

1st Step. Group

Assignment

The group

assignment was to characterize the 3D printing machinery available in our

fablab. We got one 3D printing test file and printed it with all the 3D

printers in each of the different labs.

·

Assignment

3. Group Assignment. 3D Scanning and Printing.

We

worked with one of the printers for each one of the students in Mexico City.

2nd step. Using

the printer

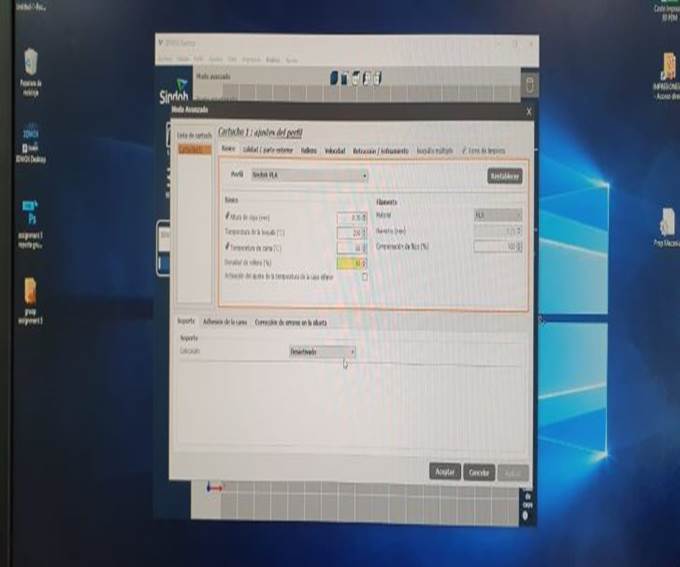

Once the

local equipment was characterized, we could start making the first tests to be

able to understand the logic behind the 3D printers. This was a very important

step, because while we were doing the group assignment only one person at a

time can control the equipment. So, the first thing I learned was that the

equipment we have in our Fablab there are two standard setup menus: basic setup

and advanced setup. The basic setup has a few default settings whose main goal

is to ensure the correct execution of typical work, while the advanced setup

gives us the chance to modify certain parameters to achieve one or more of the

following goals: a reduction in material usage, a reduction in time of

execution, and/or to develop figures or geometries which the basic settings

will not do, mainly through the construction of custom supports or bases.

3rd step.

Designing process

We were told

that the assignment was to be able to print a design that was not achievable

through a subtraction process (i.e., cutting), so I started visiting webpages

to learn what has been done with 3D printers, and to understand the reason to

use this process and not laser cutting. During this research, I found that one

of the functions that I could not find in our laser-cutting assignment was to

achieve joints that were able to move, and that there are hundreds of examples

where people can get their models to move through this joint. To understand the

process behind these pieces I printed one model that I downloaded from the web.

With this, I accomplished two objectives, to use the printer and get to know

the consequences of moving the parameters and settings, and to check how did

other people had built these joints.

4th step. Making

my own design

Once I knew

what I needed to do, the next step was to start making the design of my own

prototype. The goal is to continue testing different materials to build the

bridge I designed the last assignment:

·

Assignment

3. Laser-cutting.

I had

to develop new joints for the bridge, this time they were made using

3D-Printing. Using the information obtained from the last example (the

hummingbird), the beams were designed thinking in letting them move freely in

one axis, just as the truss elements work in larger designs.

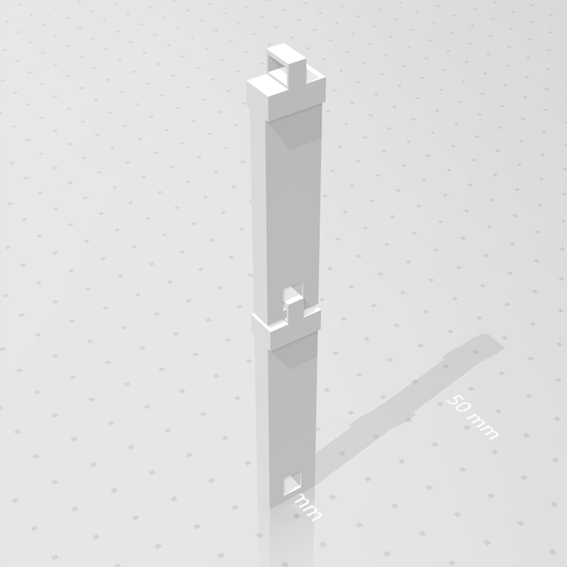

Once

the design requirements were defined, I started designing them in Fusion 360.

The beams were designed to be interlocked to deter movement in two axis and to

provide free movement in the other one. As with every design made for this

course, the design has parametric constraints to allow size changes to be done

without any difficulties.

5th step. 3d

Printing

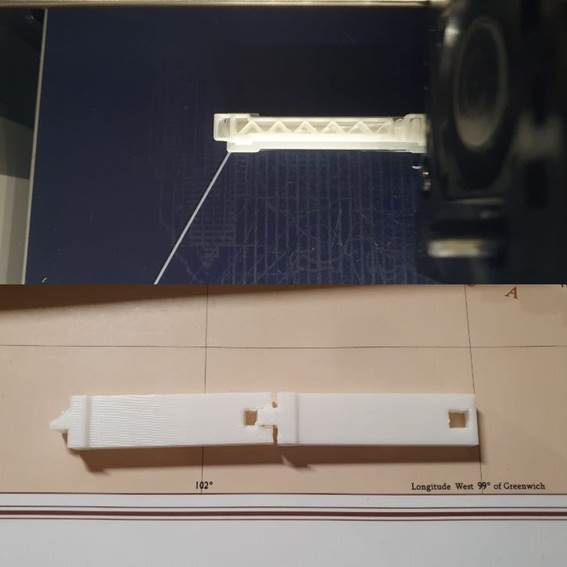

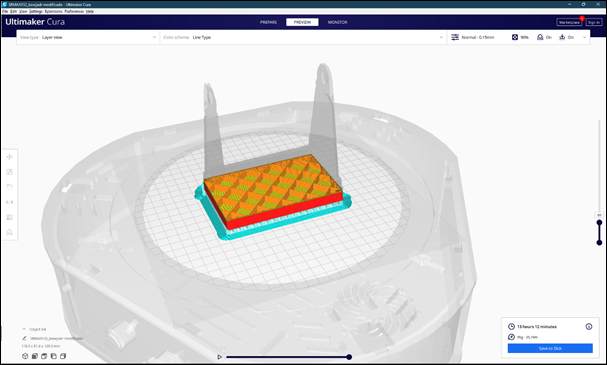

Finally, I had the joint design

ready. Then, I converted the file into a format that the printer would

recognize [stl] and proceeded to print. There were a

few problems at the beginning because the model wouldn't stay up, After

evaluating using different kinds of internal supports, The main axis was rotated

so that the plastic had time to cool down and gain resistance, so finally it

worked and the model was printed.

6th step. Further

changes

Once

it was printed, I noticed that my design can be upgraded, for example, I could

fillet the edges so each piece could rotate freely without bumping into the

next piece, and that I could change the joint into a circle so the design would

not require any more support that I had to take away after the printing.

I

will make these upgrades during the following days so I could get all the

pieces together and build the truss bridge.

7th step. Final

project 3D Printing

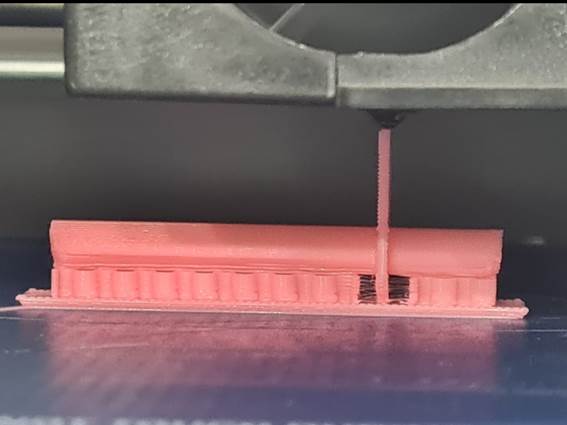

For

my final project, I have two components which are going to be 3D printed: a

bucket and a device to translate the movement from the bucket to the sensor,

these two components have different needs, mainly because one of them is larger

and made with a square design, the other one is not only smaller, but it needs

to be completely round and of an exact diameter.

The

first part was easily printed in the 3DWOX printer, which is the most used

printer in the lab, and having good overall results.

The

second component was printed in the same printer, but as the diameter is not as

precise as expected, it became very difficult to assemble once in the main

project.

The

fastest solution was to use an Objet 3D Printer, this

is a different technology printer as it uses a PolyJet

technology to print with a fluid material instead of using a filament thus

rendering possible to create an almost perfect circle in the small diameters I

am using (1 mm – 1/24 in.).

8th step. Scanning

Scanning

is a process where we can convert any object into a 3D file to be able to work

with it or simply to print it. This process may be achieved with different

kinds of scanners that are available in the market. Each scanner is optimized

for an specific purpose, so, when choosing the scanner to be used, you should

take this into account (in this case is even more important than in any other

equipment available in the Fablab).

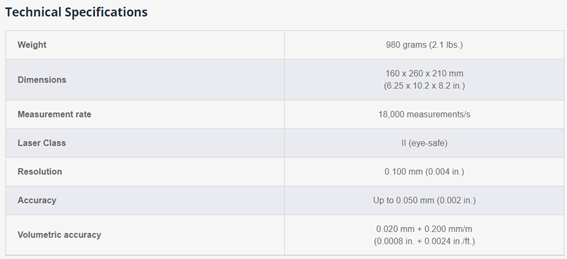

My

first approach was with the Creaform Revscan Scanner. This is a reverse engineering and design

applications dedicated scanner. This means that we will have a very high

resolution file, but that limits the size of the object to be scanned.

It

starts with defining the size of the file you will be getting after the

scanning process, that will help to set the resolution that you are going to

need, this is very important because with this equipment you can get large

files that will become difficult to manage.

Once

you define the resolution, there are two ways to make the actual scanning:

1.

Grid of points: You should tape or

paste all over the object to be scanned a grid of reflective points that will

help the scanner to navigate around the object, allowing you to start in any

position and pause the scanning process without having any troubles to finish

the work later. Once you have made a pre-scan to let the scanner make a map of

the reflective points, you can start with the thorough scanning process, which

will be automatically adjusted into the reflective points map. This process is

easy and effective when scanning an object that lets you paste the reference

points.

2.

Direct scanning: If you cannot paste

the reflective points, then you can still make the scanning but without a

reference grid that allows you to restart the scanning process at any point.

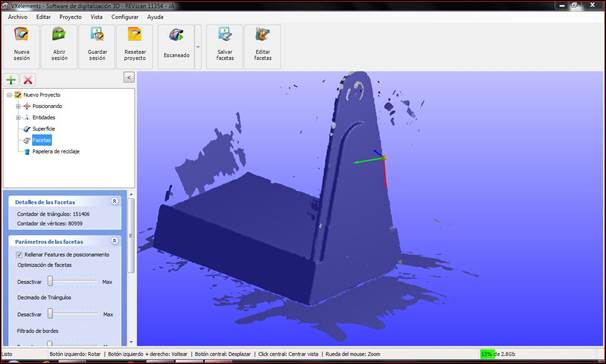

For

this assignment we decided to scan the lower base of my colleague Jose Antonio.

I followed the same steps:

1.

Use the position features to allow the

scanner to navigate around the object:

2.

Scan

the surfaces and create an object within the system.

3.

Correct the surfaces by erasing the

areas not intended to be part of the 3D object.

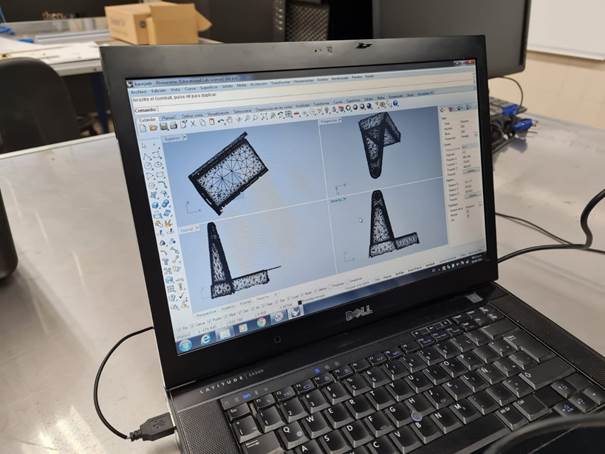

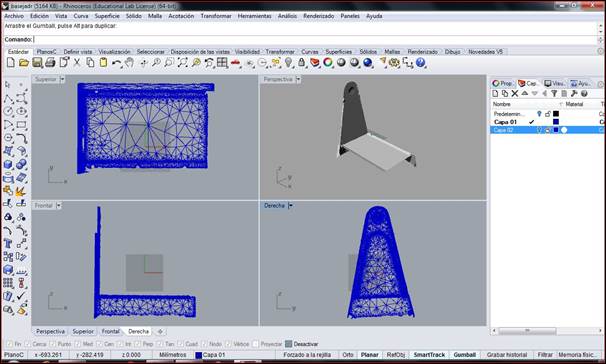

4.

Export the file and modify it by

adding the second part of the object. I did this because it was a symmetric

object that could be easily get finished with Rhino. If not, we could just finish

the scanning process.

5.

Export the final object as a stl file.

Conclussions

It was important to learn that there

is no perfect technology to create something, the PolyJet

is more expensive but has a higher precision, on the other hand the Filament 3D

Printer can help me to easily create different versions of the object I am

trying to design, allowing me having different versions and analyze the

advantages of each one.

Original

Files

If you wish to see or download the original

files, please follow the links:

1.

Fusion

360

2.

STL

File

Nueval

Checklist

1.

Linked to the group assignment page.

2.

Explained what you learned from

testing the 3D printers.

3.

Documented how you designed and made

your object and explained why it could not be easily made subtractively.

4.

Documented how you scanned and

prepared an object (for 3D printing).

5.

Included your original design files for

3D printing (both CAD and common format for 3D printing.

6.

Included your hero shots.

2022