Molding Casting

Objective for this assignment :

The assignment was to read the safety data sheet for different casting material and make a test cast with them.

To make the mold we used one of the current student's wax model.

What is a Mold ?

A mold is a hollow container used to give shape to molten or hot liquid material when it cools and hardens.

What is a Casting?

An object made by pouring molten metal or other material into a mould.

OOMOO-30

OOMOO-30 was used to make the mold.

* OOMOO 30 has negligible shrinkage.

* Volume ratio part A : part B , 1A : 1B

* Mix ratio 100A : 130B by weight.

* OOMOO 30 has a 30-minute pot life, with a six-hour cure time.

Find OOMOO 30 Datasheet here : OOMOO 25/30

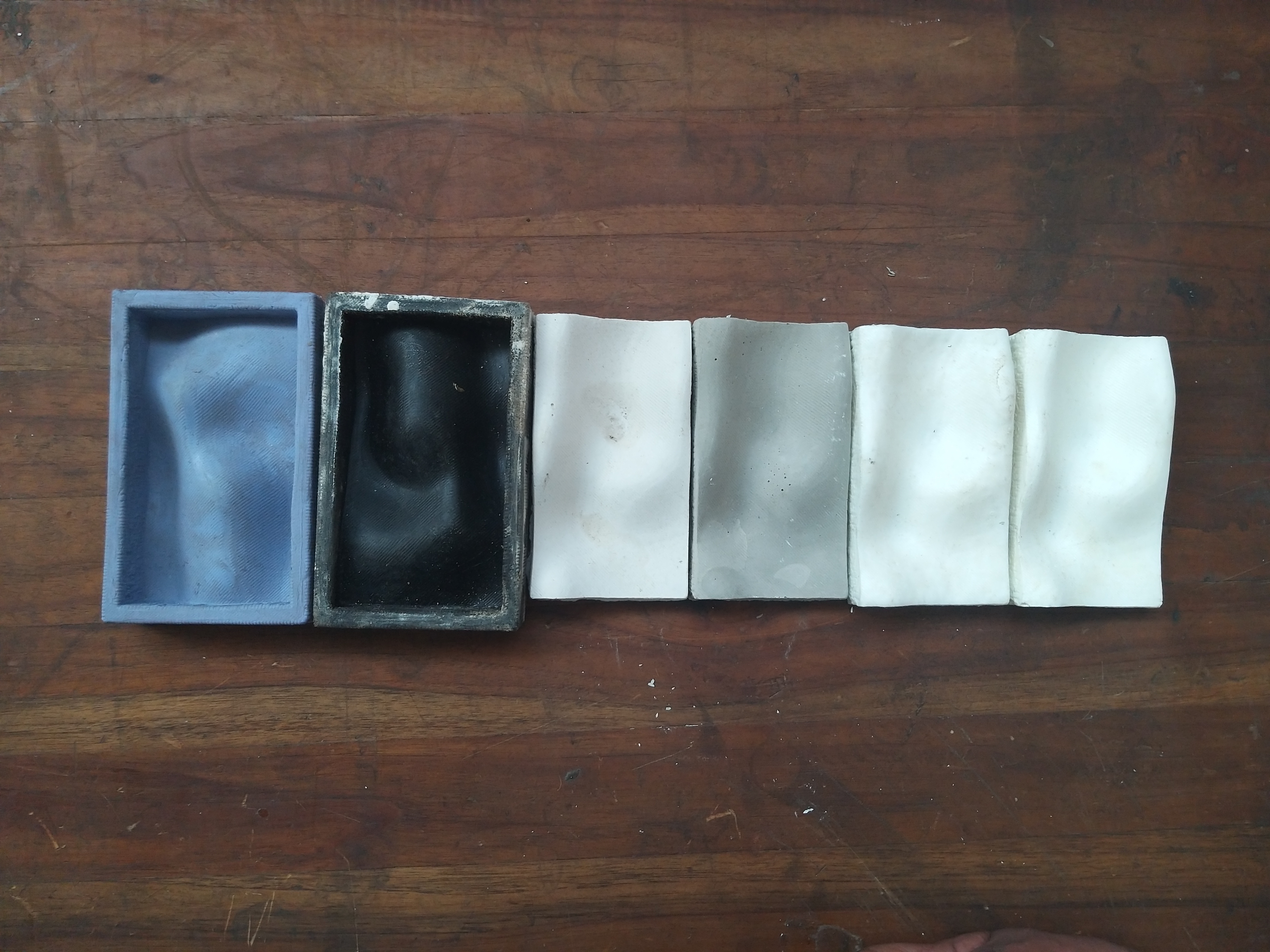

OOMOO 30 Mold

PMC-780

To make mold we used Smooth-On PMC -780 DRY.

* Mix Part A and Part B in 1:2 ratio

* Pour your mixture in a single spot at the lowest point of the containment field.

* Curing - Allow the mold to cure (at least 48 hours) at room temperature (73°F/23°C) before demolding. Do not cure rubber in temperatures less than 65°F/18°C.

* Post Curing - After rubber has cured at room temperature, heating the rubber to 150°F (65°C) for 4 to 8 hours will increase physical properties and performance.

* Performance & Storage - Fully cured rubber is tough, durable and will perform if properly used and stored.

Safety Instructions

-Materials should be stored and used at room temperature (73°F/23°C).

-Humidity should be low

-Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

-Good ventilation (room size) is necessary.

Find OOMOO 30 Datasheet here : PMC-780 Dry

PMC-780 Mold

What is a Casting?

An object made by pouring molten/liquid metal or other material into a mould.

SmoothCast - 300 and 305

The Smooth-Cast® 300 Series of liquid plastics are ultra-low viscosity casting resins that yield castings that are bright white and virtually bubble free.

Easy to measure and mix - 1:1 mix ratio by volume - no scale required

Low viscosity - captures excellent detail - no degassing necessary

Resin cures to a bright white finish.

Find SmoothCast 300 Series Datasheet here : Smooth cast-300 Dry

Find SmoothCast 305 Series Datasheet here : Smooth cast-305 Dry

USG DryStone Casting Media

USG Drystone™ Casting Media is a unique product designed for the fabrication of solid cast interior use pieces. Because it requires absolutely no drying, it can be cast, painted, packaged and shipped in a single day. Placing the cast piece(s) in front of a fan yields a finished product in two hours that can be decorated in roughly 2-4 hours (after setting) with typical paint.

-For 100 Parts of drystone 18-20 parts of water must be mixed

-Curing takes about 30mins with the pot life of 10 mins

-Eliminates the need for expensive drying procedures

-Achieves the highest compressive strength in its category and highest early “green strength”

-Provides an environmentally safe alternative to resin-based products with respect to air quality

-Can be used with the majority of mold materials including silicone, latex, and urethane

-Offers a high density that produces a quality feel and excellent duplication of intricate details

-Can be aggregated for a variety of looks and feel.

Find Drystone Casting Media Datasheet here : Drystone

USG HydroStone® Super X Gypsum Cement

USG Hydro-Stone Super X Gypsum Cement is extremely hard, has high compressive strength, and has high water absorption resistance while giving extremely fine detail duplication.

-Use potable water at temperatures between 70 °F (21 °C) and 100 °F (38 °C).

-For 100 Parts of HydroStone 20-22 parts of water must be mixed

-Curing takes about 30mins with the pot life of 10 mins

-Sift or strew USG Hydro-Stone Gypsum Cement into the water slowly and evenly. Do not drop large amounts of USG Hydro-Stone Gypsum Cement directly into the water as proper soaking of the USG Hydro-Stone Gypsum Cement may not occur.

-To prevent air entrainment and provide a uniform, smooth surface, careful pouring of USG Hydro- Stone Gypsum Cement slurry is necessary. Agitation/vibration of the filled mold is a further step used to prevent air at or near the mold surface.

-All casts should be dried as quickly as is safely possible after manufacture so that maximum physical properties can develop. Dry to a constant weight.

-The maximum temperature at which USG Hydro-Stone Gypsum Cement molds are safe from calcination is 120 °F (49 °C).

Find HydroStone Casting Media Datasheet here : HydroStone Dry

Cast Output

1. OOMOO-30

2.PMC -780

3.Gypsum

4.Hydrostone X

5.Smooth Cast 300

6.SmoothCast 305