Inspiration

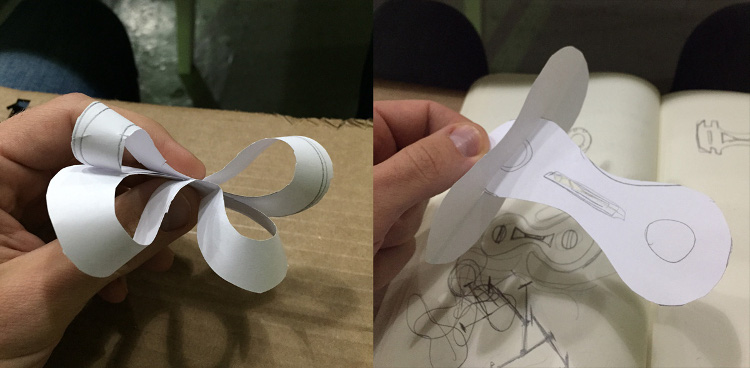

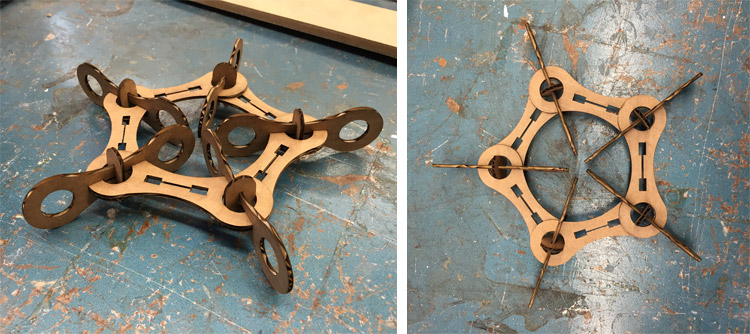

I started the process with a brainstorming session using some paper shapes cutted by hand, just to make the 3D imagination easier. My design inspiration was from Holger Strom, his most famous project is the IQlight.

"Infinito" / press fit construction kit

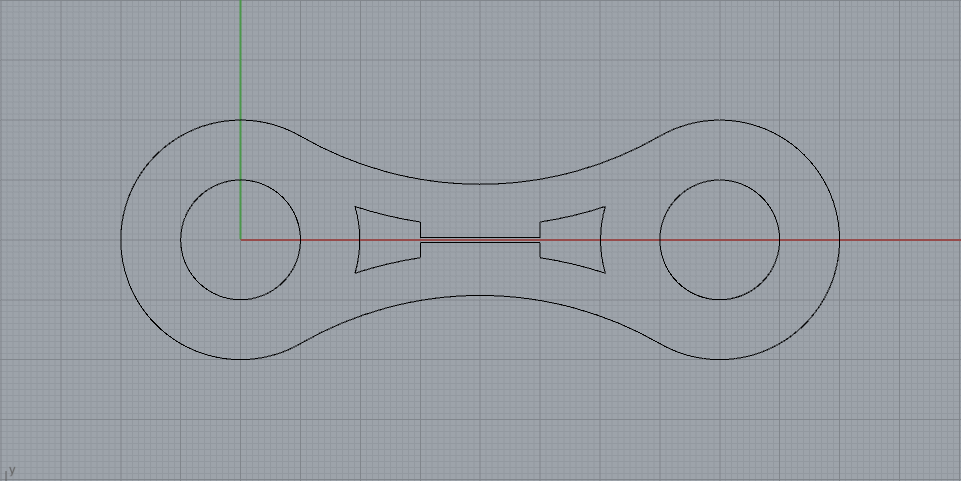

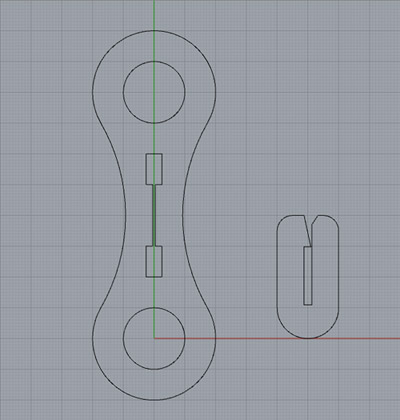

Software used:After the brainstorming I started to design the shape that I tried on paper. Here's my first draw:

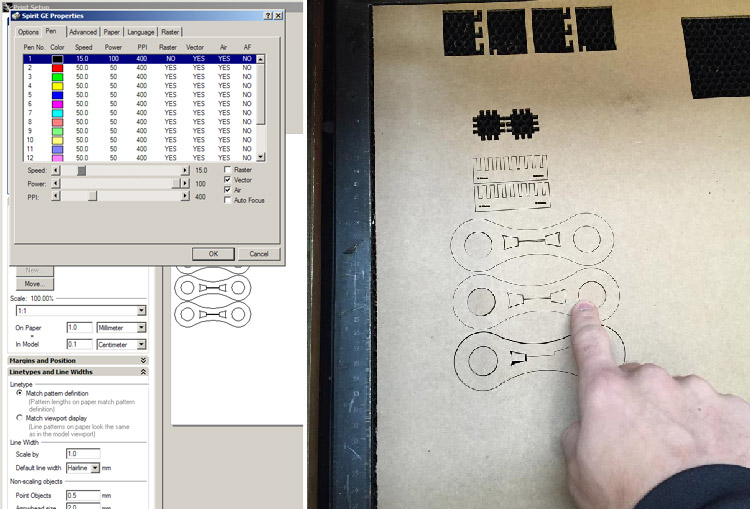

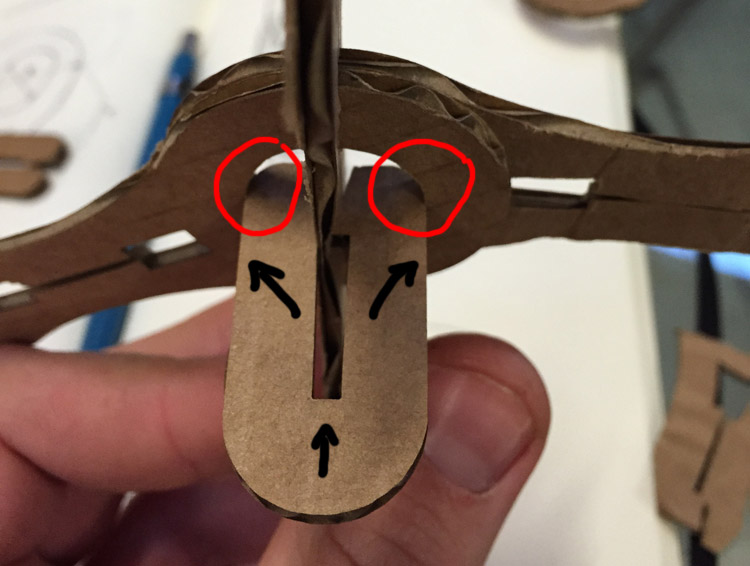

So I went to the Laser cutter to make 3 pieces of my first draw, using 3mm cardboard, and also to make a template with 8 rectangular different sized cuts since 2.8mm until 2.0mm, it helped me to know witch dimension will be better fitted. Then I discovered that the perfect width of the cut to fit two pieces together with 3mm cardboard is 2.5mm.

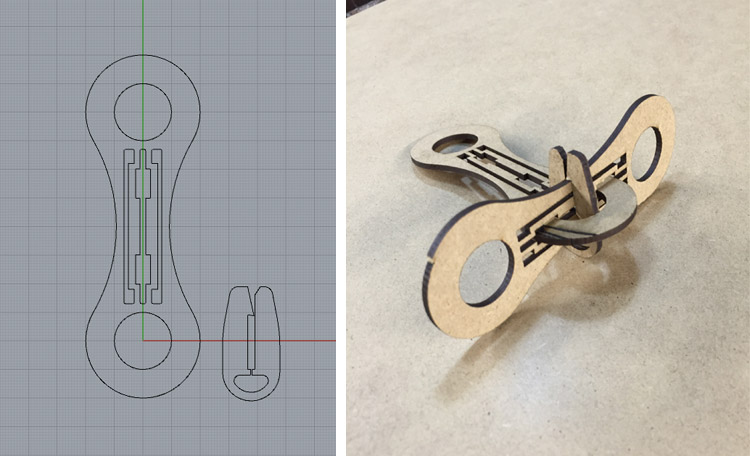

I also discovered that my draw should be changed in some points because it was too loose. So I made some changes and created a new piece to avoid that the assembly breaks a part. Another important thing that I noted with this first trial, to my project works fine, is the cardboard fiber direction, it must be parallel to the largest dimension of the piece otherwise, due the snap system, it won't have the enough strength to push against the next piece. Here's the new draw with the new "clip":

The clip also had to be changed because I made the width with the same dimension of the hole where it should pass, but as you can see in the picture below, this piece has a snap system that makes it open a little before fit, so I removed some material form both sides of the clip and it's fine.

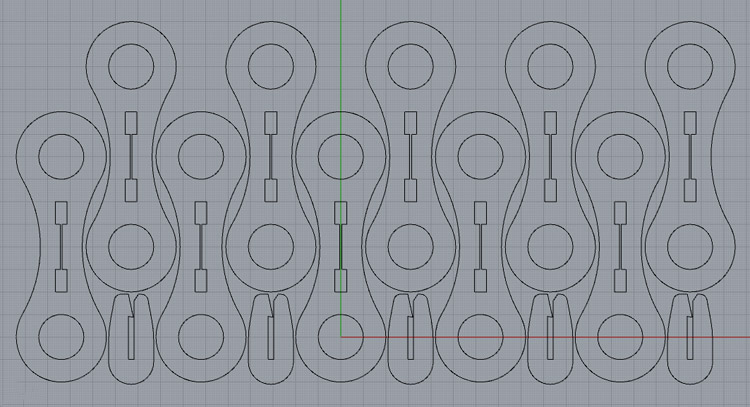

A nice thing about this project, besides the endless possibilities to assemble it, is the nesting result that improve the material usage, as you can see below. Here's the Infinito press fit construction kit final version:

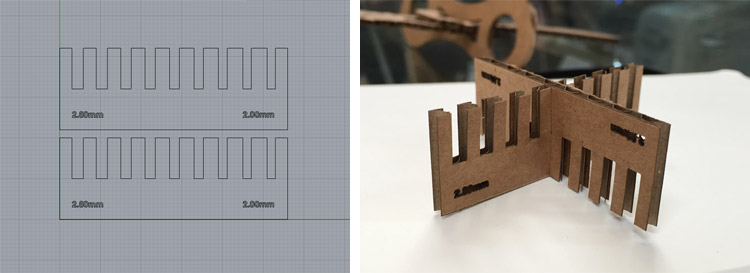

I decided to make a wood version with this same concept. The material that we have is a 2.5mm MDF. So I made some changes on the drawing trying to adapt it since there's a diference between the material thickness and hardness. The MDF needs more space between the pieces and I made some rips, trying to turn it more flexible, on strategic points to facilitate the assembly.

Unfortunately it didn't work the MDF broke, but I think it could be possible if added some chamfers on the edges of the middle hole, causing a better distribution of the forces, and also increasing the material thickness.

Final result

| File | Material | Machine |

|---|---|---|

| infinito.dxf | Cardboard (3.0mm) | Lasercutter |

| infinito.3dm | Cardboard (3.0mm) | Lasercutter |

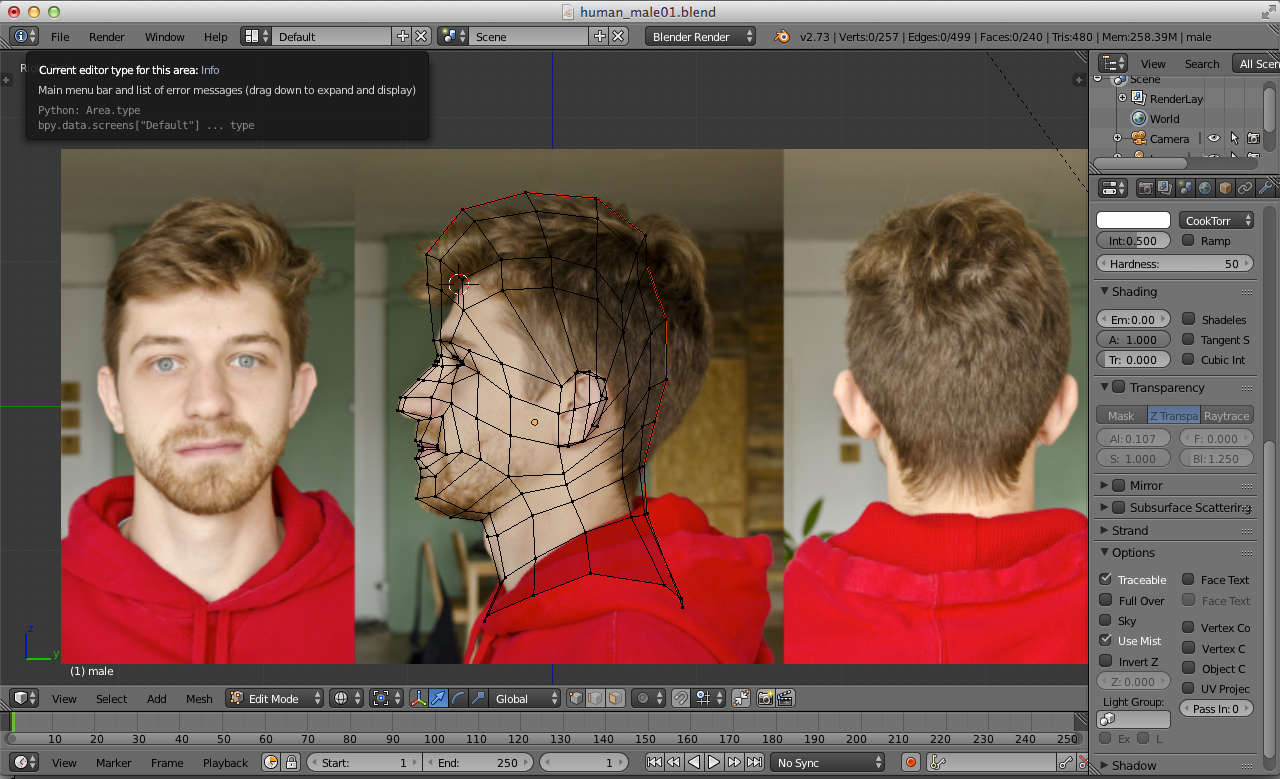

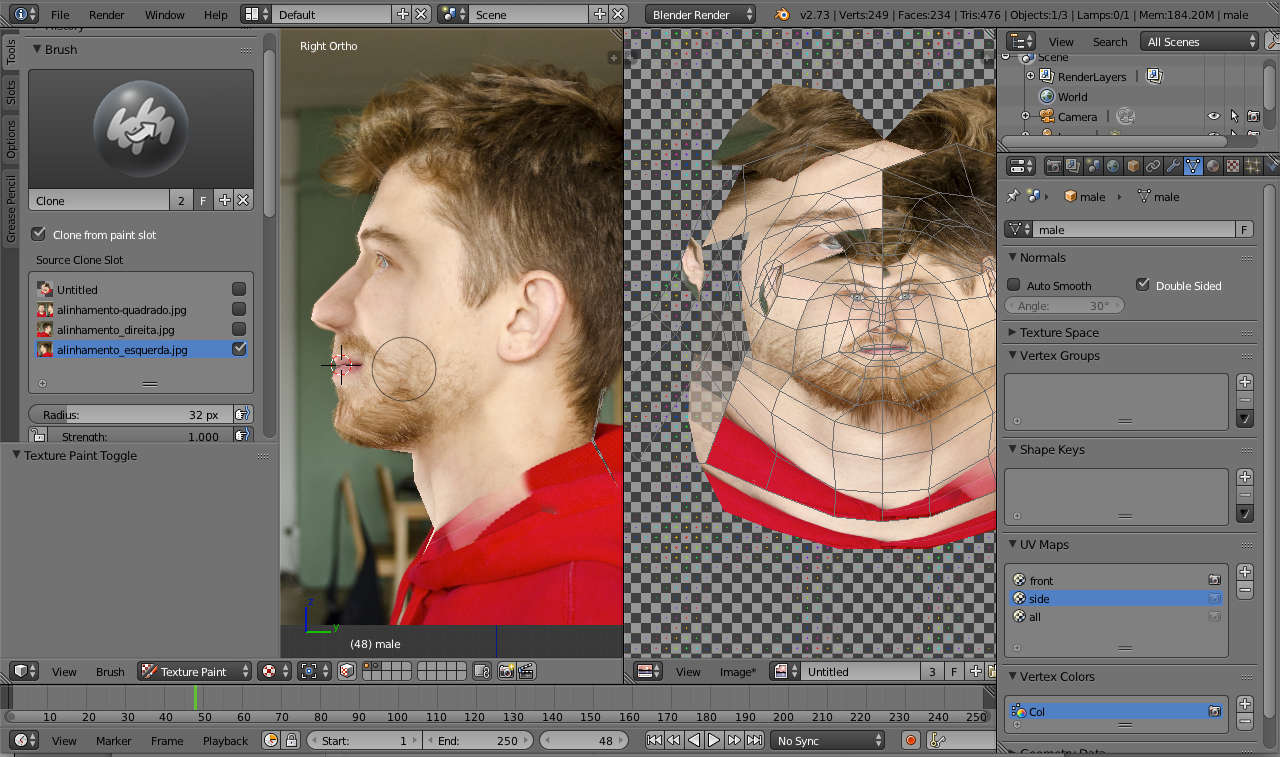

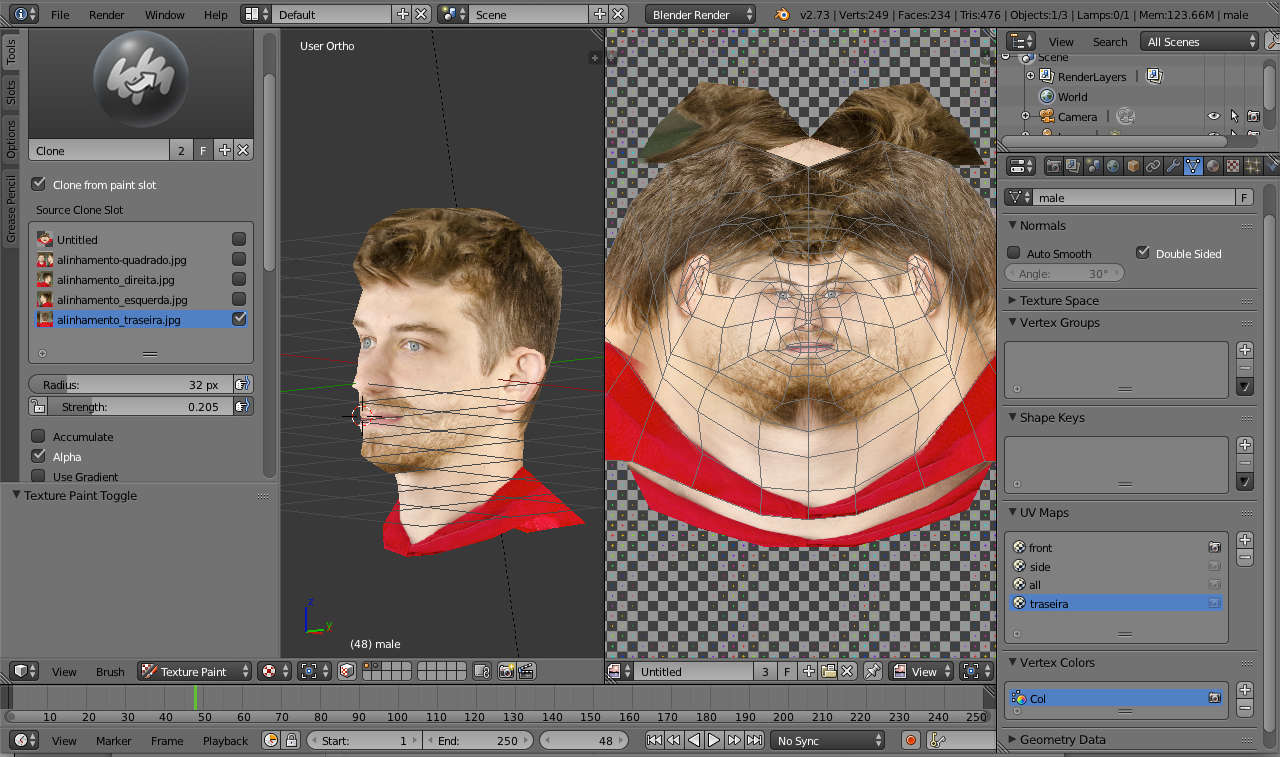

Paperhead

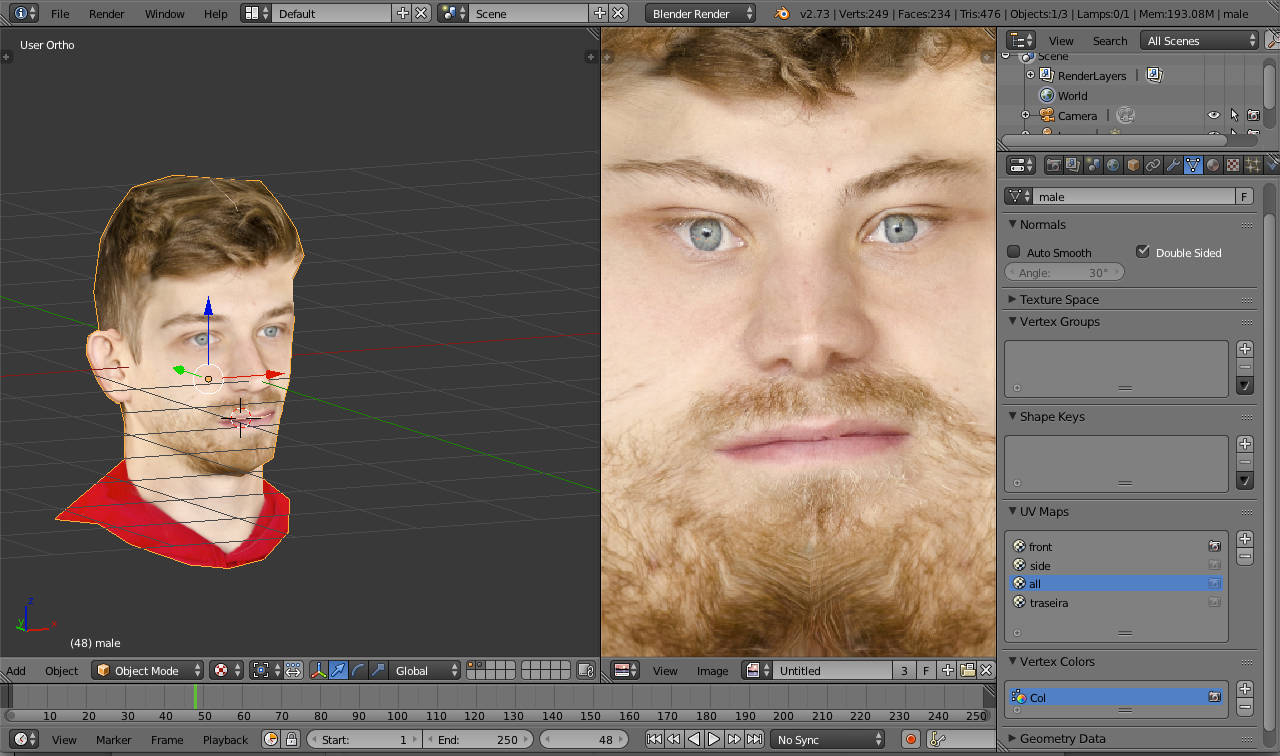

I started to make a paperhead using Blender and 4 pictures of my head. The ideia is make something like that:

I'm wondering to make a tutorial, as soon as I finish the paper model, to show how to do make it.

| ← week 2 / computer-aided design | week 4 / eletronics production → |

|---|