A Twist for a Spin: Controlling a DC Motor with a Potentiometer

You remember last week when I was boasting about my soon-to-be very own Théoduino? Well, I kind of ended up putting it on hold. I spent one day trying to do some troubleshooting, to then simply realized that designing and refining such a piece could be a final project in itself, and that I might as well focus on my current project rather than dividing my attention. Ok, developing a new Fabduino is indeed quite cool, but an open-source rotational casting machine can be AS cool… right?

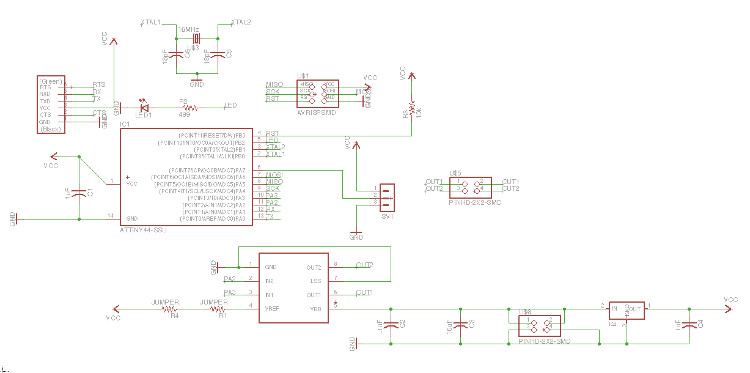

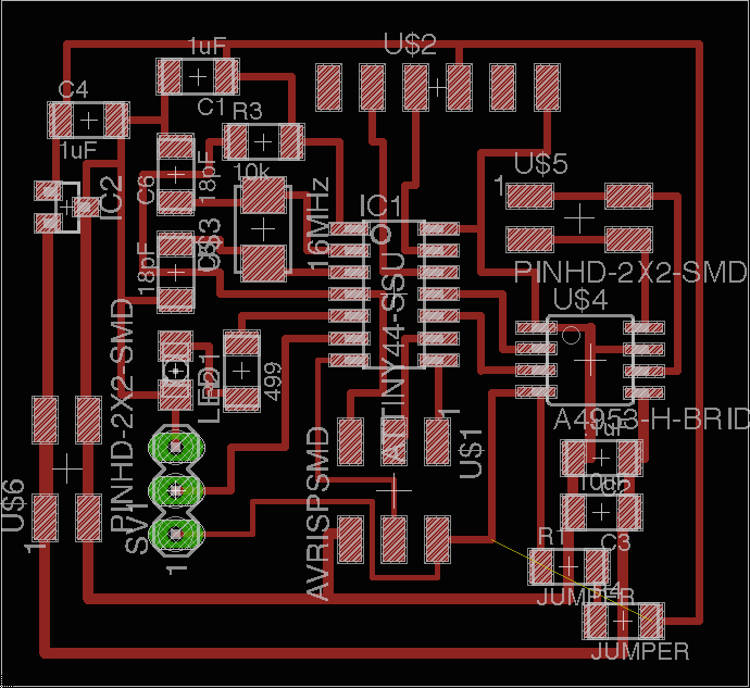

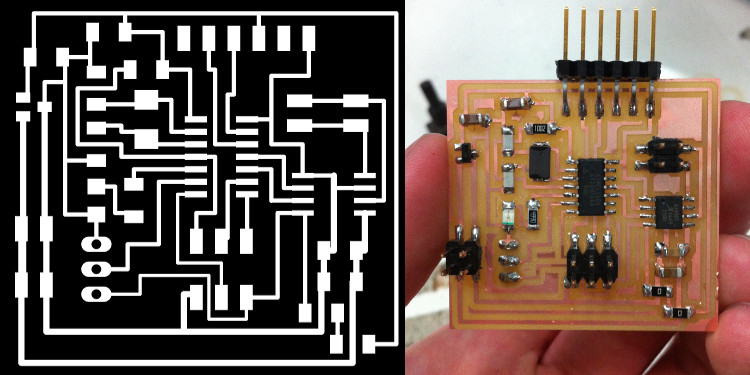

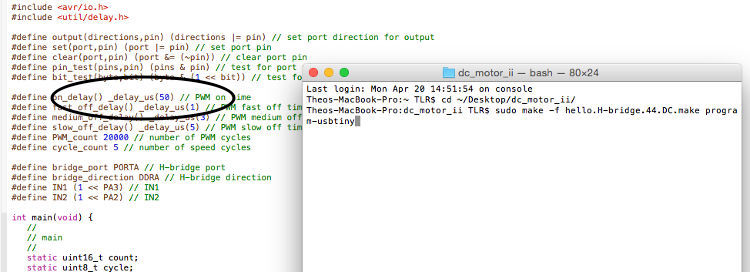

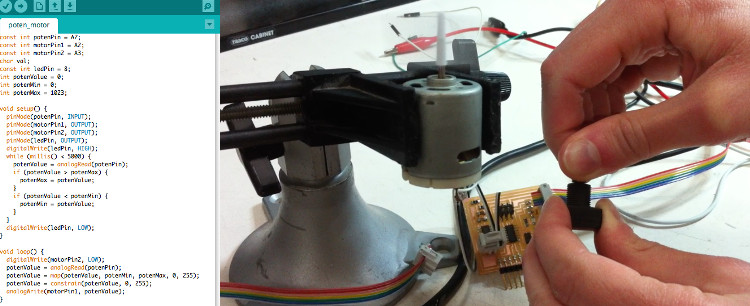

I therefore dedicated the rest of the week to the development of what could be the electronic component of my final project – a piece translating a potentiometer input into a DC motor output with various speeds and intensities. The design part went flawlessly, as I mixed together my pre-existing potentiometer board and Neil’s DC motor one. The resulting board affords one analog input pin, a digital pin connected to a LED to signify the begin and the end of the board’s calibration, two analog pins connected to a H-bridge motor driver, and two additional headers to, respectively, connect the board to a motor as well as to an external source of energy (5V not being enough to furnish the motor in energy). Click here for the Eagle files.

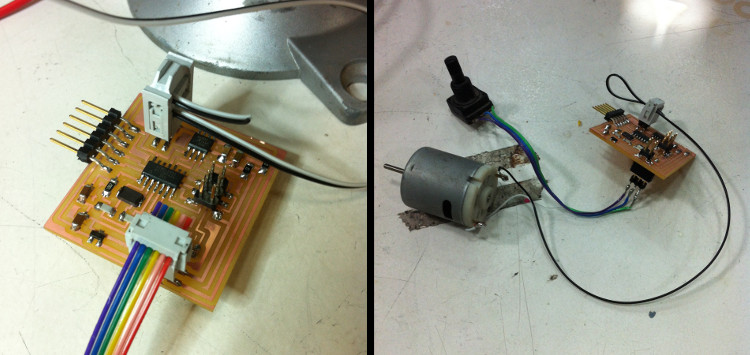

This first part went well, and I could quickly start to experiment with different scripts. In the first case, I made sure that my board’s input worked by uploading my script from last week, to then try Neil’s C-code, DC motor sketch and did some troubleshooting with it, and finally wrote an Arduino script to control the speed of my DC motor with the potentiometer (downloadable here). I still need to refine the latter, as the motor’s reactivity does not react linearly to the input (i.e. an analog input of something like 0 to 100 doesn’t create any visible movement, while an input from 200 onward doesn’t afford any noticeable acceleration), but I feel like I am getting quite close to something that I could directly use in my final project.

Potentiometer-Controlled Motor (Kind Of) from Theo L. Richer on Vimeo.

See below for all the details/for each step.

- Week: 11

- Subject: Output Devices

- Tools: Eagle, GIMP, Modela, Arduino, Xcode (C language)

- Objective: Add an output device to a microcontroller board you've designed and program it to do something

- Files: Click here