Milling, soldering, and programming a board; or, the discreet charm of troubleshooting

This week’s project was probably is probably among the least ‘creative’ of the whole course – for we pretty much all have to do the same thing – but I was especially curious to get my head around electronics production by building a simple board à la Arduino (well, a fairly tone down version of it). Having worked before with Arduino boards and the like, I was already a bit familiar with programming electronic pieces yet had never tackled this work from an hardware perspective. I have in fact tended during my studies to stay closer to the ‘software studies’ part of computational architecture – engaging principally with the work of scholars like Luciana Parisi, Eugene Thacker, Wendy Chun and Alexander Galloway – but I now recognize that it is partly because my engagement with its hardware dimension has always been more limited. Maybe it is easier to make more radical claims like Friedrich Kittler’s “there is no software” if one has some basics in electronic engineering, who knows?

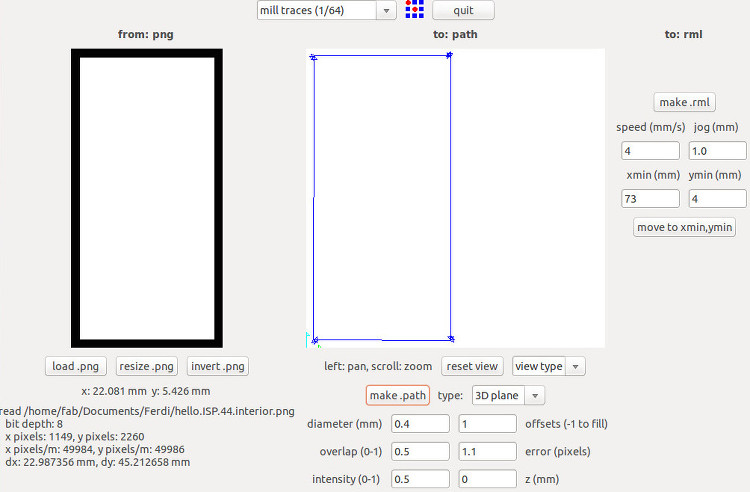

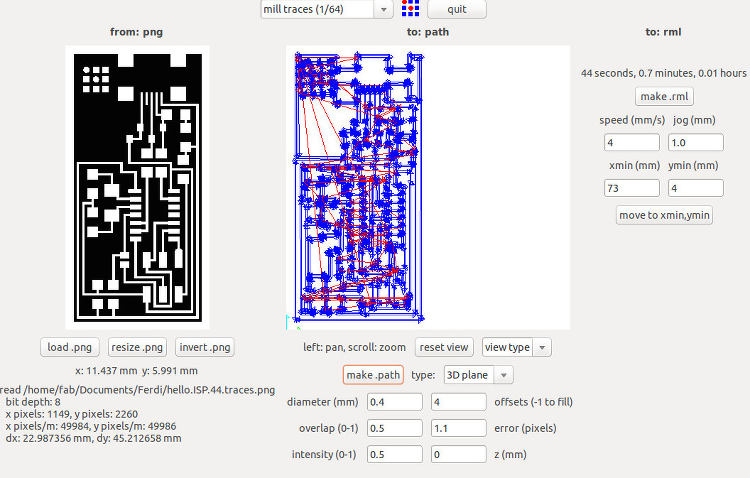

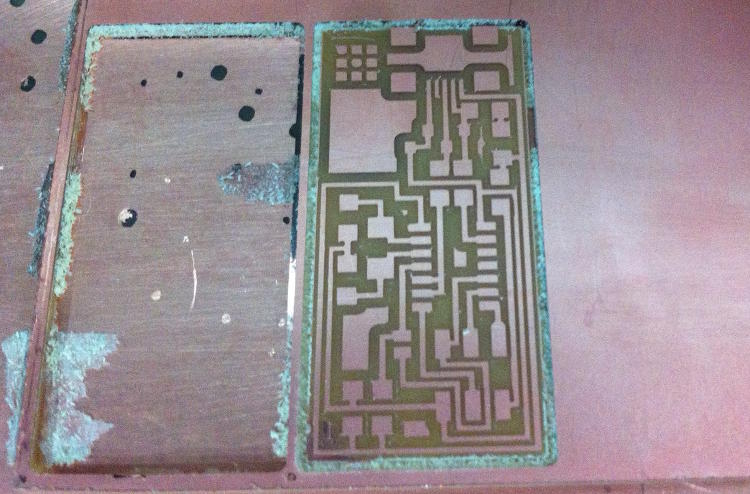

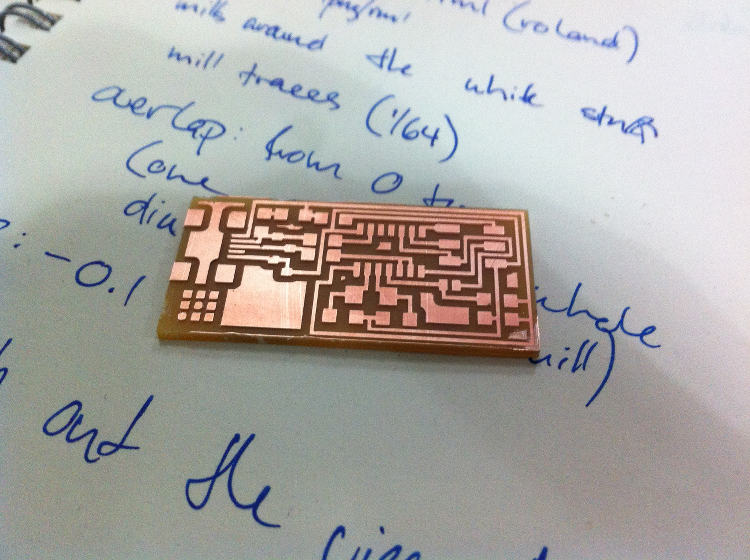

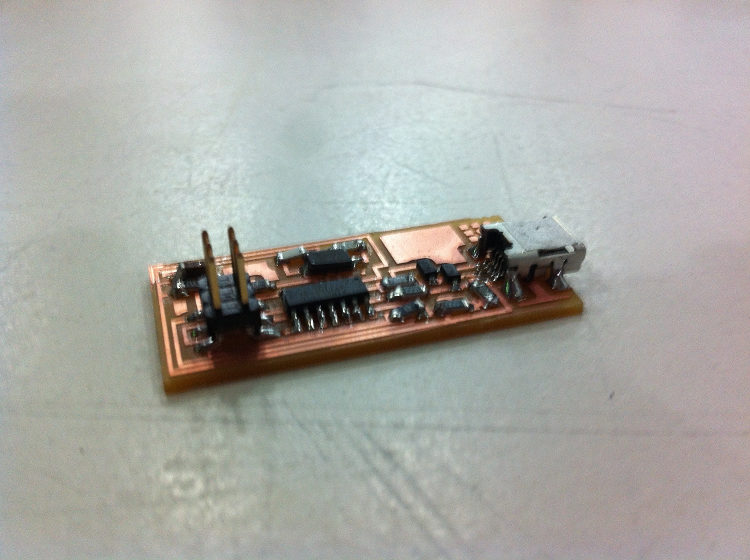

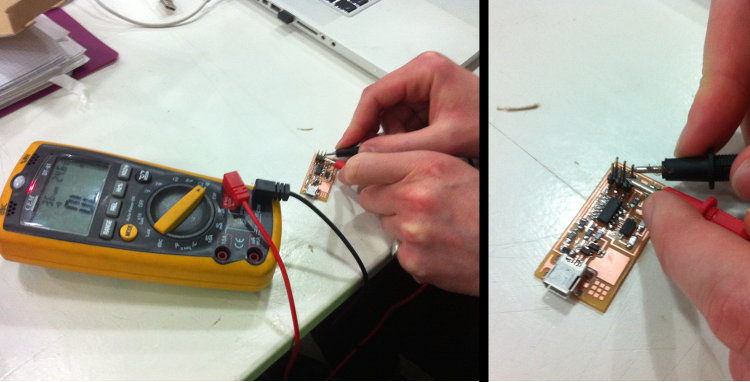

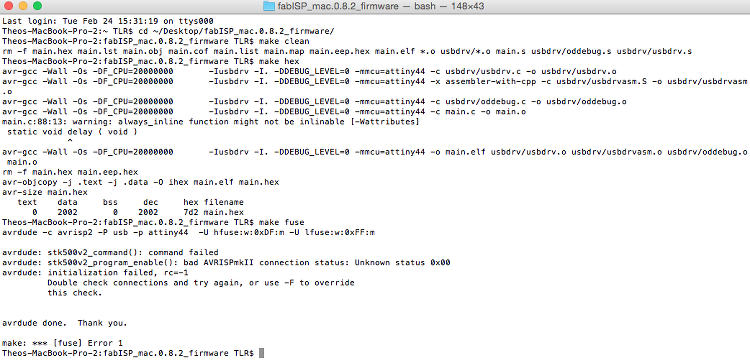

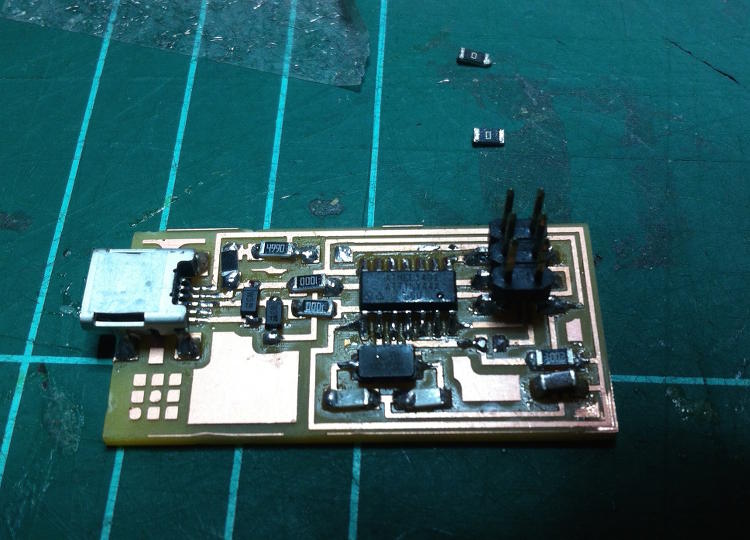

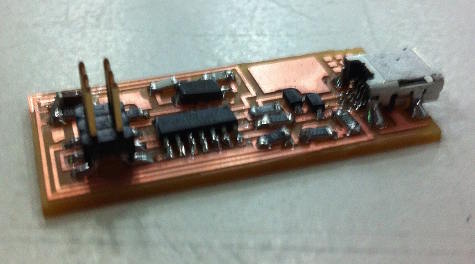

Anyway, back to basics (as I am still far from having developed the necessary digital fabrication skills to build upon these questions). We can divide this week’s exercise in three main parts – milling the board, soldering it and programming it – but my personal experience involved a fourth step that ended up being the most problematic and time-consuming one – troubleshooting. To begin with, we had the opportunity to decide among three different boards – Neil’s, Andy’s and Valentin’s – with all of them pretty much doing the same thing and sharing a common genealogy of one having influenced the development of the others and vice versa. I decided to do Neil’s as I thought that it would be easier to do the biggest of the three for a beginner like me, but it is the only one with a USB port, which happens to be the trickiest piece to solder.

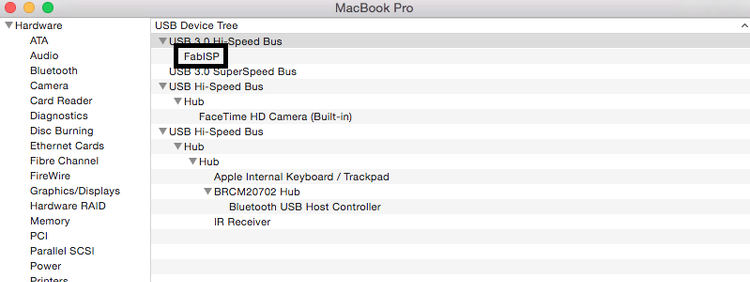

In the end, the milling part went well and the soldering surprisingly smoothly – and after two days of troubleshooting and Ferdi’s invaluable support (and patience) – I finally got the board to work properly. Please see below for all the details.

- Week: 04

- Subject: Electronics Production

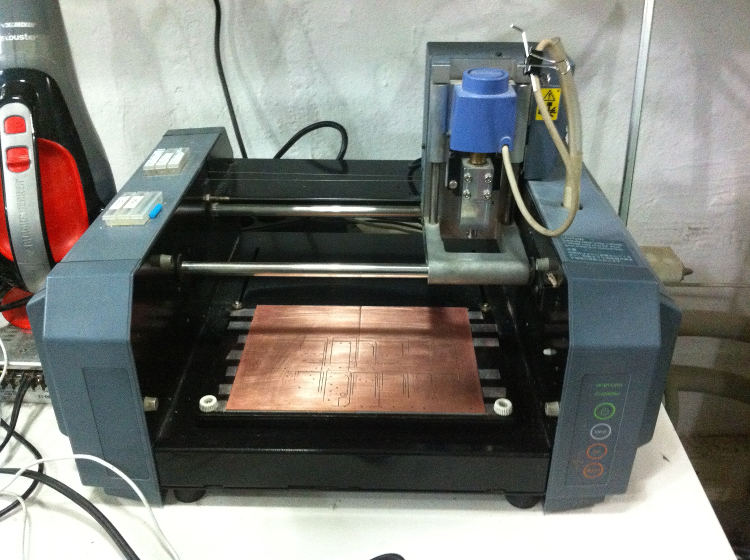

- Tools: Fab Module, Milling Machine, Solder Iron, ATAVRISP2 programmer

- Objective: Milling, soldering and programming one of the three FabISP models