INPUT

In this assignment I had to design and make a 3D mold (~ft2), and produce a fiber composite part in it.

LESSON >> video recording - web

In this assignment I had to design and make a 3D mold (~ft2), and produce a fiber composite part in it.

LESSON >> video recording - web

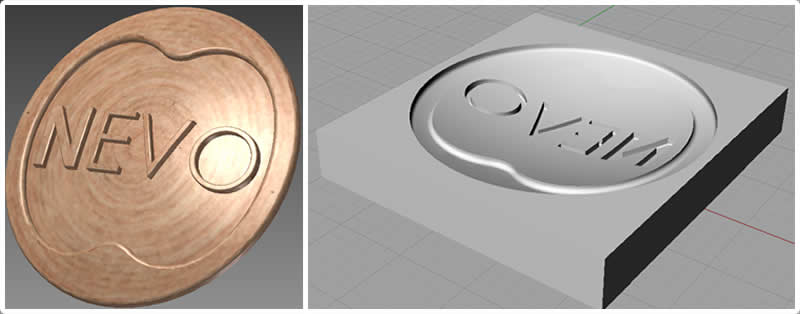

>>> DESIGNING

In this case I used Inventor to make the positive mold and Rhinoceros to make the negative mold of my shield

>>> MANUFACTURING

>>> MANUFACTURING

I need to glue two pieces of plywood.

And I used SHOPBOT to make the 3D mold.

And I used SHOPBOT to make the 3D mold.

Parameters

I used 2 types of mills: 1/4" Ball point and 1/8" Flat Point end mill and 2 softwares to create the 3D paths (PartWorks and PartWorks-3D).

You can see my COMPUTER CONTROLLED MACHINNING to know more about how works with SHOPBOT.  >>> PREPARING COMPOSITE

>>> PREPARING COMPOSITE

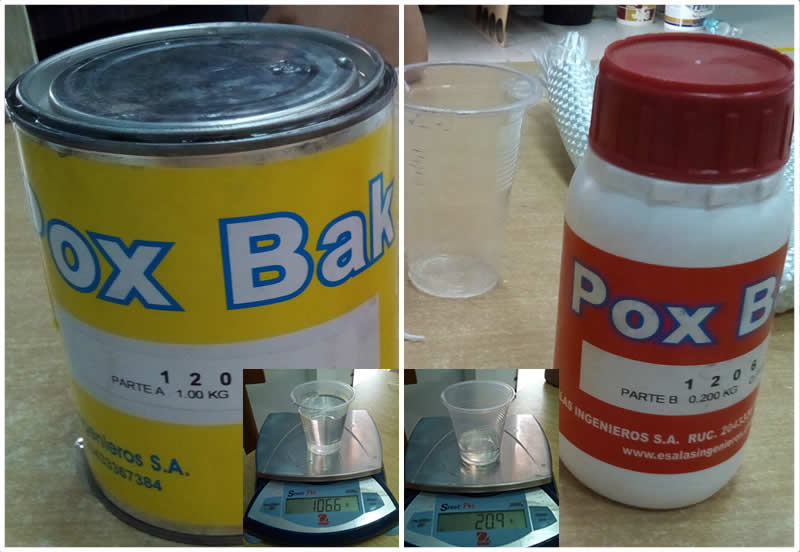

I used POX BAK, It is an epoxy resin that have multiple purpose and combined with its catalyst B, it is catalyzed at ambient temperature, without any contraction, presenting excellent mechanical properties. The proportion are 100-20.

My first work

I used plastic as a release agent and combined the epoxy resin with fiberglass.

My first work

I used plastic as a release agent and combined the epoxy resin with fiberglass.

My second work

When you se my First Result in OUTPUT SECTION you are going to see that I hac some problems with borders in my design because the plastic.

My second work

When you se my First Result in OUTPUT SECTION you are going to see that I hac some problems with borders in my design because the plastic.

So I tried to improve this using heat but I did not have better results.

My third work

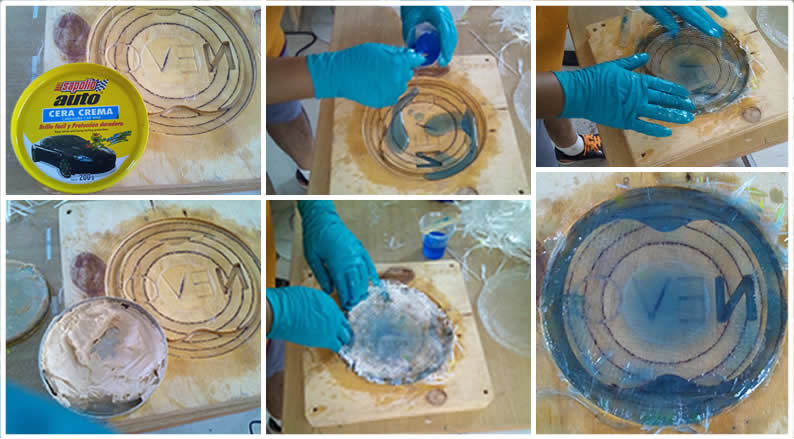

In this case I used a car wax cream as a release agent and created blue color with paint.

My third work

In this case I used a car wax cream as a release agent and created blue color with paint.

>>> FINAL WORK

My First Result

After 4 hours, in my case I left it until next day and because of my design it had a few mistakes.

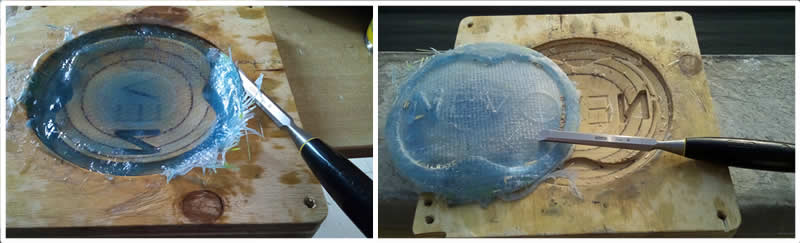

My Third result

In this case I had a better result but my mold was destroyed.

My Third result

In this case I had a better result but my mold was destroyed.

FILES >>

Here are the files that I created if you wish to study or replicate this assignment:

FILES >>

Here are the files that I created if you wish to study or replicate this assignment:

Shield in Rhino