Claudia Aguilar

FAB ACADEMY 2015

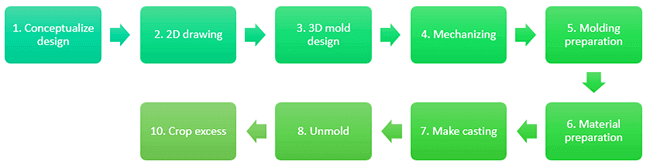

This is an assignment I wanted to make so bad. net you can se the work flow I followed to get it.

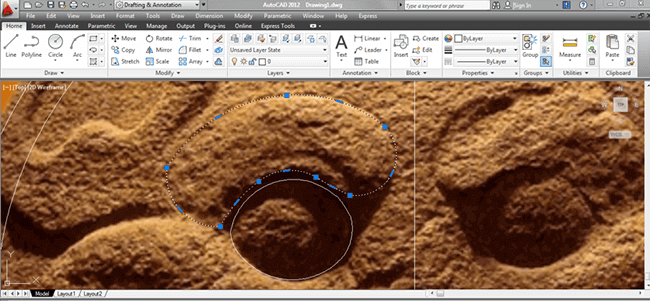

The conceptualization of my work comes from an important archaeological piece from El Salvador called "Jaguar Face Disk" so to start I searched for a nice image of it and vector it in AutoCAD and next.

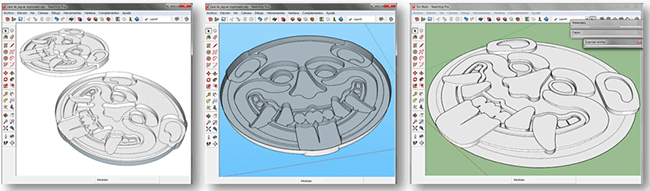

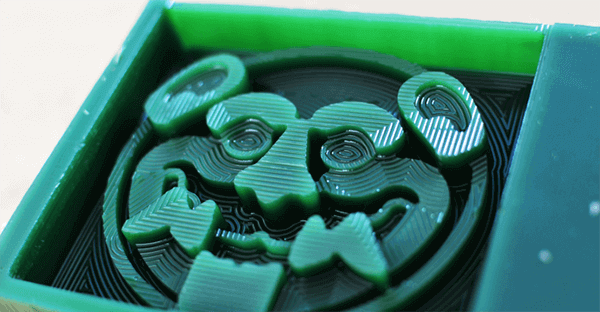

The next step is to generate a 3D mold design, for this I use SketchUp and it was useful to make cross sections to uderstand how the extrusion heights worked.

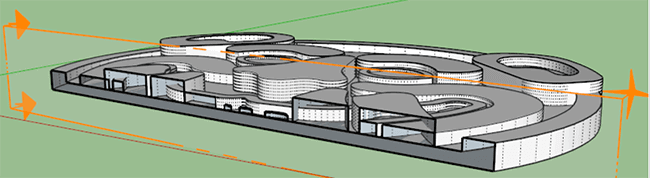

You can see next the final look of how I want my casting parts to look like.

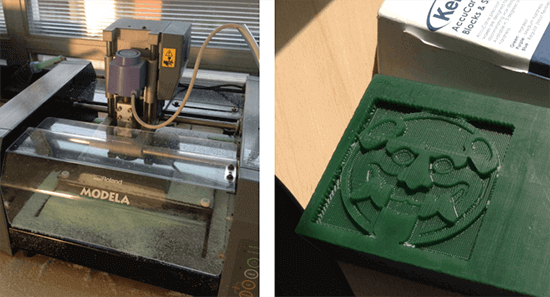

Now having the 3D design its time to mechanize, for this I use mechanizable wax and I also did a bigger mold in 15mm plywood mechanized in the Shopbot CNC. Next you can see the images of the modella screenshots.

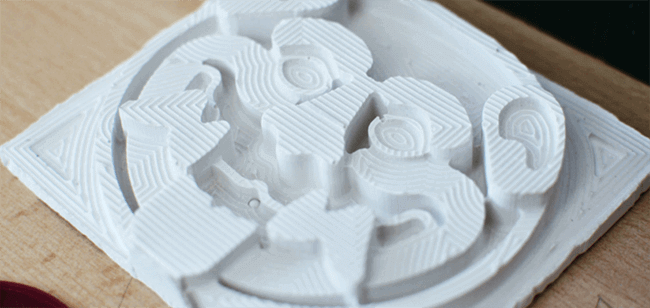

This first try didn't give me the look I wanted. It took more than two hour to make.

I improved the design after the first try and the result was more like what I was expecting.

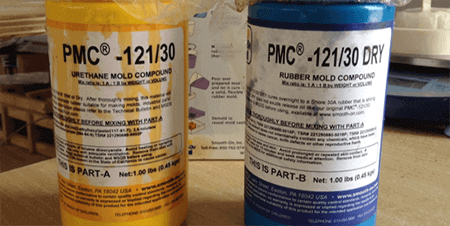

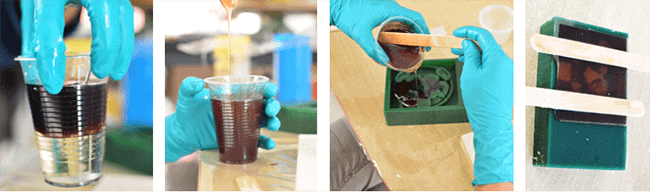

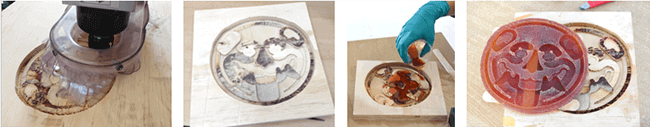

For the mold I use Urethane to make it you just have to mix two same size amounts of liquid together and mix it for 3 to 5 minutes.

I realy loved this material as it was so easy to make, use, mix and it also took small time to harden being readi in just 2 hours.

The first casting part I dis is a withe cement test, it worked very well with a mixture of 100 parts of cement and 19 parts of watter, I though it wasn't going to work but it was perfect.

Then I did a test with liquid plastic again in this case two equal parts of both components, when mixing parts to join it has a heating reaxion and when you mix in the urethane mold the cast and the mold adhered together so I had to cut it to see what had happened to the material. I stop trying with this and started trying with the bigger mold.

Here you can see the bigger mold I did in plywood, again I use urethane and I only use unmoding liquid in the wood so it would stick together and it worked fine.

with this mold I di three test one with liquid plastic and it worked really good, another one with white cement that worked fine and then I gave it a finishing using a combination of water, glue and coffee waste. With this coffee waste I had I did one test ( first image) only usin it and mixing it with glue and water to see what will happend and well... you can see it wasn't realy good but it was fun to make the try.

You can download al the files used for this assignment in here.

Click here to see this class content

Click here to see this class recorded video