About me

Final project -

development

Final project

Weekly projects

Wk 16 Machine Design (May 20)

Assignment:

• Make a machine, including the

end effector

• build the passive parts and operate it manually

• document the group project and your individual

contribution

Note: Fablab

were providing

4

x

machine kits

(including 4 x

stepper motors

/ spindles, 4

x nodes plus

assembly

components).

I

document my individual participation for the group

assignment below and the group documentation can be

foud here.

I was tasked with taking photos and essential

documentation of the key stages for the group

project, so that the process would not be lost nor

time wasted on duplicate efforts. This means that

this individual documentation page looks very

similar to the group documentation page.

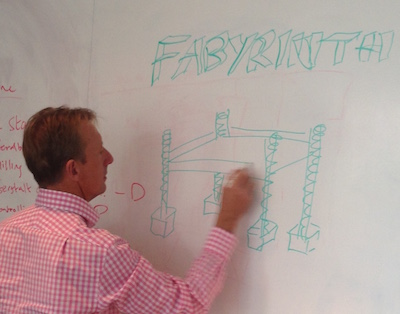

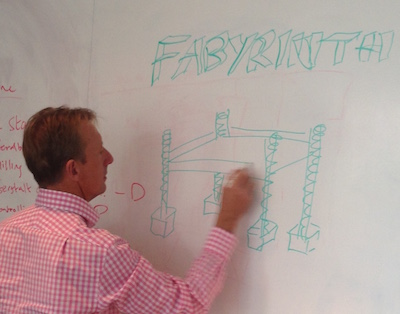

Settling

on an idea

Over the course of

the first few days, we all brought different ideas that might suit the

challenge of Mechanical and Machine Design and Build week. These

included a 3D scanning

bed; golf

putting exercise

machine; roulette-style

game to name a

few.

The

one that got

the overall

approval

by the group,

was an idea

from Philip

Hemstead

- a digitally

controlled

ball

tilting

maze game.

To crystallize

the project,

we titled it "Fabaryinth".

In this

game, incremental

movement of stepper

motors would

provide

the control

over

the tilt

level

of a

plane, upon

which the user

(through a PC

user interface

with

a

simple control

console,

would

try to guide a

ball

over a maze

obstacle

course

and into

a target

hole.

This

game would

include the

following

areas of

learning:

Machine

Design

Electronics

and stepper motor

control

(using

multiple

nodes)

Lasercutting /

Milling

Electronics

Assemby

of parts

Networking

of single node

communication

system

Programming

(input and

output)

See

tutorial

for overview.

Machine

Design

In

the first

instance, the

suggestion was

to use

all 4 stepper

motors

(probably as

it would be

stable,

and 4 were

provided, not

sure why).

I

challenged

this as I did

not think 4

stepper motors

would be

necessary - the

movement

could be

established

with maximum 2

or 3 if

the

design was

adapted. I

could see that

in order to

acheive a tilt,

a

certain degree

of freedom

of movement

would be

required. I

found this an

interesting

problem. To

see how much freedom,

I

quickly

cut three slots

in a flat

piece of cardboard

and placed it

over 3

leadscrews. It

revealed the

range of

free movement

that

would be

required

between the game-bed

and 3

guiding

leadscrews to

enable the

tilt, which,

to roll

a ball, would

only have to be

minimal.

This

is

demonstrated

below:

Personally,

I

am more

interested in

design

than

electronics

and programming,

and looking

back I would

have liked for

more

time to have

been allocated

for

each person to

present their

ideas on design development

and rationale,

especially on

transferring

the tilt to

the

game bed

effectively.

I

felt we moved

too quickly,

without asking

enough

questions

before

progressing.

However, I

acknowledge

that if my

team mates

hadn't applied

momentum, we

probably

would not have

finished the

task as

fully.

I

also

felt that to

some degree,

the cardboard

housing

template

supplied,

hindered our

thinking; the

heavy

framework was

unnecessary

for our

application.

I

couldnt help

but wonder if

we should

have stepped

back and

considered giving

a lighter

touch to the

housing and

attempting to

integrate

the

links

to the

game-bed?

Again as a

group, with a

big

task to

complete under

a

time

limit,

this would

have been a

big ask, so I

daren't

voice it!

With

a

broad

vision of the

extra

systems

required to

make the game

work,

essentially

a

custom-made

game-bed

and a

flexible

linkage

to transfer

the movement,

some

of the initial

tasks

were taken up

by the

four members

of our

group.

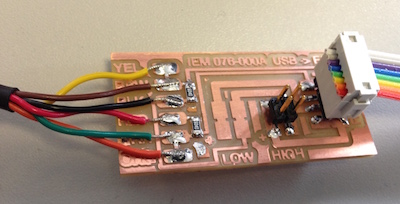

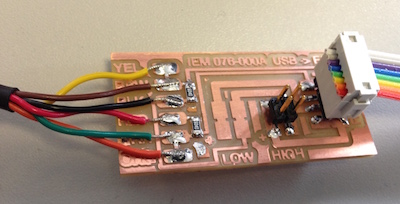

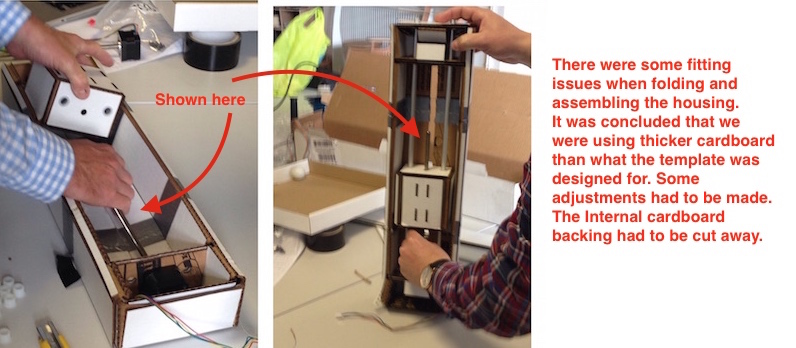

Electronics

I

looked into

the tutorials

on the Fabnet

Adaptor

board, downloaded

the file,

milled

it

on the Modela

and

soldered the

components

onto the board.

The ftdi cable

had to be customised

to suit the

board and the

single nodes.

The

detail is

shown

in the photos

/ diagram

below:

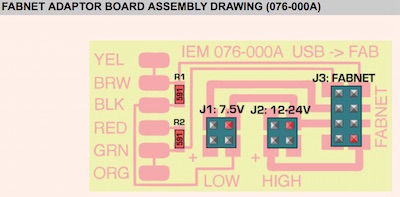

I

joined David

to follow the

testing of the

network

for connections

to Node

1,

PC

and

power

supply.

To help me

understand the

network and

for the

purpose of

documentation,

I suggested

placing the

network on

some cardboard

so that we could

mark up and identify

each part -

this is shown

below:

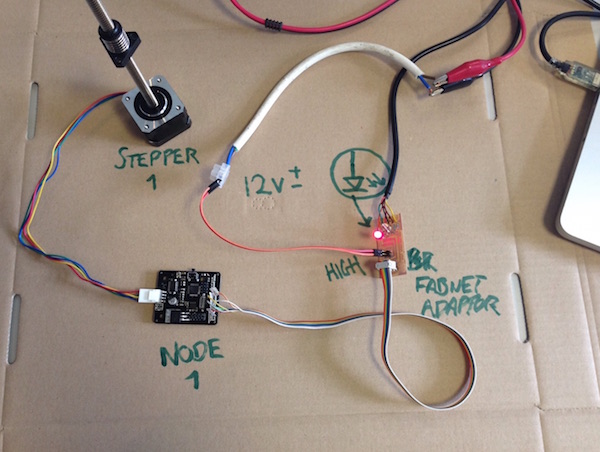

Cardboard

housing

The

main

part of this

task was

taken

up by Philip

and Michael.

This was

fiddly;

I tracked

the

process, and they

had to make

some

adjustments

and cut

some cardboard

leafs

away in

order to

create more

space inside

the housing so

that the spindles

would be in

true alignment

with

the housing

support guides.

Game-bed

This

task had been

assigned to

Kasper, but

nonetheless I

suggested the

idea

of

creating a

simple organic undulating

landscape form

in Solidworks

and then

to mill

it on the

shopbot using

a light foam board.

In my

rationale,

this material

would offer a

lightness to

the choice of

materials. A

light material

would be beneficial

in reducing

the

stress,

therefore torsion on

the linkage

between the

game-bed

and its

connection to

each leg and

relative to

each other.

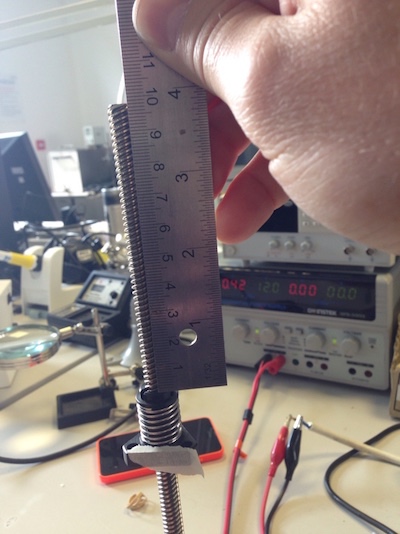

Calibration

Next

I joined in

with the

debate with

David and

Kasper around

the

discrepancy

between the distance

of travel

requested in

the

python code

(written by

James

and

David)

versus actual

distance

travelled.

Without

stating the

word

'calibration'

once (!) we

worked

out that

we needed to

ascertain the

distance

travelled by

one revoution

of the

leadscrew

and amend

this amount

accordingly

in the code.

Currently,

the amount defined

in the code

(6.096mm)

was

relating to a

leadscrew with

a different

lead / pitch.

This lead travelled

by the

leadscrew

in our kit was

tested and

shown to be

8.0mm.

David changed

this

definition

in the code,

thus

completing the

mystery of the

discrepancy

and performing

an essential

calibration.

Therefore,

following

calibration,

an instrcution

in code to

traverse the

stepper motor

by 10mm would

deliver a true

10mm.

For

the remainder

of

the project,

I shadowed

David Mason

and James

Fletcher

in

the following

areas (see

group page for

fuller documentation):

•

creating

the control

console with

wx python

•

contributing

ideas to improve

the

flexibility of

the linkage

between the

bed and each

leadscrew housing.

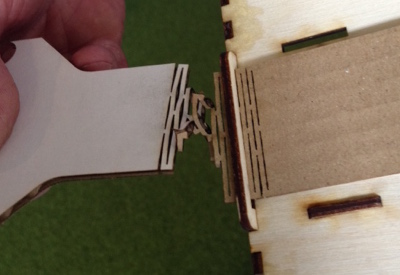

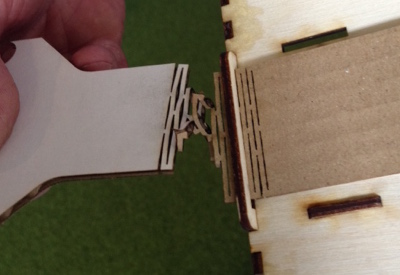

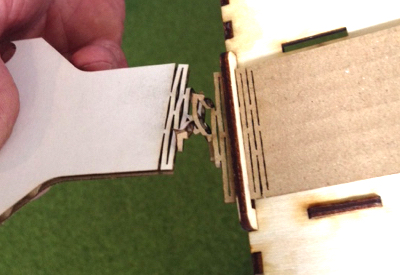

I

felt that whilst

it was an

attractive

solution, we

were

introducing

unneccessary

complexity

into the

design by

using a

living

hinge.

In earlier

tests, the

simplicity of

string had

proved to be totally

effective in

providing a

problem-free

solution

to tilting

the game bed;

one that had

no problem

with torsion

or attachment.

More

than once the

torsion upon

the living

hinge was

fatal, as

shown below

(although this

was cardboard,

it was also

very fragile

in 3mm

plywood):

However,

with sheer

grit and determination

the

team managed

to get Fabaryinth

up and running

for the

presentation

to Neil.

David managed

to score a

live goal in

under 15

seconds. I

would call

that a

success.

Link

to Tutorials:

Fab

in a Box

Tutorial

Explanation

of Fabnet

Download

files:

Fabnet

Board